Display device, door including the same, and refrigerator including the door

Kang , et al. J

U.S. patent number 10,528,087 [Application Number 15/270,677] was granted by the patent office on 2020-01-07 for display device, door including the same, and refrigerator including the door. This patent grant is currently assigned to SAMSUNG ELECTRONICS CO., LTD.. The grantee listed for this patent is SAMSUNG ELECTRONICS CO., LTD.. Invention is credited to Nak-Won Choi, Sang On Choi, Kun Sok Kang, Kyung-Hoon Lee, Ho June Yoo.

View All Diagrams

| United States Patent | 10,528,087 |

| Kang , et al. | January 7, 2020 |

Display device, door including the same, and refrigerator including the door

Abstract

A display device, a door including the display device and a refrigerator including the door are provided. A display device includes: a frame configured to be rotatably mounted to a base object; a display panel mounted to the frame; a detector disposed in the frame, and configured to detect a movement of the frame and output a signal corresponding to the movement; and a controller configured to determine a movement state of the frame based on the signal, and control the display panel based on the movement state.

| Inventors: | Kang; Kun Sok (Suwon-si, KR), Yoo; Ho June (Seoul, KR), Lee; Kyung-Hoon (Seoul, KR), Choi; Nak-Won (Gwangmyeong-si, KR), Choi; Sang On (Suwon-si, KR) | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Applicant: |

|

||||||||||

| Assignee: | SAMSUNG ELECTRONICS CO., LTD.

(Suwon-si, KR) |

||||||||||

| Family ID: | 58386328 | ||||||||||

| Appl. No.: | 15/270,677 | ||||||||||

| Filed: | September 20, 2016 |

Prior Publication Data

| Document Identifier | Publication Date | |

|---|---|---|

| US 20170089632 A1 | Mar 30, 2017 | |

Foreign Application Priority Data

| Sep 24, 2015 [KR] | 10-2015-0135605 | |||

| Current U.S. Class: | 1/1 |

| Current CPC Class: | G09G 5/003 (20130101); A47F 3/0434 (20130101); F25D 23/028 (20130101); G09F 9/35 (20130101); A47F 3/0426 (20130101); G06F 3/14 (20130101); G06F 1/1677 (20130101); G09G 2320/08 (20130101); F25D 2400/36 (20130101); G09F 23/065 (20130101); G09G 2380/00 (20130101); F25D 27/005 (20130101); G09G 2330/021 (20130101); G09G 3/3406 (20130101); G09G 3/3648 (20130101); A47F 3/001 (20130101); F25D 2400/18 (20130101); F25D 2700/06 (20130101); F25D 2400/361 (20130101); F25D 29/00 (20130101); G09G 2370/10 (20130101); G09G 2300/04 (20130101); G09G 2320/0626 (20130101); G09G 2370/16 (20130101); G06F 3/0412 (20130101); F25D 2700/02 (20130101) |

| Current International Class: | A47F 3/04 (20060101); F25D 23/02 (20060101); G06F 1/16 (20060101); G06F 3/14 (20060101); G09G 5/00 (20060101); G09F 23/06 (20060101); G09F 9/35 (20060101); G09G 3/34 (20060101); A47F 3/00 (20060101); F25D 27/00 (20060101); G06F 3/041 (20060101); F25D 29/00 (20060101); G09G 3/36 (20060101) |

References Cited [Referenced By]

U.S. Patent Documents

| 4412292 | October 1983 | Sedam et al. |

| 4970870 | November 1990 | Midlang et al. |

| 5589958 | December 1996 | Lieb |

| 5712621 | January 1998 | Andersen |

| 6182050 | January 2001 | Ballard |

| 6208976 | March 2001 | Kinebuchi et al. |

| 6271751 | August 2001 | Hunt |

| 6359270 | March 2002 | Bridson |

| 6377228 | April 2002 | Jenkin et al. |

| 6427772 | August 2002 | Oden et al. |

| 6504580 | January 2003 | Thompson et al. |

| 6843011 | January 2005 | Hillstrom |

| 6950095 | September 2005 | Kim et al. |

| 7164432 | January 2007 | Amemiya |

| 7391397 | June 2008 | Sato et al. |

| 7596899 | October 2009 | Michael et al. |

| 7812724 | October 2010 | Boss |

| 8149225 | April 2012 | Lee |

| 8219152 | July 2012 | Oh et al. |

| 8253563 | August 2012 | Burnard |

| 8290595 | October 2012 | Kieval et al. |

| 8400607 | March 2013 | Cappaert et al. |

| 8493364 | July 2013 | Charlier et al. |

| 8582282 | November 2013 | Kim et al. |

| 8758524 | June 2014 | Backherms et al. |

| 9062911 | June 2015 | Keller et al. |

| 9164581 | October 2015 | Robinson et al. |

| 9311834 | April 2016 | Lee et al. |

| 9910518 | March 2018 | Bliss |

| 2002/0003531 | January 2002 | Kim et al. |

| 2002/0018027 | February 2002 | Sugimoto |

| 2002/0181722 | December 2002 | Hibino |

| 2002/0198571 | December 2002 | Puskas |

| 2003/0030412 | February 2003 | Matsuda et al. |

| 2003/0071941 | April 2003 | Mizuno |

| 2003/0103023 | June 2003 | Ootsuka et al. |

| 2003/0214619 | November 2003 | Masuda et al. |

| 2003/0223025 | December 2003 | Fujishiro |

| 2003/0229897 | December 2003 | Frisco et al. |

| 2004/0017365 | January 2004 | Hatano et al. |

| 2004/0073334 | April 2004 | Terranova |

| 2004/0160388 | August 2004 | O'Keeffe |

| 2005/0004836 | January 2005 | Ruttenberg |

| 2005/0029080 | February 2005 | Rupp |

| 2005/0166220 | July 2005 | McKay |

| 2005/0168399 | August 2005 | Palmquist |

| 2005/0178131 | August 2005 | Ryu et al. |

| 2005/0259084 | November 2005 | Popovich et al. |

| 2006/0044286 | March 2006 | Kohlhaas |

| 2006/0152618 | July 2006 | Yamasaki |

| 2006/0192767 | August 2006 | Murakami |

| 2006/0250056 | November 2006 | Fitzgerald |

| 2007/0016478 | January 2007 | Hill |

| 2007/0081344 | April 2007 | Cappaert et al. |

| 2007/0189042 | August 2007 | Pai et al. |

| 2007/0291015 | December 2007 | Mori |

| 2008/0024047 | January 2008 | Juo et al. |

| 2008/0048954 | February 2008 | Lee et al. |

| 2008/0129059 | June 2008 | Chang |

| 2008/0230497 | September 2008 | Strickland et al. |

| 2008/0278408 | November 2008 | Strickland |

| 2009/0036208 | February 2009 | Pennington et al. |

| 2009/0046212 | February 2009 | Tsubata et al. |

| 2009/0051531 | February 2009 | Boss |

| 2009/0052206 | February 2009 | Matsui et al. |

| 2009/0109324 | April 2009 | Kaplan et al. |

| 2009/0121970 | May 2009 | Ozbek |

| 2009/0167729 | July 2009 | Hino |

| 2009/0212943 | August 2009 | Burnard |

| 2009/0276319 | November 2009 | Lungu et al. |

| 2009/0278766 | November 2009 | Sako et al. |

| 2009/0279240 | November 2009 | Karppanen |

| 2009/0289874 | November 2009 | Ha |

| 2009/0295731 | December 2009 | Kim et al. |

| 2009/0295753 | December 2009 | King et al. |

| 2010/0018240 | January 2010 | Hecht et al. |

| 2010/0056220 | March 2010 | Oh et al. |

| 2010/0093401 | April 2010 | Moran et al. |

| 2010/0097469 | April 2010 | Blank et al. |

| 2010/0141689 | June 2010 | Johnson |

| 2010/0152892 | June 2010 | Gavra et al. |

| 2010/0157063 | June 2010 | Basso et al. |

| 2010/0206204 | August 2010 | Shimizu et al. |

| 2010/0227650 | September 2010 | Kim et al. |

| 2010/0240988 | September 2010 | Varga et al. |

| 2010/0252825 | October 2010 | Yamazaki et al. |

| 2010/0253541 | October 2010 | Seder et al. |

| 2010/0298032 | November 2010 | Lee |

| 2011/0041368 | February 2011 | Chua et al. |

| 2011/0098849 | April 2011 | Hudis et al. |

| 2011/0131610 | June 2011 | Lee et al. |

| 2011/0159932 | June 2011 | Richardson |

| 2011/0163986 | July 2011 | Lee et al. |

| 2011/0173082 | July 2011 | Breitenbach et al. |

| 2011/0181792 | July 2011 | Hammonds |

| 2011/0184862 | July 2011 | Lanier et al. |

| 2011/0216045 | September 2011 | Tsuchida |

| 2011/0241758 | October 2011 | Futter |

| 2012/0030726 | February 2012 | Winter et al. |

| 2012/0062475 | March 2012 | Locker et al. |

| 2012/0086877 | April 2012 | Kaoh |

| 2012/0102438 | April 2012 | Robinson |

| 2012/0105424 | May 2012 | Lee |

| 2012/0163021 | June 2012 | Bohn |

| 2012/0242698 | September 2012 | Haddick et al. |

| 2012/0242865 | September 2012 | Vartanian et al. |

| 2012/0285089 | November 2012 | Artwohl et al. |

| 2013/0099715 | April 2013 | Fuhge |

| 2013/0271378 | October 2013 | Hulford |

| 2013/0271696 | October 2013 | Dunn |

| 2013/0314348 | November 2013 | Luo |

| 2014/0007375 | January 2014 | McRoskey |

| 2014/0035850 | February 2014 | Shin et al. |

| 2014/0039730 | February 2014 | Loubiere |

| 2014/0078407 | March 2014 | Green |

| 2014/0321105 | October 2014 | Meyer |

| 2015/0220299 | August 2015 | Kim |

| 2017/0329438 | November 2017 | Kobel |

| 2018/0061374 | March 2018 | Wygonik |

| 1556664 | Dec 2004 | CN | |||

| 1657853 | Aug 2005 | CN | |||

| 101223329 | Jul 2008 | CN | |||

| 101557533 | Oct 2009 | CN | |||

| 101594403 | Dec 2009 | CN | |||

| 201476445 | May 2010 | CN | |||

| 101726155 | Jun 2010 | CN | |||

| 101846434 | Sep 2010 | CN | |||

| 103578400 | Feb 2014 | CN | |||

| 203657351 | Jun 2014 | CN | |||

| 2 681 730 | Sep 2012 | EP | |||

| 2 599 424 | Jun 2013 | EP | |||

| 7-244492 | Sep 1995 | JP | |||

| 2000-146 | Jan 2000 | JP | |||

| 2001-356714 | Dec 2001 | JP | |||

| 2003125904 | May 2003 | JP | |||

| 2003-241680 | Aug 2003 | JP | |||

| 2004-159964 | Jun 2004 | JP | |||

| 2005-172301 | Jun 2005 | JP | |||

| 2006-343374 | Dec 2006 | JP | |||

| 2007-61446 | Mar 2007 | JP | |||

| 2009-237493 | Oct 2009 | JP | |||

| 5071041 | Nov 2012 | JP | |||

| 1236377 | Jan 2006 | KR | |||

| 10-2010-0003913 | Jan 2010 | KR | |||

| 1020140062920 | May 2014 | KR | |||

| 2183864 | Jun 2002 | RU | |||

| M334925 | Jun 2008 | TW | |||

| 02/101188 | Dec 2002 | WO | |||

| 2012/119109 | Sep 2012 | WO | |||

| 2013/056109 | Apr 2013 | WO | |||

Other References

|

Communication dated Apr. 15, 2015 issued by the Australian Patent Office in Australian Patent Application No. 2011321257. cited by applicant . Communication dated Aug. 21, 2014, issued by the Australian Patent Office in Australian Application No. 2011321257. cited by applicant . Communication dated Feb. 17, 2015, issued by the Russian Patent Office in Russian Application No. 2013119740/12. cited by applicant . Communication dated Sep. 15, 2015 issued by the Japanese Patent Office in Japanese Application No. 2013-536496. cited by applicant . Communication dated Jul. 3, 2015 issued by the Russian Patent Office in Russian Application No. 2013119740. cited by applicant . Communication dated Oct. 22, 2014 issued by the European Patent Office in European Application No. 11836549.3. cited by applicant . Communication dated Dec. 3, 2014, issued by the State Intellectual Property Office of P.R. China in Chinese Application No. 201180063571.4. cited by applicant . International Search Report dated Mar. 23, 2012 in counterpart application No. PCT/KR2011/007347 (PCT/ISA/210). cited by applicant . Notice of Allowance issued in U.S. Appl. No. 13/278,504 dated Dec. 4, 2015. cited by applicant . Office Action issued in U.S. Appl. No. 13/278,504 dated Apr. 25, 2014. cited by applicant . Office Action issued in U.S. Appl. No. 13/278,504 dated Aug. 15, 2013. cited by applicant . Office Action issued in U.S. Appl. No. 13/278,504 dated Feb. 5, 2015. cited by applicant . Office Action issued in U.S. Appl. No. 13/278,504 dated Jul. 1, 2015. cited by applicant . Office Action issued in U.S. Appl. No. 13/278,504 dated Sep. 25, 2014. cited by applicant . Techfresh.net, "Samsung uVending Machines", Internet citation, Jan. 8, 2014, XP 002664085, Retrieved from the Internet: URL: http://web.archive.org/web/20100206151319/http://www.techfresh.net/samsun- g-uvending-machines/, Retrieved on Nov. 22, 2011. cited by applicant . International Search Report dated Oct. 12, 2016, issued by the International Searching Authority in counterpart International Application No. PCT/KR2016/008029 (PCT/ISA/210). cited by applicant . Communication dated Jul. 6, 2016 by the State Intellectual Property Office of P.R. China in counterpart Chinese Patent Application No. 201180063571.4. cited by applicant . Communication dated Jul. 5, 2016 by Japanese Intellectual Property Office in counterpart Japanese Patent Application No. 2013-536496. cited by applicant . Office Action dated Nov. 7, 2016 by the United States Patent and Trademark Office in U.S. Appl. No. 15/075,877. cited by applicant . Office Action dated May 4, 2017 by the United States Patent and Trademark Office in U.S. Appl. No. 15/075,877. cited by applicant . Anonymous., "Window of Opportunity: Touch screens will enable shoppers to find information", Nov. 4, 1998, Professional Engineering 11, 20, p. 22. cited by applicant . "Futuristic Smart Fridge: Input Ingredients, Receive Recipes!". Jun. 2, 2010. Designs & Ideas on Dornob, (4 Pages Total) https://web-beta.archive.Org/web/20100602233622/http://dornob.com/futuris- tic-smart-fridge-input-ingredients-receive-recipes/. cited by applicant . Office Action dated Jul. 28, 2017 by the United States Patent and Trademark Office in U.S. Appl. No. 15/075,877. cited by applicant . Communication dated Jun. 16, 2017 by the Korean Intellectual Property Office in counterpart Korean Application No. 10-2011-0040408. cited by applicant . Communication dated May 18, 2017 by the Indonesian Patent Office counterpart Indonesian Application No. W00201302143. cited by applicant . Communication dated Jun. 9, 2017, from the European Patent Office in counterpart European Application No. 11836549.3. cited by applicant . Notice of Allowance dated Sep. 8, 2017 by the United States Patent and Trademark Office in U.S. Appl. No. 15/075,877. cited by applicant . Notice of Allowance dated Jan. 25, 2018 by the United States Patent and Trademark Office in U.S. Appl. No. 15/075,877. cited by applicant . Communication dated Dec. 7, 2017 by the Indonesian Patent Office in counterpart Indonesian Application No. W00201302143. cited by applicant . Communication dated Dec. 28, 2017 by the Korean Intellectual Property Office in counterpart Korean Application No. 10-2011-0040408. cited by applicant . Communication dated Dec. 5, 2017 by the Japanese Patent Office in counterpart Japanese Application No. 2016-217438. cited by applicant . Communication dated Apr. 24, 2018 by the European Patent Office in counterpart European Patent Application No. 16848784.1. cited by applicant . Communication dated Jul. 12, 2018 by the European Patent Office in counterpart European Patent Application No. 16848784.1. cited by applicant . Communication dated May 3, 2018, issued by the State Intellectual Property Office of P.R. China in counterpart Chinese Application No. 201610833709.9. cited by applicant . Notice of Allowance dated Jun. 19, 2018, issued by the United States Patent and Trademark Office in U.S. Appl. No. 15/075,877. cited by applicant . Notice of Allowance dated Aug. 28, 2018 issued by the Canadian Intellectual Property Office in counterpart Canadian Patent Application No. 2815355. cited by applicant . Communication dated Sep. 4, 2018 issued by the Japanese Patent Office in counterpart Japanese Patent Application No. 2016-217438. cited by applicant . Communication dated Jan. 4, 2019, issued by the State Intellectual Property Office of People's Republic of China in counterpart Chinese Application No. 201610833709.9. cited by applicant . Communication dated Jan. 29, 2019, issued by the Indian Intellectual Property Office in corresponding Indian Application No. 3747/DELNP/2013. cited by applicant . Communication dated Dec. 11, 2018 issued by the European Patent Office in counterpart European Patent Application No. 16848784.1. cited by applicant . Office Action dated Jan. 22, 2019, issued by the U.S. Patent and Trademark Office in U.S. Appl. No. 16/159,163. cited by applicant . Communication dated Apr. 2, 2019 issued by the Japanese Patent Office in counterpart Japanese Application No. 2016-217438. cited by applicant . Communication dated May 9, 2019, issued by the State Intellectual Property Office of P.R. China in counterpart Chinese Application No. 201610833709.9. cited by applicant . Communication dated Sep. 3, 2019 issued by the State Intellectual Property Office of P.R. China in counterpart Chinese Application No. 201680038841.9. cited by applicant. |

Primary Examiner: Lee; Gene W

Attorney, Agent or Firm: Sughrue Mion, PLLC

Claims

What is claimed is:

1. A display device comprising: a frame configured to be rotatably mountable to a base object; a display panel mounted to the frame; a detector disposed in the frame, and configured to detect a movement of the frame and output a signal corresponding to the movement; and a controller configured to: identify a movement state of the frame based on the signal output by the detector, and control the display panel to display different images based on the identified movement state of the frame, wherein the movement state of the frame includes a completely opened state, a completely closed state, and an ongoing state indicating that the frame is between the completely opened state and the completely closed state, and wherein, based on the movement state of the frame being the completely closed state, the controller is further configured to identify whether the signal output by the detector is an impact signal caused by closure of the frame or a noise signal caused by external force.

2. The display device according to claim 1, wherein the detector is further configured to detect whether the frame is moving away from the base object or moving closer to the base object, wherein the detector comprises at least one of an acceleration sensor, a gyro sensor, and a geomagnetic sensor.

3. The display device according to claim 1, wherein the ongoing state includes a currently opening state and a currently closing state, and wherein the controller is configured to identify a direction of the movement based on the signal, identify that the frame is in the currently opening state when the identified direction is a first direction, and identify that the frame is in the currently closing state when the identified direction is a second direction, wherein the currently opening state indicates that the frame is moving away from the base object, and the currently closing state indicates that the frame is moving closer to the base object.

4. The display device according to claim 3, wherein the display panel comprises a backlight unit; and wherein the controller is configured to control the backlight unit to be dimmed in response to identifying that the frame is in the currently opening state.

5. The display device according to claim 1, wherein the controller is further configured to adjust transparency of the display panel based on the movement state of the frame.

6. The display device according to claim 1, wherein the ongoing state includes a currently opening state and a currently closing state, and wherein the detector comprises an inductance sensor, wherein the controller is configured to identify the frame is in the currently opening state when an inductance value indicated by the signal increases, and identify the frame is in the currently closing state when the inductance value decreases, and wherein the currently opening state indicates that the frame is moving away from the base object, and the currently closing state indicates that the frame is moving closer to the base object.

7. A refrigerator comprising: a main body comprising a storage chamber and an opening; and a door rotatably mounted to the main body to open or close the opening, wherein the door comprises: a frame; a display panel mounted to the frame; a detector disposed in the frame, and configured to detect a movement of the door and output a signal corresponding to the movement; and a controller configured to identify a movement state of the frame based on the signal output from the detector, and control the display panel based on the movement state, wherein the movement state of the frame includes a complete state and an ongoing state, wherein the complete state includes a completely opened state and a completely closed state, and the ongoing state indicates that the frame is between the completely opened state and the completely closed state, and wherein the controller is further configured to control the display panel to operate differently based on whether the frame is in the completely opened state or in the ongoing state.

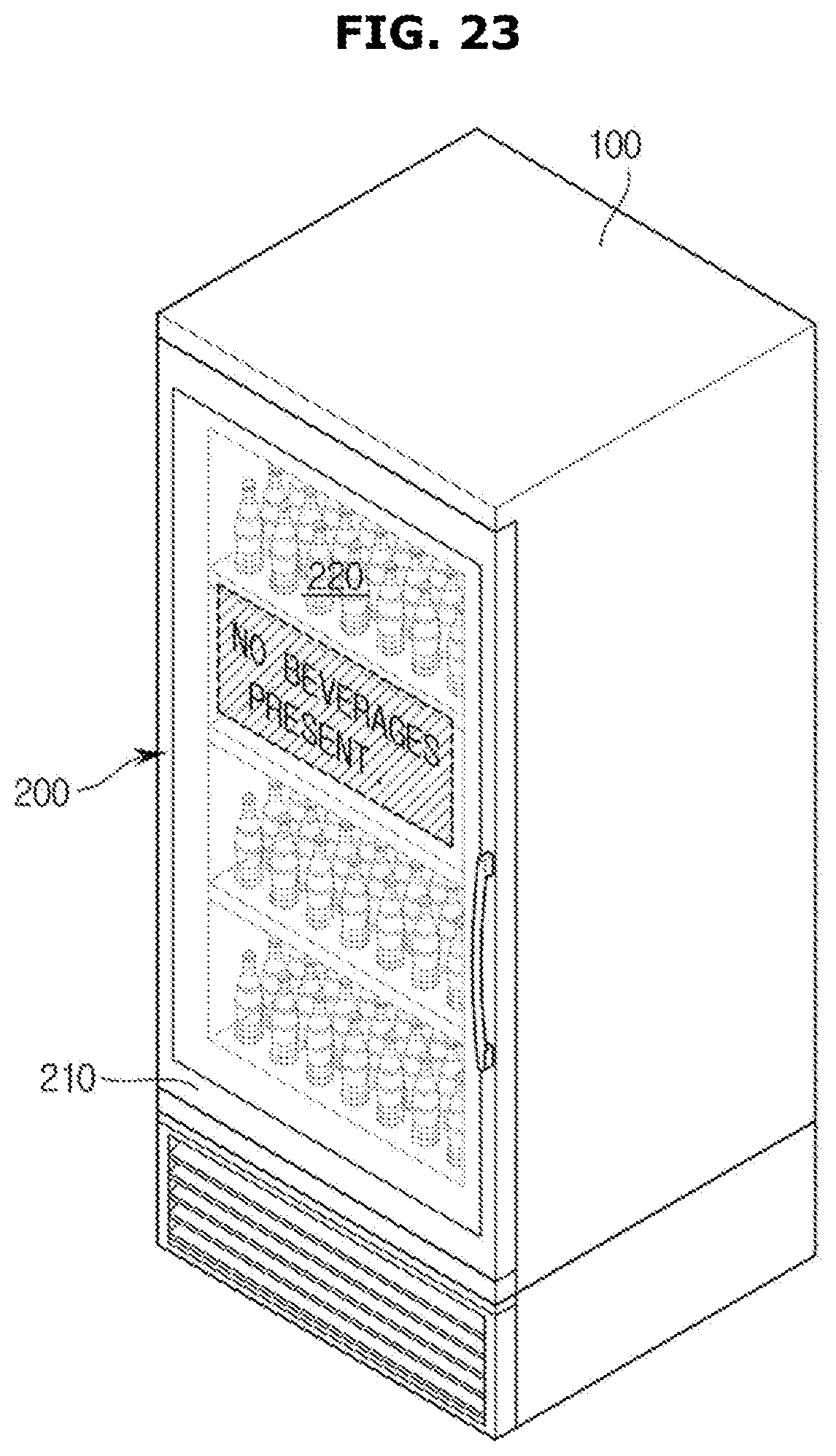

8. The refrigerator according to claim 7, wherein the detector is configured to scan an inside of the storage chamber, and wherein the controller is configured to identify an empty region from among plural regions contained in the storage chamber based on a result of scanning by the detector, and control the display panel to display information regarding the identified empty region.

9. The refrigerator according to claim 7, wherein the ongoing state includes a currently opening state and a currently closing state, wherein the controller is further configured to control a position of the frame based on the signal output from the detector, identify the movement state to be the completely opened state when the identified position of the frame is a first target position, identify the movement state to be the completely closed state when the identified position of the frame is a second target position, identify the movement state to be the currently closing state when the identified position of the frame is moving from the first target position to the second target position, and identify the movement state to be the currently opening state when the identified position of the frame is moving from the second target position to the first target position, and wherein the controller is configured to change images displayed on the display panel when the door is identified to be moving based on the signal.

10. The refrigerator according to claim 9, wherein the controller is configured to control the display panel to change currently displayed images in response to identifying the door is continuously moving for a predetermined time period based on the signal.

11. The refrigerator according to claim 7, wherein the controller is configured to control the display panel to display event information when the door is identified to be moving based on the signal.

12. The refrigerator according to claim 7, wherein the controller is configured to control the display panel to display advertisement information when the door is identified to be moving based on the signal.

13. The refrigerator according to claim 7, wherein the display panel is a transparent display panel, and wherein the controller is configured to control a backlight unit of the display panel to be dimmed when the door is identified to be moving based on the signal.

14. The refrigerator according to claim 7, wherein the display panel is a transparent display panel, and wherein the controller is configured to control a backlight unit of the display panel to be turned off when the door is identified to be moving based on the signal.

15. The refrigerator according to claim 7, wherein the detector comprises at least one of an acceleration sensor, a gyro sensor, and a geomagnetic sensor.

16. The refrigerator according to claim 15, wherein the controller is configured to reduce brightness of the display panel in response to identifying the door is continuously moving for a predetermined time period based on the signal.

17. The refrigerator according to claim 7, wherein the ongoing state includes a currently opening state and a currently closing state, wherein the controller is configured to identify a direction of the movement of the door based on the signal, identify that the door is in the currently opening state when the identified direction is a first direction, and identify that the door is in the currently closing state when the identified direction is a second direction, and wherein the second direction indicates that the identified position of the frame is moving from a first target position to a second target position, the first direction indicates that the identified position of the frame is moving from the second target position to the first target position, and wherein the currently opening state indicates that the door is moving away from the main body, and the currently closing state indicates that the door is moving closer to the main body.

18. The refrigerator according to claim 17, wherein the controller is configured to: in response to the identified direction being the second direction, identify whether there are fluctuations in the signal equal to or more than a predetermined number of times; and in response to identifying there are fluctuations in the signal equal to or more than the predetermined number of times, identify that the door is in the completely closed state.

19. The refrigerator according to claim 7, wherein the ongoing state includes a currently opening state and a currently closing state; wherein the detector comprises an inductance sensor, and wherein the controller is configured to identify that the door is in the currently opening state, which indicates that the door is moving away from the main body, when an inductance value indicated by the signal increases, and identify that the door is in the currently closing state, which indicates that the frame is moving closer to the main body, when the inductance value decreases.

20. A door comprising: a frame configured to be rotatably mountable to a base object; a display panel mounted to the frame; a detector disposed in the frame, and configured to detect a movement of the frame and output a signal corresponding to the movement; and a controller configured to identify a movement state of the frame and a direction of the movement based on the signal, identify whether the door is in a currently opening state or in a currently closing state based on the identified direction, and control at least one of a transparency and displayed image of the display panel based on whether the door is in the currently opening state or in the currently closing state, wherein the movement state of the frame includes a complete state and an ongoing state, the ongoing state including the currently opening state and the currently closing state, wherein the complete state includes a completely opened state and a completely closed state, and the ongoing state indicates that the frame is between the completely opened state and the completely closed state, wherein the controller is further configured to control the display panel to operate differently based on whether the frame is in the completely opened state or in the ongoing state, and wherein the currently opening state indicates that the frame is moving away from the base object, and the currently closing state indicates that the frame is moving closer to the base object.

Description

CROSS-REFERENCE TO RELATED APPLICATION

This application claims priority from Korean Patent Application No. 10-2015-0135605, filed on Sep. 24, 2015 in the Korean Intellectual Property Office, the disclosure of which is incorporated herein by reference in its entirety.

BACKGROUND

1. Field

One or more exemplary embodiments relate to a display device having a display panel on which images are displayed, a door including a display panel, and a refrigerator to which the door is rotatably mounted.

2. Description of the Related Art

Generally, display devices have been rapidly developed from an early cathode ray tube (CRT) type monochrome display device, which has a large volume, to a recent thin film type large-area full color display device.

Also, the information provided by display devices has evolved from simple letters and images to more elaborate and high-definition images.

The conventional display device often occupies a large space when installed at home or public places, causing difficulty in improving space utilization. In addition, the conventional display device may disturb the user's view, deteriorating space aesthetics. As a result, there is a limitation in application of the conventional display device.

However, various methods for obviating the above-mentioned problems of the conventional display devices have been recently proposed.

One such method is to use a transparent display device. For example, a transparent display device is widely used for advertising panels, doors of refrigerators, etc.

SUMMARY

One or more exemplary embodiments provide a display device for controlling image display while movement or motion occurs, a door including the same, and a refrigerator including the door.

One or more exemplary embodiments also provide a display device for scanning the region of a storage chamber and then displaying scan information, a door including the same, and a refrigerator including the door.

According to an aspect of an exemplary embodiment, there is provided a display device including: a frame configured to be rotatably mounted to a base object; a display panel mounted to the frame; a detector disposed in the frame and configured to detect a movement of the frame and output a signal corresponding to the movement; and a controller configured to determine a movement state of the frame based on the signal, and control the display panel based on the movement state.

The detector may include at least one of an acceleration sensor, a gyro sensor, and a geomagnetic sensor.

The controller may be configured to determine a direction of the movement based on the signal, determine that the frame is in an opening state when the determined direction is a first direction, determine that the frame is in a closing state when the determined direction is a second direction, wherein the opening state indicates that the frame is moving away from the base object, and the closing state indicates that the frame is moving closer to the base object.

The display panel may include a backlight unit; and the controller may be configured to control the backlight unit to be dimmed, if the frame is in the opening state.

The display panel may include a backlight unit, and the controller may be configured to control the backlight unit to be turned off, if the frame is in the opening state.

The detector may include an inductance sensor, and the controller may be configured to determine the frame is in the opening state when an inductance value indicated by the signal increases, and determine the frame is in the closing state when the inductance value decreases, wherein the opening state indicates that the frame is moving away from the base object, and the closing state indicates that the frame is moving closer to the base object.

According to an aspect of another exemplary embodiment, there is provided a refrigerator including: a main body including a storage chamber and an opening; and a door rotatably mounted to the main body to open or close the opening, wherein the door includes: a frame; a display panel mounted to the frame; a detector disposed in the frame and configured to detect a movement of the door and output a signal corresponding to the movement; and a controller configured to determine a movement state of the frame based on the signal, and control the display panel based on the movement state.

The detector may be configured to scan an inside of the storage chamber, and the controller may determine an empty region from among plural regions contained in the storage chamber based on a result of scanning of the detector, and control the display panel to display information regarding the determined empty region.

The controller may be configured to control the display panel to change images when the door is determined to be moving based on the signal.

The controller may be configured to control the display panel to display event information when the door is determined to be moving based on the signal.

The controller may be configured to control the display panel to display advertisement information when the door is determined to be moving based on the signal.

The display panel may be a transparent display panel, and the controller may be configured to control a backlight unit of the display panel to be dimmed when the door is determined to be moving based on the signal.

The display panel may be a transparent display panel, and the controller may be configured to control a backlight unit of the display panel to be turned off when the door is determined to be moving based on the signal.

The detector may include at least one of an acceleration sensor, a gyro sensor, and a geomagnetic sensor.

The controller may be configured to determine a direction of the movement of the door based on the signal, determine that the door is in an opening state when the determined direction is a first direction, and determine that the door is in a closing state when the determined direction is a second direction, wherein the opening state indicates that the door is moving away from the main body, and the closing state indicates that the door is moving closer to the main body.

The controller may be configured to: if the determined direction of the signal is the second direction, determine whether there are fluctuations in the signal equal to or more than a predetermined number of times; and if there are fluctuations in the signal equal to or more than a predetermined number of times, determine that the door is in a completely closed state.

The controller may be configured to: if the door is determined to be continuously moving for a predetermined time period based on the signal, control the display panel to change currently displayed images.

The controller may be further configured to reduce brightness of the display panel if the door is determined to be continuously moving for a predetermined time period based on the signal.

The detector may include an inductance sensor, and the controller may be configured to determine that the door is in an opening state, which indicates that the door is moving away from the main body, when an inductance value indicated by the signal increases, and determine that the door is in a closing state, which indicates that the frame is moving closer to the main body, when the inductance value decreases.

According to an aspect of another exemplary embodiment, there is provided a door including: a frame configured to be rotatably mounted to a base object; a display panel mounted to the frame; a detector disposed in the frame and configured to detect a movement of the frame and output a signal corresponding to the movement; and a controller configured to determine a direction of the movement based on the signal, determine whether the door is in an opening state or in a closing state based on the determined direction, and control at least one of a transparency and displayed image of the display panel based on whether the door is in the opening state or in the closing state, wherein the opening state indicates that the frame is moving away from the base object, and the closing state indicates that the frame is moving closer to the base object.

BRIEF DESCRIPTION OF THE DRAWINGS

The above and/or other aspects will become apparent and more readily appreciated from the following description of exemplary embodiments, taken in conjunction with the accompanying drawings of which:

FIG. 1 is a perspective view illustrating a refrigerator including a door according to an exemplary embodiment.

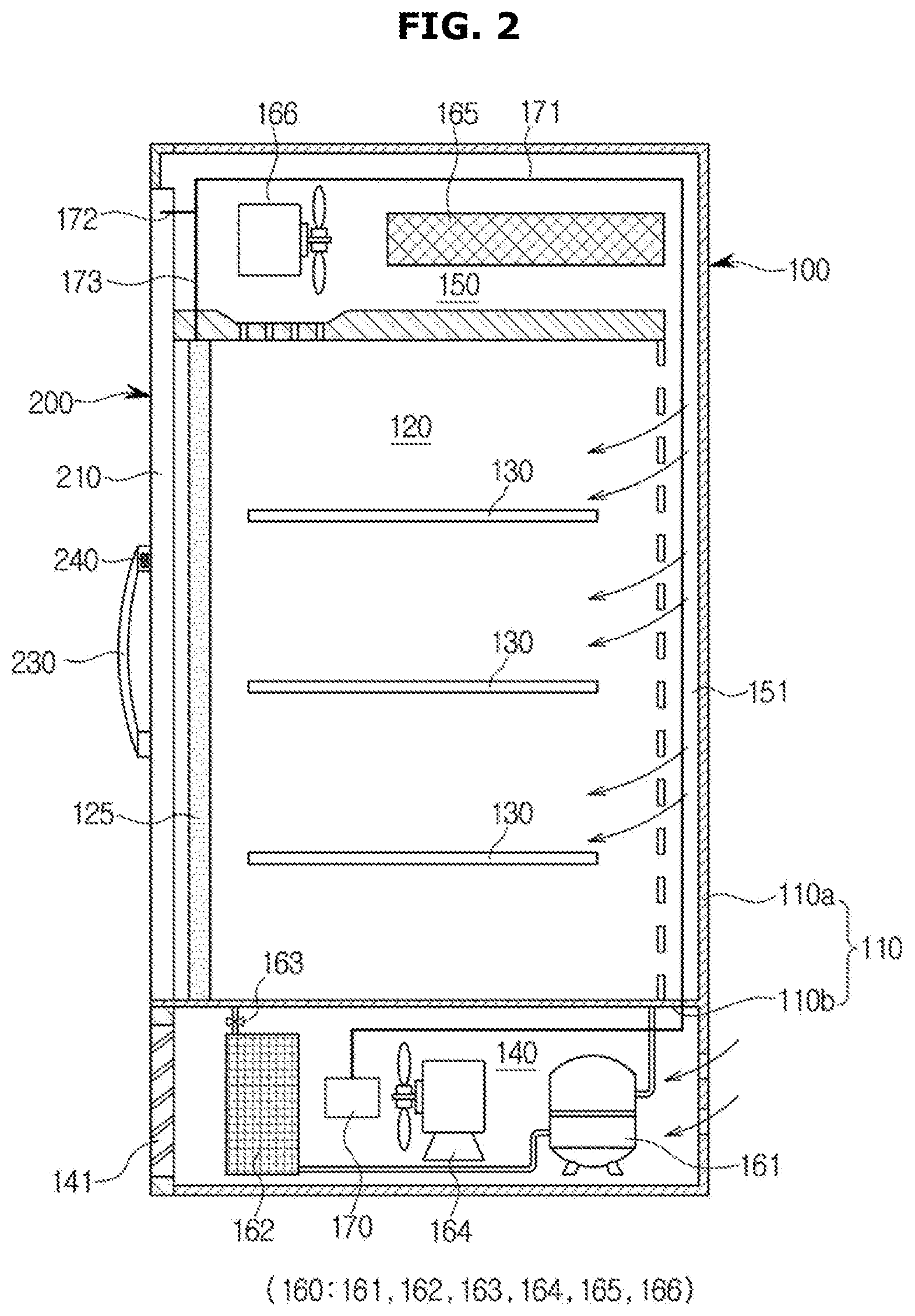

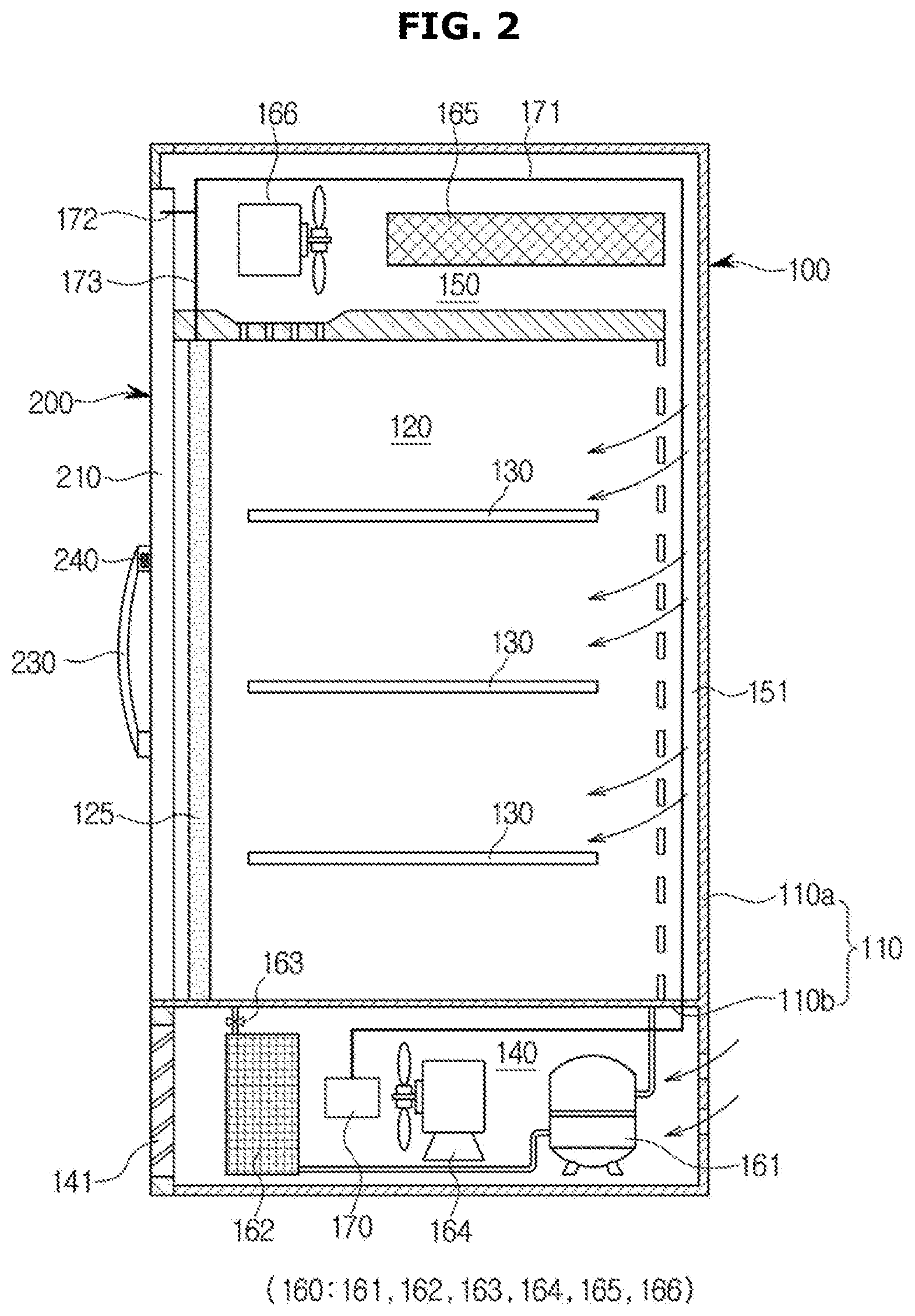

FIG. 2 is a view illustrating an internal structure of a refrigerator including a door according to an exemplary embodiment.

FIG. 3 is a view illustrating a door according to an exemplary embodiment.

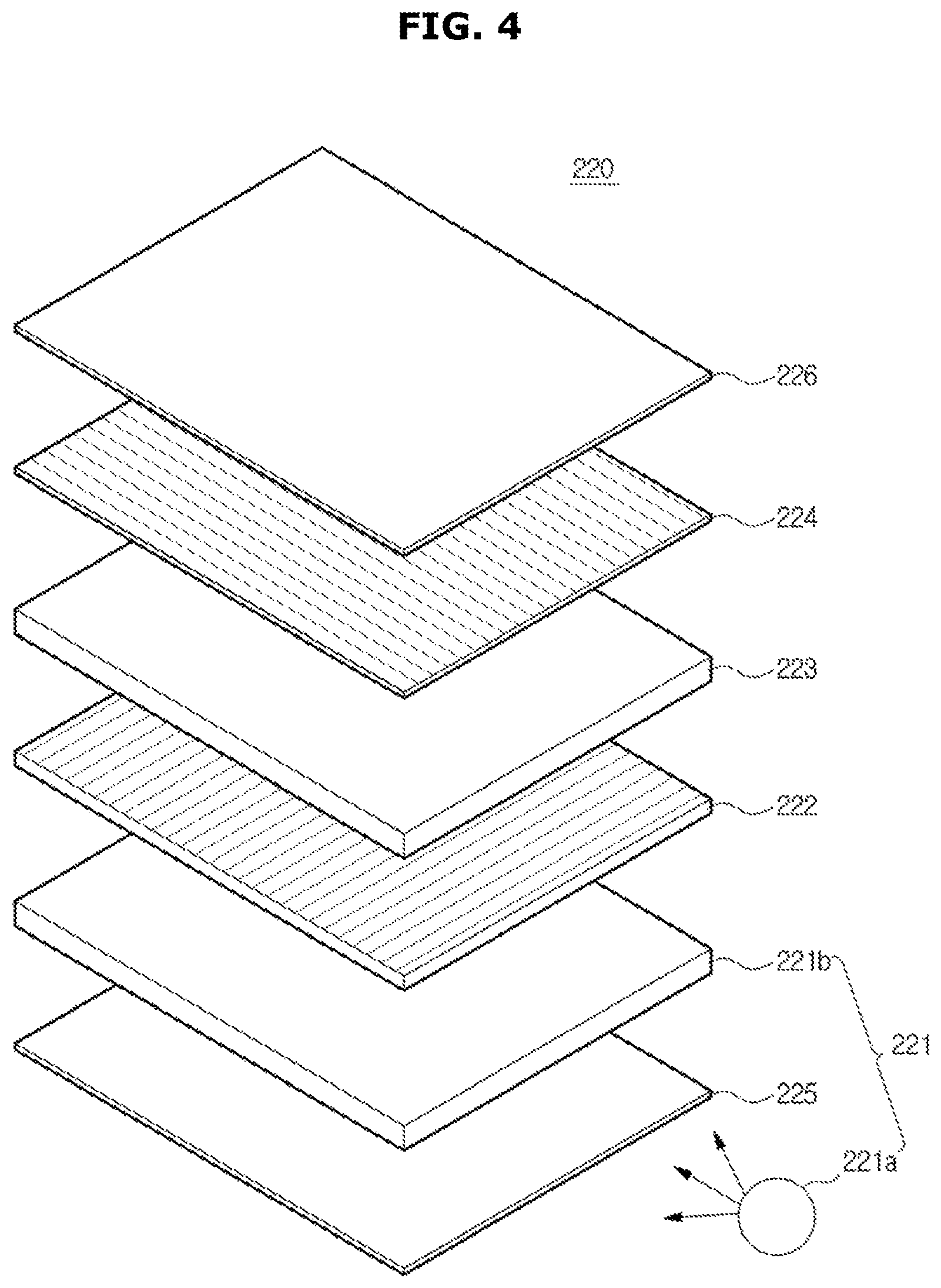

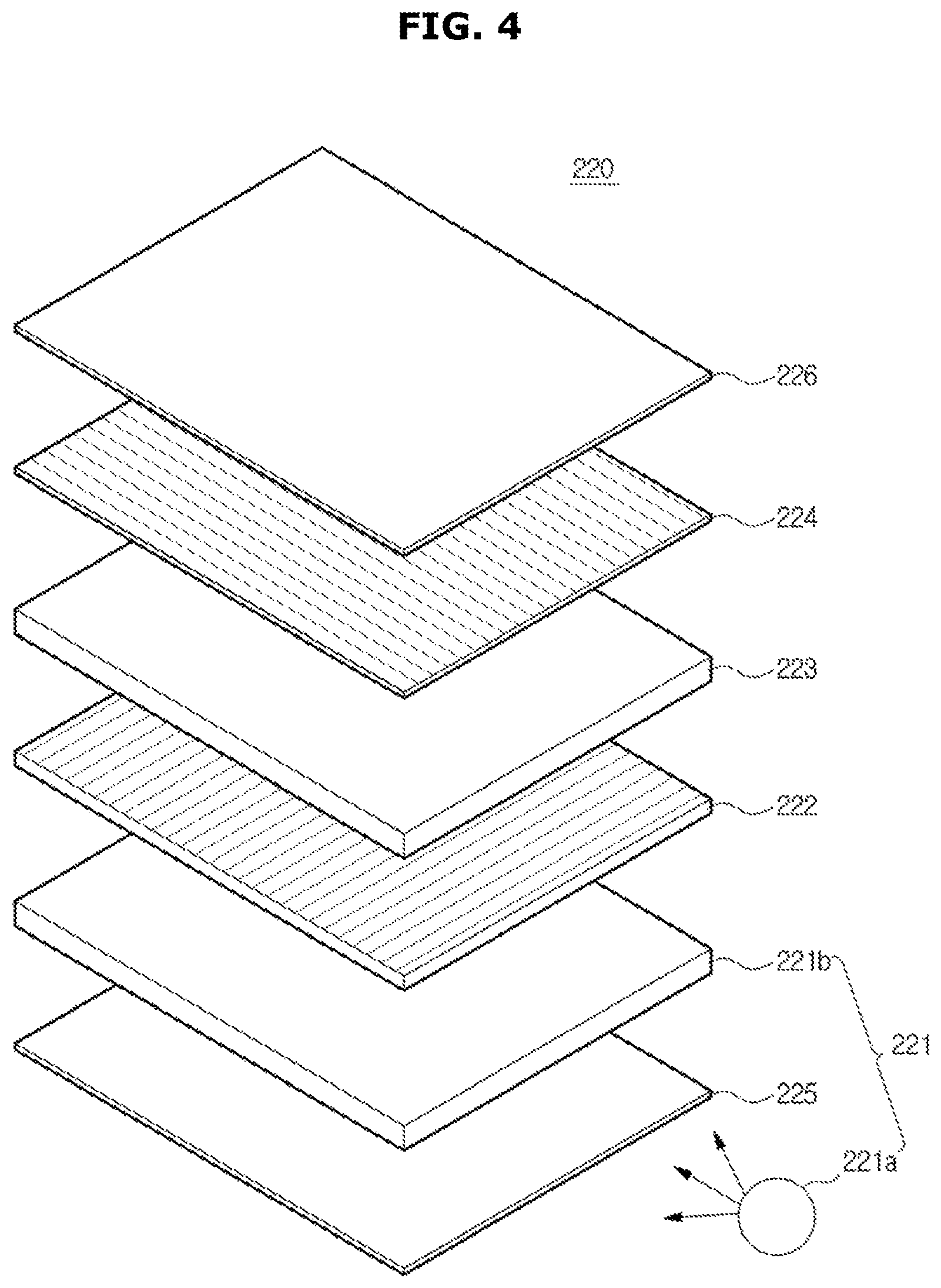

FIG. 4 is a view illustrating a display panel mounted to a door according to an exemplary embodiment.

FIG. 5 is a block diagram illustrating a refrigerator including a door according to an exemplary embodiment.

FIG. 6 is a detailed block diagram illustrating a controller contained in a drive module of a door according to an exemplary embodiment.

FIG. 7 is a perspective view illustrating a refrigerator having an opened door according to an exemplary embodiment.

FIG. 8 is a conceptual diagram illustrating output signals of an acceleration sensor according to an exemplary embodiment.

FIGS. 9A and 9B are conceptual diagrams illustrating output signals of an acceleration sensor according to an exemplary embodiment.

FIGS. 10A to 10C are conceptual diagrams illustrating output signals of an acceleration sensor according to an exemplary embodiment.

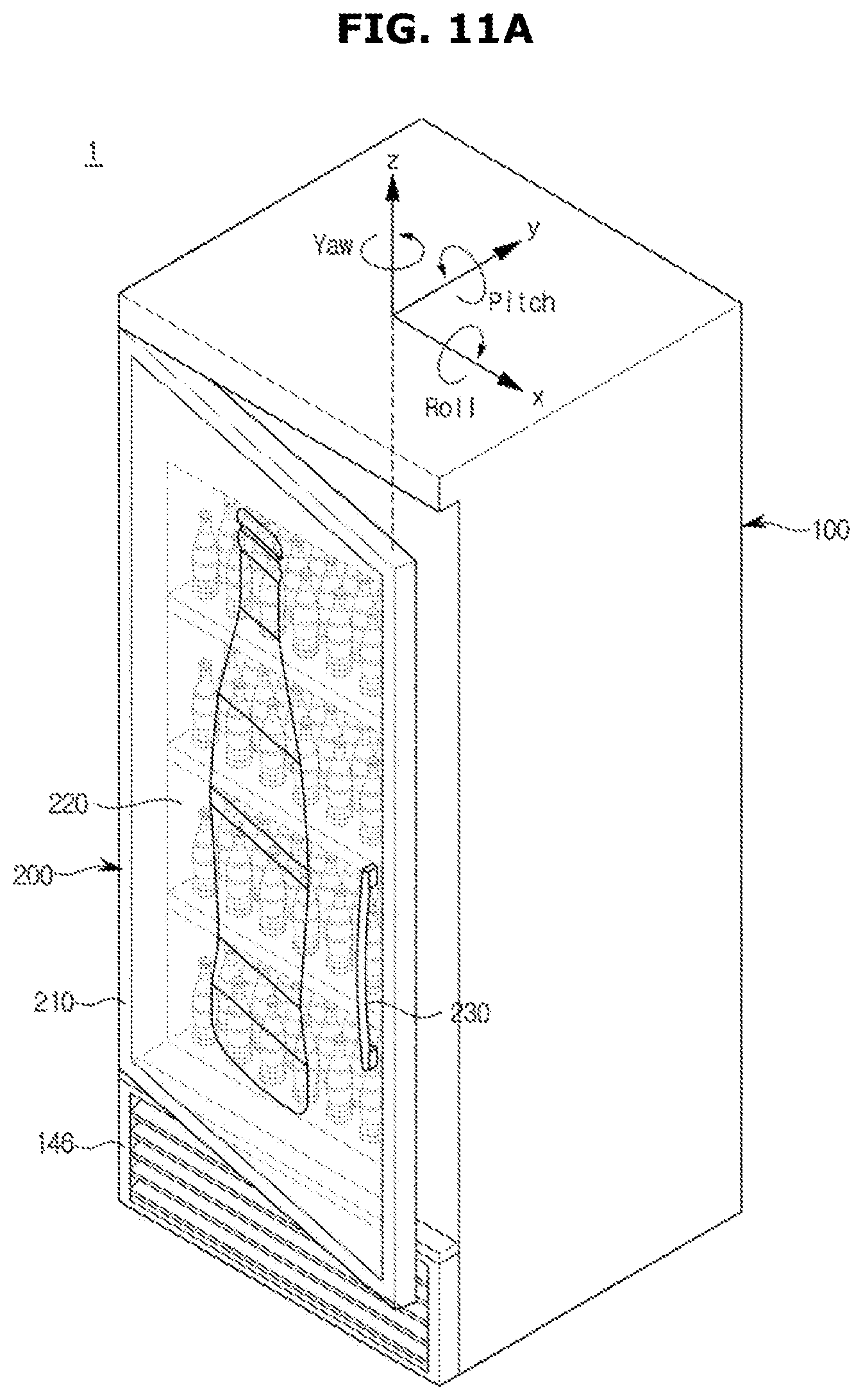

FIGS. 11A and 11B are conceptual diagrams illustrating output signals of a gyro sensor according to an exemplary embodiment.

FIG. 12 is a conceptual diagram illustrating an inductance sensor mounted to a door according to an exemplary embodiment.

FIG. 13 is a conceptual diagram illustrating output signals of an inductance sensor according to an exemplary embodiment.

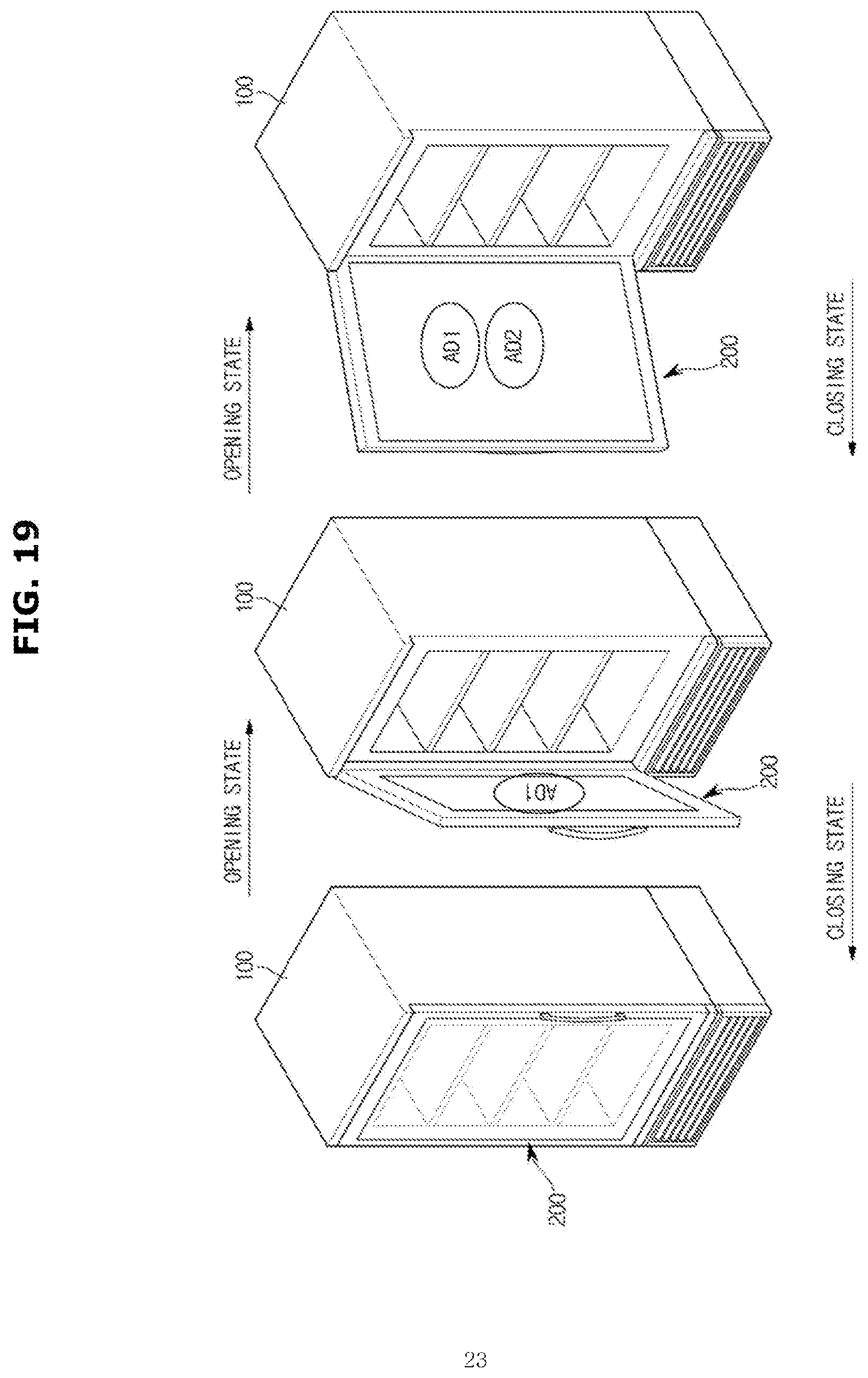

FIGS. 14 to 20 are conceptual diagrams illustrating exemplary images displayed on a display panel of a door according to an exemplary embodiment.

FIG. 21 is a conceptual diagram illustrating a refrigerator including a door according to another embodiment.

FIG. 22 is a block diagram illustrating a refrigerator including a door according to another embodiment.

FIGS. 23 and 24 are conceptual diagrams illustrating a display panel including a door according to another embodiment.

FIG. 25 is a block diagram illustrating a refrigerator including a door according to another embodiment.

DETAILED DESCRIPTION OF EXEMPLARY EMBODIMENTS

Reference will now be made in detail to the exemplary embodiments of the present disclosure, examples of which are illustrated in the accompanying drawings, wherein like reference numerals refer to like elements throughout.

A display device according to an exemplary embodiment may include a frame, a display panel mounted to the frame so as to display images thereon, a detector disposed in a frame so as to detect movement of the frame, and a drive module disposed in the frame in a manner that a transparent state of the display panel on the basis of frame movement detected by the detector is controlled or image display of the display panel is controlled on the basis of frame movement detected by the detector.

The display device is movably mounted to an advertisement panel or a target object (e.g., a main body), such that the display device may be implemented as a door for opening or closing the opening of the target object, a directional sign, etc.

The exemplary embodiment in which the display device is implemented as a door will hereinafter be described with reference to the attached drawings.

FIG. 1 is a perspective view illustrating a refrigerator including a door according to an exemplary embodiment. FIG. 2 is a view illustrating an internal structure of a refrigerator including the door according to an exemplary embodiment. FIG. 3 is a view illustrating a door according to an exemplary embodiment. FIG. 4 is a view illustrating a display panel mounted to the door according to an exemplary embodiment.

A door according to an exemplary embodiment may be mounted to a refrigerator, as will be described hereinafter with reference to the attached drawings.

Referring to FIGS. 1 and 2, the refrigerator 1 may include a main body 100 which forms the external appearance and has the opening, and a door 200 rotatably mounted to the main body 100 to open or close the opening of the main body 100 while in motion between a first target position and a second target position.

The main body 100 may include an outer wall 100a exposed to the outside, and a housing 110 having an inner wall 110b connected to the outer wall 110a.

The main body 100 may include a storage chamber 120 formed by the inner wall 110b of the housing, a light 125 disposed in the storage chamber 120 to adjust indoor brightness, and a plurality of shelves 130 detachably mounted to the storage chamber 130 such that foods are placed on multiple stages through the plurality of shelves. If the door 200 is closed, the storage chamber 130 may be sealed from the outside. If the door 200 is opened, the storage chamber 130 may be exposed to the outside.

The plurality of shelves 130 may divide the storage chamber 120 into a plurality of spaces such that plural foods can be stored and arranged in the storage chamber 120 while being sorted according to individual regions.

The main body 100 may include a machine chamber 140 and a cool air circulation chamber 150. The machine chamber 140 may be formed between the outer wall 110a and the inner wall 110b, may be spatially separated from the storage chamber 120, and may be located below the storage chamber 120. The cool air circulation chamber 150 may be formed between the outer wall 110a and the inner wall 110b, may be spatially connected to the storage chamber 120, and may be located above the storage chamber 120, such that air is circulated between the storage chamber 120 and the cool air circulation chamber 150.

An indoor space of the machine chamber 140 may be opened or closed by a cover 141. The cover 141 may include one or more openings and may be detachably mounted to the machine chamber 140.

The cool air circulation chamber 150 may further include a duct 151 through which cool air flows. The duct 151 may be located at the back surface of the storage chamber 120.

A plurality of holes may be formed at the surface of a wall located between the duct 151 and the storage chamber 120. Cool air may circulate between the duct 151 and the storage chamber 120 through the plurality of holes.

The main body 100 may include a freezing cycle unit 160 disposed in the machine chamber 140 and the cool air circulation chamber 150; and a first power-supplier 170 which is connected to an external commercial power source, converts the commercial power source into power needed to drive respective constituent elements, and provides the respective constituent elements with the converted power.

The freezing cycle unit 160 may include a compressor 161 disposed in the machine chamber 140 to compress refrigerant; a condenser 162 to condense high-temperature and high-pressure refrigerant compressed by the compressor 161; a valve 163 disposed between the condenser 162 and the evaporator 165 in a manner that the valve 163 is opened or closed according to a temperature of the storage chamber 120; and a cooling fan 164 to cool the compressor 161 and the condenser 162 in a manner that ambient air exchanges heat with the condenser 162.

The freezing cycle unit 160 may further include an evaporator 165 disposed in the cool air circulation chamber 150 so that indoor air of the storage chamber 120 is heat-exchanged; and a blowing fan 166 to blow cool air having exchanged heat with the evaporator 165 into the storage chamber 120.

If the valve 163 is opened, refrigerant is supplied from the condenser 162 to the evaporator 165. Here, the evaporator 165 may perform the cooling function in which low-temperature liquid refrigerant is changed to gaseous refrigerant such that ambient latent heat is absorbed.

As a result, ambient air of the evaporator 165 and indoor air of the storage chamber 120 are cooled. In other words, the evaporator 165 may cool indoor air of the storage chamber 120 such that low-temperature air is supplied to the storage chamber 120.

The evaporator 165 and the blowing fan 166 may also be mounted to the duct 151 disposed at the back surface of the storage chamber 120.

The first power-supplier 170 may include a plurality of cables (171, 172, 173).

The cables may include a first cable 171 connected to the first power-supplier, and a second cable 172 and a third cable 173 branched from the first cable 171.

The first power-supplier 170 may provide the door 200 with power through the first cable 171 and the second cable 172, and may also provide the light 125 with power through the first cable 171 and the third cable 173.

The main body 100 may further include a cooling controller configured to control the freezing cycle unit 160 in a manner that indoor air of the storage chamber 120 can be maintained at a target temperature.

The door 200 acting as a hinged door may be rotatably mounted to the opening of the front surface of the main body 100, may be mounted to the opening corresponding to the region of the storage chamber 120 in a manner that the storage chamber 120 can be shielded from the outside so as to prevent cool air from escaping.

That is, through the opening or closing of the door, the user may put food in the storage chamber 120 or may take food out of the storage chamber 120.

Referring to FIG. 1, the door 200 may include a frame 210 to form the border, a display panel 220 disposed in the frame 210 and disposed in the internal region of the frame 210, and a handle member 230 disposed in the frame 210 and grasped by the user.

The frame 210 may include guide holes formed along an outer circumference, and the display panel 220 may be inserted and arranged in the guide holes.

The frame 210 may be arranged at the outer wall of the display panel 220 such that the border of the display panel 220 is achieved.

Referring to FIG. 3, the door 200 may further include a packing unit 211 and one or more hinge units 212. The packing unit 211 may be disposed in the frame 210, may be disposed at the surface contacting the main body 100, such that the frame 210 is in close contact with the main body 100 when the storage chamber 120 is closed. In addition, when the door 200 contacts the main body 100, the packing unit 211 may absorb impact. The hinge units 212 may be respectively arranged at upper and lower parts of one side of the frame 210, and may allow the door 200 to rotate.

In other words, the door 200 may rotate in a forward direction, i.e., an opening direction, and a backward direction, i.e., a closing direction, on the basis of the hinge units arranged at the upper and lower parts of one side of the frame.

The door may allow one side of the frame to move between a first target position and a second target position.

In this case, the first target position may be a position at which the frame stops moving in a completely opened state of the door, and the second target position may be a position at which the frame stops moving in a completely closed state of the door.

Although the door 200 according to the exemplary embodiment illustrated in FIG. 3 is implemented as the hinged door configured to rotate on the basis of one pair of hinge units, it is not limited thereto. For example, the door 200 may also be implemented as the sliding door. The sliding door may open the opening of the main body while simultaneously moving toward the first target position, and may close the opening of the main body while simultaneously moving toward the second target position.

The display panel 220 may be implemented as a transparent display panel configured to display images such that the images are displayed on the basis of movement of the door 200, which may be detected by the detector 240.

The transparent display panel 220 may be, for example, any one of a liquid crystal display (LCD) panel and an organic light emitting diode (OLED) panel. For convenience of description and better understanding of the present disclosure, it is assumed that the transparent display panel 220 is implemented as an LCD.

Referring to FIG. 4, the display panel 220 may include a backlight unit 221, a first polarization plate 222, a liquid crystal panel 223, a second polarization plate 224, a first sheet 225, and a second sheet 226.

The backlight unit 221 may include a light source 221a and a light guide plate 221b.

The backlight unit according to an exemplary embodiment may be implemented as an edge-type backlight unit including the light source 221a arranged in a lateral direction of the light guide plate 221b.

The light source 211a may be, for example, any one of a lamp (e.g., a cold cathode fluorescent lamp (CCFL) or an external electrode fluorescent lamp (EEFL)), an LED array, a light 125 installed in the storage chamber 120, and natural light.

Light emitted from the light source 211a may include circularly polarized light composed of a left-handed polarization component and a right-handed polarization component.

The light guide plate 221b may allow light emitted from the light source to be incident upon the first polarization plate 222. The light guide plate 221b may include first and second refractive layers. In this case, the second refractive layer may be formed of a medium having a higher refractive index than the first refractive layer, such that light emitted from the light source is fully reflected and the fully reflected light is incident upon the first polarization plate 222 located in the forward direction.

The light guide plate 221b may allow natural light to be incident upon the liquid crystal panel 223 through the first refractive layer and the second refractive layer.

Each of the first and second polarization plates (222, 224) may include cholesteric liquid crystals, and the cholesteric liquid crystals of the first and second polarization plates (222, 224) may include a plurality of cholesteric liquid crystal molecules.

In this case, the cholesteric liquid crystal molecules may include a levorotatory screw structure and a dextrorotatory screw structure. In this case, left-handed circularly polarized light may be penetrated and right-handed circularly polarized light may be reflected by cholesteric liquid crystal molecules of the levorotatory screw structure.

In addition, left-handed circularly polarized light may be reflected and right-handed circularly polarized light may be penetrated by cholesteric liquid crystal molecules of the right dextrorotatory screw structure.

Therefore, polarized light penetrated by the first polarization plate 222 may be P waves, and the reflected polarized light may be S waves.

Meanwhile, the S waves reflected by the first polarization plate 222 may be incident upon the light guide plate 221b, and the S waves may be reflected by the second refractive layer of the light guide plate 221b. In this case, the reflected light may be converted into P waves, and the P waves may be penetrated by the first polarization plate 222. Therefore, the light guide plate 221b may serve as the reflection plate.

The liquid crystal panel 223 may include a thin film transistor (TFT) acting as a switching element; a first substrate having a pixel electrode electrically connected to the TFT; black matrices arranged at intervals of a predetermined distance so as to interrupt incident light from the light source; a color filter pattern formed between the black matrices; a second substrate having an overcoat layer formed over the color filter pattern; and a liquid crystal layer implanted between the first substrate and the second substrate.

The liquid crystal panel 223 may adjust light transmittance of liquid crystal cells according to image information received from a drive module 250, resulting in formation of images.

P waves incident from the first polarization plate 222 may pass through or may not pass through the liquid crystal panel 223 according to the driving of liquid crystal cells.

That is, the amount of light transmission may be adjusted according to the driving of liquid crystal cells of the liquid crystal panel 223, such that images having a gray scale may be displayed.

In more detail, the phase of P waves may be changed according to driving of the liquid crystal panel 223. When the P-wave phase is changed to 90.degree., the maximum light amount may pass through the second polarization plate 224, such that a white gray scale is implemented. When the P-wave phase is changed to 45.degree., a smaller amount of light may pass through the second polarization plate 224, such that a medium gray scale is implemented.

Therefore, displacement of liquid crystal may be changed according to strength of the electric field applied to liquid crystal cells of the liquid crystal panel 213. The P-wave phase may be changed in the range from 0.degree. to 90.degree. according to such displacement, resulting in implementation of a desired gray scale.

The second polarization plate 224 may be arranged at one side of the liquid crystal panel 223, and may have a polarization axis perpendicular to the first polarization plate 222. Therefore, the phase of polarization of the first polarization plate 222 may be changed according to driving of the liquid crystal of the liquid crystal panel 223, such that light transmission may be adjusted according to the changed polarization phase.

The first sheet 225 may be an insulation sheet arranged at one side (i.e., one side of the light wave guide 221b) adjacent to the storage chamber 120 from among both sides of the transparent display panel 220. The first sheet 225 may prevent an indoor temperature of the storage chamber 120 from increasing due to heat generated by driving of the transparent display panel 220.

The second sheet 226 may be a non-reflective coating film arranged at one side (i.e., one side of the second polarization plate 224) exposed outside from among both sides of the transparent display panel 210. The second sheet 226 may prevent light reflection, such that the inside of the storage chamber 120 and images of the transparent display panel 220 can be easily viewed at a side of the showcase or even on a bright sunny day.

If necessary, it may be possible for the display panel 220 to maintain a transparent state by natural light, irrespective of a display drive command.

Referring to FIG. 2, the door 200 may further include a detector 240 disposed in the handle member 230 to detect movement of the door 200 according to change of the door position.

According to an exemplary embodiment, the detector 240 may also be disposed in the frame 210 instead of the handle member 230 of the door.

The door movement may be detected as the storage chamber 120 is opened or closed.

The detector 240 may include one or more sensors, e.g., an acceleration sensor, a gyro sensor, an inductance sensor, and/or a geomagnetic sensor.

Referring to FIG. 3, the door 200 may further include a drive module 250 disposed in a space between the frame 210 and a packing unit 211 so as to control driving of the display panel 220.

In other words, the drive module 250 may be protected from external impact by the frame 210 and the packing 240.

The drive module 250 may also be disposed in the indoor space of the frame 210. In this case, the frame 210 may be formed in a tube shape.

The door 200 may display advertisement information, foodstuff information, event information, etc. on the display panel 220 in response to a command of the drive module 250.

As a result, the user may view advertisements or foodstuff information through the display panel 220 of the door, and at the same time may view various foodstuffs arranged in the storage chamber 120.

FIG. 5 is a block diagram illustrating a refrigerator according to an exemplary embodiment.

The refrigerator 1 may include a first power-supplier 170, display panel 220, a detector 240, a drive module 250, a second power-supplier 260, an input 270, and a speaker 280. The display panel 220 may be driven by a control signal of the drive module 250.

The first power-supplier 170 may be connected to the external commercial power source such that it receives power from the commercial power source. The first power-supplier 170 may convert the received power into a current or voltage needed to drive the freezing cycle unit 160, and may supply the current or voltage to the freezing cycle unit 160. In addition, the first power-supplier 170 may transmit the supplied power to the second power-supplier 260.

The second power-supplier 260 may receive power from the first power-supplier 170, and may supply the received power to respective constituent elements (e.g., the drive module 250, the display panel 220, the speaker 280, the detector 240, the input 270, etc.) of the door. The second power-supplier 260 may convert the supplied power into a current or voltage needed to drive the respective constituent elements, and may transmit the current or voltage to the respective constituent elements.

The second power-supplier 260 may receive power needed to drive the constituent elements through the cable 172 connected to the first power-supplier 170. In addition, power supplied to the second power-supplier 260 may be transmitted to the display panel 220 through a fourth cable 174.

The second power-supplier 260 may perform AC/DC conversion and DC/DC conversion.

The second power-supplier 260 may also be disposed in the drive module 250 as necessary.

The detector 240 may detect movement of the door 200, and may output a signal corresponding to the door movement.

As aforementioned, the detector 240 may include one or more sensors, e.g., an acceleration sensor, a gyro sensor, an inductance sensor, and/or a geomagnetic sensor.

The acceleration sensor may detect 3-axis acceleration of the moving door and impact strength of the moving door, and may output a signal corresponding to the detected 3-axis acceleration and impact strength.

When the door starts moving from a stop (or idle) state, the acceleration sensor may output a signal corresponding to directional acceleration on the basis of the stop position.

In the stop state, the acceleration sensor may output a reference value of each axis as acceleration of each axis.

Each of reference values of two axes other than the direction of gravity may be approximately zero "0", and gravity may be applied to a reference value of the gravity directional axis.

The movement direction of each axis may include a forward direction corresponding to an opening direction of the door from the stop position and a reverse direction, i.e., a closing direction of the door, which is opposite to the forward direction. Each directional signal may be output as a positive(+) signal or a negative(-) signal.

The gyro sensor may detect 3-axis angular speed (i.e., the number of rotations per unit time) of the rotating door, and may output a signal corresponding to the detected 3-axis angular speed.

When the door starts moving from the stop state, the gyro sensor may output a signal corresponding to angular speed for each direction moving on the basis of the stop position.

In the stop state, the gyro sensor may output a reference value of each axis as the angular speed of each axis.

A reference value of the gravity directional axis may be approximately zero "0".

The movement (i.e., rotation) direction of the gravity directional axis may include a forward direction corresponding to a predetermined direction from the stop position and a reverse direction opposite to the forward direction. Each directional signal may be output as a positive(+) signal or a negative(-) signal.

If magnetic flux is changed according to variation in the distance between the inductance sensor and the housing 110 of the main body contacting the frame 210 of the door, an output signal of the inductance sensor may be changed according to Faraday's law of electromagnetic induction. In more detail, the inductance sensor may detect inductance change of the coil excited at a high frequency, and may output a signal changing in response to the detected inductance change.

The inductance sensor may output a signal indicating change of the distance between the metal main body and the inductance sensor.

The inductance sensor may output a reference value while being in contact with the main body. The separation distance between the inductance sensor and the main body is proportional to inductance change. As a result, the inductance sensor may generate a higher output value.

The output value may indicate the magnitude of a voltage signal or the magnitude of a digital signal.

The geomagnetic sensor may detect strength of a 3-axis magnetic field, and may output a signal corresponding to the detected 3-axis magnetic field.

The drive module 250 may be formed of at least one printed circuit board (PCB).

The drive module 250 may include a controller 251, a communicator 252, and a display driver 253. The controller 251 may include a decision module 251a configured to decide the movement state of the door, and a processor 251b configured to control image display. A detailed description thereof will hereinafter be given with reference to FIG. 6.

FIG. 6 is a block diagram illustrating a controller of a drive module of a door according to an exemplary embodiment.

A movement state of the door may include an opening state and a closing state.

The controller 251 may be implemented using a processor, a central processor (CPU), a micro-processor (MCU), etc.

The decision module 251a may include a signal processor (a1) configured to perform signal processing of the output signal of the detector 240; a decision unit (a2) configured to confirm the signal processed value and decide the movement state of the door on the basis of the confirmed value; and a storage (a3) configured to store a reference value for the movement state of the door, the movement direction, and the number of reference fluctuations.

The decision unit (a2) may decide various states of the door, which include, for example, a completely opened state, a completely closed state, a currently opening state, and/or a currently closing state. The movement direction of the door may be used to decide the state of the door.

Detailed description about constituent elements for detecting and deciding the door state will be described later.

The storage (a3) may include a volatile memory in which read/write (R/W) operation of data is possible, and/or a non-volatile memory. The volatile memory may be a random access memory (RAM), SRAM or DRAM. The non-volatile memory may include at least one of flash memory, Read Only Memory (ROM), Erasable Programmable Read Only Memory (EPROM), Electrically Erasable Programmable Read Only Memory (EEPROM), etc.

The processor 251b may control images displayed on the display panel 220 to be changed to other images on the basis of the decided movement state of the door.

The processor 251b may control the direction of images displayed on the display panel 220 to be inverted on the basis of the decided movement state of the door.

The processor 251b may perform dimming of the backlight unit mounted to the display panel 220 or may switch off the backlight unit according to the decided movement state of the door.

If necessary, the processor 251b may also change a transparent state (e.g., an opaque, transparent or semi-transparent state) on the basis of the decided movement state of the door.

The processor 251b may control display of any one of plural images, and may also sequentially display the plural images at intervals of a predetermined time.

The communicator 252 may communicate with the external device, and may transmit information received from the external device to the controller 251.

The communicator 252 may perform at least one of wired communication and wireless communication.

The communicator 252 may receive a command from the external device. The command may include an image change command, an image ON/OFF command, and a command for updating various images (e.g., an advertisement image, an event image, and a coupon image).

The above images may further include format information indicating a format of the images, for example, pictures, photos, words, and moving images.

The external device may include a terminal (or user equipment: UE) 310 and a server 320.

The terminal 310 may perform wireless communication (e.g., Wi-Fi or Bluetooth) with the communicator 252, and the server 320 may perform at least one of wired communication and wireless communication with the communicator 252.

The terminal 310 may directly control the display panel 220 using an administrator's terminal.

If the terminal 310 is a smartphone, an application for controlling display of the showcase may be installed in the smartphone. This application may be downloaded from an Application Store or a server, and may also be upgraded and updated.

A display driver 253 may be driven by a command of the controller 251 in a manner that images can be displayed on the display panel 220.

In other words, the display driver 253 may drive liquid crystal cells of the liquid crystal panel 223 in response to a command of the controller 251, such that images can be displayed on the display panel 220 and transparency can be adjusted.

The input 270 may receive the ON/OFF commands of the display panel, an image display command of the display panel, and an image update command, etc.

The input 270 may also receive an image display mode as necessary.

The image display mode may include a transparent mode, an opaque mode, a semi-transparent mode, an advertisement mode, an event mode, a product information display mode, etc.

The speaker 280 may output a sound signal corresponding to the image displayed on the display panel 220.

If necessary, the speaker 280 may output a user-selected song or a user-selected melody as a background sound.

If necessary, the speaker may also output a sound signal indicating information regarding the product stored in the storage chamber of the main body.

A structure for deciding a state of the door 200 on the basis of signals detected by the detector 240 will hereinafter be described with reference to FIGS. 7 to 13.

Referring to FIG. 7, when the door is opened by a predetermined distance d, it may be determined whether the door is continuously opened or closed on the basis of the signals detected by the detector 240.

That is, the drive module 250 may recognize the change of the door's position, and may determine the movement direction according to two positions (i.e., the current position and the previous position of the door).

(1) Structure for Detecting Door Movement and Door State Using the Acceleration Sensor

The structure for detecting the door's movement and the door's state using the acceleration sensor will hereinafter be described with reference to FIGS. 8 to 10C. In FIGS. 8 to 10C, it is assumed that the door is implemented as a hinged door.

Referring to FIG. 8, the door's state may include a completely closed state (CLOSE: S1), a currently opening state (Opening: S2), a completely opened state (OPEN: S3), and a currently closing state (Closing: S4).

It is assumed that the gravity direction is an X-axis negative direction. It is also assumed that, from a user's perspective facing the door, a right direction is a negative direction, i.e., opening direction, of the Y-axis, a forward direction is a positive direction, i.e., opening direction, of a Z-axis, and the door's initial state is the completely closed state.

Assuming that the door is implemented as a hinged door and there is no vertical movement of the door, the drive module 250 may not use signals of the gravity directional axis from among respective axes' signals received from the detector, when deciding the door's state.

Referring to FIGS. 9A and 9B, assuming that the door is in the completely closed state (S1), this means that the door does not move at all, such that the detector 240 may output individual reference values as Y-axis and X-axis signal values. Here, each reference value may be approximately zero.

The drive module 250 may detect the value of a signal of each axis (Y, Z), received from the detector 240. If the signal value of each axis (Y, Z) is a reference value of each axis (Y, Z), the drive module 250 may determine that the door is continuously maintained in the completely closed state of the door.

If the door is released from the completely closed state (S1) and is moving, the detector 240 may output Y-axis and Z-axis signals corresponding to the door's movement.

The drive module 250 may receive a signal value of each axis (Y, Z) from the detector 240, and may compare the signal value of each axis (Y, Z) with a reference value of each axis (Y, Z). If the signal value of each axis (Y, Z) is less than the reference value of each axis (Y, Z), the drive module 250 may determine that the door is in the currently opening state (S2).

That is, assuming that the signal value of each axis (Y, Z) is a negative(-) value less than zero, the drive module 250 may determine that the door has moved in the forward direction, i.e., the opening direction.

After the door is in the currently opening state (S2) at a first time point, the drive module 250 may detect the signal value of each axis at a second time point which is later than the first time point. If the signal value of each axis (Y, Z) at the second time point is a reference value of each axis, the drive module 250 may determine that the door has moved from the currently opening state to the stop state (i.e., the completely opened state) S3. If the signal value of each axis at the second time point is a negative(-) value less than a reference value of each axis, the drive module 250 may determine that the door has further moved in the opening direction.

That is, the drive module 250 may determine that the door is continuously being opened, remaining in the currently opening state (S2).

For example, if the door is opened by a first distance at a first time point and is in the currently opening state at a second time point which is later than the first time point, this means that the door is now opened by a second distance which is longer than the first distance. In addition, assuming that the door is in the currently opening state at a third time point, this means that the door is opened by a third distance which longer than the second distance.

That is, it may be determined that the door is first opened by the first distance, stops moving, is then opened by a second distance, stops moving, and is finally opened by a third distance.

In this case, the first distance, the second distance, or the third distance may indicate the distance between the housing of the main body and the door's frame.

In addition, when deciding the door's state, the drive module 250 may also determine the door's state using only the signal of one axis from among the signals of two axes (Y, Z).

If the door is released from the currently opening state and then stops moving for a predetermined time or longer, this means that the door is in the completely opened state.

In addition, assuming that a signal received in the currently opening state (S2) of the door has a negative(-) value less than the reference value and the next reception signal is an impact signal, the drive module 250 may also determine the completely opened state of the door.

After the drive module 250 determines the currently opening state (S2) of the door, the drive module 250 may detect the signal value of each axis at a second time point which is later than the first time point, and may compare the signal value of each axis (Y, Z) of the second time point with the reference value of each axis. If the signal value of each axis is higher than the reference value of each axis, the drive module 250 may determine the currently closing state of the door.

That is, assuming that the signal value of each axis (Y, Z) is a positive(+) value greater than zero, the drive module 250 may determine that the door has moved in the closing direction.

After the drive module 250 determines the currently closing state of the door, the drive module 250 may detect the signal value of each axis. If the signal value of each axis (Y, Z) is the reference value, the drive module 250 may determine that the door is released from the currently closing state and then stops moving. In this case, the door is still opened.

If the signal value of each axis is higher than the reference value of each axis while the door is in the stop state S3, the drive module 250 may determine that the door has moved in the closing direction. In this case, the drive module 250 may determine that the door is in the currently closing state S4.

For example, if the door is opened by a first angle at a first time point, and the door is then in the currently closing state at a second time point, this means that the door is now opened by a second angle which is less than the first angle. In addition, if the door is in the currently closing state at a third time point, this means that the door is opened by a third angle less than the second angle.

That is, the door is opened by the first angle, stops moving, closed a little until the door is opened by the second angle, stops moving, and closed until the door is opened by the third angle.

Since the door is opened before reaching the completely closed state, the opening angle of the door may be gradually reduced in the currently closing state.

If the signal value of each axis is less than the reference value of each axis, the drive module 250 may determine that the door has moved in the opening direction. In this case, the door may re-enter the currently opening state.

Assuming that the signal value of each axis is higher than the reference value of each axis, the drive module 250 may determine that the door has moved in the closing direction. In addition, assuming that the signal value of each axis is higher than the reference value of each axis, the drive module 250 may determine that the door has moved in the closing direction. Assuming that the signal received in the currently closing state is the impact signal and the tail signal of the impact signal has the same value as the reference value, the drive module 250 may determine the completely closed state S1.

In this case, the above situation in which the tail signal of the impact signal has the same value as the reference value may indicate the stop state of the door.

FIG. 9A is a graph illustrating signal values on a time axis when the door is opened by about 30.degree. and then closed, and FIG. 9B is a graph illustrating signal values on the time axis when the door is opened by about 90.degree. and then closed. Although signal output time points of the detector differ according to the opening angle of the door, it can be recognized that signals having the same directivities are output in response to the movement direction of the door when the door is opened or closed.

When the door 200 is released from the completely closed state and then opened, the detector 240 may output the signal corresponding to the currently opening state. When the door 200 is released from the open state and then closed, the detector 240 may output the signal corresponding to the currently closing state and then output signals having different directivities.

The signal directivity may be recognized by determining whether the corresponding signal is set to any one of a positive(+) signal higher than the reference value or a negative(-) signal less than the reference value.

When the door 200 is in contact with the main body 100, the detector 240 may output the impact signal corresponding to impact between the main body 100 and the door 200.

In this case, the impact signal may include a noise signal caused by external force.

Therefore, the drive module 250 may detect fluctuation of the received signal, and may discriminate between the impact signal caused by the closed door and the noise signal. A detailed description thereof will hereinafter be given with reference to FIGS. 10A, 10B, and 10C.

FIG. 10A is a graph illustrating signal values on the time axis when the door collides with the main body by closing the door. FIG. 10B is a graph illustrating signal values on the time axis when weak external force is applied to the door. FIG. 10C is a graph illustrating signal values on the time axis when strong external force is applied to the door.

The drive module 250 may confirm each signal value on the time axis, and may confirm the number of fluctuations according to the change of signal values for a predetermined time. If the number of confirmed fluctuations is equal to or higher than a reference number of fluctuations, the drive module 250 may determine the occurrence of an impact signal caused by closing the door. If the number of confirmed fluctuations is less than the reference number of fluctuations, the drive module 250 may determine the occurrence of a noise signal caused by external force.

In this case, the number of fluctuations may be increased or reduced on the basis of a reference value. For example, the number of fluctuations may be adjusted on the basis of the reference value, such that the number of fluctuations may be equal to or higher than the reference value or may be equal to or less than the reference value.

In this case, the number of fluctuations may be a predetermined number of times obtained by tests and learning.

Even in the case in which the detector is a geomagnetic sensor having X-axis, Y-axis, and Z-axis, the detector may also be implemented in the same manner as in the acceleration sensor.

(2) Structure for Detecting Door Movement and Door State Using the Gyro Sensor

The structure for detecting the door's movement and the door's state using the gyro sensor will hereinafter be described with reference to FIGS. 11A and 11B.

Referring to FIG. 11A, the gyro sensor may include a rotation shaft composed of X-, Y-, and Z-axes. In this case, when the door is pulled, it is assumed that a horizontal axis is denoted by the X-axis, a forward and backward directional axis is denoted by the Y-axis, and the gravity directional axis is denoted by the Z-axis.

It is assumed that the door is implemented as a hinged door that moves around the gravity direction through the hinge, and the initial state of the door is the completely closed state.

Referring to FIG. 11B, the door state may include the completely closed state (CLOSE) S1, the currently opening state (OPENING) S2, the completely opened state (OPEN) S3, and the currently closing state (CLOSING) S4.

In addition, considering that the door is implemented as the hinged door and only the rotation movement of the gravity directional axis of the door occurs, the drive module 250 may use only the signal of the gravity directional axis (Z axis) from among respective axes' signals generated from the detector when deciding the door state.