Implant having locking holes with collection cavity for shavings

Rush , et al. February 23, 2

U.S. patent number 10,925,651 [Application Number 16/230,880] was granted by the patent office on 2021-02-23 for implant having locking holes with collection cavity for shavings. This patent grant is currently assigned to DePuy Synthes Products, Inc.. The grantee listed for this patent is DePuy Synthes Products, Inc.. Invention is credited to Simon M. Bosshard, Christopher Keegan, Michael McGurk, Jesse B. Rush.

| United States Patent | 10,925,651 |

| Rush , et al. | February 23, 2021 |

Implant having locking holes with collection cavity for shavings

Abstract

A bone plate includes locking holes that reconfigured to threadedly mate with locking screws to fix the bone plate to an underlying bone. Some of the locking holes are standard-type locking holes. Alternatively or additionally, some of the locking holes are variable-angle locking holes. The bone plate defines a collection cavity in the locking holes that are configured to collect shavings that can be produced if the bone screw is cross threaded in the locking hole.

| Inventors: | Rush; Jesse B. (Telford, PA), Keegan; Christopher (Hatboro, PA), McGurk; Michael (Williamstown, NJ), Bosshard; Simon M. (Bern, CH) | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Applicant: |

|

||||||||||

| Assignee: | DePuy Synthes Products, Inc.

(Raynham, MA) |

||||||||||

| Family ID: | 71098124 | ||||||||||

| Appl. No.: | 16/230,880 | ||||||||||

| Filed: | December 21, 2018 |

Prior Publication Data

| Document Identifier | Publication Date | |

|---|---|---|

| US 20200197056 A1 | Jun 25, 2020 | |

| Current U.S. Class: | 1/1 |

| Current CPC Class: | A61B 17/1728 (20130101); A61B 17/8057 (20130101); A61B 17/8061 (20130101); A61B 17/808 (20130101); A61B 17/8014 (20130101); A61B 17/8605 (20130101); A61B 17/8004 (20130101) |

| Current International Class: | A61B 17/17 (20060101); A61B 17/80 (20060101); A61B 17/86 (20060101) |

References Cited [Referenced By]

U.S. Patent Documents

| 327296 | September 1885 | Mcginnis |

| 1105105 | July 1914 | Sherman |

| 1203546 | October 1916 | Parsons |

| 2228584 | January 1941 | Piace |

| 2352297 | June 1944 | Wales |

| 2414882 | January 1947 | Longfellow |

| 2443363 | June 1948 | Kenneth et al. |

| 2477430 | July 1949 | Swanstrom |

| 2496126 | January 1950 | Haboush |

| 2526959 | October 1950 | Lorenzo |

| 2612159 | September 1952 | Collison |

| 2627855 | February 1953 | Price |

| 2699774 | January 1955 | Livingston |

| 2772676 | December 1956 | Pohl |

| 2801631 | August 1957 | Charnley |

| 2846701 | August 1958 | Bedford, Jr. |

| 2874691 | February 1959 | Mason |

| 3025853 | March 1962 | Mason |

| 3229743 | January 1966 | Derby |

| 3263949 | August 1966 | Conrad |

| 3314326 | April 1967 | Bedford, Jr. |

| 3364807 | January 1968 | Holton |

| 3374786 | March 1968 | Callender, Jr. |

| 3388732 | June 1968 | Holton |

| 3463148 | August 1969 | Treace |

| 3489143 | January 1970 | Halloran |

| 3534731 | October 1970 | Muller |

| 3551389 | December 1970 | Prince, Jr. |

| 3552389 | January 1971 | Allgower et al. |

| 3561437 | February 1971 | Orlich |

| 3577601 | May 1971 | Mariani et al. |

| 3630261 | December 1971 | Gley |

| 3668972 | June 1972 | Allgower et al. |

| 3688972 | September 1972 | Mahon |

| 3695259 | October 1972 | Yost |

| 3695618 | October 1972 | Woolley et al. |

| 3716050 | February 1973 | Johnston |

| 3741205 | June 1973 | Markolf et al. |

| 3744488 | July 1973 | Cox |

| 3779240 | December 1973 | Kondo |

| 3782374 | January 1974 | Fischer |

| 3824995 | July 1974 | Getscher et al. |

| 3842825 | October 1974 | Wagner |

| 3877339 | April 1975 | Muenchinger |

| RE28841 | June 1976 | Martin et al. |

| 3967049 | June 1976 | Brandt |

| 3996834 | December 1976 | Reynolds |

| 3996931 | December 1976 | Callender, Jr. |

| 4009712 | March 1977 | Burstein et al. |

| 4029091 | June 1977 | Von et al. |

| 4040129 | August 1977 | Steinemann et al. |

| 4095591 | June 1978 | Graham et al. |

| 4120298 | October 1978 | Fixel |

| 4172452 | October 1979 | Forte et al. |

| 4175555 | November 1979 | Herbert |

| 4219015 | August 1980 | Steinemann |

| 4236512 | December 1980 | Aginsky |

| 4263904 | April 1981 | Judet |

| 4269180 | May 1981 | Dall et al. |

| 4304039 | December 1981 | Asmus |

| 4338926 | July 1982 | Kummer et al. |

| 4355198 | October 1982 | Gartland, Jr. |

| 4379451 | April 1983 | Getscher |

| 4388921 | June 1983 | Sutter et al. |

| 4408601 | October 1983 | Wenk |

| 4429690 | February 1984 | Angelino-Pievani |

| 4438762 | March 1984 | Kyle |

| 4454876 | June 1984 | Mears |

| RE31628 | July 1984 | Allgower et al. |

| 4484570 | November 1984 | Sutter et al. |

| 4484750 | November 1984 | Scruggs |

| 4488543 | December 1984 | Tornier |

| 4491317 | January 1985 | Bansal |

| 4493317 | January 1985 | Klaue |

| 4494535 | January 1985 | Haig |

| 4513744 | April 1985 | Klaue |

| 4537185 | August 1985 | Stednitz |

| 4565193 | January 1986 | Streli |

| 4580225 | April 1986 | Thompson |

| 4612920 | September 1986 | Lower |

| 4612923 | September 1986 | Kronenthal |

| 4616638 | October 1986 | Griggs |

| 4617922 | October 1986 | Griggs |

| 4621629 | November 1986 | Koeneman |

| 4628923 | December 1986 | Medoff |

| 4629455 | December 1986 | Kanno |

| 4630985 | December 1986 | Simons |

| 4651724 | March 1987 | Berentey et al. |

| 4657001 | April 1987 | Fixel |

| 4683878 | August 1987 | Carter |

| 4717613 | January 1988 | Ottaviano |

| 4747613 | May 1988 | Brichoud et al. |

| 4776329 | October 1988 | Treharne |

| 4776330 | October 1988 | Chapman et al. |

| 4781183 | November 1988 | Casey et al. |

| 4791918 | December 1988 | Von Hasselbach |

| 4794918 | January 1989 | Wolter |

| 4795473 | January 1989 | Grimes |

| 4800874 | January 1989 | David et al. |

| 4838252 | June 1989 | Klaue |

| 4848328 | July 1989 | Laboureau et al. |

| 4858601 | August 1989 | Glisson |

| 4867144 | September 1989 | Karas et al. |

| 4903691 | February 1990 | Heinl |

| 4905680 | March 1990 | Tunc |

| 4927421 | May 1990 | Goble et al. |

| 4955886 | September 1990 | Pawluk |

| 4957496 | September 1990 | Schmidt |

| 4957497 | September 1990 | Hoogland et al. |

| 4964403 | October 1990 | Karas et al. |

| 4966599 | October 1990 | Pollock |

| 4973332 | November 1990 | Kummer |

| 4973333 | November 1990 | Treharne |

| 4988350 | January 1991 | Herzberg |

| 5002544 | March 1991 | Klaue et al. |

| 5006120 | April 1991 | Carter |

| 5013313 | May 1991 | Surer |

| 5013315 | May 1991 | Barrows |

| 5015248 | May 1991 | Burstein et al. |

| 5027904 | July 1991 | Miller et al. |

| 5039265 | August 1991 | Rath et al. |

| 5041113 | August 1991 | Biedermann et al. |

| 5041114 | August 1991 | Chapman et al. |

| 5041116 | August 1991 | Wilson |

| 5053036 | October 1991 | Perren et al. |

| 5085660 | February 1992 | Lin |

| 5087260 | February 1992 | Fixel |

| 5108399 | April 1992 | Eitenmuller et al. |

| 5108449 | April 1992 | Gray |

| 5116336 | May 1992 | Frigg |

| 5127914 | July 1992 | Calderale et al. |

| 5129901 | July 1992 | Decoste |

| 5139497 | August 1992 | Tilghman et al. |

| 5147361 | September 1992 | Ojima et al. |

| 5147363 | September 1992 | Haerle |

| 5151103 | September 1992 | Tepic et al. |

| 5152794 | October 1992 | Davidson |

| 5190544 | March 1993 | Chapman et al. |

| 5197966 | March 1993 | Sommerkamp |

| 5201733 | April 1993 | Etheredge, III |

| 5261910 | November 1993 | Warden et al. |

| 5269784 | December 1993 | Mast |

| 5275601 | January 1994 | Gogolewski et al. |

| 5290281 | March 1994 | Tschakaloff |

| 5300074 | April 1994 | Frigg |

| 5304180 | April 1994 | Slocum |

| 5306275 | April 1994 | Bryan |

| 5324290 | June 1994 | Zdeblick et al. |

| 5324292 | June 1994 | Meyers |

| 5336224 | August 1994 | Selman |

| 5356410 | October 1994 | Pennig |

| 5360429 | November 1994 | Jeanson et al. |

| 5360448 | November 1994 | Thramann |

| 5364398 | November 1994 | Chapman et al. |

| 5364399 | November 1994 | Lowery et al. |

| 5372598 | December 1994 | Luhr et al. |

| 5376126 | December 1994 | Lin |

| 5395372 | March 1995 | Holt et al. |

| 5403136 | April 1995 | Mathys |

| 5413577 | May 1995 | Pollock |

| 5429641 | July 1995 | Gotfried |

| 5433719 | July 1995 | Pennig |

| 5458654 | October 1995 | Tepic |

| 5462547 | October 1995 | Weigum |

| 5484439 | January 1996 | Olson et al. |

| 5514138 | May 1996 | McCarthy |

| 5520690 | May 1996 | Errico et al. |

| 5522902 | June 1996 | Yuan et al. |

| 5531746 | July 1996 | Errico et al. |

| 5534032 | July 1996 | Hodorek |

| 5558674 | September 1996 | Heggeness et al. |

| 5569248 | October 1996 | Mathews |

| 5571109 | November 1996 | Bertagnoli |

| 5571198 | November 1996 | Drucker et al. |

| 5586985 | December 1996 | Putnam et al. |

| 5591168 | January 1997 | Judet et al. |

| 5601551 | February 1997 | Taylor et al. |

| 5601553 | February 1997 | Trebing et al. |

| 5607426 | March 1997 | Ralph et al. |

| 5607427 | March 1997 | Tschakaloff |

| 5607428 | March 1997 | Lin |

| 5620445 | April 1997 | Brosnahan et al. |

| 5647872 | July 1997 | Gilbert et al. |

| 5655089 | August 1997 | Bucci |

| 5658339 | August 1997 | Tronzo et al. |

| 5662655 | September 1997 | Laboureau et al. |

| 5674222 | October 1997 | Berger et al. |

| 5676667 | October 1997 | Hausman |

| 5681311 | October 1997 | Foley et al. |

| D385963 | November 1997 | Hansson |

| 5690633 | November 1997 | Taylor et al. |

| 5693055 | December 1997 | Zahiri et al. |

| 5702396 | December 1997 | Hoenig et al. |

| 5702399 | December 1997 | Kilpela et al. |

| 5709682 | January 1998 | Medoff |

| 5709686 | January 1998 | Talos et al. |

| 5709687 | January 1998 | Pennig |

| 5718704 | February 1998 | Medoff |

| 5718705 | February 1998 | Sammarco |

| 5728099 | March 1998 | Tellman et al. |

| 5733287 | March 1998 | Tepic et al. |

| 5735853 | April 1998 | Olerud |

| 5741256 | April 1998 | Bresina |

| 5741258 | April 1998 | Klaue et al. |

| 5743912 | April 1998 | Lahille et al. |

| 5749872 | May 1998 | Kyle et al. |

| 5766175 | June 1998 | Martinotti |

| 5772662 | June 1998 | Chapman et al. |

| 5779706 | July 1998 | Tschakaloff |

| 5785713 | July 1998 | Jobe |

| 5797916 | August 1998 | McDowell |

| 5800553 | September 1998 | Albrektsson et al. |

| 5810821 | September 1998 | Vandewalle |

| 5810822 | September 1998 | Mortier |

| 5810823 | September 1998 | Klaue et al. |

| 5827286 | October 1998 | Incavo et al. |

| 5853413 | December 1998 | Carter et al. |

| 5921988 | July 1999 | Legrand |

| 5928084 | July 1999 | Green |

| 5931801 | August 1999 | Burbank et al. |

| 5931839 | August 1999 | Medoff |

| 5938664 | August 1999 | Winquist et al. |

| 5954722 | September 1999 | Bono |

| 5961524 | October 1999 | Crombie |

| 5968046 | October 1999 | Castleman |

| 5968047 | October 1999 | Reed |

| 5973223 | October 1999 | Tellman et al. |

| 5976139 | November 1999 | Bramlet |

| 5976141 | November 1999 | Haag et al. |

| 5989255 | November 1999 | Pepper et al. |

| 5999940 | December 1999 | Ranger |

| 6001099 | December 1999 | Huebner |

| 6007535 | December 1999 | Rayhack et al. |

| 6022352 | February 2000 | Vandewalle |

| 6030162 | February 2000 | Huebner |

| 6030389 | February 2000 | Wagner et al. |

| 6059785 | May 2000 | Schavan et al. |

| 6066141 | May 2000 | Dall et al. |

| 6096040 | August 2000 | Esser |

| 6113603 | September 2000 | Medoff |

| 6129728 | October 2000 | Schumacher et al. |

| 6129730 | October 2000 | Bono et al. |

| 6152927 | November 2000 | Farris et al. |

| 6155756 | December 2000 | Mericle et al. |

| 6183474 | February 2001 | Bramlet et al. |

| 6183475 | February 2001 | Lester et al. |

| 6187007 | February 2001 | Frigg et al. |

| 6206881 | March 2001 | Frigg et al. |

| 6221073 | April 2001 | Weiss et al. |

| 6221075 | April 2001 | Toermala et al. |

| D443060 | May 2001 | Benirschke et al. |

| 6224602 | May 2001 | Hayes |

| 6228085 | May 2001 | Theken et al. |

| 6235032 | May 2001 | Link |

| 6235033 | May 2001 | Brace et al. |

| 6258250 | July 2001 | Weissenbacher et al. |

| 6261291 | July 2001 | Talaber et al. |

| 6283969 | September 2001 | Grusin et al. |

| 6287309 | September 2001 | Baccelli et al. |

| 6290703 | September 2001 | Ganem |

| 6306136 | October 2001 | Baccelli |

| 6306140 | October 2001 | Siddiqui |

| 6322562 | November 2001 | Wolter |

| 6325803 | December 2001 | Schumacher et al. |

| 6338734 | January 2002 | Burke et al. |

| 6342055 | January 2002 | Eisermann et al. |

| 6348052 | February 2002 | Sammarco |

| 6350265 | February 2002 | Blaustein et al. |

| 6355041 | March 2002 | Martin |

| 6355042 | March 2002 | Winquist et al. |

| 6358250 | March 2002 | Orbay |

| 6364882 | April 2002 | Orbay |

| 6375657 | April 2002 | Doubler et al. |

| 6379359 | April 2002 | Dahners |

| D458374 | June 2002 | Bryant et al. |

| D458683 | June 2002 | Bryant et al. |

| D458684 | June 2002 | Bryant et al. |

| D458996 | June 2002 | Bryant et al. |

| 6423064 | July 2002 | Kluger |

| 6440131 | August 2002 | Haidukewych |

| 6440135 | August 2002 | Orbay et al. |

| D463557 | September 2002 | Bryant et al. |

| D463558 | September 2002 | Bryant et al. |

| D463559 | September 2002 | Bryant et al. |

| 6454769 | September 2002 | Wagner et al. |

| 6454770 | September 2002 | Klaue |

| D464136 | October 2002 | Bryant et al. |

| D464731 | October 2002 | Bryant et al. |

| 6468278 | October 2002 | Mueckter |

| 6488685 | December 2002 | Manderson |

| D469532 | January 2003 | Bryant et al. |

| D469533 | January 2003 | Bryant et al. |

| D469534 | January 2003 | Bryant et al. |

| 6503252 | January 2003 | Hansson |

| 6503281 | January 2003 | Mallory |

| 6508819 | January 2003 | Orbay |

| D469874 | February 2003 | Bryant et al. |

| D469875 | February 2003 | Bryant et al. |

| D470588 | February 2003 | Bryant et al. |

| 6525525 | February 2003 | Azinger |

| 6527776 | March 2003 | Michelson |

| 6533789 | March 2003 | Hall et al. |

| 6565525 | May 2003 | Burbank et al. |

| 6565569 | May 2003 | Assaker et al. |

| 6575975 | June 2003 | Brace et al. |

| 6602256 | August 2003 | Hayes |

| 6605090 | August 2003 | Trieu et al. |

| D479331 | September 2003 | Pike et al. |

| D480141 | September 2003 | Benirschke et al. |

| 6623486 | September 2003 | Weaver et al. |

| 6648891 | November 2003 | Kim |

| 6666868 | December 2003 | Fallin |

| 6669700 | December 2003 | Farris et al. |

| 6669701 | December 2003 | Steiner et al. |

| 6712820 | March 2004 | Orbay |

| 6719759 | April 2004 | Wagner et al. |

| 6730091 | May 2004 | Pfefferle et al. |

| 6767351 | July 2004 | Orbay et al. |

| 6835197 | December 2004 | Roth et al. |

| 6863483 | March 2005 | Koenig et al. |

| 6866665 | March 2005 | Orbay |

| 6875215 | April 2005 | Taras et al. |

| 6893443 | May 2005 | Frigg et al. |

| 6955677 | October 2005 | Dahners |

| 6974461 | December 2005 | Wolter |

| 7001388 | February 2006 | Orbay et al. |

| 7044953 | May 2006 | Capanni |

| 7128744 | October 2006 | Weaver et al. |

| 7169149 | January 2007 | Hajianpour |

| 7179260 | February 2007 | Gerlach et al. |

| 7229445 | June 2007 | Hayeck et al. |

| 7282053 | October 2007 | Orbay |

| 7294130 | November 2007 | Orbay |

| 7309340 | December 2007 | Fallin et al. |

| 7316687 | January 2008 | Aikins et al. |

| 7338491 | March 2008 | Baker et al. |

| 7341589 | March 2008 | Weaver et al. |

| 7354441 | April 2008 | Frigg |

| 7517350 | April 2009 | Weiner et al. |

| 7527639 | May 2009 | Orbay et al. |

| 7537596 | May 2009 | Jensen |

| 7635381 | December 2009 | Orbay |

| 7637928 | December 2009 | Fernandez |

| 7641677 | January 2010 | Weiner et al. |

| 7695472 | April 2010 | Young |

| 7695502 | April 2010 | Orbay et al. |

| 7766916 | August 2010 | Leyden et al. |

| 7771433 | August 2010 | Orbay et al. |

| 7771457 | August 2010 | Kay et al. |

| 7776076 | August 2010 | Grady et al. |

| 7776916 | August 2010 | Freeman et al. |

| 7857838 | December 2010 | Orbay |

| 7867260 | January 2011 | Meyer et al. |

| 7905909 | March 2011 | Orbay et al. |

| 7951176 | May 2011 | Grady et al. |

| 8075561 | December 2011 | Wolter |

| 8092505 | January 2012 | Sommers |

| 8118846 | February 2012 | Leither et al. |

| 8118848 | February 2012 | Ducharme et al. |

| 8337535 | December 2012 | White et al. |

| 8343196 | January 2013 | Schneider |

| 8403967 | March 2013 | Orbay |

| 8506607 | August 2013 | Eckhof et al. |

| 8518042 | August 2013 | Winslow et al. |

| 8556945 | October 2013 | Orbay |

| 8574268 | November 2013 | Chan et al. |

| 8579946 | November 2013 | Orbay |

| 8641744 | February 2014 | Weaver et al. |

| 8758346 | June 2014 | Koay et al. |

| 8814918 | August 2014 | Orbay et al. |

| 8845698 | September 2014 | Schneider |

| 8852245 | October 2014 | Schneider |

| 8876873 | November 2014 | Schneider |

| 8894693 | November 2014 | Petit et al. |

| 8940029 | January 2015 | Leung et al. |

| 9072558 | July 2015 | Orbay |

| 9107711 | August 2015 | Hainard |

| 9168075 | October 2015 | Dell Oca |

| 9265542 | February 2016 | Koay et al. |

| 9277947 | March 2016 | Koay et al. |

| 9295505 | March 2016 | Schneider |

| 9308034 | April 2016 | Grady |

| 9314284 | April 2016 | Chan et al. |

| 9387022 | July 2016 | Koay |

| 9433454 | September 2016 | Paolino et al. |

| 9498267 | November 2016 | Pfeiffer et al. |

| 9510880 | December 2016 | Terrill et al. |

| 9554909 | January 2017 | Donner et al. |

| 9855083 | January 2018 | Mighell et al. |

| 9867643 | January 2018 | Terrill et al. |

| 9931148 | April 2018 | Grady |

| 2001/0000186 | April 2001 | Bramlet et al. |

| 2001/0011172 | August 2001 | Orbay et al. |

| 2001/0012940 | August 2001 | Tunc |

| 2002/0013587 | January 2002 | Winquist et al. |

| 2002/0032446 | March 2002 | Orbay |

| 2002/0045901 | April 2002 | Wagner et al. |

| 2002/0049445 | April 2002 | Hall et al. |

| 2002/0062127 | May 2002 | Schumacher et al. |

| 2002/0065516 | May 2002 | Winquist et al. |

| 2002/0128654 | September 2002 | Steger et al. |

| 2002/0143337 | October 2002 | Orbay et al. |

| 2002/0143338 | October 2002 | Orbay et al. |

| 2002/0156474 | October 2002 | Inack et al. |

| 2002/0183752 | December 2002 | Steiner et al. |

| 2002/0183753 | December 2002 | Manderson |

| 2003/0040748 | February 2003 | Aikins et al. |

| 2003/0055435 | March 2003 | Barrick |

| 2003/0060827 | March 2003 | Coughlin |

| 2003/0083660 | May 2003 | Orbay |

| 2003/0083661 | May 2003 | Orbay et al. |

| 2003/0105461 | June 2003 | Putnam |

| 2003/0125738 | July 2003 | Khanna |

| 2003/0135212 | July 2003 | Y Chow |

| 2003/0135216 | July 2003 | Sevrain |

| 2004/0030339 | February 2004 | Wack et al. |

| 2004/0049193 | March 2004 | Capanni |

| 2004/0059334 | March 2004 | Weaver et al. |

| 2004/0059335 | March 2004 | Weaver et al. |

| 2004/0073218 | April 2004 | Dahners |

| 2004/0097937 | May 2004 | Pike et al. |

| 2004/0097941 | May 2004 | Weiner et al. |

| 2004/0111089 | June 2004 | Stevens et al. |

| 2004/0215198 | October 2004 | Marnay et al. |

| 2004/0254579 | December 2004 | Buhren et al. |

| 2004/0260291 | December 2004 | Jensen |

| 2004/0260306 | December 2004 | Fallin et al. |

| 2005/0015089 | January 2005 | Young et al. |

| 2005/0049593 | March 2005 | Duong et al. |

| 2005/0080421 | April 2005 | Weaver et al. |

| 2005/0085818 | April 2005 | Huebner |

| 2005/0107796 | May 2005 | Gerlach et al. |

| 2005/0165400 | July 2005 | Fernandez |

| 2005/0171544 | August 2005 | Falkner, Jr. |

| 2005/0187555 | August 2005 | Biedermann et al. |

| 2005/0216001 | September 2005 | David |

| 2005/0261688 | November 2005 | Grady et al. |

| 2005/0277937 | December 2005 | Leung et al. |

| 2006/0004361 | January 2006 | Hayeck et al. |

| 2006/0009771 | January 2006 | Orbay et al. |

| 2006/0058797 | March 2006 | Mathieu et al. |

| 2006/0200151 | September 2006 | Ducharme et al. |

| 2006/0217722 | September 2006 | Dutoit et al. |

| 2006/0235400 | October 2006 | Schneider |

| 2006/0264946 | November 2006 | Young |

| 2007/0016205 | January 2007 | Beutter et al. |

| 2007/0083207 | April 2007 | Ziolo et al. |

| 2007/0088360 | April 2007 | Orbay |

| 2007/0162016 | July 2007 | Matityahu |

| 2007/0206244 | September 2007 | Kobayashi |

| 2007/0208378 | September 2007 | Bonutti et al. |

| 2007/0225716 | September 2007 | Deffenbaugh et al. |

| 2007/0260244 | November 2007 | Wolter |

| 2007/0276386 | November 2007 | Gerlach et al. |

| 2007/0276402 | November 2007 | Frankel et al. |

| 2008/0065070 | March 2008 | Freid et al. |

| 2008/0132960 | June 2008 | Weaver et al. |

| 2008/0140130 | June 2008 | Chan et al. |

| 2008/0208259 | August 2008 | Gilbert et al. |

| 2008/0234749 | September 2008 | Forstein |

| 2008/0234752 | September 2008 | Dahners |

| 2008/0300637 | December 2008 | Austin et al. |

| 2009/0018557 | January 2009 | Pisharodi |

| 2009/0018588 | January 2009 | Eckhof et al. |

| 2009/0036933 | February 2009 | Dube et al. |

| 2009/0076553 | March 2009 | Wolter |

| 2009/0076554 | March 2009 | Huebner et al. |

| 2009/0099610 | April 2009 | Johnson et al. |

| 2009/0118768 | May 2009 | Sixto et al. |

| 2009/0143824 | June 2009 | Austin et al. |

| 2009/0143825 | June 2009 | Graham et al. |

| 2009/0216242 | August 2009 | Riemer et al. |

| 2009/0281543 | November 2009 | Orbay et al. |

| 2009/0287258 | November 2009 | Vannemreddy |

| 2009/0292318 | November 2009 | White et al. |

| 2009/0312803 | December 2009 | Austin |

| 2010/0016858 | January 2010 | Michel |

| 2010/0030277 | February 2010 | Haidukewych et al. |

| 2010/0057086 | March 2010 | Price et al. |

| 2010/0076496 | March 2010 | Fernandez |

| 2010/0094357 | April 2010 | Wallenstein et al. |

| 2010/0100134 | April 2010 | Mocanu |

| 2010/0137919 | June 2010 | Wolter |

| 2010/0274296 | October 2010 | Appenzeller et al. |

| 2010/0312285 | December 2010 | White et al. |

| 2010/0312286 | December 2010 | Dell Oca |

| 2011/0046681 | February 2011 | Prandi et al. |

| 2011/0087229 | April 2011 | Kubiak et al. |

| 2011/0106081 | May 2011 | Graham et al. |

| 2011/0224671 | September 2011 | Koay et al. |

| 2011/0301608 | December 2011 | Roth et al. |

| 2012/0143193 | June 2012 | Hulliger |

| 2012/0197307 | August 2012 | Fritzinger et al. |

| 2012/0245642 | September 2012 | Giannoudis et al. |

| 2013/0096631 | April 2013 | Leung |

| 2013/0116735 | May 2013 | Schneider |

| 2013/0172943 | July 2013 | Austin et al. |

| 2013/0190828 | July 2013 | Schneider |

| 2013/0197589 | August 2013 | Schneider |

| 2013/0245699 | September 2013 | Orbay et al. |

| 2013/0261675 | October 2013 | Fritzinger |

| 2014/0005728 | January 2014 | Koay |

| 2014/0018862 | January 2014 | Koay et al. |

| 2014/0180345 | June 2014 | Chan et al. |

| 2014/0207194 | July 2014 | Wolter |

| 2014/0236154 | August 2014 | Liao et al. |

| 2014/0271028 | September 2014 | Arnett |

| 2014/0277180 | September 2014 | Paolino et al. |

| 2014/0316473 | October 2014 | Pfeiffer et al. |

| 2014/0324108 | October 2014 | Orbay et al. |

| 2015/0051651 | February 2015 | Terrill et al. |

| 2015/0105829 | April 2015 | Laird |

| 2015/0257802 | September 2015 | Wolf et al. |

| 2015/0327897 | November 2015 | Hulliger |

| 2015/0327898 | November 2015 | Martin |

| 2015/0359575 | December 2015 | Pech et al. |

| 2016/0074081 | March 2016 | Weaver et al. |

| 2016/0089191 | March 2016 | Pak et al. |

| 2016/0143676 | May 2016 | Koay et al. |

| 2016/0166294 | June 2016 | Schneider |

| 2016/0242829 | August 2016 | Kim et al. |

| 2016/0278826 | September 2016 | Epperly |

| 2016/0310184 | October 2016 | Kazanovicz et al. |

| 2016/0317205 | November 2016 | Baker |

| 2016/0367299 | December 2016 | Paolino et al. |

| 2017/0265915 | September 2017 | Langdale |

| 2017/0319248 | November 2017 | Milella et al. |

| 2018/0008326 | January 2018 | Hulliger et al. |

| 2018/0036049 | February 2018 | Kobayashi |

| 2018/0064476 | March 2018 | Lopez et al. |

| 2018/0064477 | March 2018 | Lopez |

| 2018/0064479 | March 2018 | Lopez et al. |

| 2018/0132913 | May 2018 | Davison |

| 2018/0235681 | August 2018 | Chambers |

| 2019/0290338 | September 2019 | Bosshard |

| 2019/0298426 | October 2019 | Bosshard et al. |

| 1112803 | Nov 1981 | CA | |||

| 2047521 | Jan 1992 | CA | |||

| 2536960 | Mar 2005 | CA | |||

| 611147 | May 1979 | CH | |||

| 670755 | Jul 1989 | CH | |||

| 672245 | Nov 1989 | CH | |||

| 675531 | Oct 1990 | CH | |||

| 1486162 | Mar 2004 | CN | |||

| 2933637 | Apr 1980 | DE | |||

| 3442004 | Apr 1986 | DE | |||

| 3722852 | Jan 1989 | DE | |||

| 3743638 | Jul 1989 | DE | |||

| 4004941 | Aug 1990 | DE | |||

| 3942326 | Jun 1991 | DE | |||

| 4201531 | Jul 1993 | DE | |||

| 4341980 | Jun 1995 | DE | |||

| 4343117 | Jun 1995 | DE | |||

| 4438264 | Mar 1996 | DE | |||

| 19636733 | Apr 1997 | DE | |||

| 19629011 | Jan 1998 | DE | |||

| 9321544 | Sep 1999 | DE | |||

| 19832513 | Feb 2000 | DE | |||

| 19858889 | Jun 2000 | DE | |||

| 10015734 | Sep 2001 | DE | |||

| 10125092 | Dec 2001 | DE | |||

| 20309361 | Sep 2003 | DE | |||

| 20317651 | Mar 2004 | DE | |||

| 10319781 | Aug 2004 | DE | |||

| 102004009429 | Sep 2005 | DE | |||

| 102005042766 | Jan 2007 | DE | |||

| 202006019220 | May 2007 | DE | |||

| 202008000914 | Mar 2008 | DE | |||

| 202007017159 | May 2008 | DE | |||

| 102010048052 | Apr 2012 | DE | |||

| 102016112845 | Jan 2018 | DE | |||

| 202014011161 | Mar 2018 | DE | |||

| 0053999 | Jun 1982 | EP | |||

| 0158030 | Oct 1985 | EP | |||

| 0180532 | May 1986 | EP | |||

| 0207884 | Jan 1987 | EP | |||

| 0241914 | Oct 1987 | EP | |||

| 0244782 | Nov 1987 | EP | |||

| 0251583 | Jan 1988 | EP | |||

| 0266146 | May 1988 | EP | |||

| 0274713 | Jul 1988 | EP | |||

| 0290138 | Nov 1988 | EP | |||

| 0291632 | Nov 1988 | EP | |||

| 0299160 | Jan 1989 | EP | |||

| 0337288 | Oct 1989 | EP | |||

| 0360139 | Mar 1990 | EP | |||

| 0381462 | Aug 1990 | EP | |||

| 0382256 | Aug 1990 | EP | |||

| 0410309 | Jan 1991 | EP | |||

| 0436885 | Jul 1991 | EP | |||

| 0471418 | Feb 1992 | EP | |||

| 0506420 | Sep 1992 | EP | |||

| 0515828 | Dec 1992 | EP | |||

| 0530585 | Mar 1993 | EP | |||

| 0532421 | Mar 1993 | EP | |||

| 0546460 | Jun 1993 | EP | |||

| 0649635 | Apr 1995 | EP | |||

| 0668059 | Aug 1995 | EP | |||

| 0760231 | Mar 1997 | EP | |||

| 0848600 | Jun 1998 | EP | |||

| 1132052 | Sep 2001 | EP | |||

| 1468655 | Oct 2004 | EP | |||

| 1568329 | Aug 2005 | EP | |||

| 1604619 | Dec 2005 | EP | |||

| 1658015 | May 2006 | EP | |||

| 1712197 | Oct 2006 | EP | |||

| 1741397 | Jan 2007 | EP | |||

| 1767160 | Mar 2007 | EP | |||

| 1878394 | Jan 2008 | EP | |||

| 2529685 | Dec 2012 | EP | |||

| 0742618 | Mar 1933 | FR | |||

| 2233973 | Jan 1975 | FR | |||

| 2405062 | May 1979 | FR | |||

| 2405705 | May 1979 | FR | |||

| 2405706 | May 1979 | FR | |||

| 2496429 | Jun 1982 | FR | |||

| 2606268 | May 1988 | FR | |||

| 2622431 | May 1989 | FR | |||

| 2650500 | Feb 1991 | FR | |||

| 2671966 | Jul 1992 | FR | |||

| 2674118 | Sep 1992 | FR | |||

| 2677876 | Dec 1992 | FR | |||

| 2706763 | Dec 1994 | FR | |||

| 2739151 | Mar 1997 | FR | |||

| 2757370 | Jun 1998 | FR | |||

| 2802082 | Jun 2001 | FR | |||

| 0997733 | Jul 1965 | GB | |||

| 1237405 | Jun 1971 | GB | |||

| 1250413 | Oct 1971 | GB | |||

| 1312189 | Apr 1973 | GB | |||

| 1385398 | Feb 1975 | GB | |||

| 2017502 | Oct 1979 | GB | |||

| 1575194 | Sep 1980 | GB | |||

| 2090745 | Jul 1982 | GB | |||

| 2245498 | Jan 1992 | GB | |||

| 2257913 | Jan 1993 | GB | |||

| 02-121652 | May 1990 | JP | |||

| 03-058150 | Mar 1991 | JP | |||

| 03-158150 | Jul 1991 | JP | |||

| 04-138152 | May 1992 | JP | |||

| 06-045941 | Feb 1994 | JP | |||

| 06-125918 | May 1994 | JP | |||

| 06-245941 | Sep 1994 | JP | |||

| 08-098846 | Apr 1996 | JP | |||

| 08-126650 | May 1996 | JP | |||

| 08-257034 | Oct 1996 | JP | |||

| 08-266562 | Oct 1996 | JP | |||

| 09-108237 | Apr 1997 | JP | |||

| 10-118096 | May 1998 | JP | |||

| 11-076259 | Mar 1999 | JP | |||

| 11-299804 | Aug 1999 | JP | |||

| 11-276501 | Oct 1999 | JP | |||

| 11-512004 | Oct 1999 | JP | |||

| 11-318930 | Nov 1999 | JP | |||

| 2000-000247 | Jan 2000 | JP | |||

| 2000-152944 | Jun 2000 | JP | |||

| 2001-149379 | Jun 2001 | JP | |||

| 2001-161704 | Jun 2001 | JP | |||

| 2001-514039 | Sep 2001 | JP | |||

| 2001-525701 | Dec 2001 | JP | |||

| 2001-525702 | Dec 2001 | JP | |||

| 2002-095673 | Apr 2002 | JP | |||

| 2002-232185 | Aug 2002 | JP | |||

| 2002-532185 | Oct 2002 | JP | |||

| 2002-345836 | Dec 2002 | JP | |||

| 2002-542875 | Dec 2002 | JP | |||

| 2003-024344 | Jan 2003 | JP | |||

| 2003-038508 | Feb 2003 | JP | |||

| 2003-038509 | Feb 2003 | JP | |||

| 2003-509107 | Mar 2003 | JP | |||

| 2003-521303 | Jul 2003 | JP | |||

| 10-2007-0034449 | Mar 2007 | KR | |||

| 10-2008-0028917 | Apr 2008 | KR | |||

| 1037911 | Aug 1983 | SU | |||

| 1279626 | Dec 1986 | SU | |||

| 87/00419 | Jan 1987 | WO | |||

| 87/06982 | Nov 1987 | WO | |||

| 88/03781 | Jun 1988 | WO | |||

| 92/11819 | Jul 1992 | WO | |||

| 93/11714 | Jun 1993 | WO | |||

| 93/15678 | Aug 1993 | WO | |||

| 93/22982 | Nov 1993 | WO | |||

| 94/02073 | Feb 1994 | WO | |||

| 95/32674 | Dec 1995 | WO | |||

| 96/17556 | Jun 1996 | WO | |||

| 96/25892 | Aug 1996 | WO | |||

| 96/29948 | Oct 1996 | WO | |||

| 97/08999 | Mar 1997 | WO | |||

| 97/09000 | Mar 1997 | WO | |||

| 97/20514 | Jun 1997 | WO | |||

| 98/02105 | Jan 1998 | WO | |||

| 98/05263 | Feb 1998 | WO | |||

| 98/51226 | Nov 1998 | WO | |||

| 98/51368 | Nov 1998 | WO | |||

| 99/25266 | May 1999 | WO | |||

| 99/44529 | Sep 1999 | WO | |||

| 00/53110 | Sep 2000 | WO | |||

| 00/53111 | Sep 2000 | WO | |||

| 00/66012 | Nov 2000 | WO | |||

| 01/19267 | Mar 2001 | WO | |||

| 01/19268 | Mar 2001 | WO | |||

| 01/26566 | Apr 2001 | WO | |||

| 01/54601 | Aug 2001 | WO | |||

| 01/89400 | Nov 2001 | WO | |||

| 02/71963 | Sep 2002 | WO | |||

| 02/96309 | Dec 2002 | WO | |||

| 03/02856 | Jan 2003 | WO | |||

| 03/22166 | Mar 2003 | WO | |||

| 03/28567 | Apr 2003 | WO | |||

| 03/57055 | Jul 2003 | WO | |||

| 2004/043277 | May 2004 | WO | |||

| 2004/089233 | Oct 2004 | WO | |||

| 2004/107957 | Dec 2004 | WO | |||

| 2005/018472 | Mar 2005 | WO | |||

| 2005/044121 | May 2005 | WO | |||

| 2007/014279 | Feb 2007 | WO | |||

| 2007/108734 | Sep 2007 | WO | |||

| 2009/023666 | Feb 2009 | WO | |||

| 2009/058969 | May 2009 | WO | |||

| 2011/032140 | Mar 2011 | WO | |||

| 2012/112327 | Aug 2012 | WO | |||

| 2013/045713 | Apr 2013 | WO | |||

| 2017/048909 | Mar 2017 | WO | |||

Other References

|

Zimmer Advertisement, J. of Orthopaedic Trauma, vol. 12, No. 5, Jun./Jul. 1998. cited by applicant . Vattolo, M., Thesis, "The Effect of Grooves in Osteosynthesis Plates on the Restructuring of the Corticalis," Laboratory for Experimental Surgery, Swiss Research Institute, 1986 (original in German, translation to English attached with Certification). cited by applicant . U.S. Appl. No. 15/940,761, Locking Structures for Affixing Bone Anchors to a Bone Plate, and Related Systems and Methods, filed Mar. 29, 2018. cited by applicant . U.S. Appl. No. 15/926,390, Bone Plate With Form-Fitting Variable-Angle Locking Hole, filed Mar. 20, 2018. cited by applicant . Update, Titanium LC-DCP Condylar Buttress Plate, Jun. 15,1995 (Synthes) ("The LC-DCP update"). cited by applicant . Universelle Rekonstruktionsplatte URP 2 4-3.2 (UniRecon-Registered), Swiss Dent, 17,1996, pp. 19-25. cited by applicant . The Titanium Distal Radius Plate Technique Guide, published by Synthes, 1997. cited by applicant . The Titanium Distal Radius Plate Technique Guide, (the "DRP Guide") published by Synthes in 1996. cited by applicant . The Locking Reconstruction Plate Technique Guide, published by Synthes, 1997. cited by applicant . The Distal Radius Plate Instrument and Implant Set Technique Guide, (Synthes) ("1999 Radius Plate Guide"). cited by applicant . The Distal Radius Plate Instrument and Implant Set Technique Guide, (Synthes) ("1998 Radius Plate Guide"). cited by applicant . Technique Guide: 2.4 mm Variable Angle LCP Distal Radius System. Synthes, 2008,43 pages. cited by applicant . Technique Guide, Less Invasive Stabilization (LISS), Oct. 2003. cited by applicant . Synthes' Supporting Memorandum for Reconsideration of Claim Construction (without supporting Declaration) in the Pennsylvania Action, dated Feb. 19, 2008. cited by applicant . Synthes' Summary Judgment Motion of No Invalidity Based on K982222 Summary including supporting memorandum, and declarations of A. Silversti and B. Liu (with supporting exhibits), dated Sep. 10, 2008. cited by applicant . Synthes' Responsive Claim Construction Brief (without exhibits) for the Pennsylvania Action, dated Apr. 20, 2007. cited by applicant . Synthes' Response to Smith & Nephew's Statement of Facts in Support of Smith & Nephew's Motion for Summary Judgment of Invalidity of the '744 patent; dated Sep. 29, 2008; 19 pages. cited by applicant . Synthes' Response to Motion for Leave to Amend Answer, Civil Action No. Mar. 0084 (E.D. Pa.), dated Aug. 9, 2007. cited by applicant . Synthes' Reply to Smith & Nephew's Opposition to Synthes Motion for Reconsideration of Claim Construction for the '486 patent in the Pennsylvania Action, dated Mar. 14, 2008. cited by applicant . Synthes' Opposition to Smith & Nephew's Motion for Summary Judgment of Invalidity of the '744 patent; dated Sep. 29, 2008; 22 pages. cited by applicant . Synthes' Opening Claim Construction Brief (without supporting declaration and attached exhibits but including Appendix A & B) for the Pennsylvania Action, dated Mar. 16, 2007 (Dkt. 54) (Ex. 5). cited by applicant . Synthes' 1996 Titanium Modular Hand System brochure (the "Hand System Brochure") [SNI-0290287-294] (Ex. 47). cited by applicant . Synthes Titanium Modular Hand System, 1996. cited by applicant . Synthes Opposition to Smith & Nephew's Motion for Summary Judgment of Invalidity of Claims 10-12 of the '486 Patent, dated Sep. 29, 2008 (Dkt. 159) (Ex 67). cited by applicant . Synthes 1997 Catalog, published by Synthes, Mar. 1997; part 2, 261 pgs. cited by applicant . Synthes 1997 Catalog, published by Synthes, Mar. 1997; part 1, 200 pgs. cited by applicant . Sutter, F., et al., "Titanplasma-beschichtetes Hohlschrauben--und Rekonstructions-platten-System (THRP) zur Oberbriickung van Kieferdefekten," Chirurg No. 55, pp. 741-748,1984 [SNI-0006164-171], and translation thereof [SNI-0006152-163] (Ex. 33). cited by applicant . Surgical Instruments Catalog, Collin & Co., 1935 (original in French, translation to English of pp. 392-397 attached with certification). cited by applicant . Supplemental Expert Report of Clifford FI. Turen, M.D., May 2009 (with Exhibit 1), dated Aug. 8, 2008(Ex.60). cited by applicant . Supplement to Apr. 9, 2008 Expert Report of John F. Witherspoon (without exhibits), dated May 14, 2008 (Ex. 74). cited by applicant . Supplement to Apr. 9, 2008 Expert Report of J. Lawrence Marsh in the Pennsylvania Action (with Exhibit 1), dated May 14, 2008 (Ex. 46). cited by applicant . Summary of Safety and Effectiveness Information [510(k) Summary], K982222, Jul. 29, 1998. cited by applicant . Stryker, "VariAx Distal Radius: Locking Plate System", wwvv.osteosynthesis.stryker.com, 2006, 12 pages. cited by applicant . Stay Order in Pennsylvania Action, dated Jul. 13, 2009. cited by applicant . Smith and Nephew's Opposition to Synthes Motion for Summary Judgment of No Invalidity Based on K982222(including Opposition Memorandum, Statement of Undisputed Facts, K. Doyle Declaration with Exhibits A-F and R. King's Declaration with Exhibits A-D), dated Sep. 29, 2008( Dkt. 154) (Ex. 63). cited by applicant . Smith & Newphew Statement of Undisputed Facts in Support of its Motion for Summary Judgment of Invalidity of U.S. Pat. No. 7,128,744; dated Sep. 29, 2008; 8 pages. cited by applicant . Smith & Nephew, Inc. v. Rea, Federal Circuit Opinion dated Jul. 9, 2013, 18 pages. cited by applicant . Smith & Nephew's Third Supplemental Response to Interrogatories Nos. 4, 5, 6, 8 and 9; Second Supplemental Responses to Interrogatories Nos. 1,2, 3,10,11 and 12; and First Supplemental Responses to Interrogatories Nos. 13,15 and 17 (with Smith & Nephew Exhibit 1 thereto), dated Aug. 11, 2008 (Ex. 14). cited by applicant . Smith & Nephew's Responsive Claim Construction Brief (without exhibits) for the Pennsylvania Action, dated Apr. 20, 2007 (Dkt. 60) (Ex. 8). cited by applicant . Smith & Nephew's Responses and Objections to Plaintiffs Fourth Set of Interrogatories Nos. 15-16, dated May 21, 2008 (Ex. 55). cited by applicant . Smith & Nephew's Opposition to Synthes' Motion for Reconsideration of Claim Construction for the '486 Patent in the Pennsylvania Action, dated Mar. 4, 2008 (Dkt. 108) (Ex. 11). cited by applicant . Smith & Nephew's Opening Claim Construction Brief (without exhibits) for the Pennsylvania Action, dated Mar. 16, 2007 (Dkt. 53) (Ex. 6). cited by applicant . Smith & Nephew's Memorandum in Support of Motion for Leave to file Amended Answer in the Pennsylvania Action, dated Aug. 7, 2007 (Dkt. 77) (Ex. 70). cited by applicant . Smith & Nephew's Memorandum in Support of its Motion for Summary Judgment of Invalidly of U.S. Pat. No. 7,128,744; dated Sep. 10, 2008; 22 pages. cited by applicant . Smith & Nephew's Memorandum in Support of its Motion for Partial Summary Judgment of Invalidity of Claims 10-12 of the '486 patent, dated Sep. 10, 2008. cited by applicant . Smith & Nephew's Amended Answer in the Pennsylvania Action (without Exhibits A-S ) in the Pennsylvania Action, dated Aug. 7, 2007. cited by applicant . Smith & Nephew Amended Answer and Counterclaims of Defendant, Civil Action No. 03-0084 (E.D. Pa.), dated Aug. 7, 2007. cited by applicant . Second Supplement to Apr. 9, 2008 Expert Report of J. Lawrence Marsh (with Exhibit 1), dated Sep. 3, 2008. cited by applicant . Second Supplement to Apr. 9, 2008 Expert Report of David Seligson, M.D., dated Sep. 3, 2008. cited by applicant . Schuhli Technique Guide, published by Synthes, 1995. cited by applicant . Schuhli Technique Guide 1998, (Synthes) ("Schuhli Guide"). cited by applicant . Schmoker, The Locking Reconstruction Plate 2.4-3.2, originally published in Swiss Dent 17,1996. cited by applicant . Schandelmaier, et al., Distal Femur Fractures and LISS Stabilization, Injury, Int. J. Care Injured, vol. 32, Suppl. 3, 55-63, 2001. cited by applicant . Ring, D., et al. "Prospective Multicenter Trial of a Plate for Distal Fixation of Distal Radius Fractures," J. of Hand Surgery, vol. 22a(5), pp. 777-784, Sep. 1997. cited by applicant . Ring, D., et al,"A New Plate for Internal Fixation of the Distal Radius," AO.ASIF Dialogue, vol. IX, issue I, Jun. 1996 [SNI-0254971-973] (Ex. 53). cited by applicant . Reply to Counterclaims, Civil Action No. 03-0084 (E.D. Pa.), filed Jan. 2, 2007. cited by applicant . Rebuttal Expert Report of Russell Parsons, Ph.D., (with Exhibit 1), dated Jul. 15, 2008. cited by applicant . Rebuttal Expert Report of Mad Truman, P.E., (with Exhibit 2), dated May 14, 2008 (Ex. 79). cited by applicant . Rebuttal Expert Report of Eric R. Gozna, M.D., P.ENG., (with Exhibit 1), dated May 13, 2008 (Ex. 56). cited by applicant . Rebuttal Expert Report of Clifford H. Turen, M.D., (with Exhibit 1 ), dated May 14, 2008. cited by applicant . Rebuttal Expert Report of Charles E. Van Horn (without Exhibits), dated May 12, 2008 (Ex. 77). cited by applicant . Pure Titanium Implants Catalog, published Dec. 1993 (Synthes) ("PTI") [SN10259670-673] (Ex. 23). cited by applicant . Printout of http://www.aofoundation.org web site, dated May 23, 2007 (attached as Exhibit L to Amended Answer). cited by applicant . Printout from USFDA 510(k) Premarket Notification Database, dated May 23, 2007, listing Synthes Distal Femur Plate (DFP) System, and bearing 510(k) No. K982222 (attached as Exhibit N to Amended Answer. cited by applicant . Printout from USFDA 510(k) Premarket Notification Database, dated May 22, 2007, listing Synthes 2.4 mm Universal Locking Plate System, and bearing 510(k) No. K961421 (attached as Exhibit R to Amended Answer). cited by applicant . Printout from US FDA 510(k) Premarket Notification Database, dated May 22, 2007, listing Synthes Anatomical Locking Plate System, and bearing 510(k) No. K961413 (attached as Exhibit P to Amended Answer). cited by applicant . Photographs of the Bolhofner Distal Femur Plating System (Bolhofner DFPS), Apr. 14, 2008. cited by applicant . Perren, S., et al., "Early Temporary Porosis of Bone Induced by Internal Fixation Implants," Clinical Orthopaedics and Related Research, No. 232, Jul. 1988, 139-151. cited by applicant . Perren, et al., "The Limited Contact Dynamic Compression Plate (LC-DCP)," Arch. Orthopaedic & Trauma Surg., 1990, vol. 109, 304-310. cited by applicant . Ms. Truman's Jul. 24, 2008 deposition transcript in the Pennsylvania Action (Ex. 81). cited by applicant . Mr. Van Horn's Jul. 15, 2008 deposition transcript in the Pennsylvania Action (Ex. 78). cited by applicant . Marsh Exhibit C, Declaration of J. Lawrence Marsh, MD., in support of Smith & Nephew's, Inc's Motion for Partial Summary Judgement of Invalidity of Claims 10-12 of U.S. Pat. No. 6,623,486, dated Sep. 9, 2008, pp. 1-20. cited by applicant . Marsh Exhibit B, Supplement to Apr. 9, 2008 Expert Report of J. Lawrence Marsh, MD, Civil Action No. 03-0084, dated May 14, 2008 , pp. 1-19. cited by applicant . Marsh Exhibit A, Releasable 510(k) Search, Aug. 7, 2000, http://web.archive.org/web/19970615015534/www.fda.gov/egibin/htmlscript? 510k.hts+showcat-OR. cited by applicant . Marsh Exhibit A, Initial Expert Report of J. Lawrence Marsh, MD, Civil Action No. 03-0084, dated Apr. 9, 2008 , pp. 1-181. cited by applicant . Marsh Exhibit 1, Curriculum Vitae, Dec. 2006, pp. 1-34. cited by applicant . Marsh Exhibit 1, Affidavit of Christopher Butler dated Aug. 24, 2010. cited by applicant . Manual of Internal Fixation, Techniques Recommended by the AO-ASIG Group, Springer-Verlag, 1991,200-251. cited by applicant . Luthi, U., etal., "Kontackflache zwischen Osteosyntheseplatte and Knochen," Aktuel. Traumatol. 10:131-136,1980 ("Luthi") [SNI-0258572-577] (Ex. 31). cited by applicant . Less Invasive Stabilization System LISS Surgical Technique Proximal Tibia, (Draft), 2000,11 pgs. cited by applicant . Krettek et al.; "Distale Femurfrakturen"; Swiss Surg.; 1998; 4; p. 263-278 with English abstract. cited by applicant . Krettek et al, "LISS less Invasive Stabilization System," AO International Dialogue, vol. 12, Issue I, Jun. 1999. cited by applicant . Koval, k., et al., "Distal Femoral Fixation: A Biomechanical Comparison of the Standard Condylar Buttress Plate, a Locked Buttress Plate, and the 95-Degree Blade Plate," J. of Orthopaedic Trauma, val. 11(7), pp. 521-524, Lippencott-Raven Publishers, Oct. 1997. cited by applicant . Kolodziej, P., et al. "Biomechanical Evaluation of the Schuhli Nut," Clinical Orthopaedics and Related Research, No. 34 7, pp. 79-85, Lippencott-Raven Publishers, Feb. 1988 ("Kolodziej") [SNI-0256042-048] (Ex. 28). cited by applicant . Kassab, et al., "Patients Treated for Nonunions with Plate and Screw Fixation and Adjunctive Locking Nuts," Clinical Orthopaedics and Related Research, 1998, 347, 86-92. cited by applicant . Joint submission selling forth agreed claim construction in the Pennsylvania Action, dated Jul. 31, 2007. cited by applicant . International Search Report for International Application No. PCT/CH03/00577, dated Apr. 28, 2004, English language translation of the German language version. cited by applicant . International Patent Application No. PCT/US2008/072894: International Search Report dated Mar. 19, 2009, 18 pages. cited by applicant . Initial Expert Report of J. Lawrence Marsh, M.D., Apr. 9, 2008 (with Exhibits 1-2 and Appendices A-L), dated Apr. 9, 2008 (Ex. 41). cited by applicant . Initial Disclosures of Defendant, Civil Action No. 03-0084 (E.D. Pa), dated Jan. 12, 2007. cited by applicant . Information Disclosure Statement in U.S. Appl. No. 09/660,287, dated Nov. 13, 2000 (attached as Exhibit G to Amended Answer). cited by applicant . Information Disclosure Statement bearing, dated May 4, 2001 (attached as Exhibit F to Amended Answer). cited by applicant . Haas, N.P., et al., "LISS-Less Invasive Stabilization System--A New Internal Fixator for Distal Femur Fractures," OP J., vol. 13(3), pp. 340-344, Georg Thieme Verlag, Dec. 1997 (in English). cited by applicant . Gautier, E., et al., "Porosity and Remodelling of Plated Bone After Internal Fixation: Result of Stress Shielding of Vascular Damage?", Biomaterials and Biomechanics 1983, Elsevier Science Publishers B.V. 1984 ("Gautier"). cited by applicant . Expert Report of John F. Witherspoon (w/o Exhibits A-C) in the Pennsylvania Action, dated Apr. 9, 2008; 36 pages. cited by applicant . European Patent Application No. 12006617: Extended European Search Report dated Jan. 21, 2013, 8 pages. cited by applicant . European Patent Application No. 12006615.4: Extended European Search Report dated Jan. 21, 2013, 7 pages. cited by applicant . European Patent Application No. 12006606.3: Extended European Search Report dated Jan. 21, 2013, 7 pages. cited by applicant . English translation of International Patent Application No. PCT/CH03/00577: International Search Report dated Apr. 28, 2004, 6 pages. cited by applicant . English translation of International Patent Application No. PCT/CH03/00577: International Search Report dated Apr. 28, 2004, 4 pages. cited by applicant . Dr. Turen's Aug. 15, 2008 deposition transcript in the Pennsylvania Action (Ex. 61). cited by applicant . Dr. Parsons Aug. 7, 2008 deposition transcript in the Pennsylvania Action (Ex. 58). cited by applicant . Dr. Marsh's Jul. 26, 2008 Deposition transcript in the Pennsylvania Action (Ex. 52). cited by applicant . Docket sheet for the Pennsylvania Action--2:03-cv-0084 (CDJ) (Ex. 4) filed Jan. 7, 2003. cited by applicant . Docket sheet for the California Action--3:07-cv-00309-L-AJB (Ex. 1) Filed Feb. 14, 2007. cited by applicant . Defendant's Motion for Leave to Amend Answer to Assert Allegations of Inequitable Conduct, Civil Action No. 03-0084 (E.D. Pa.), dated Aug. 7, 2007. cited by applicant . Declaration of Robert A. King in Support of their Motion for Partial Summary Judgment of Invalidity of Claims 10-12 of U.S. Pat. No. 6,623,486 (without exhibits), dated Sep. 10, 2008. cited by applicant . Declaration of J. Russell Parsons, Ph.D. in Support of Synthes Opposition to Smith & Nephew's Motion for Summary Judgement of Invalidity of the '744 patent (w/o Exhibits 1-4) dated Sep. 29, 2008; 15 pages. cited by applicant . Declaration of J. Russell Parsons, Ph.D. in Support of Synthes Opposition to Smith & Nephew's Motion for Partial Summary Judgment of Invalidity of Method Claims 10-12 of U.S. Pat. No. 6,623,486 (with Exhibits 1-4), dated Sep. 29, 2008 (Dkt. 160) (Ex. 68). cited by applicant . Declaration of J. Lawrence Marsh, M.D. dated Nov. 22, 2010. cited by applicant . Declaration of J. Lawrence Marsh, M.D. dated Jun. 25, 2010. cited by applicant . Declaration of J. Lawrence Marsh, M.D. dated Jun. 3, 2010. cited by applicant . Declaration of Dr. Seligson in Support of Smith & Nephew's Motion for Partial Summary 175 Judgment of Invalidity of Claims 10-12 of U.S. Pat. No. 6,623,486 dated Sep. 9, 2008 (with Exhibit 1, pp. 16-66 dated Sep. 10, 2008). cited by applicant . Declaration of Clifford H. Turen, M.D. in Support of Synthes' Opposition to Smith & Nephew's Motion for Partial Summary Judgment of Invalidity of Method Claims 10-12 of U.S. Pat. No. 6,623,486 (with Exhibits 1-4 ), dated Sep. 29, 2008. cited by applicant . Declaration of Charles E. Van Horn, Esq., in Support of Synthes Opposition to Smith & Nephew's Motion for Summary Judgement of Invalidity of the '744 patent (w/o Exhibits 1-6) dated Sep. 29, 2008; 12 pages. cited by applicant . Court Order denying Synthes' Motion for Reconsideration of Claim Construction for the '486 Patent in the Pennsylvania Action, dated Jun. 30, 2008. cited by applicant . Collins Instruments de Chirurgie, published 1935, as illustrated at http://www.litos.com/pages/winkelstabilitaet e.html (Sep. 26, 2007) ("Collin Catalog") [SNI-0258552-556] (Ex. 20). cited by applicant . Claim Construction Order in Pennsylvania Action, dated Feb. 4, 2008. cited by applicant . Brief in Support of Defendants' Motion for Leave to Amend Answer to Assert Allegations of Inequitable Conduct, Civil Action No. 03-0084 (E.D. Pa.), dated Aug. 7, 2007. cited by applicant . Bolhofner, et al., The Results of Open Reduction and Internal Fixation of Distal Femur Fractures Using a Biologic (Indirect) Reduction Technique; Journal of Orthopedic Trauma, vol. 10, No. 6, pp. 372-377, Liooincort-Raven Publishers, Copyright 1996. cited by applicant . AO/ASIF Instruments and Implants, A Technical Manual, Springer-Verlag, 1994 (the "AO-ASIF Manual"). cited by applicant . Answer to Amended Complaint and Counterclaims, Civil Action No. 03-0084 (E . . . D. Pa), filed Dec. 5, 2006. cited by applicant . Amended Complaint for Patent Infringement, Civil Action No. 03-0084 (E.D. Pa.), filed Nov. 13, 2006. cited by applicant . ACE SymmetryTM, "Curves in All the Right Places", 1996, 3 pages. cited by applicant . ACE Symmetry, "Curves in All the Right Places", 1996, 3 pages. cited by applicant . ACE Symmetry Trademark Titanium Upper Extremity Plates, ACE Medical Company, 1996, 2 pages. cited by applicant . ACE Symmetry (Trademark), "Curves in All the Right Places", Titanium Upper Extremity Plates, Ace Medical Company, 1996, 6 pages. cited by applicant . 510(k) Summary for Synthes (USA)'s Distal Femur Plate (DFP) System (K982222), dated Jul. 29, 1998 (attached as Exhibit 0 to Amended Answer). cited by applicant . 510(k) Summary for Synthes (USA)'s Anatomical Locking Plate System (K961413), dated Aug. 7, 1996 (attached as Exhibit Q to Amended Answer). cited by applicant . 510(k) Summary for Synthes (USA)'s 2.4 mm Universal Locking Plate System (K961421 ), dated Jun. 26, 1996 (attached as Exhibit S to Amended Answer). cited by applicant . 510(k) Disclosure K982732, Oct. 8, 1998 (Synthes) ("K982732") [SNI-0259741-744] (Ex. 39). cited by applicant . 510(k) Disclosure K963798, Nov. 27, 1996 (Synthes) ("K963798") [SNI-0258398] (Ex. 38). cited by applicant . 510(k) Disclosure K962616, Sep. 3, 1996 (Synthes) ("K962616") [SNI-0258397] (Ex. 37). cited by applicant . 510(k) Disclosure K961421, Jun. 26, 1996 (Synthes) ("K961421 ") [SNI-0258396] (Ex. 36). cited by applicant . 510(k) Disclosure K961413, Aug. 7, 1996 (Synthes) ("K961413") [SNI-0259751] (Ex. 35). cited by applicant . 4.5 mm Cannulated Screw Technique Guide, published 1995 (Synthes) [SNI-0259703-714] (Ex. 21). cited by applicant . 35 U.S.C. .sctn.282 Notice in the Pennsylvania Action, dated Oct. 10, 2008 (Ex. 40). cited by applicant . 35 U.S.C. .sctn.282 Notice in the Pennsylvania Action, dated Oct. 10, 2008. cited by applicant . "VariAx TM Distal Radius Locking Plate System", Stryker R, Copyright 2009,12 pages. cited by applicant . "The New Comprehensive Stryker R VariAx TM Distal Radius Locking Plate System", Copyright 2009,20 pages. cited by applicant . "Multiple Offerings of Plates, Screws and Pegs", Small Bone Innovations, Inc., Dec. 2009, 2 pages. cited by applicant . "less Invasive Stabilization System (LISS) Technique Guide," Synthes (USA) Copyright 2000 (attached as Exhibit K to Amended Answer). cited by applicant . "Cone Drive History and Double Enveloping Technology", http://conedrive.com/history/html., accessed Apr. 20, 2006, 9 pages. cited by applicant. |

Primary Examiner: Lawson; Matthew J

Attorney, Agent or Firm: BakerHostetler

Claims

What is claimed:

1. A bone plate configured to receive a locking bone screw, the bone plate comprising: an inner surface configured to face the underlying bone, and an outer surface opposite the inner surface along an axial direction; and a threaded internal locking surface that extends between the outer surface and the inner surface so as to define a locking hole that is oriented along a central hole axis, wherein the threaded internal locking surface is defined prior to insertion of the locking bone screw in the locking hole, and the threaded internal locking surface defines a collection cavity disposed between the outer surface and the inner surface, wherein the collection cavity is configured to collect a shaving that is produced from one of the bone plate and the locking bone screw while the locking bone screw is threadedly mated with the bone plate, and wherein the threaded internal locking surface defines at least one thread that is configured to threadedly mate with a threaded head of the locking bone screw, and the collection cavity interrupts the at least one thread.

2. The bone plate as recited in claim 1, wherein a first portion of the at least one thread extends axially outward with respect to the collection cavity, and a second portion of the at least one thread extends axially inward with respect to the collection cavity.

3. The bone plate as recited in claim 1, wherein the collection cavity is configured as a collection recess that is swept circumferentially about the central hole axis.

4. The bone plate as recited in claim 3, wherein the at least one thread is continuous along greater than one revolution about the central hole axis.

5. The bone plate as recited in claim 3, wherein the at least one thread is configured to threadedly purchase with the locking bone screw both when the locking bone screw is oriented coincident with the central hole axis and when the locking bone screw is at an angle relative to the central hole axis within a range of angles at which the locking bone screw is configured to threadedly purchase with the at least one thread.

6. The bone plate as recited in claim 5, wherein the threaded internal locking surface defines a plurality of threaded regions that carry the at least one thread, and further defines a plurality of relief regions between adjacent ones of the threaded regions, wherein the bone plate is configured to threadedly purchase with the locking bone screw at the threaded regions and not at the relief regions.

7. The bone plate as recited in claim 6, wherein the collection recess is defined by a collection surface that is recessed radially outward with respect to the at least one threaded region.

8. The bone plate as recited in claim 7, wherein the threaded internal locking surface defines a relief recess at each of the relief regions, wherein the relief recesses circumferentially interrupt the at least one thread so as to define a plurality of thread segments, and axially aligned ones of the thread segments combine to define a plurality of threaded columns that are configured to threadedly purchase with the locking bone screw.

9. The bone plate as recited in claim 8, wherein the collection surface interrupts the thread segments of the columns along the axial direction.

10. The bone plate as recited in claim 9, wherein the collection recess is open to adjacent ones of the relief recesses.

11. The bone plate as recited in claim 9, wherein the threaded internal locking surface defines relief surfaces that at least partially define the relief recesses, and the collection surface has a radial depth that is greater than that of circumferentially outer portions of the relief surfaces, and less than that of circumferentially middle portions of the relief surfaces that are disposed circumferentially between the circumferential outer portions of the relief surfaces.

12. The bone plate as recited in claim 9, wherein the collection surface defines an axial length at least twice a pitch of each of the thread segments.

13. The bone plate as recited in claim 8, wherein the collection recess has a radial depth greater than a maximum height of the thread segments.

14. The bone plate as recited in claim 7, wherein the collection surface defines an axially inner end and an axially outer end, and the axially inner end is offset with respect to the axially outer end in a radially inward direction toward the central hole axis.

15. The bone plate as recited in claim 14, wherein each of the axially outer end and the axially inner end is spaced from the central hole axis a respective constant distance along an entire length of the collection recess.

16. The bone plate as recited in claim 7, wherein the collection surface is oriented along a plane that is oriented perpendicular to the central hole axis.

17. A bone fixation system comprising the bone plate as recited in claim 1, and the locking bone screw.

18. A bone plate configured to receive a locking bone screw, the bone plate comprising: an inner surface configured to face the underlying bone, and an outer surface opposite the inner surface along an axial direction; and a threaded internal locking surface that extends between the outer surface and the inner surface so as to define a locking hole that is oriented along a central hole axis, wherein the threaded internal locking surface defines a collection cavity disposed between the outer surface and the inner surface, wherein the collection cavity is configured as a collection recess that is swept circumferentially about the central hole axis, and the collection cavity is configured to collect a shaving that is produced from one of the bone plate and the locking bone screw while the locking bone screw is threadedly mated with the bone plate, wherein the collection recess is defined by a collection surface that is recessed radially outward with respect to the at least one threaded region, wherein the at least one thread is configured to threadedly purchase with the locking bone screw when the locking bone screw is oriented at an angle relative to the central hole axis within a range of angles at which the locking bone screw is configured to threadedly purchase with the at least one thread, wherein the threaded internal locking surface defines a plurality of threaded regions that carry the at least one thread, and further defines a plurality of relief regions between adjacent ones of the threaded regions, wherein the bone plate is configured to threadedly purchase with the locking bone screw at the threaded regions and not at the relief regions, wherein the internal surface defines a relief recess at each of the relief regions, wherein the relief recesses circumferentially interrupt the at least one thread so as to define a plurality of thread segments, and axially aligned ones of the thread segments combine to define a plurality of threaded columns that are configured to threadedly purchase with the locking bone screw, wherein the collection surface interrupts the thread segments of the columns along the axial direction, and wherein the threaded internal locking surface defines relief surfaces that at least partially define the relief recesses, and the collection surface has a radial depth that is greater than that of circumferentially outer portions of the relief surfaces, and less than that of circumferentially middle portions of the relief surfaces that are disposed circumferentially between the circumferential outer portions of the relief surfaces.

19. A bone plate configured to receive a locking bone screw, the bone plate comprising: an inner surface configured to face the underlying bone, and an outer surface opposite the inner surface along an axial direction; and a threaded internal locking surface that extends between the outer surface and the inner surface so as to define a locking hole that is oriented along a central hole axis, wherein the threaded internal locking surface defines a collection cavity disposed between the outer surface and the inner surface, wherein the collection cavity is configured to collect a shaving that is produced from one of the bone plate and the locking bone screw while the locking bone screw is threadedly mated with the bone plate, wherein the collection cavity is configured as a collection recess that is swept circumferentially about the central hole axis, and the collection recess is defined by a collection surface that is recessed radially outward with respect to the at least one threaded region, wherein the at least one thread is configured to threadedly purchase with the locking bone screw when the locking bone screw is oriented at an angle relative to the central hole axis within a range of angles at which the locking bone screw is configured to threadedly purchase with the at least one thread, wherein the threaded internal locking surface defines a plurality of threaded regions that carry the at least one thread, and further defines a plurality of relief regions between adjacent ones of the threaded regions, wherein the bone plate is configured to threadedly purchase with the locking bone screw at the threaded regions and not at the relief regions, wherein the threaded internal locking surface defines a relief recess at each of the relief regions, wherein the relief recesses circumferentially interrupt the at least one thread so as to define a plurality of thread segments, and axially aligned ones of the thread segments combine to define a plurality of threaded columns that are configured to threadedly purchase with the locking bone screw, and wherein the collection surface interrupts the thread segments of the columns along the axial direction, and the collection surface defines an axial length at least twice a pitch of each of the thread segments.

Description

BACKGROUND

When bones are damaged through trauma, disease, distraction osteogenesis, or orthognathic surgery, the defect is typically reduced, and bone fixation plates are commonly applied to the bone on sides of the defect to ensure union in the desired position. Bone screws can be sized to be driven through respective fixation holes of the plate and into the underlying bone to secure the bone plate to the bone. One common bone screw used in such applications is generally referred to as a locking screw that mate with threaded locking fixation holes of the bone plate. Locking screws have threaded heads that purchase with the threads in the locking fixation holes of the plate to reach a stable construct that prevents loosening or backing out of the screws. In particular, the locking screw can be driven through the plate fixation hole and into the underlying bone until the head threadedly mates with the bone plate in the locking fixation hole. The threaded heads of locking screws typically do not apply a compressive force against the bone plate toward the underlying bone.

One consideration when designing locking screws and locking fixation holes is the prevention the threads of the screw head from cross-threading with the threads in the locking fixation hole of the bone plate. Such cross-threading is associated with the production of shavings from the screw head, the bone plate, or both.

SUMMARY

According to one example of the present disclosure, a bone plate is configured to receive a locking bone screw. The bone plate defines an inner surface configured to face the underlying bone, and an outer surface opposite the inner surface along an axial direction. The bone plate can include a threaded internal locking surface that extends between the outer surface and the inner surface so as to define a locking hole that is oriented along a central hole axis. The internal locking surface can define a collection cavity disposed between the outer surface and the inner surface. The collection cavity can be configured to collect a shaving that is produced from one of the bone plate and the locking bone screw while the locking bone screw is threadedly mated with the bone plate.

BRIEF DESCRIPTION OF THE DRAWINGS

The foregoing summary, as well as the following detailed description of illustrative embodiments of the present application, will be better understood when read in conjunction with the appended drawings. For the purposes of illustrating the locking structures of the present application, there is shown in the drawings illustrative embodiments. It should be understood, however, that the application is not limited to the precise arrangements and instrumentalities shown. In the drawings:

FIG. 1 is an exploded perspective view of a bone fixation system including a bone plate and a plurality of bone screws configured to be fixed to an underlying bone;

FIG. 2 is an enlarged perspective view of a portion of the bone plate illustrated in FIG. 1, showing a standard-type locking hole;

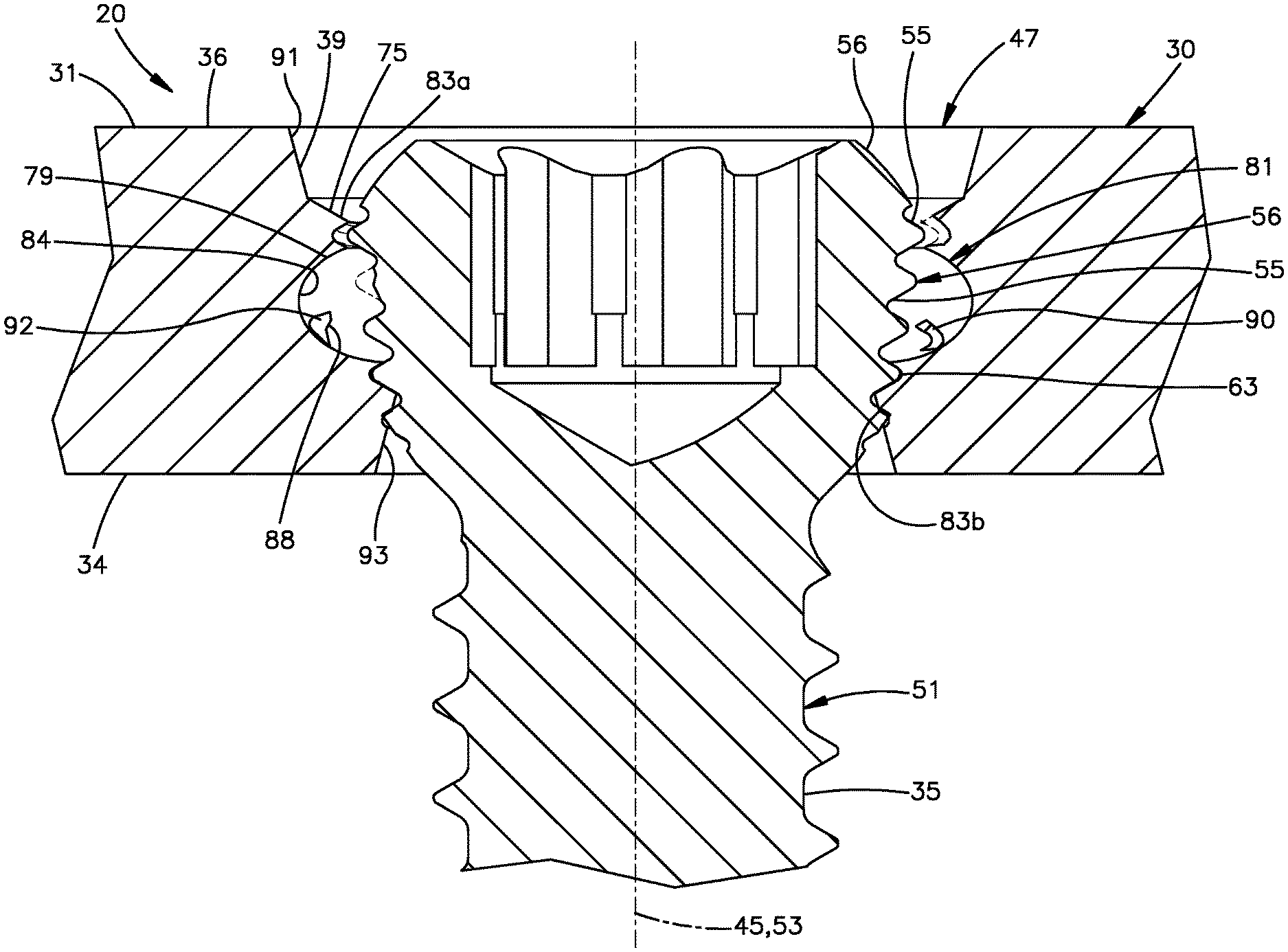

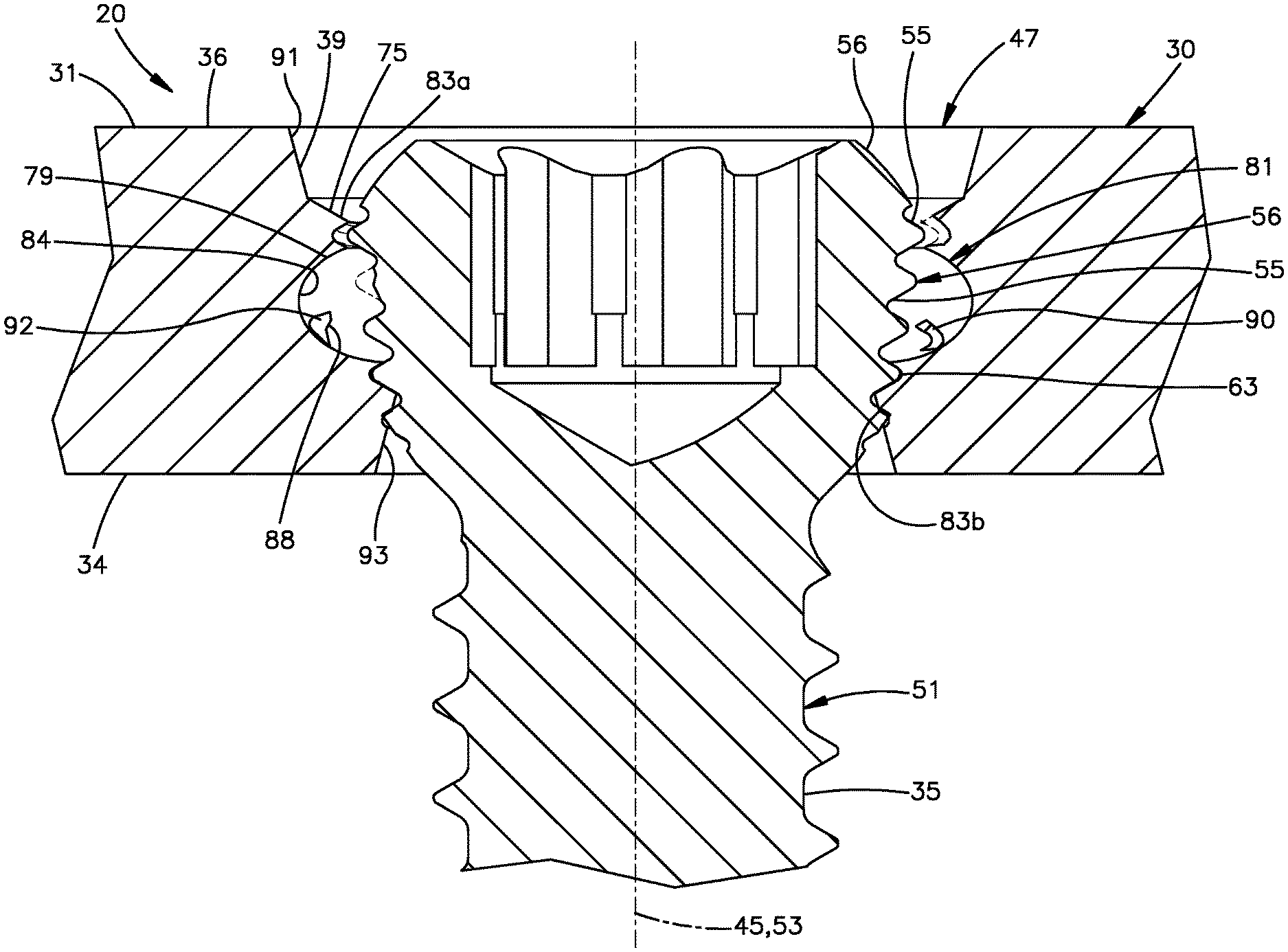

FIG. 3 is a sectional side elevation view of the portion of the bone plate illustrated in FIG. 2, taken along line 3-3;

FIG. 4 is a sectional plan view of the portion of the bone plate illustrated in FIG. 3, taken along line 4-4;

FIG. 5 is a sectional side elevation view of the portion of the bone plate illustrated in FIG. 2, shown with the bone screw illustrated in FIG. 1 being driven into the hole and producing shavings;

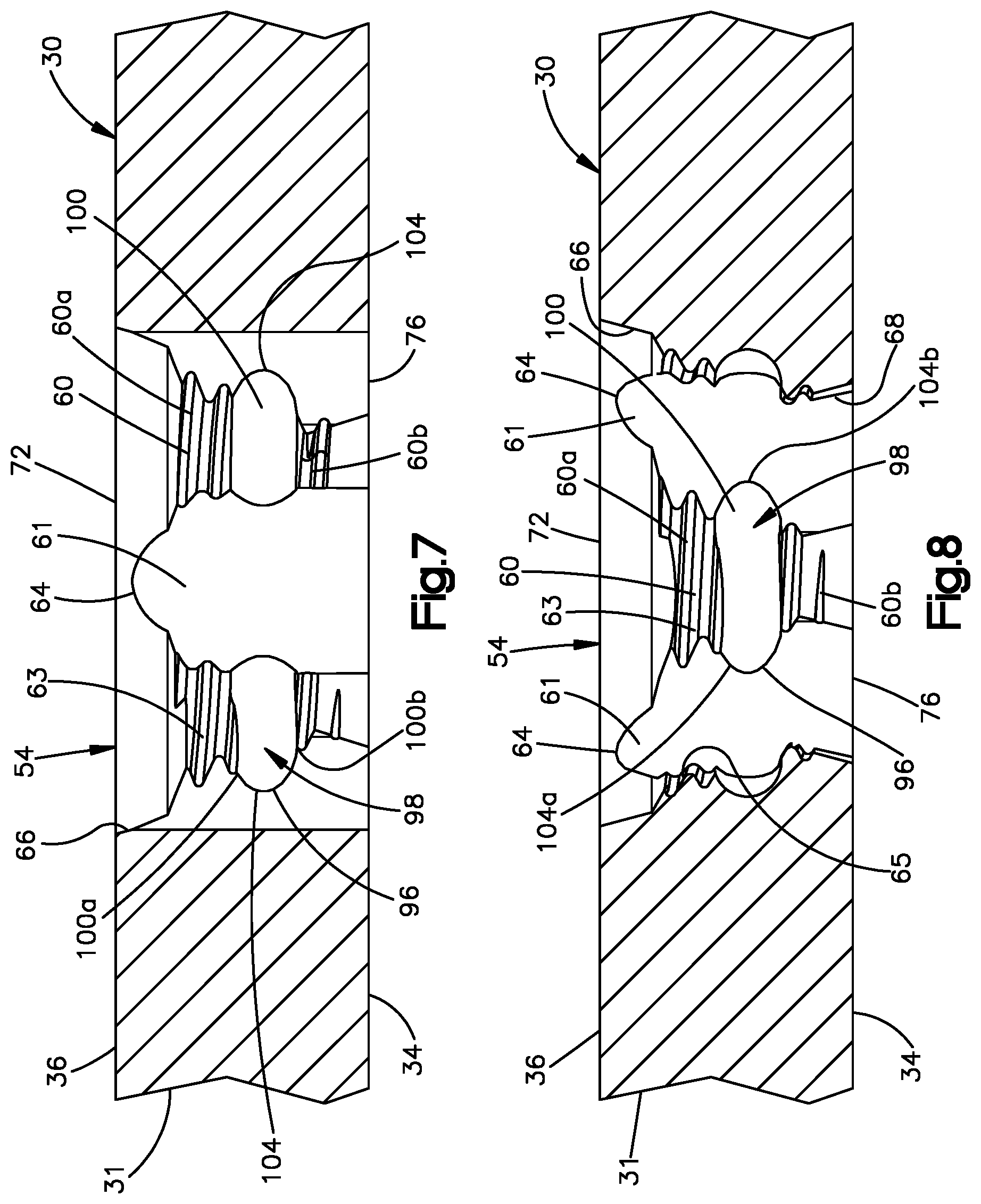

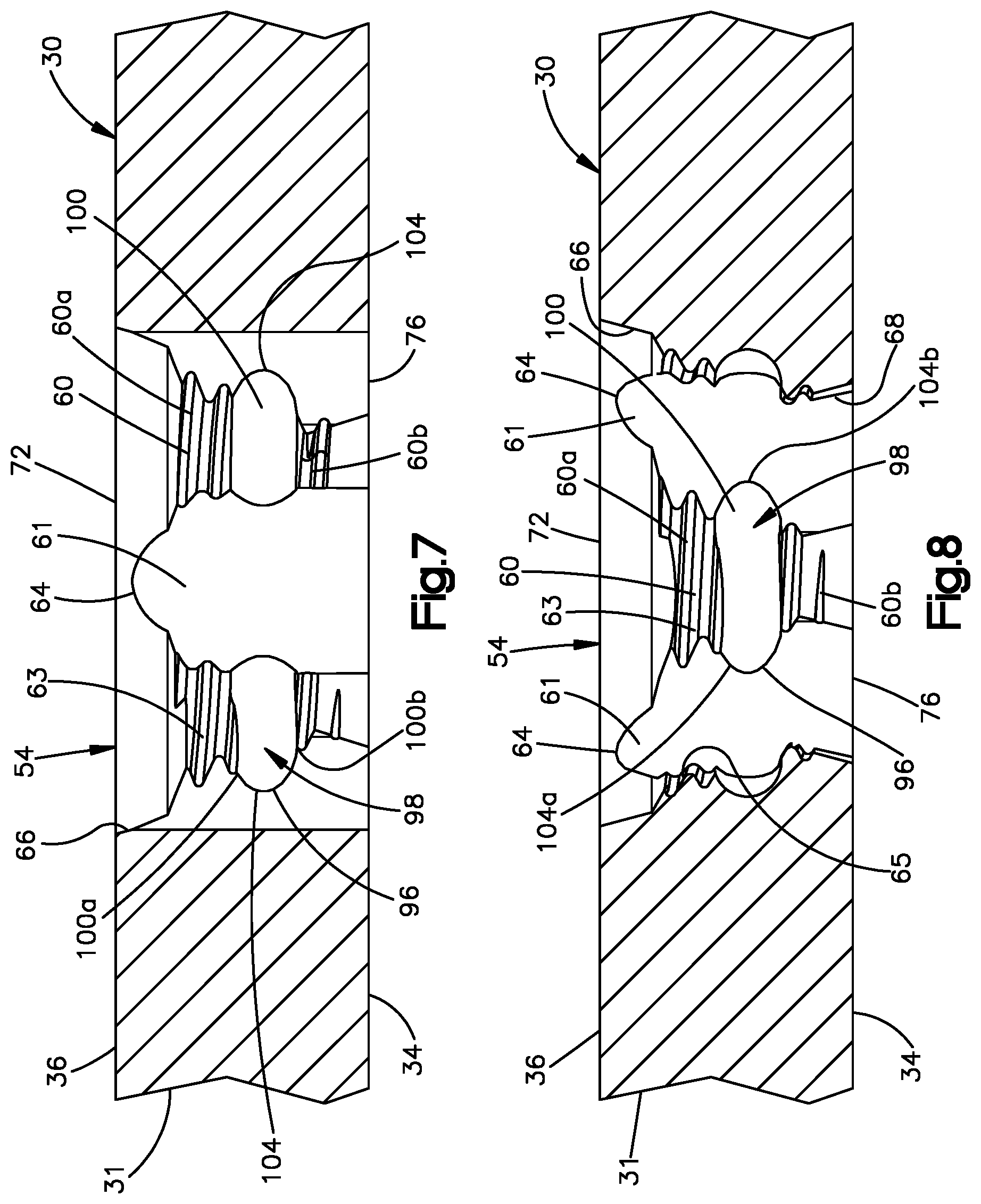

FIG. 6 is an enlarged perspective view of a portion of the bone plate illustrated in FIG. 1, showing a variable-angle locking hole;

FIG. 7 is a to plan view of the portion of the bone plate illustrated in FIG. 7;

FIG. 8 is a sectional side elevation view of the portion of the bone plate illustrated in FIG. 7, taken along line 8-8;

FIG. 9 is another sectional side elevation view of the portion of the bone plate illustrated in FIG. 7, taken along line 9-9; and

FIG. 10 is a sectional side elevation view of the portion of the bone plate illustrated in FIG. 9, but shown with the variable-angle bone screw illustrated in FIG. 1 being driven into the variable-angle screw hole and producing shavings.

DETAILED DESCRIPTION

The present disclosure can be understood more readily by reference to the following detailed description taken in connection with the accompanying figures and examples, which form a part of this disclosure. It is to be understood that this disclosure is not limited to the specific devices, methods, applications, conditions or parameters described and/or shown herein, and that the terminology used herein is for the purpose of describing particular embodiments by way of example only and is not intended to be limiting of the scope of the present disclosure. Also, as used in the specification including the appended claims, the singular forms "a," "an," and "the" include the plural, and reference to a particular numerical value includes at least that particular value, unless the context clearly dictates otherwise.

The term "plurality", as used herein, means more than one. When a range of values is expressed, another embodiment includes from the one particular value and/or to the other particular value. Similarly, when values are expressed as approximations, by use of the antecedent "about," it will be understood that the particular value forms another embodiment. All ranges are inclusive and combinable.

Referring initially to FIG. 1, a bone fixation system 20 is configured to be implanted onto bone 22 so as to stabilize a first bone segment 24 with respect to a second bone segment 26 that is separated from the first bone segment 24 by a defect 28. In one example, the first bone segment 24 can be defined by the diaphysis of the bone, while the second bone segment 26 can be defined by the epiphysis of the bone. It should be appreciated, however, that the first and second bone segments 24 and 26 can be defined by any region of the bone 22 as desired. Further, the bone 22 can be any bone in the human or animal anatomy suitable for bone plate fixation. Further still, while the bone 22 is illustrated having first and second bone segments 24 and 26, it is appreciated that the bone 22 can include any number of defects or bone fragments as desired that are configured for fixation using the bone fixation system 20. For instance, the diaphysis of the bone can include a plurality of bone fragments.

The bone fixation system 20 can include a bone plate 30 and a plurality of bone anchors 32 that are configured to fix the bone plate 30 to the underlying bone 22, and in particular to each of the first and second bone segments 24 and 26. The bone anchors 32 include a head 33 and a shaft 35 that extends out with respect to the head 33 along a respective central axis 53. The shaft 35 can extend directly from the head 33, or can extend from a neck that is disposed between the head 33 and the shaft 35. The shaft 35 can be threaded, such that the bone anchor 32 is configured as a bone screw 37 whose shaft 35 extends out relative to the head 33 along the central axis 53, which can also be referred to as a central screw axis 53.

The threaded shaft 35 can be configured to threadedly purchase in the underlying bone 22. For instance, one or more up to all of the bone screw 37 can be configured as a cortical screw whose threaded shaft 35 is designed and configured to threadedly mate to cortical bone. Alternatively or additionally, one or more of the bone screws 37 can be configured as a cancellous screw whose threaded shaft 35 is designed and configured to threadedly mate to cancellous bone. It is appreciated that cancellous bone screws typically have threads that have a greater pitch than threads of cortical bone screws. Further, the threads of cancellous bone screws typically extend out from the shaft of the bone screw a greater distance than the threads of cortical bone screws.

The bone plate 30 defines a bone plate body 31. The bone plate body 31, and thus the bone plate 30, defines a bone-facing inner surface 34 configured to face the underlying bone 22, and an outer surface 36 that is opposite the inner surface 34 along a transverse direction T. The bone plate 30 further defines a plurality of fixation holes 38 that extend through the bone plate body 31 from the inner surface 34 to the outer surface 36. In particular, each of the fixation holes 38 extends through the bone plate body 31, and thus through the bone plate 30, along a respective central hole axis 45. The central hole axis 45 is oriented along an axial direction. The axial direction can be coincident with the transverse direction T. Thus, the central hole axis 45 can be oriented normal to each of the inner surface 34 and the outer surface 36. It should be appreciated, of course, that the axial direction defined by the central hole axis 45 can be oriented in any suitable direction as desired, including a direction oblique to the transverse direction T.

The fixation holes 38 are each sized to receive the shaft 35 of a respective one of the bone screws 37. The bone screws 37 that extend through fixation holes 38 are permanent bone screws, meaning that they remain after completion of the surgical procedure. This is distinguished from temporary fixation holes that, for instance, can be configured to receive temporary fixation members, such as Kirschner wires that are removed prior to completion of the surgical procedure. In this regard, the fixation holes 38 can be referred to as permanent fixation holes. Accordingly, during operation, the shaft 35 of the bone screw 37 can be inserted through a respective one of the fixation holes 38 and into the underlying bone 22. The bone screw 37 can then be rotated so as to cause the threaded shaft 35 to be driven into the underlying bone 22 as the threaded shaft 35 threadedly purchases with the underlying bone. The threaded shaft 35 can be driven into the underlying bone 22 until the head 33 engages the bone plate 30. The heads 33 of the bone screws 37 can engage the bone plate 30 in various different manners as will now be described.

For instance, certain ones of the fixation holes 38 can be unthreaded compression fixation holes 52, while certain others of the fixation holes 38 can be threaded locking holes 44. Still other ones of the fixation holes 38 can be a combination hole, whereby a threaded locking hole 44 and an unthreaded compression hole 52 intersect each other to define a combination hole.

Thus, one or more of the bone screws 37 can be configured as a compression screw 49 whose head 33 defines a compression head 58 that is configured to bear against the bone plate 30 in the compression hole 52 so as to apply a compressive force against the bone plate 30 toward the underlying bone 22. In particular, the bone plate 30 can define an internal compression surface 57 that can extend between the outer surface 36 and the inner surface 34 so as to at least partially define the compression hole 52. During operation, the shaft 35 of the compression screw 49 can be inserted through the compression hole 52 and driven into the underlying bone 22 as described above. In particular, rotation of the bone screw 37 causes the compression head 58 to compress against the internal compression surface 57. As a result, the compression head 58 causes the bone plate 30 to apply a compressive force against the underlying bone. At least a portion of the internal compression surface 57 is typically spherical or otherwise tapered with respect to the central hole axis 45 as it extends in an axially inward direction from the outer surface 36 toward the inner surface 34. The taper of the internal compression surface 57 prevents the compression head 58 from passing completely through the compression hole 52. The compression head 58 typically has an unthreaded external surface. Similarly, at least a portion up to an entirety of the internal compression surface 57 that abuts the unthreaded external surface of the compression head 58 is typically unthreaded. Thus, it is common to drive compression screws 49 into the unthreaded compression holes 52.

With continuing reference to FIG. 1, the bone plate 30 can alternatively or additionally define at least one or more threaded locking holes 44 that are each configured to threadedly purchase with a respective one of the bone screws 37. For instance, the bone plate 30 can define a plurality of threaded internal locking surfaces 65 that can extend from the bone-facing inner surface 34 to the outer surface 36. Thus, the threaded internal locking surfaces 65 can at least partially define respective ones of the locking holes 44.