Systems and methods for nucleic acid sequencing

Esfandyarpour , et al. Ja

U.S. patent number 10,544,456 [Application Number 15/655,616] was granted by the patent office on 2020-01-28 for systems and methods for nucleic acid sequencing. This patent grant is currently assigned to GENAPSYS, INC.. The grantee listed for this patent is GenapSys, Inc.. Invention is credited to Meysam R. Barmi, Hesaam Esfandyarpour, Paul Kenney, Ali Nabi, Saurabh Paliwal, Kosar Parizi, Hamid Rategh, Seth Stern.

View All Diagrams

| United States Patent | 10,544,456 |

| Esfandyarpour , et al. | January 28, 2020 |

Systems and methods for nucleic acid sequencing

Abstract

Provided herein are systems and methods for processing and analyzing nucleic acids and other biomolecules. Methods may include processing nucleic acid molecules in an emulsion of droplets. Methods of analyzing nucleic acid molecules may include coupling nucleic acids to a bead or other support. Methods may include analysis of nucleic acid molecules using a redox mediator. In some cases, analysis of the nucleic acid molecule includes determining a nucleotide sequence of the nucleic acid molecule.

| Inventors: | Esfandyarpour; Hesaam (Redwood City, CA), Parizi; Kosar (Redwood City, CA), Paliwal; Saurabh (Mountain View, CA), Stern; Seth (Menlo Park, CA), Kenney; Paul (Sunnyvale, CA), Barmi; Meysam R. (Menlo Park, CA), Nabi; Ali (Belmont, CA), Rategh; Hamid (Cupertino, CA) | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Applicant: |

|

||||||||||

| Assignee: | GENAPSYS, INC. (Redwood City,

CA) |

||||||||||

| Family ID: | 60996038 | ||||||||||

| Appl. No.: | 15/655,616 | ||||||||||

| Filed: | July 20, 2017 |

Prior Publication Data

| Document Identifier | Publication Date | |

|---|---|---|

| US 20180100190 A1 | Apr 12, 2018 | |

Related U.S. Patent Documents

| Application Number | Filing Date | Patent Number | Issue Date | ||

|---|---|---|---|---|---|

| 62364489 | Jul 20, 2016 | ||||

| 62375197 | Aug 15, 2016 | ||||

| 62418101 | Nov 4, 2016 | ||||

| 62444700 | Jan 10, 2017 | ||||

| Current U.S. Class: | 1/1 |

| Current CPC Class: | C12Q 1/6869 (20130101); C12Q 1/6869 (20130101); C12Q 2563/116 (20130101); C12Q 2563/149 (20130101); C12Q 2565/607 (20130101) |

| Current International Class: | C12Q 1/6869 (20180101) |

References Cited [Referenced By]

U.S. Patent Documents

| 2014761 | September 1935 | Faust |

| 4072576 | February 1978 | Arwin et al. |

| 5344545 | September 1994 | Tsukada et al. |

| 5407799 | April 1995 | Studier et al. |

| 5466348 | November 1995 | Holm-Kennedy |

| 5602042 | February 1997 | Farber |

| 5612181 | March 1997 | Fourmentin-Guilbert |

| 5795782 | August 1998 | Church et al. |

| 5834197 | November 1998 | Parton |

| 6046097 | April 2000 | Hsieh et al. |

| 6087095 | July 2000 | Rosenthal et al. |

| 6210891 | April 2001 | Nyren et al. |

| 6327410 | December 2001 | Walt et al. |

| 6632655 | October 2003 | Mehta et al. |

| 6833246 | December 2004 | Balasubramanian |

| 6870235 | March 2005 | Abstreiter et al. |

| 6953958 | October 2005 | Baxter et al. |

| 7081192 | July 2006 | Wang et al. |

| 7095010 | August 2006 | Scherer et al. |

| 7223540 | May 2007 | Pourmand et al. |

| 7238536 | July 2007 | Schlenoff |

| 7242241 | July 2007 | Toumazou et al. |

| 7270981 | September 2007 | Armes et al. |

| 7282370 | October 2007 | Bridgham et al. |

| 7291496 | November 2007 | Holm-Kennedy |

| 7312085 | December 2007 | Chou et al. |

| 7317216 | January 2008 | Holm-Kennedy |

| 7323305 | January 2008 | Leamon et al. |

| 7361466 | April 2008 | Korlach et al. |

| 7399590 | July 2008 | Piepenburg et al. |

| 7435561 | October 2008 | Piepenburg et al. |

| 7485428 | February 2009 | Armes et al. |

| 7615382 | November 2009 | Wang et al. |

| 7645596 | January 2010 | Williams et al. |

| 7649358 | January 2010 | Toumazou et al. |

| 7666598 | February 2010 | Piepenburg et al. |

| 7682837 | March 2010 | Jain et al. |

| 7686929 | March 2010 | Toumazou et al. |

| 7692219 | April 2010 | Holm-Kennedy |

| 7695907 | April 2010 | Miyahara et al. |

| 7763427 | July 2010 | Piepenburg et al. |

| 7824890 | November 2010 | Hoser et al. |

| 7835871 | November 2010 | Kain et al. |

| 7875440 | January 2011 | Williams et al. |

| 7888013 | February 2011 | Miyahara et al. |

| 7932034 | April 2011 | Esfandyarpour et al. |

| 7948015 | May 2011 | Rothberg et al. |

| 8023113 | September 2011 | El Gamal et al. |

| 8030000 | October 2011 | Piepenburg et al. |

| 8039817 | October 2011 | Feng et al. |

| 8062848 | November 2011 | Goldstein et al. |

| 8062850 | November 2011 | Piepenburg et al. |

| 8071308 | December 2011 | Piepenburg et al. |

| 8114591 | February 2012 | Toumazou et al. |

| 8128796 | March 2012 | Ishige et al. |

| 8129118 | March 2012 | Weindel et al. |

| 8137569 | March 2012 | Harnack et al. |

| 8152991 | April 2012 | Briman et al. |

| 8154093 | April 2012 | Bradley et al. |

| 8173080 | May 2012 | Lebl et al. |

| 8173401 | May 2012 | Chang et al. |

| 8179296 | May 2012 | Kelly et al. |

| 8257925 | September 2012 | Brown et al. |

| 8274040 | September 2012 | Zhong et al. |

| 8301394 | October 2012 | Chen et al. |

| 8315817 | November 2012 | Kain et al. |

| 8392126 | March 2013 | Mann |

| 8426134 | April 2013 | Piepenburg et al. |

| 8460875 | June 2013 | Armes et al. |

| 8486625 | July 2013 | Gunderson et al. |

| 8518670 | August 2013 | Goldstein et al. |

| 8574846 | November 2013 | Piepenburg et al. |

| 8580507 | November 2013 | Piepenburg et al. |

| 8585973 | November 2013 | Esfandyarpour |

| 8637253 | January 2014 | Piepenburg et al. |

| 8649011 | February 2014 | Mccaffrey et al. |

| 8673560 | March 2014 | Leamon et al. |

| 8778848 | July 2014 | Lin et al. |

| 8778849 | July 2014 | Bowen et al. |

| 8865077 | October 2014 | Chiou et al. |

| 8865078 | October 2014 | Chiou et al. |

| 8914241 | December 2014 | Kain et al. |

| 8969002 | March 2015 | Esfandyarpour et al. |

| 9045796 | June 2015 | Gunderson et al. |

| 9063117 | June 2015 | Gourley |

| 9150915 | October 2015 | Esfandyarpour et al. |

| 9184099 | November 2015 | Baghbani-Parizi et al. |

| 9187783 | November 2015 | Esfandyarpour et al. |

| 9188594 | November 2015 | Fahmy et al. |

| 9274077 | March 2016 | Esfandyarpour et al. |

| 9399217 | July 2016 | Oldham et al. |

| 9434983 | September 2016 | Esfandyarpour |

| 9533305 | January 2017 | Esfandyarpour et al. |

| 9689835 | June 2017 | Liu et al. |

| 9809852 | November 2017 | Esfandyarpour et al. |

| 9822401 | November 2017 | Oberstrass et al. |

| 9926596 | March 2018 | Esfandyarpour et al. |

| 9945807 | April 2018 | Baghbani-Parizi et al. |

| 9990381 | June 2018 | Eltoukhy et al. |

| 10059982 | August 2018 | Esfandyarpour et al. |

| 10093975 | October 2018 | Esfandyarpour et al. |

| 10100356 | October 2018 | Esfandyarpour et al. |

| 10125393 | November 2018 | Esfandyarpour et al. |

| 10260095 | April 2019 | Esfandyarpour et al. |

| 10266892 | April 2019 | Esfandyarpour et al. |

| 10472674 | November 2019 | Esfandyarpour et al. |

| 10494672 | December 2019 | Esfandyarpour et al. |

| 2002/0132245 | September 2002 | Boles et al. |

| 2002/0148739 | October 2002 | Liamos et al. |

| 2003/0078314 | April 2003 | Johnson et al. |

| 2003/0209432 | November 2003 | Choong et al. |

| 2004/0014201 | January 2004 | Kim et al. |

| 2004/0023253 | February 2004 | Kunwar et al. |

| 2004/0033492 | February 2004 | Chen |

| 2004/0136866 | July 2004 | Pontis et al. |

| 2004/0197793 | October 2004 | Hassibi et al. |

| 2005/0009022 | January 2005 | Weiner et al. |

| 2005/0019784 | January 2005 | Su et al. |

| 2005/0032076 | February 2005 | Williams et al. |

| 2005/0084980 | April 2005 | Koo et al. |

| 2005/0098434 | May 2005 | Gundel et al. |

| 2005/0123937 | June 2005 | Thorp et al. |

| 2005/0129526 | June 2005 | Dukhin et al. |

| 2005/0200648 | September 2005 | Doak et al. |

| 2005/0218464 | October 2005 | Holm-Kennedy |

| 2006/0008824 | January 2006 | Ronaghi et al. |

| 2006/0105373 | May 2006 | Pourmand et al. |

| 2006/0147955 | July 2006 | Allawi et al. |

| 2006/0170931 | August 2006 | Guo et al. |

| 2006/0199193 | September 2006 | Koo et al. |

| 2006/0222569 | October 2006 | Barten et al. |

| 2007/0132043 | June 2007 | Bradley et al. |

| 2007/0184463 | August 2007 | Molho et al. |

| 2007/0275375 | November 2007 | Van Eijk et al. |

| 2008/0009420 | January 2008 | Schroth et al. |

| 2008/0032294 | February 2008 | Kawarada et al. |

| 2008/0032295 | February 2008 | Toumazou et al. |

| 2008/0161200 | July 2008 | Yu et al. |

| 2008/0166727 | July 2008 | Esfandyarpour et al. |

| 2008/0171325 | July 2008 | Brown et al. |

| 2008/0176817 | July 2008 | Zhou et al. |

| 2008/0187915 | August 2008 | Polonsky et al. |

| 2008/0241841 | October 2008 | Murakawa et al. |

| 2008/0286762 | November 2008 | Miyahara et al. |

| 2008/0302732 | December 2008 | Soh et al. |

| 2008/0318243 | December 2008 | Haga et al. |

| 2009/0000957 | January 2009 | Dubin et al. |

| 2009/0005259 | January 2009 | Drmanac |

| 2009/0026082 | January 2009 | Rothberg et al. |

| 2009/0029385 | January 2009 | Christians et al. |

| 2009/0032401 | February 2009 | Ronaghi et al. |

| 2009/0048124 | February 2009 | Leamon et al. |

| 2009/0127589 | May 2009 | Rothberg et al. |

| 2009/0166221 | July 2009 | Ishige et al. |

| 2009/0170716 | July 2009 | Su et al. |

| 2009/0170724 | July 2009 | Balasubramanian et al. |

| 2009/0181385 | July 2009 | Mckernan et al. |

| 2009/0191594 | July 2009 | Ohashi |

| 2010/0000881 | January 2010 | Franzen et al. |

| 2010/0035252 | February 2010 | Rothberg et al. |

| 2010/0072080 | March 2010 | Karhanek et al. |

| 2010/0078325 | April 2010 | Oliver |

| 2010/0105035 | April 2010 | Hashsham et al. |

| 2010/0112588 | May 2010 | Farinas et al. |

| 2010/0137143 | June 2010 | Rothberg et al. |

| 2010/0151479 | June 2010 | Toumazou et al. |

| 2010/0159461 | June 2010 | Toumazou et al. |

| 2010/0163414 | July 2010 | Gillies et al. |

| 2010/0167938 | July 2010 | Su et al. |

| 2010/0188073 | July 2010 | Rothberg et al. |

| 2010/0197507 | August 2010 | Rothberg et al. |

| 2010/0209922 | August 2010 | Williams et al. |

| 2010/0255595 | October 2010 | Toumazou et al. |

| 2010/0282617 | November 2010 | Rothberg et al. |

| 2010/0300559 | December 2010 | Schultz et al. |

| 2010/0300895 | December 2010 | Nobile et al. |

| 2010/0301398 | December 2010 | Rothberg et al. |

| 2010/0304982 | December 2010 | Hinz et al. |

| 2010/0317531 | December 2010 | Balasubramanian et al. |

| 2010/0330570 | December 2010 | Vander Horn et al. |

| 2011/0008775 | January 2011 | Gao et al. |

| 2011/0039266 | February 2011 | Williams et al. |

| 2011/0117026 | May 2011 | Tseng et al. |

| 2011/0118139 | May 2011 | Mehta et al. |

| 2011/0123991 | May 2011 | Hoser |

| 2011/0159481 | June 2011 | Liu et al. |

| 2011/0171655 | July 2011 | Esfandyarpour et al. |

| 2011/0177498 | July 2011 | Clarke et al. |

| 2011/0183321 | July 2011 | Williams et al. |

| 2011/0195253 | August 2011 | Hinz et al. |

| 2011/0195459 | August 2011 | Hinz et al. |

| 2011/0201057 | August 2011 | Carr et al. |

| 2011/0201506 | August 2011 | Hinz et al. |

| 2011/0217697 | September 2011 | Rothberg et al. |

| 2011/0230375 | September 2011 | Rothberg et al. |

| 2011/0241081 | October 2011 | Rothberg et al. |

| 2011/0247933 | October 2011 | Rothberg et al. |

| 2011/0248319 | October 2011 | Rothberg et al. |

| 2011/0248320 | October 2011 | Rothberg et al. |

| 2011/0259745 | October 2011 | Dehlinger et al. |

| 2011/0263463 | October 2011 | Rothberg et al. |

| 2011/0287432 | November 2011 | Wong et al. |

| 2011/0287945 | November 2011 | Rothberg et al. |

| 2011/0294115 | December 2011 | Williams et al. |

| 2011/0311979 | December 2011 | Brown et al. |

| 2012/0013392 | January 2012 | Rothberg et al. |

| 2012/0014837 | January 2012 | Fehr et al. |

| 2012/0021918 | January 2012 | Bashir et al. |

| 2012/0034607 | February 2012 | Rothberg et al. |

| 2012/0037961 | February 2012 | Rothberg et al. |

| 2012/0040844 | February 2012 | Rothberg et al. |

| 2012/0045844 | February 2012 | Rothberg et al. |

| 2012/0052489 | March 2012 | Gordon et al. |

| 2012/0055811 | March 2012 | Rothberg et al. |

| 2012/0055813 | March 2012 | Rothberg et al. |

| 2012/0061239 | March 2012 | Elibol et al. |

| 2012/0061255 | March 2012 | Rothberg et al. |

| 2012/0061256 | March 2012 | Rothberg et al. |

| 2012/0061733 | March 2012 | Rothberg et al. |

| 2012/0065093 | March 2012 | Rothberg et al. |

| 2012/0071363 | March 2012 | Rothberg et al. |

| 2012/0085660 | April 2012 | Rothberg et al. |

| 2012/0088682 | April 2012 | Rothberg et al. |

| 2012/0094871 | April 2012 | Hinz et al. |

| 2012/0129173 | May 2012 | Piepenburg et al. |

| 2012/0129703 | May 2012 | Rothberg et al. |

| 2012/0129728 | May 2012 | Rothberg et al. |

| 2012/0129732 | May 2012 | Rothberg et al. |

| 2012/0135870 | May 2012 | Rothberg et al. |

| 2012/0135893 | May 2012 | Drmanac et al. |

| 2012/0138460 | June 2012 | Baghbani-Parizi et al. |

| 2012/0156728 | June 2012 | Li et al. |

| 2012/0157322 | June 2012 | Myllykangas et al. |

| 2012/0173159 | July 2012 | Davey et al. |

| 2012/0175252 | July 2012 | Toumazou et al. |

| 2012/0222496 | September 2012 | Mamigonians |

| 2012/0247977 | October 2012 | Rothberg et al. |

| 2012/0258456 | October 2012 | Armes et al. |

| 2012/0258499 | October 2012 | Piepenburg et al. |

| 2012/0264617 | October 2012 | Pettit |

| 2012/0295819 | November 2012 | Leamon et al. |

| 2012/0302454 | November 2012 | Esfandyarpour |

| 2012/0322054 | December 2012 | Rothberg et al. |

| 2012/0322113 | December 2012 | Erlander et al. |

| 2013/0005613 | January 2013 | Leamon et al. |

| 2013/0023011 | January 2013 | Leamon et al. |

| 2013/0059290 | March 2013 | Armes |

| 2013/0059762 | March 2013 | Leamon et al. |

| 2013/0090860 | April 2013 | Sikora et al. |

| 2013/0109577 | May 2013 | Korlach et al. |

| 2013/0183211 | July 2013 | Senftleber |

| 2013/0203634 | August 2013 | Jovanovich et al. |

| 2013/0225421 | August 2013 | Li et al. |

| 2013/0231254 | September 2013 | Kawashima et al. |

| 2013/0281307 | October 2013 | Li et al. |

| 2014/0034497 | February 2014 | Davis et al. |

| 2014/0099674 | April 2014 | Piepenburg et al. |

| 2014/0106338 | April 2014 | Fischer et al. |

| 2014/0235457 | August 2014 | Esfandyarpour et al. |

| 2014/0272952 | September 2014 | May et al. |

| 2014/0329699 | November 2014 | Esfandyarpour |

| 2015/0316502 | November 2015 | Mohanty et al. |

| 2015/0344943 | December 2015 | Oberstrass |

| 2015/0368707 | December 2015 | Esfandyarpour et al. |

| 2015/0376681 | December 2015 | Gupta et al. |

| 2015/0376692 | December 2015 | Esfandyarpour et al. |

| 2016/0076097 | March 2016 | Esfandyarpour et al. |

| 2016/0077049 | March 2016 | Baghbani-Parizi et al. |

| 2016/0273032 | September 2016 | Esfandyarpour et al. |

| 2016/0340721 | November 2016 | Esfandyarpour |

| 2017/0065977 | March 2017 | Esfandyarpour et al. |

| 2017/0073750 | March 2017 | Esfandyarpour et al. |

| 2017/0088575 | March 2017 | Ju et al. |

| 2017/0211141 | July 2017 | Gordon et al. |

| 2019/0177790 | June 2019 | Esfandyarpour et al. |

| 2019/0177791 | June 2019 | Esfandyarpour et al. |

| 1337580 | Feb 2002 | CN | |||

| 101120098 | Feb 2008 | CN | |||

| 101405083 | Apr 2009 | CN | |||

| 101848757 | Sep 2010 | CN | |||

| 101918590 | Dec 2010 | CN | |||

| 102980922 | Mar 2013 | CN | |||

| 0676623 | Oct 1995 | EP | |||

| 1333089 | Aug 2003 | EP | |||

| 1499738 | Jul 2008 | EP | |||

| 1992706 | Nov 2008 | EP | |||

| 2290096 | Mar 2011 | EP | |||

| 2336361 | Jun 2011 | EP | |||

| 2428588 | Mar 2012 | EP | |||

| 2287341 | Feb 2013 | EP | |||

| 1759012 | May 2013 | EP | |||

| 2660336 | Nov 2013 | EP | |||

| 2006512583 | Apr 2006 | JP | |||

| 2008525822 | Jul 2008 | JP | |||

| 2010513869 | Apr 2010 | JP | |||

| 2010517040 | May 2010 | JP | |||

| 2010517041 | May 2010 | JP | |||

| 2010518401 | May 2010 | JP | |||

| WO-0118246 | Mar 2001 | WO | |||

| WO-0137958 | May 2001 | WO | |||

| WO-0142508 | Jun 2001 | WO | |||

| WO-0227909 | Apr 2002 | WO | |||

| WO-02061146 | Aug 2002 | WO | |||

| WO-2004027024 | Apr 2004 | WO | |||

| WO-2004076683 | Sep 2004 | WO | |||

| WO-2005008450 | Jan 2005 | WO | |||

| WO-2005108612 | Nov 2005 | WO | |||

| WO-2005121363 | Dec 2005 | WO | |||

| WO-2006050346 | May 2006 | WO | |||

| WO-2007030505 | Mar 2007 | WO | |||

| WO-2007041619 | Apr 2007 | WO | |||

| WO-2007098049 | Aug 2007 | WO | |||

| WO-2008076406 | Jun 2008 | WO | |||

| WO-2008132643 | Nov 2008 | WO | |||

| WO-2009012112 | Jan 2009 | WO | |||

| WO-2009052348 | Apr 2009 | WO | |||

| WO-2009074926 | Jun 2009 | WO | |||

| WO-2009122159 | Oct 2009 | WO | |||

| WO-2009150467 | Dec 2009 | WO | |||

| WO-2010008480 | Jan 2010 | WO | |||

| WO-2010026488 | Mar 2010 | WO | |||

| WO-2010037085 | Apr 2010 | WO | |||

| WO-2010041231 | Apr 2010 | WO | |||

| WO-2010047804 | Apr 2010 | WO | |||

| WO-2010075188 | Jul 2010 | WO | |||

| WO-2010138187 | Dec 2010 | WO | |||

| WO-2010141940 | Dec 2010 | WO | |||

| WO-2011106556 | Sep 2011 | WO | |||

| WO-2012047889 | Apr 2012 | WO | |||

| WO-2012166742 | Dec 2012 | WO | |||

| WO-2013082619 | Jun 2013 | WO | |||

| WO-2013119765 | Aug 2013 | WO | |||

| WO-2013188582 | Dec 2013 | WO | |||

| WO-2014012107 | Jan 2014 | WO | |||

| WO-2014043143 | Mar 2014 | WO | |||

| WO-2014152625 | Sep 2014 | WO | |||

| WO-2015089238 | Jun 2015 | WO | |||

| WO-2015138696 | Sep 2015 | WO | |||

| WO-2015161054 | Oct 2015 | WO | |||

| WO-2018017884 | Jan 2018 | WO | |||

| WO-2019060628 | Mar 2019 | WO | |||

Other References

|

Co-pending U.S. Appl. No. 16/033,437, filed Jul. 21, 2018. cited by applicant . Co-pending U.S. Appl. No. 16/105,480, filed Aug. 20, 2018. cited by applicant . Co-pending U.S. Appl. No. 16/115,344, filed Aug. 28, 2018. cited by applicant . Co-pending U.S. Appl. No. 16/137,408, filed Sep. 20, 2018. cited by applicant . U.S. Appl. No. 16/007,969 Notice of Allowance dated Nov. 26, 2018. cited by applicant . U.S. Appl. No. 14/361,902 Office Action dated Oct. 7, 2016. cited by applicant . U.S. Appl. No. 14/859,725 Notice of Allowance dated Sep. 11, 2018. cited by applicant . U.S. Appl. No. 15/360,369 Office Action dated Nov. 29, 2018. cited by applicant . U.S. Appl. No. 16/007,829 Office Action dated Sep. 17, 2018. cited by applicant . U.S. Appl. No. 14/859,725 Notice of Allowance dated Jun. 19, 2018. cited by applicant . Andreotti, et al. Immunoassay of infectious agents. Biotechniques. Oct. 2003;35(4):850-9. cited by applicant . Bell, et al. Detection of Bacillus anthracis DNA by LightCycler PCR. J Clin Microbiol. Aug. 2002;40(8):2897-902. cited by applicant . Boo, et al. Electrochemical nanoneedle biosensor based on multiwall carbon nanotube. Anal Chem. Jan. 15, 2006;78(2):617-20. cited by applicant . Brouns, et al. Small CRISPR RNAs guide antiviral defense in prokaryotes. Science. Aug. 15, 2008;321(5891):960-4. cited by applicant . Cagnin, et al. Overview of electrochemical DNA biosensors: new approaches to detect the expression of life. Sensors (Basel). 2009;9(4):3122-48. doi: 10.3390/s90403122. Epub Apr. 24, 2009. cited by applicant . Carte, et al., Cas6 is an endoribonuclease that generates guide RNAs for invader defense in prokaryotes. Genes Dev. Dec. 15, 2008;22(24):3489-96. cited by applicant . Cho, et al. Bis-aptazyme sensors for hepatitis C virus replicase and helicase without blank signal. Nucleic Acids Res. Nov. 27, 2005;33(20):e177. cited by applicant . Co-pending U.S. Appl. No. 15/726,193, filed Oct. 5, 2017. cited by applicant . Co-pending U.S. Appl. No. 15/726,217, filed Oct. 5, 2017. cited by applicant . Daniels, et al. Label-Free Impedance Biosensors: Opportunities and Challenges. Electroanalysis. Jun. 2007;19(12):1239-1257. cited by applicant . Daniels, et al. Simultaneous Measurement of Nonlinearity and Electrochemical Impedance for Protein Sensing Using Two-Tone Excitation. 30th Annual International IEEE EMBS Conference. Vancouver, British Columbia, Canada, Aug. 20-24, 2008. 5753-5756. cited by applicant . Didion, et al., Invaders: Recognition of Double-Stranded DNA by Using Duplexes Modified with Interstrand Zippers of 2'-O-(Pyren-1-yl)methyl-ribonucleotides. Chembiochem. Sep. 2, 2013;14(13):1534-1538. doi: 10.1002/cbic.201300414. Epub 2013 Aug. 23, 2013. cited by applicant . Dimov, et al. Stand-alone self-powered integrated microfluidic blood analysis system (SIMBAS). Lab Chip. Mar. 7, 2011;11(5):845-50. cited by applicant . Edman, et al. Electric field directed nucleic acid hybridization on microchips. Nucleic Acids Res. Dec. 15, 1997; 25(24): 4907-14. cited by applicant . Ellington, et al. In vitro selection of RNA molecules that bind specific ligands. Nature. Aug. 30, 1990;346(6287):818-22. cited by applicant . Esfandyarpour, et al. 3D modeling of impedance spectroscopy for protein detection in nanoneedle biosensors. Proceedings of the COMSOL Conference 2007, Boston. cited by applicant . Esfandyarpour, et al. 3D Modeling of Impedance Spectroscopy for Protein Detection in Nanoneedle Biosensors. Proceedings of the International COMSOL Conference 2007, Boston, MA, USA, pp. 169-173 (Oct. 4-6, 2007). cited by applicant . Esfandyarpour, et al. A Novel Nanoneedle Biosensor for DNA Sequencing (abstract). Dec. 31, 2008. Available at http://www.nsti.org/Nanotech2008/showabstract.html?absno=1522. cited by applicant . Esfandyarpour, et al. Geometrical Optimization of Pyrophosphate Concentration in Thermosequencing Platform for DNA Sequencing. Proceedings of the COMSOL Conf. 2007, Boston. cited by applicant . European search report and search opinion dated Jan. 5, 2015 for EP Application No. 12792216.9. cited by applicant . European search report and search opinion dated Mar. 12, 2014 for EP Application No. 11831452.5. cited by applicant . European search report and search opinion dated Jul. 13, 2015 for EP Application No. 12852490.7. cited by applicant . European Search Report dated Oct. 11, 2017 for European Patent Application No. EP14869402.9. cited by applicant . Finn, et al. Efficient incorporation of positively charged 2', 3'-dideoxynucleoside-5'-triphosphates by DNA polymerases and their application in `direct-load` DNA sequencing. Nucleic Acids Res. Aug. 15, 2003;31(16):4769-78. cited by applicant . Gao, et al. Silicon nanowire arrays for label-free detection of DNA. Anal Chem. May 1, 2007;79(9):3291-7. Epub Apr. 4, 2007. cited by applicant . Gardeniers, et al. Silicon micromachined hollow microneedles for transdermal liquid transport. Journal of Microelectromechanical Systems. 2003;12(6):855-862. cited by applicant . Guiducci, et al. A Biosensor for Direct Detection of DNA Sequences Based on Capacitance Measurements. ESSDERC 2002, pp. 479-482. cited by applicant . Haurwitz, et al. Sequence- and structure-specific RNA processing by a CRISPR endonuclease. Science. Sep. 10, 2010;329(5997):1355-8. cited by applicant . Hollis, et al. Structure of the gene 2.5 protein, a single-stranded DNA binding protein encoded by bacteriophage T7. Proc Natl Acad Sci U S A. Aug. 14, 2001;98(17):9557-62. Epub Jul. 31, 2001. cited by applicant . International search report and written opinion dated Feb. 26, 2013 for PCT/US2012/039880. cited by applicant . International search report and written opinion dated Mar. 19, 2013 for PCT/US2012/067645. cited by applicant . International search report and written opinion dated Apr. 13, 2012 for PCT/US2011/054769. cited by applicant . International search report and written opinion dated Aug. 21, 2014 for PCT Application No. PCT/US2014/027544. cited by applicant . International search report and written opinion dated Oct. 26, 2015 for PCT/US2015/026135. cited by applicant . Javanmard, et al. A microfluidic platform for electrical detection of DNA hybridization. Sens Actuators B Chem. May 20, 2011;154(1):22-27. Epub Mar. 30, 2010. cited by applicant . Javanmard, et al. Electrical Detection of Proteins and DNA Using Bioactivated Microfluidic Channels: Theoretical and Experimental Considerations. J Vac Sci Technol B Microelectron Nanometer Struct Process Meas Phenom. Nov. 2009;27(6):3099-3103. cited by applicant . Kaushik, et al. Lack of pain associated with microfabricated microneedles. Anesth Analg. Feb. 2001;92(2):502-4. cited by applicant . Kim, et al. Replication of DNA microarrays prepared by in situ oligonucleotide polymerization and mechanical transfer. Anal Chem. Oct. 1, 2007;79(19):7267-74. cited by applicant . Kitano, et al. Molecular structure of RNA polymerase and its complex with DNA. J Biochem. Jan. 1969;65(1):1-16. cited by applicant . Kunin, et al. Evolutionary conservation of sequence and secondary structures in CRISPR repeats. Genome Biol. 2007;8(4):R61. cited by applicant . Kurosaki, et al. Rapid and simple detection of Ebola virus by reverse transcription-loop-mediated isothermal amplification. J Virol Methods. Apr. 2007;141(1):78-83. cited by applicant . Lee, et al. Ion-sensitive field-effect transistor for biological sensing. Sensors (Basel). 2009;9(9):7111-31. doi: 10.3390/s90907111. Epub Sep. 7, 2009. cited by applicant . Lin, et al. Replication of DNA microarrays from zip code masters. J Am Chem Soc. Mar. 15, 2006;128(10):3268-72. cited by applicant . Liu, et al. Immobilization of DNA onto poly(dimethylsiloxane) surfaces and application to a microelectrochemical enzyme-amplified DNA hybridization assay. Langmuir. Jul. 6, 2004;20(14):5905-10. cited by applicant . Makarova, et al. A putative RNA-interference-based immune system in prokaryotes: computational analysis of the predicted enzymatic machinery, functional analogies with eukaryotic RNAi, and hypothetical mechanisms of action. Biol Direct. Mar. 16, 2006;1:7. cited by applicant . Manickam, et al. A CMOS Electrochemical Impedance Spectroscopy (EIS) Biosensor Array. IEEE Trans Biomed Circuits Syst. Dec. 2010;4(6):379-90. doi: 10.1109/TBCAS.2010.2081669. cited by applicant . Margulies, et al. Genome sequencing in microfabricated high-density picolitre reactors. Nature. Sep. 15, 2005;437(7057):376-80. Epub Jul. 31, 2005. cited by applicant . Notice of allowance dated Mar. 28, 2016 for U.S. Appl. No. 13/481,858. cited by applicant . Notice of Allowance dated May 12, 2017 for U.S. Appl. No. 14/653,230. cited by applicant . Notice of allowance dated May 19, 2016 for U.S. Appl. No. 13/481,858. cited by applicant . Notice of allowance dated Jun. 3, 2015 for U.S. Appl. No. 14/596,111. cited by applicant . Notice of allowance dated Jul. 1, 2015 for U.S. Appl. No. 13/824,129. cited by applicant . Notice of Allowance dated Jul. 6, 2017 for U.S. Appl. No. 14/653,230. cited by applicant . Notice of Allowance dated Jul. 10, 2017 for U.S. Appl. No. 14/688,764. cited by applicant . Notice of allowance dated Jul. 13, 2015 for U.S. Appl. No. 14/596,111. cited by applicant . Notice of Allowance dated Jul. 20, 2017 for U.S. Appl. No. 14/688,764. cited by applicant . Notice of Allowance dated Jul. 31, 2017 for U.S. Appl. No. 14/119,859. cited by applicant . Notice of allowance dated Aug. 25, 2015 for U.S. Appl. No. 14/596,111. cited by applicant . Notice of allowance dated Sep. 1, 2015 for U.S. Appl. No. 14/596,111. cited by applicant . Notice of Allowance dated Sep. 8, 2017 for U.S. Appl. No. 14/653,230. cited by applicant . Notice of allowance dated Nov. 21, 2014 for U.S. Appl. No. 13/632,513. cited by applicant . Notice of allowance dated Dec. 3, 2015 for U.S. Appl. No. 13/838,816. cited by applicant . Notice of allowance dated Dec. 15, 2015 for U.S. Appl. No. 13/838,816. cited by applicant . Notomi, et al. Loop-mediated isothermal amplification of DNA. Nucl Acids Res. Jun. 15, 2000; 28(12):E63. cited by applicant . Office action dated Jan. 28, 2014 for U.S. Appl. No. 13/838,816. cited by applicant . Office action dated Jan. 29, 2014 for U.S. Appl. No. 13/481,858. cited by applicant . Office action dated Jan. 30, 2015 for U.S. Appl. No. 13/481,858. cited by applicant . Office Action dated Feb. 14, 2017 for U.S. Appl. No. 14/653,230. cited by applicant . Office Action dated Mar. 4, 2016 for U.S. Appl. No. 14/081,358. cited by applicant . Office Action dated Apr. 5, 2017 for U.S. Appl. No. 14/859,725. cited by applicant . Office action dated Apr. 6, 2016 for U.S. Appl. No. 14/835,070. cited by applicant . Office action dated Apr. 9, 2015 for U.S. Appl. No. 14/596,111. cited by applicant . Office Action dated Apr. 24, 2017 for U.S. Appl. No. 14/119,859. cited by applicant . Office action dated May 1, 2015 for U.S. Appl. No. 13/824,129. cited by applicant . Office action dated Jul. 18, 2013 for U.S. Appl. No. 13/481,858. cited by applicant . Office action dated Jul. 23, 2014 for U.S. Appl. No. 13/824,129. cited by applicant . Office action dated Jul. 25, 2014 for U.S. Appl. No. 13/481,858. cited by applicant . Office Action dated Sep. 1, 2017 for U.S. Appl. No. 14/361,902. cited by applicant . Office action dated Sep. 2, 2014 for U.S. Appl. No. 13/632,513. cited by applicant . Office Action dated Oct. 5, 2015 for U.S. Appl. No. 14/081,358. cited by applicant . Office action dated Oct. 7, 2015 for U.S. Appl. No. 13/838,816. cited by applicant . Office Action dated Oct. 23, 2017 for U.S. Appl. No. 14/859,725. cited by applicant . Office action dated Nov. 5, 2013 for U.S. Appl. No. 13/632,513. cited by applicant . Office action dated Dec. 17, 2015 for U.S. Appl. No. 13/481,858. cited by applicant . Office action dated Dec. 17, 2015 for U.S. Appl. No. 14/835,070. cited by applicant . Office action dated Dec. 19, 2014 for U.S. Appl. No. 13/838,816. cited by applicant . Patolsky, et al. Electrical detection of single viruses. Proc Natl Acad Sci U S A. Sep. 28, 2004;101(39):14017-22. Epub Sep. 13, 2004. cited by applicant . Patolsky, et al. Fabrication of silicon nanowire devices for ultrasensitive, label-free, real-time detection of biological and chemical species. Nat Protoc. 2006;1(4):1711-24. cited by applicant . Peng et al. Interdigitated Array Electrodes with Magnetic Function as a Particle-Based Biosensor. Sensors, 2007 IEEE. pp. 1097-1100. cited by applicant . Piepenburg, et al. DNA detection using recombination proteins. PLoS Biol. Jul. 2006;4(7):e204. cited by applicant . Ren, et al. Rapid and sensitive detection of hepatitis B virus 1762T/1764A double mutation from hepatocellular carcinomas using LNA-mediated PCR clamping and hybridization probes. Journal of Virological Methods. 2009; 158(1-2):24-29. cited by applicant . Roosen-Runge, et al. Protein diffusion in crowded electrolyte solutions. Biochim Biophys Acta. Jan. 2010;1804(1):68-75. doi: 10.1016/j.bbapap.2009.07.003. Epub Jul. 17, 2009. cited by applicant . Rothberg, et al. An integrated semiconductor device enabling non-optical genome sequencing. Nature. Jul. 20, 2011; 475(7356); pp. 348-352. With Supplementary Information, 25 pages. cited by applicant . Sabounchi, et al. Sample concentration and impedance detection on a microfluidic polymer chip. Biomed Microdevices. Oct. 2008;10(5):661-70. doi: 10.1007/s10544-008-9177-4. cited by applicant . Safir, et al. Fabrication of an insulated probe on a self-assembled metallic nanowire for electrochemical probing in cells. IEEE 2006, pp. 898-900. cited by applicant . Saias et al. Design, modeling and characterization of microfluidic architectures for high flow rate, small footprint microfluidic systems. Lab Chip. Mar. 7, 2011;11(5):822-32. cited by applicant . Senapati, et al. A nonamembrane-based nucleic acid sensing platform for portable diagnostics. Topics in Current Chemistry. Apr. 27, 2011; 304:153-169. cited by applicant . Sivamani, et al. Microneedles and transdermal applications. Expert Opin Drug Deliv. Jan. 2007;4(1):19-25. cited by applicant . Sosnowski, et al. Rapid determination of single base mismatch mutations in DNA hybrids by direct electric field control. Proc Natl Acad Sci U S A. Feb. 18, 1997; 94(4): 1119-1123. cited by applicant . Tamayol et al. Laminar Flow in Microchannels With Noncircular Cross Section. J. Fluids Eng 132(11), Dec. 1, 2011 (Nov. 3, 2010) (9 pages). cited by applicant . Terns, et al. CRISPR-based adaptive immune systems. Curr Opin Microbiol. Jun. 2011;14(3):321-7. cited by applicant . Van Der Oost, et al. CRISPR-based adaptive and heritable immunity in prokaryotes. Trends Biochem Sci. Aug. 2009;34(8):401-7. cited by applicant . Voelkerding, et al. Next generation sequencing: from basic research to diagnostics. Clin. Chem. 2009; 55(4):641-658. cited by applicant . Wang, et al. Interaction of the Cas6 riboendonuclease with CRISPR RNAs: recognition and cleavage. Structure. Feb. 9, 2011;19(2):257-64. cited by applicant . Yazdanpanah, et al. Selective self-assembly at room temperature of individual freestanding Ag2Ga alloy nanoneedles. J. Appl. Phys. 98, pp. 073510-7 (2005). cited by applicant . Zhang, et al. Dielectrophoresis for manipulation of micro/nano particles in microfluidic systems. Anal Bioanal Chem. Jan. 2010;396(1): 401-20. cited by applicant . Zheng, et al. Multiplexed electrical detection of cancer markers with nanowire sensor arrays. Nat Biotechnol. Oct. 2005;23(10):1294-301. Epub Sep. 18, 2005. cited by applicant . European Search Report dated Nov. 14, 2017 for European Patent Application No. EP15779780.4. cited by applicant . International Search Report and Written Opinion dated Nov. 16, 2017 for International PCT Patent Application No. PCT/US2017/43159. cited by applicant . Notice of Allowance dated Dec. 8, 2017 for U.S. Appl. No. 14/119,859. cited by applicant . Office Action dated Dec. 18, 2017 for U.S. Appl. No. 15/028,899. cited by applicant . Smolina et al. End invasion of peptide nucleic acids (PNAs) with mixed-base composition into linear DNA duplexes. Nucleic Acids Research. vol. 33. No. 11. pp. e146-e146. Sep. 25, 2005. cited by applicant . Zanoli et al. Isothermal Amplification Methods for the Detection of Nucleic Acids in Microfluidic Devices. Biosensors. vol. 3. No. 1. pp. 18-43. Dec. 27, 2012. cited by applicant . Bobrow et al. Fundamentals of Electrical Engineering, 1995, Holt, Rinehart and Winston, Inc. cited by applicant . Brown et al. AC electroosmotic flow in a DNA concentrator. Microfluid Nanofluid 2:513-523 (2006). cited by applicant . Cheng et al. Single-stranded DNA concentration by electrokinetic forces. J. Micro/Nanolith. MEMS MOEMS 8(2):021107 (Jun. 9, 2009). Abstract only. cited by applicant . Co-pending U.S. Appl. No. 15/950,005, filed Apr. 10, 2018. cited by applicant . Co-pending U.S. Appl. No. 13/397581, filed Feb. 15, 2012. cited by applicant . Co-pending U.S. Appl. No. 15/896,572, filed Feb. 14, 2018. cited by applicant . Co-pending U.S. Appl. No. 16/007,829, filed Jun. 13, 2018. cited by applicant . Co-pending U.S. Appl. No. 16/007,969, filed Jun. 13, 2018. cited by applicant . Co-pending U.S. Appl. No. 16/039,016, filed Jul. 18, 2018. cited by applicant . Cui et al., "Nanowire Nanosensors for Highly Sensitive and Selective Detection of Biological and Chemical Species", Science, vol. 293, pp. 1289-1292 (2001). cited by applicant . EP14767683.7 Extended European Search Report dated Oct. 25, 2016. cited by applicant . Esfandyarpour. Nano-Biotechnology toward Diagnostic Industry: Obstacles and Opportunities. NSTI-Nanotech, vol. 4, p. 421 (2007). Abstract Only. cited by applicant . Examination Report dated Jun. 7, 2016 for Singapore Patent Application No. SG11201402760V. cited by applicant . Fritz et al. Electronic detection of DNA by its intrinsic molecular charge. PNAS 99(22):14142-14146 (2002). cited by applicant . Hsu et al. Wafer-scale silicon nanopillars and nanocones by Langmuir-Blodgett assembly and etching. Applied Physic Lett. 93:133109-1-133109-3 (2008). cited by applicant . Kuhr. Capillary Electrophoresis. Anal. Chem. 62:403R-414R (1990). cited by applicant . Lei et al. Electrokinetic DNA concentration in Microsystems. Sensors and Actuators. A 156(2) (2009). Abstract only. cited by applicant . Moser et al. Biosensor arrays for simultaneous measurement of glucose, lactate, glutamate, and glutamine. Biosens. & Bioelect. 17:297-302 (2002). cited by applicant . Parizi et al. A Semiconductor Nanobridge Biosensor for Electrical Detection of DNA Hybridization. IEEE Int'l SOI Conference, 2 pgs. (Oct. 6-9, 2008). cited by applicant . Parizi et al. An Internally Amplified Signal SOI Nano-bridge Biosensors for Electrical Detection of DNA Hybridization. IEEE Int'l SOI Conference, 2 pgs. (Oct. 5-8, 2009). cited by applicant . Parizi et al. BioFET for Detection of Biological Species. Stanford University, CIS (Computer-Information-System) Catalog, 1 sheet (2008). cited by applicant . Parizi et al. BioFET Sensor. CIS 2007--Stanford University, 33 pgs. (2007). cited by applicant . Parizi et al. Poster--An Internally Amplified Signal SOI Nanobridge Biosensor for Electrical Detection of DNA Hybridization or Sequence. Poster--1 sheet (Summer 2009). cited by applicant . Parizi et al. Poster BioFET Sensor. CIS 2007--Stanford University, 18 pgs. (2007). cited by applicant . Parizi et al. BioFET Sensor. CIS ADCOM Fall 2009 Stanford University, 28 pgs (Nov. 2009). cited by applicant . Pascault. A Finite Element Study of the DNA Hybridization Kinetics on the Surface of Microfluidic Devices. Thesis, M.S. Chem. Engineer., Worcester Polytechnic Institute, p. 1-148 (Apr. 2007). cited by applicant . PCT/US2014/069624 International Search Report dated May 22, 2015. cited by applicant . Poghossian et al. Possibilities and limitations of label-free detection of DNA hybridization with field-effect-based devices. Sensors and Actuators B 111-112:470-480 (2005). cited by applicant . Ramos et al. AC electric-field-induced fluid flow in microelectrodes. J Colloid Interface Sci 217:420-422 (1999). cited by applicant . U.S. Appl. No. 14/859,725 Notice of Allowance dated Jul. 27, 2018. cited by applicant . U.S. Appl. No. 15/028,899 Notice of Allowance dated Jul. 25, 2018. cited by applicant . U.S. Appl. No. 16/007,969 Office Action dated Aug. 15, 2018. cited by applicant . U.S. Appl. No. 14/081,358 Notice of Allowance dated May 16, 2016. cited by applicant . U.S. Appl. No. 14/936,245 Notice of Allowance dated Sep. 22, 2017. cited by applicant . U.S. Appl. No. 14/936,245 Notice of Allowance dated Dec. 6, 2017. cited by applicant . Stein, D.; Deurvorst, Z.; van der Heyden, F. H. J.; Koopmans, W. J. A.; Gabel, A.; Dekker, C. Electrokinetic Concentration of DNA Polymers in Nanofluidic Channels. Nano Lett. 2010, 10, 765-772. cited by applicant . U.S. Appl. No. 15/028,899 Notice of Allowance dated Jun. 27, 2018. cited by applicant . U.S. Appl. No. 14/361,902 Notice of Allowance dated May 21, 2018. cited by applicant . U.S. Appl. No. 14/859,725 Notice of Allowance dated May 30, 2018. cited by applicant . U.S. Appl. No. 15/183,406 Office Action dated Jun. 21, 2018. cited by applicant . U.S. Appl. No. 15/230,048 Notice of Allowance dated Apr. 5, 2018. cited by applicant . Wilke et al. A micromachined capillary electrophoresis chip with fully integrated electrodes for separation and electochemical detection. Biosens. and Bioelect. 19:149-153 (2003). cited by applicant . Williams, et al. Etch rates for micromachining processing. Journal of Microelectromechanical Systems 5(4):761-778 (1996). cited by applicant . Betz et al. KlenTaq polymerase replicates unnatural base pairs by inducing a Watson-Crick geometry. Nat Chem Biol 8:612-614 (2012). cited by applicant . Co-pending U.S. Appl. No. 16/141,215, filed Sep. 25, 2018. cited by applicant . Park et al. Control of channel doping concentration for enhancing the sensitivity of "top-down" fabricated Si nanochannel FET biosensors. Nanotechnology 20(47):475501 (Oct. 26, 2009). cited by applicant . PCT/US2018/052072 International Search Report and Written Opinion dated Jan. 18, 2019. cited by applicant . U.S. Appl. No. 15/183,406 Office Action dated Mar. 8, 2019. cited by applicant . U.S. Appl. No. 15/655,616 Office Action dated Feb. 26, 2019. cited by applicant . U.S. Appl. No. 15/726,193 Office Action dated Apr. 16, 2019. cited by applicant . U.S. Appl. No. 15/726,217 Office Action dated Mar. 19, 2019. cited by applicant . U.S. Appl. No. 16/007,829 Notice of Allowance dated Nov. 26, 2018. cited by applicant . U.S. Appl. No. 16/283,531 Office Action dated Jul. 18, 2019. cited by applicant . U.S. Appl. No. 16/283,544 Notice of Allowance dated Jul. 11, 2019. cited by applicant . U.S. Appl. No. 15/360,369 Notice of Allowance dated Jul. 5, 2019. cited by applicant . U.S. Appl. No. 15/950,005 Office Action dated Jan. 28, 2019. cited by applicant . Sakata et al. DNA Sequencing Based on Intrinsic Molecular Charges. Angew Chem Int Ed 45:2225-2228 (2006). cited by applicant . U.S. Appl. No. 15/360,369 Notice of Allowance dated Sep. 4, 2019. cited by applicant . U.S. Appl. No. 15/726,193 Notice of Allowance dated Aug. 29, 2019. cited by applicant . U.S. Appl. No. 16/137,408 Office Action dated Aug. 9, 2019. cited by applicant . U.S. Appl. No. 15/726,217 Notice of Allowance dated Dec. 4, 2019. cited by applicant . U.S. Appl. No. 16/137,408 Office Action dated Nov. 19, 2019. cited by applicant . U.S. Appl. No. 16/283,531 Notice of Allowance dated Nov. 22, 2019. cited by applicant . Co-pending U.S. Appl. No. 16/592,545, filed Oct. 3, 2019. cited by applicant . Co-pending U.S. Appl. No. 16/598,591, filed Oct. 10, 2019. cited by applicant . Co-pending U.S. Appl. No. 16/694,367, filed Nov. 25, 2019. cited by applicant . EP19162225.7 Extended European Search Report dated Sep. 18, 2019. cited by applicant . U.S. Appl. No. 15/360,369 Notice of Allowance dated Oct. 10, 2019. cited by applicant . U.S. Appl. No. 15/726,217 Notice of Allowance dated Oct. 8, 2019. cited by applicant . U.S. Appl. No. 15/950,005 Notice of Allowance dated Sep. 13, 2019. cited by applicant. |

Primary Examiner: Bhat; Narayan K

Attorney, Agent or Firm: Wilson Sonsini Goodrich & Rosati

Parent Case Text

CROSS-REFERENCE

This application claims the benefit of U.S. Provisional Patent Application No. 62/364,489, filed Jul. 20, 2016, U.S. Provisional Patent Application No. 62/375,197, filed Aug. 15, 2016, U.S. Provisional Patent Application No. 62/418,101, filed Nov. 4, 2016, and U.S. Provisional Patent Application No. 62/444,700, filed Jan. 10, 2017, each of which is entirely incorporated herein by reference.

Claims

What is claimed is:

1. A method for sequencing a nucleic acid template, comprising: (a) contacting a nucleic acid template with a sensing fluid containing a population of nucleotides, wherein said nucleic acid template is hybridized to a primer that is coupled to a bead, which bead is positioned proximate to a sensor in a sensor array, wherein said sensor comprises at least two electrodes, wherein said sensing fluid has a sensing fluid bulk conductivity and a surface of said bead has a surface conductivity to provide a Dukhin number that is less than 1 such that (i) a conductivity measurement by said at least two electrodes with said bead positioned proximate to said sensor is substantially similar to (ii) another conductivity measurement by said at least two electrodes without said bead positioned proximate to said sensor; (b) using said at least two electrodes of said sensor to detect a conductivity change within a Debye layer of said bead upon incorporation of at least one nucleotide of said population of nucleotides into a growing nucleic acid strand, which growing nucleic acid strand is derived from said primer and is complementary to said nucleic acid template, which conductivity change is detected based at least in part on an electrical current change through said Debye layer; (c) washing said sensor array to remove unincorporated nucleotides of said population of nucleotides from said sensor array; and (d) repeating (a)-(c) to obtain sequence information for said nucleic acid template.

2. The method of claim 1, wherein an electrode of said at least two electrodes is exposed to said sensing fluid.

3. The method of claim 1, wherein (b) further comprises detecting a change in impedance within said Debye layer of said bead upon incorporation of said at least one nucleotide.

4. The method of claim 3, wherein said change in impedance within said Debye layer is detected at steady state.

5. The method of claim 1, wherein said at least two electrodes are positioned within said Debye layer of said bead.

6. The method of claim 1, wherein said sensing fluid has a solute concentration between about 0.15 millimolar and about 6 millimolar.

7. The method of claim 1, further comprising, prior to (b): (i) contacting said sensor array with a probe fluid, wherein said probe fluid has a probe fluid bulk conductivity that is at least about 50 times greater than or at least about 50 times less than said surface conductivity of said surface of said bead; and (ii) using said sensor to detect signals that are indicative of a presence of said bead in proximity to said sensor.

8. The method of claim 7, wherein an additional Dukhin number determined from said probe fluid bulk conductivity and said surface conductivity of said surface of said bead is substantially less than 1.

9. The method of claim 7, wherein an additional Dukhin number determined from said probe fluid bulk conductivity and said surface conductivity of said surface of said bead is substantially greater than 1.

10. The method of claim 7, wherein (b), (c), and (d) are performed only at sensors of said sensor array at which signals indicative of bead occupancy are observed.

Description

BACKGROUND

The human genome has created interest in technologies for rapid nucleic acid analysis, including nucleic acid sequencing, both for small and large-scale applications. Presently available nucleic acid sequencing technologies include detection of fluorescent nucleotides; detection of proton byproducts of polymerase activity; and (iii) detection of currents through nanopores. In the context of sequencing, important considerations include accuracy, speed, read length, cost, instrument size and complexity, and the amount of nucleic acid template required to generate sequencing information. Unfortunately, large-scale genome projects often remain too costly and/or infeasible, due to shortcomings in available sequencing technologies. Available sequencing technologies, such as those mentioned above, often have sample preparation, accuracy and/or scalability issues that present significant challenges their mainstream implementation.

SUMMARY

Recognized herein is the need for improved systems and methods for sensing biological reactions, including nucleic acid sequencing reactions. Systems and methods provided herein may have utility in sequencing nucleic acids associated with beads or nucleic acids associated with polymer films. In some cases, signals derived from the sequencing reaction are detected at a buffer composition and concentration that reduces the sensitivity of the system to movements of a bead relative to one or more sensors that detect such signals.

The present disclosure provides methods and systems for sample analysis or identification, such as nucleic acid sequencing. The present disclosure provides methods and systems that may enable sample preparation and identification (e.g., sequencing) without the use of particles, such as beads. This may enable a sample to be prepared and identified at substantially reduced cost and complexity as compared to other systems and methods.

The disclosure also provides systems and methods for improved nucleic acid analysis that overcome status-quo deficiencies and permit low-cost, scalable nucleic acid sequencing technologies. As knowledge of the genetic basis for human diseases increases, there will be an ever-increasing need for accurate nucleic acid analysis tools that are accurate, affordable and scalable for clinical applications. The present disclosure provides systems and methods that make use of redox mediator moieties that are detectable using electronic sensors to perform nucleic acid sequencing.

In an aspect, the present disclosure provides methods for sequencing a nucleic acid template comprising: (a) contacting a nucleic acid template with a sensing fluid containing a population of nucleotides, wherein the nucleic acid template is hybridized to a primer that is coupled to a bead, which bead is positioned proximate to a sensor in a sensor array, wherein the sensor comprises at least two electrodes, and wherein the sensing fluid has a bulk conductivity and a surface of the bead has a surface conductivity to provide a Dukhin number that is less than about 1; (b) using the sensor to detect a change in conductivity within a Debye layer of the bead upon incorporation of at least one nucleotide of the population of nucleotides into a growing nucleic acid strand, which growing nucleic acid strand is derived from the primer and is complementary to the nucleic acid template; (c) washing the sensor array to remove unincorporated nucleotides of the population of nucleotides from the sensor array; and (d) repeating (a)-(c) to obtain sequence information for the nucleic acid template.

In some embodiments, a given electrode of the at least two electrodes is exposed to the sensing fluid. In some embodiments, (b) further comprises detecting a change in impedance within the Debye layer of the bead upon incorporation of the at least one nucleotide. In some embodiments, the change in impedance within the Debye layer is detected at steady state. In some embodiments, the at least two electrodes are positioned within the Debye layer of the bead. In some embodiments, the sensing fluid has a solute concentration between about 0.15 millimolar and about 6 millimolar.

In some embodiments, the method further comprises, prior to (b): (i) contacting the sensor array with a probe fluid, wherein the probe fluid has a bulk conductivity that is at least about 50 times greater than or 50 times less than the conductivity associated with the surface of the bead; and (ii) using the sensor to detect signals that are indicative of a presence of the bead in proximity to the sensor. In some embodiments, a Dukhin number determined from the bulk conductivity of the probe fluid and the conductivity of the surface of the bead is substantially less than 1. In some embodiments, a Dukhin number determined from the bulk conductivity of the probe fluid and the conductivity of the surface of the bead is substantially greater than 1. In some embodiments, (b), (c), and (d) are performed only at sensors of the sensor array at which signals indicative of bead occupancy are observed.

In an aspect, the present disclosure provides methods for determining bead occupancy at sites of a sensor array, comprising: (a) contacting a sensor array with a plurality of beads, wherein the sensor array comprises a plurality of sensors each having at least two electrodes, to provide a given bead of the plurality of beads at a given position in proximity to an individual sensor of the plurality of sensors; (b) contacting the sensor array with a probe fluid that has a bulk conductivity that is at least about 50 times greater than or 50 times less than a conductivity associated with a surface of the given bead; (c) using the individual sensor to detect signals that are indicative of a presence of the given bead in proximity to the sensor; and (d) identifying the given position of the sensor array as occupied by the given bead.

In some embodiments, the probe fluid has a concentration of solutes between about 0.01 millimolar and about 1 molar. In some embodiments, a Dukhin number determined from the bulk conductivity of the probe fluid and the conductivity of the surface of the bead is substantially less than 1. In some embodiments, a Dukhin number determined from the bulk conductivity of the probe fluid and the conductivity of the surface of the bead is substantially greater than 1. In some embodiments, the method further comprises a nucleic acid coupled to the given bead. In some embodiments, the signals comprise electrical current. In some embodiments, a given electrode of the individual sensor is positioned within a Debye layer of the given bead.

In an aspect, the present disclosure provides methods for processing a nucleic acid sample, comprising: (a) providing a mixture comprising a first set of droplets and a second set of droplets, wherein a first droplet of the first set of droplets comprises (i) a bead, (ii) a recombinase, (iii) a polymerizing enzyme, and (iv) a nucleic acid molecule from the nucleic acid sample, and wherein a second droplet of the second set of droplets comprises an activating agent that increases a rate at which the recombinase processes the nucleic acid molecule to permit the primer to hybridize to the nucleic acid molecule to conduct a primer extension reaction in presence of the polymerizing enzyme, to generate an amplification product(s) from the nucleic acid molecule; (b) merging the first droplet with the second droplet in the mixture to generate a third droplet as part of a third set of droplets, wherein the third droplet comprises the bead having coupled thereto the nucleic acid molecule, recombinase, primer and polymerizing enzyme; and (c) conducting the primer extension reaction to generate the amplification product(s) from the nucleic acid molecule in the third droplet.

In some embodiments, the first droplet further comprises buffer, salts, crowding agents, dNTPs, primers, or any combination thereof. In some embodiments, the second droplet further comprises primers, dNTPs, ATP, recombinase loading enzyme, single-stranded DNA-binding protein, an ATP-regenerating unit, buffer, salt, and crowding agents. In some embodiments, the activating agent is a magnesium salt. In some embodiments, formation of the third droplet comprises subjecting the mixture to low speed stirring or shaking. In some embodiments, the primer extension reaction occurs under isothermal conditions.

In some embodiments, the method further comprises directing the third set of droplets through a set of obstacles to control a shape or a size of each droplet of the third set of droplets. In some embodiments, the set of obstacles have a comb-like structure. In some embodiments, the shape or the size of each droplet of the third set of droplets is controlled by flowrate, pressure, obstacle shape, and obstacle size.

In some embodiments, the method further comprises disrupting the third set of droplets with a disrupting mixture comprising an emulsion disruptor and a deactivating agent, wherein disrupting the third set of droplets forms a homogenous solution. In some embodiments, the method further comprises capturing multiple of the bead coupled to amplification product(s) with a capture bead to form a multi-bead complex. In some embodiments, the capture bead exclusively binds to the bead coupled to amplification product(s). In some embodiments, the multi-bead complex is appreciably larger than a non-complexed bead. In some embodiments, the method further comprises directing the beads through a set of obstacles to separate the multi-bead complex from the non-complexed bead via size selection.

In an aspect, the present disclosure provides methods for sequencing a nucleic acid molecule, comprising: (a) activating a sensor comprising a support comprising at least two electrodes and a polymeric material adjacent to the support, wherein the at least two electrodes are exposed to a solution comprising the polymeric material, wherein the polymeric material retains the nucleic acid molecule during a sequencing reaction; (b) subjecting the nucleic acid molecule to the sequencing reaction to yield signals indicative of individual bases of the nucleic acid molecule; (c) during the sequencing reaction, using the at least two electrodes of the sensor to detect the signals; and (d) using the signals detected in (c) to generate a sequence of the nucleic acid molecule.

In some embodiments, the at least two electrodes comprise a chemically inert conducting material. In some embodiments, the support comprises a surface modified silicon oxide or a metal oxide. In some embodiments, the polymeric material is coupled to the surface modified silicon oxide or metal oxide. In some embodiments, the polymeric material bridges or covers the at least two electrodes.

In some embodiments, the polymeric material is a hydrogel. In some embodiments, the hydrogel comprises reactive and non-reactive co-monomers. In some embodiments, the polymeric material is a porous polymer monolith. In some embodiments, the porous polymer monolith is a homopolymer, copolymer, or terepolymer comprising reactive functional groups.

In some embodiments, the polymeric material is seeded with primers and wherein the primers are reactively coupled to the polymeric material. In some embodiments, the primers participate in an amplification reaction to form clonal colonies. In some embodiments, the primers are seeded at a concentration ranging from 1 picomolar to 4000 picomolar. In some embodiments, the amplification reaction is invader amplification, bridge amplification, wildfire amplification, recombinase polymerase amplification, or polymerase chain reaction with a confinement approach.

In some embodiments, during the sequencing reaction, the at least two electrodes are coupled to a Debye layer having of the nucleic acid molecule. In some embodiments, the incorporation of nucleotides into the nucleic acid molecule is performed within the Debye layer. In some embodiments, the signals indicative of the individual bases are electrochemical signals. In some embodiments, the signals indicative of the individual bases are impedance signals. In some embodiments, the signals indicative of the individual bases are detected during steady state conditions.

In an aspect, the present disclosure provides a system for sequencing a nucleic acid molecule, comprising: a sensor comprising a support comprising at least two electrodes and a polymeric material adjacent to the support, wherein during use the at least two electrodes are exposed to a solution comprising the polymeric material, wherein the polymeric material retains the nucleic acid molecule during a sequencing reaction, which sequencing reaction yields signals indicative of individual bases of the nucleic acid molecule; and one or more computer processors operatively coupled to the sensor, wherein the one or more computer processors are programmed to (i) subject the nucleic acid molecule to the sequencing reaction to yield the signals indicative of the individual bases of the nucleic acid molecule; (ii) during the sequencing reaction, use the at least two electrodes of the sensor to detect the signals; and (iii) use the signals detected in (ii) to generate a sequence of the nucleic acid molecule.

In some embodiments, the at least two electrodes comprise a chemically inert conducting material. In some embodiments, the support comprises a surface modified silicon oxide or a metal oxide. In some embodiments, the polymeric material is coupled to the surface modified silicon oxide or metal oxide. In some embodiments, the polymeric material bridges or covers the at least two electrodes.

In some embodiments, the polymeric material is a hydrogel. In some embodiments, the hydrogel comprises reactive and non-reactive co-monomers. In some embodiments, the polymeric material is a porous polymer monolith. In some embodiments, the porous polymer monolith is a homopolymer, copolymer, or terepolymer comprising reactive functional groups.

In some embodiments, the polymeric material is seeded with primers and the primers are reactively coupled to the polymeric material. In some embodiments, the primers participate in an amplification reaction to form clonal colonies. In some embodiments, the primers are seeded at a concentration ranging from about 1 picomolar to about 4000 picomolar. In some embodiments, the amplification reaction is invader amplification, bridge amplification, wildfire amplification, recombinase polymerase amplification, or polymerase chain reaction with a confinement approach.

In some embodiments, during the sequencing reaction, the at least two electrodes are coupled to a Debye layer of the nucleic acid molecule. In some embodiments, the incorporation of nucleotides into the nucleic acid molecule is performed within the Debye layer. In some embodiments, the signals indicative of the individual bases are electrochemical signals. In some embodiments, the signals indicative of the individual bases are impedance signals. In some embodiments, the signals indicative of the individual bases are detected during steady state conditions.

In an aspect, the present disclosure provides methods for sequencing a nucleic acid molecule, the method comprising: (a) tethering a template nucleic acid molecule to a sensor or a surface in proximity to the sensor; (b) creating an elongation complex tethered to the sensor or the surface in proximity to the sensor, wherein the elongation complex comprises (i) a nucleic acid polymerase associated with the template nucleic acid molecule and (ii) an oligonucleotide hybridized to the template nucleic acid molecule; (c) contacting the elongation complex with a solution comprising nucleotides under conditions sufficient to associate a nucleotide complimentary to the template nucleic acid molecule with the elongation complex, wherein a given nucleotide of the nucleotides is coupled to a redox mediator moiety; (d) using the sensor to detect a signal indicative of the redox mediator moiety when the nucleotide is associated with the elongation complex; (e) incorporating the nucleotide into the oligonucleotide to subject the redox mediator moiety to release from the nucleotide; and (f) repeating (c)-(e), thereby sequencing the template nucleic acid molecule.

In some embodiments, a plurality of clonal template nucleic acid molecules is tethered to the sensor or the surface in proximity to the sensor. In some embodiments, the plurality of clonal template nucleic acid molecules is generated with the aid of polymerase walking. In some embodiments, the elongation complex is tethered to the sensor or the surface in proximity to the sensor via the polymerase. In some embodiments, in each iteration of (c), the solution comprises only one of the nucleotides adenine (A), cytosine (C), guanine (G), uracil (U) or thymine (T), or a variant thereof, and each iteration of (c) contacts the elongation complex with a different nucleotide.

In some embodiments, the redox mediator moiety comprises an organic compound, an organometallic compound, a nanoparticle, or a metal. In some embodiments, a plurality of redox mediator moieties are bound to the nucleotide. In some embodiments, the elongation complex is tethered to the sensor or the surface in proximity to the sensor via a binding pair. In some embodiments, the binding pair is a biotin-streptavidin binding pair. In some embodiments, the redox mediator moiety is attached to a phosphate of the nucleotide. In some embodiments, the nucleotide is associated with the elongation complex for a time period between about 10 and about 500 milliseconds (ms). In some embodiments, the sensor is among a plurality of sensors and wherein a given one of the plurality of sensors is individually addressable.

Additional aspects and advantages of the present disclosure will become readily apparent to those skilled in this art from the following detailed description, wherein only illustrative embodiments of the present disclosure are shown and described. As will be realized, the present disclosure is capable of other and different embodiments, and its several details are capable of modifications in various obvious respects, all without departing from the disclosure. Accordingly, the drawings and description are to be regarded as illustrative in nature, and not as restrictive.

INCORPORATION BY REFERENCE

All publications, patents, and patent applications mentioned in this specification are herein incorporated by reference to the same extent as if each individual publication, patent, or patent application was specifically and individually indicated to be incorporated by reference.

BRIEF DESCRIPTION OF THE DRAWINGS

The novel features of the invention are set forth with particularity in the appended claims. A better understanding of the features and advantages of the present invention will be obtained by reference to the following detailed description that sets forth illustrative embodiments, in which the principles of the invention are utilized, and the accompanying drawings (also "figure" and "FIG." herein), of which:

FIG. 1 schematically depicts an example integrated sequencing platform;

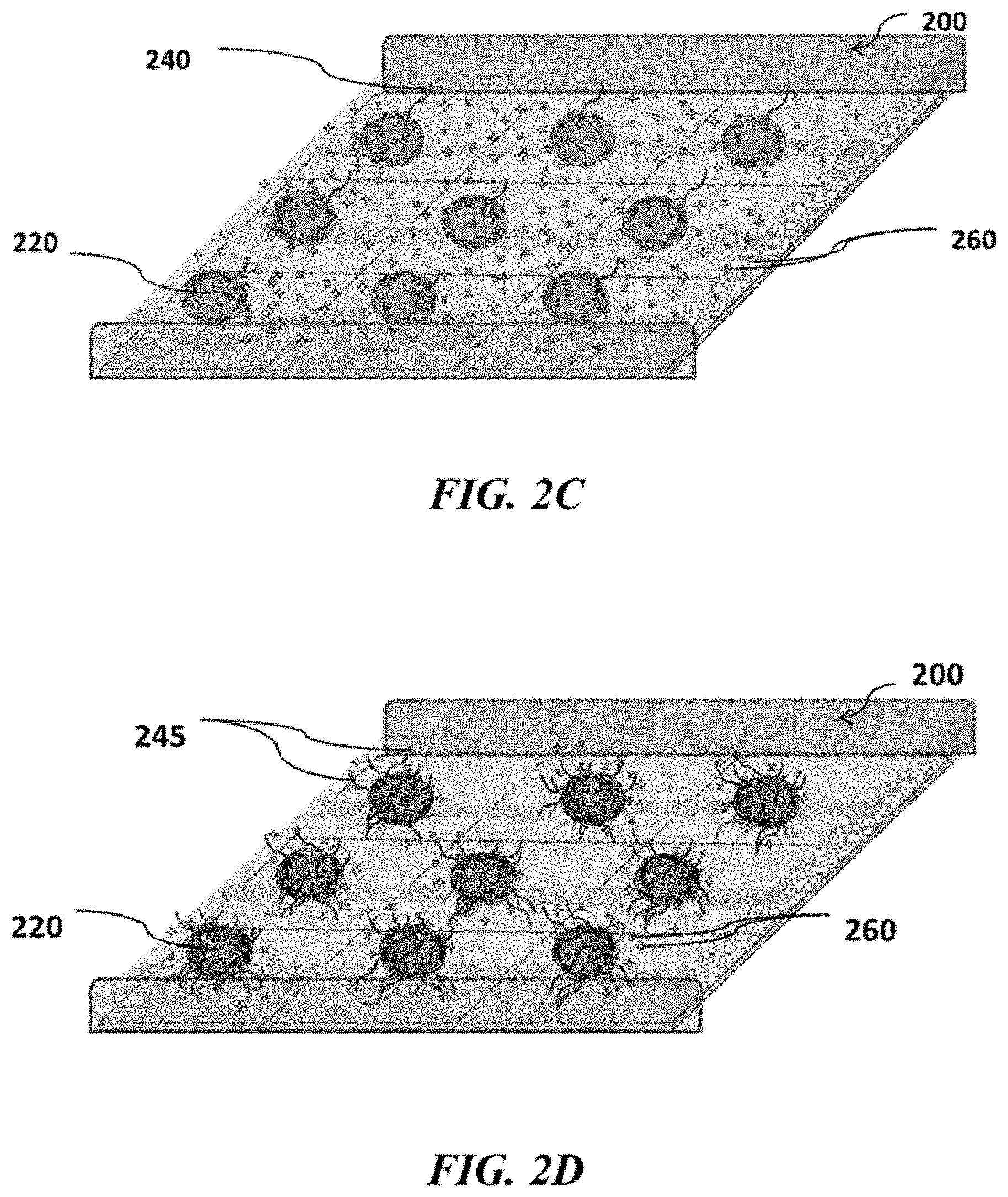

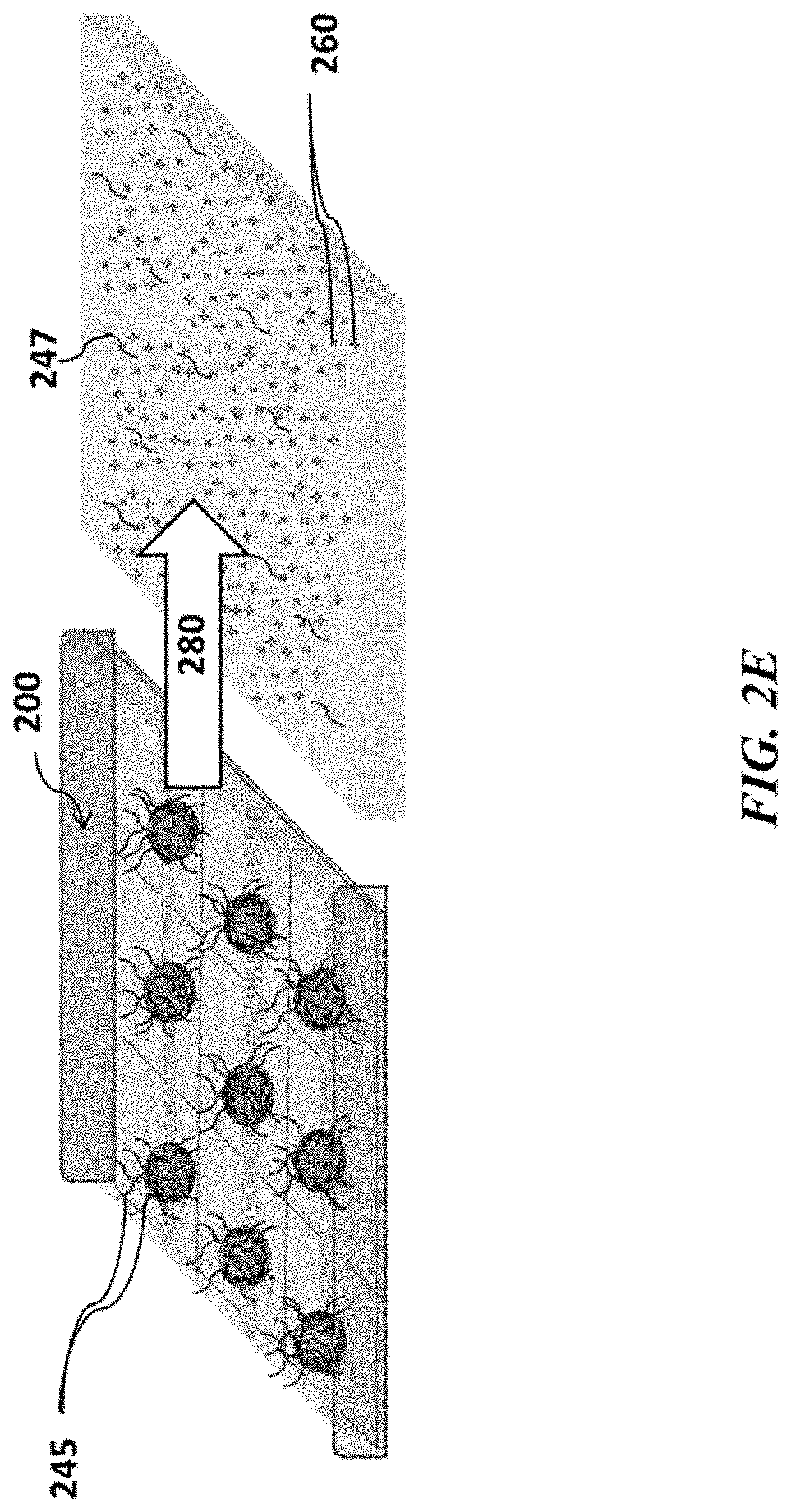

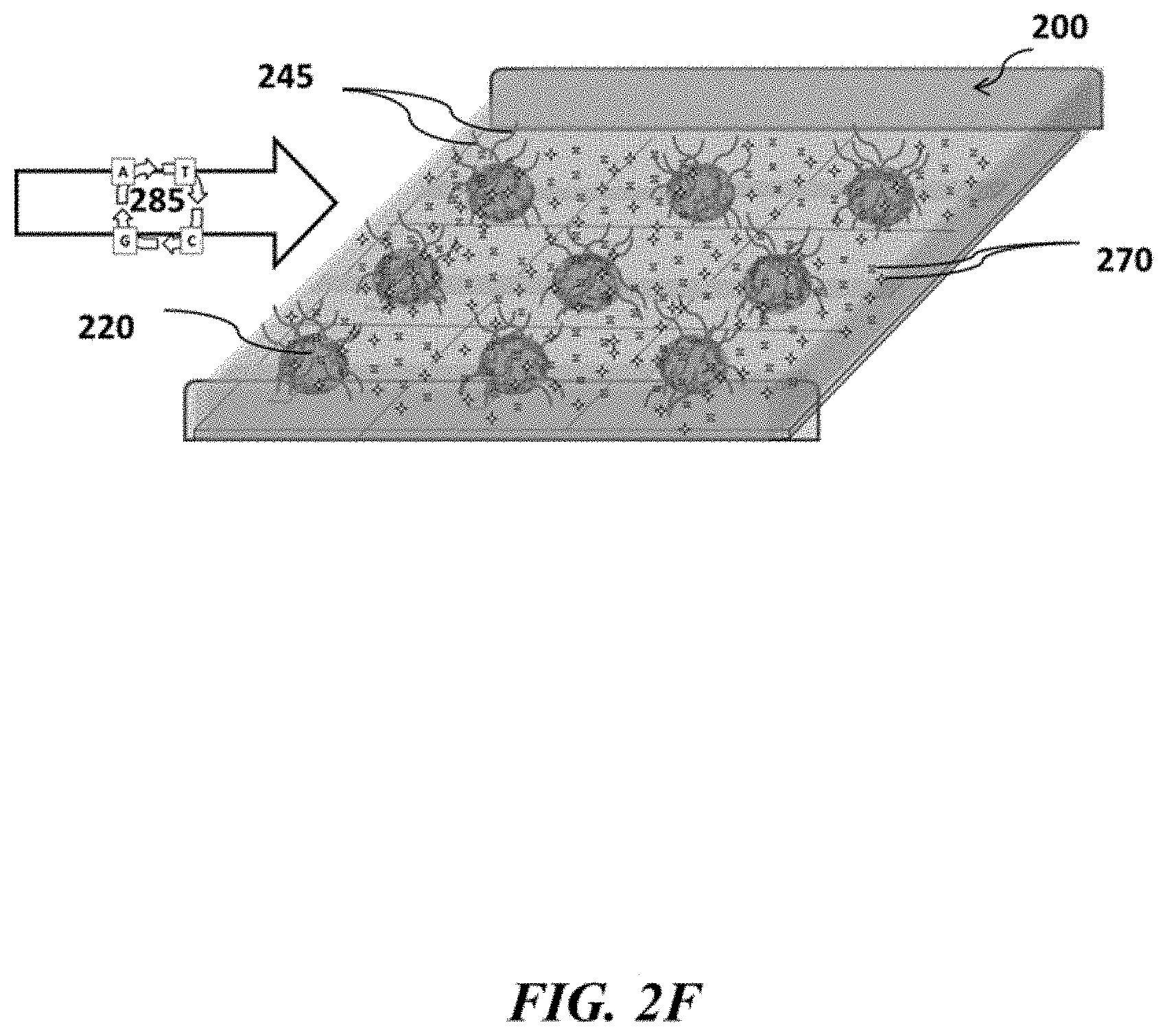

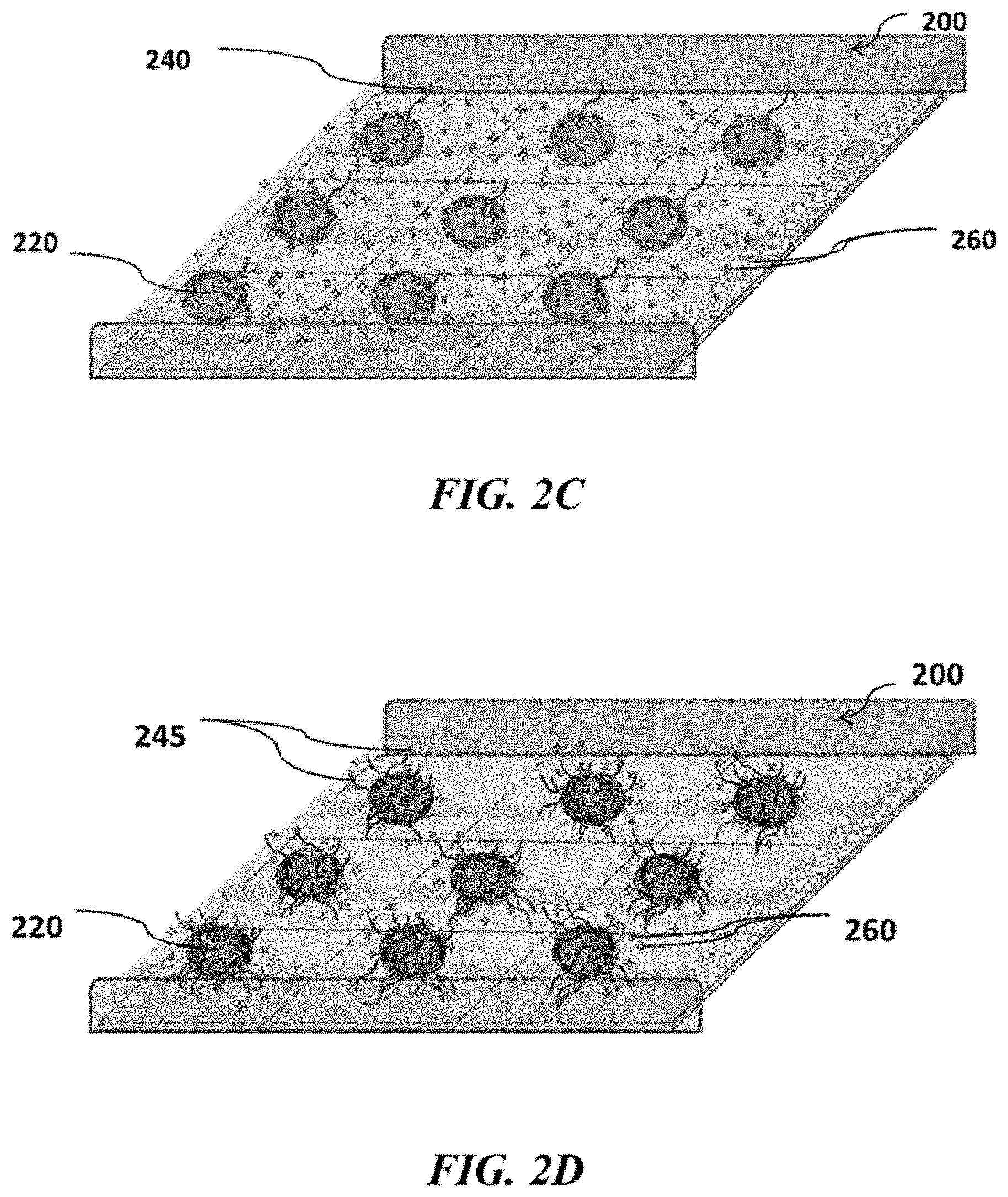

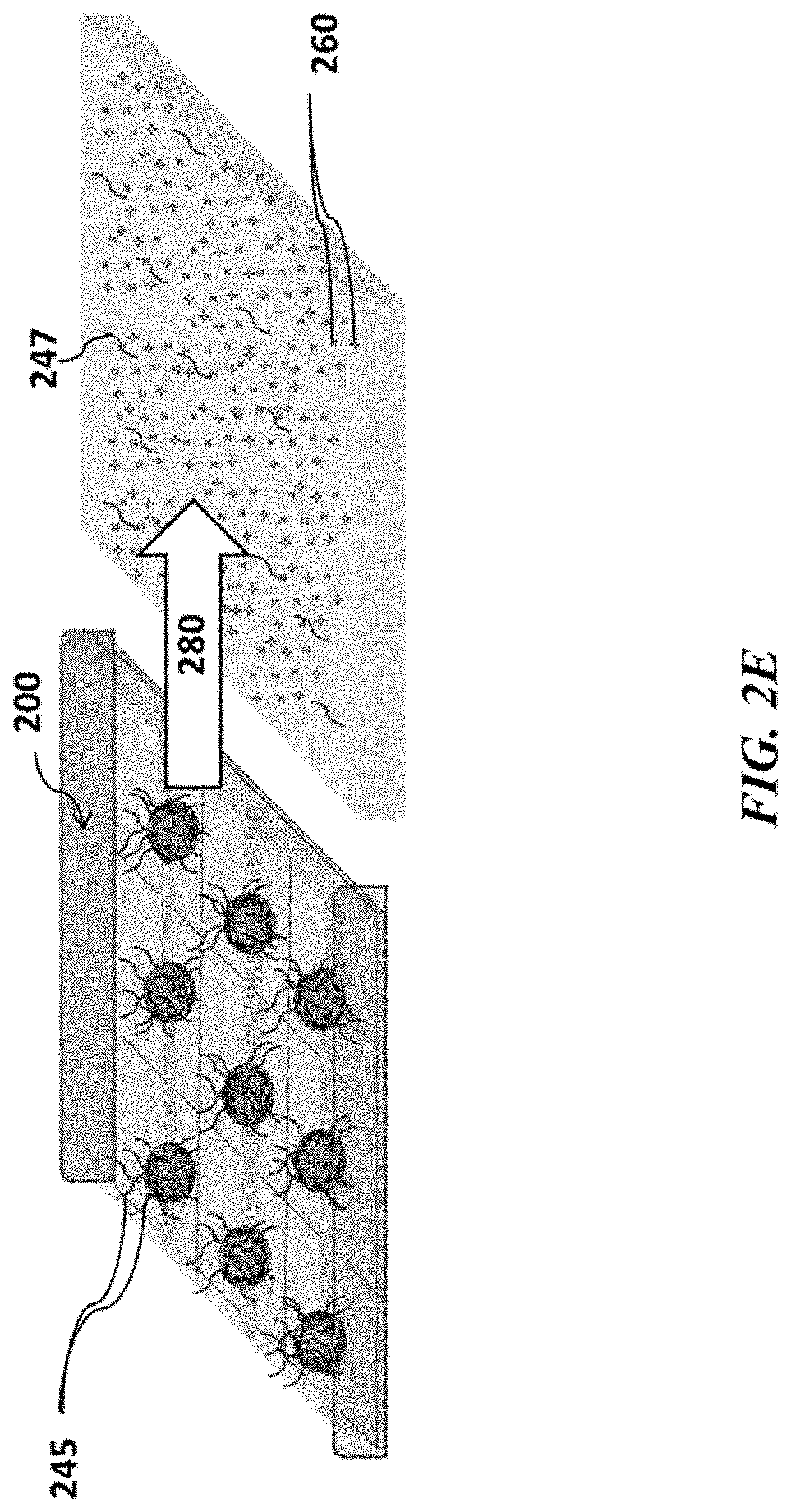

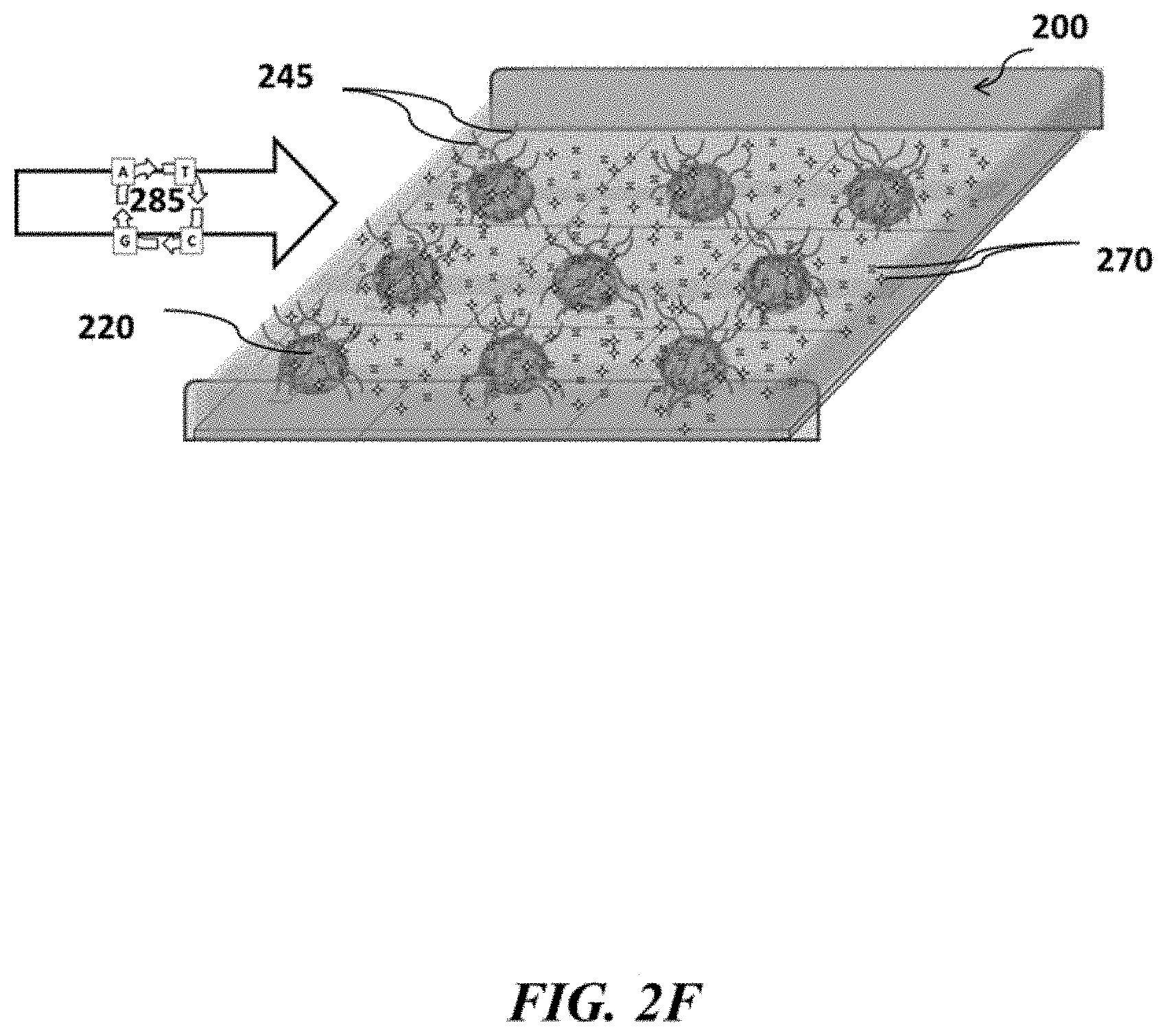

FIGS. 2A-2F show example sensor arrays and sensor use; FIG. 2A shows a schematic of an example sensor array; FIG. 2B shows a schematic of an example sensor array with beads carrying nucleic acids, which beads are immobilized to the sensor array; FIG. 2C shows a schematic of an example sensor array with beads carrying nucleic acids and immobilized to the sensor array in contact with reagents suitable for nucleic acid amplification; FIG. 2D shows a schematic of an example sensor array where nucleic acid amplification occurs on beads positioned at various sensors of the sensor array; FIG. 2E shows a schematic example of removing reagents from an example sensor array; FIG. 2F shows a schematic of an example sensor array where nucleic acids are sequenced at various positions of the sensor array;

FIG. 3 shows a an example detection device;

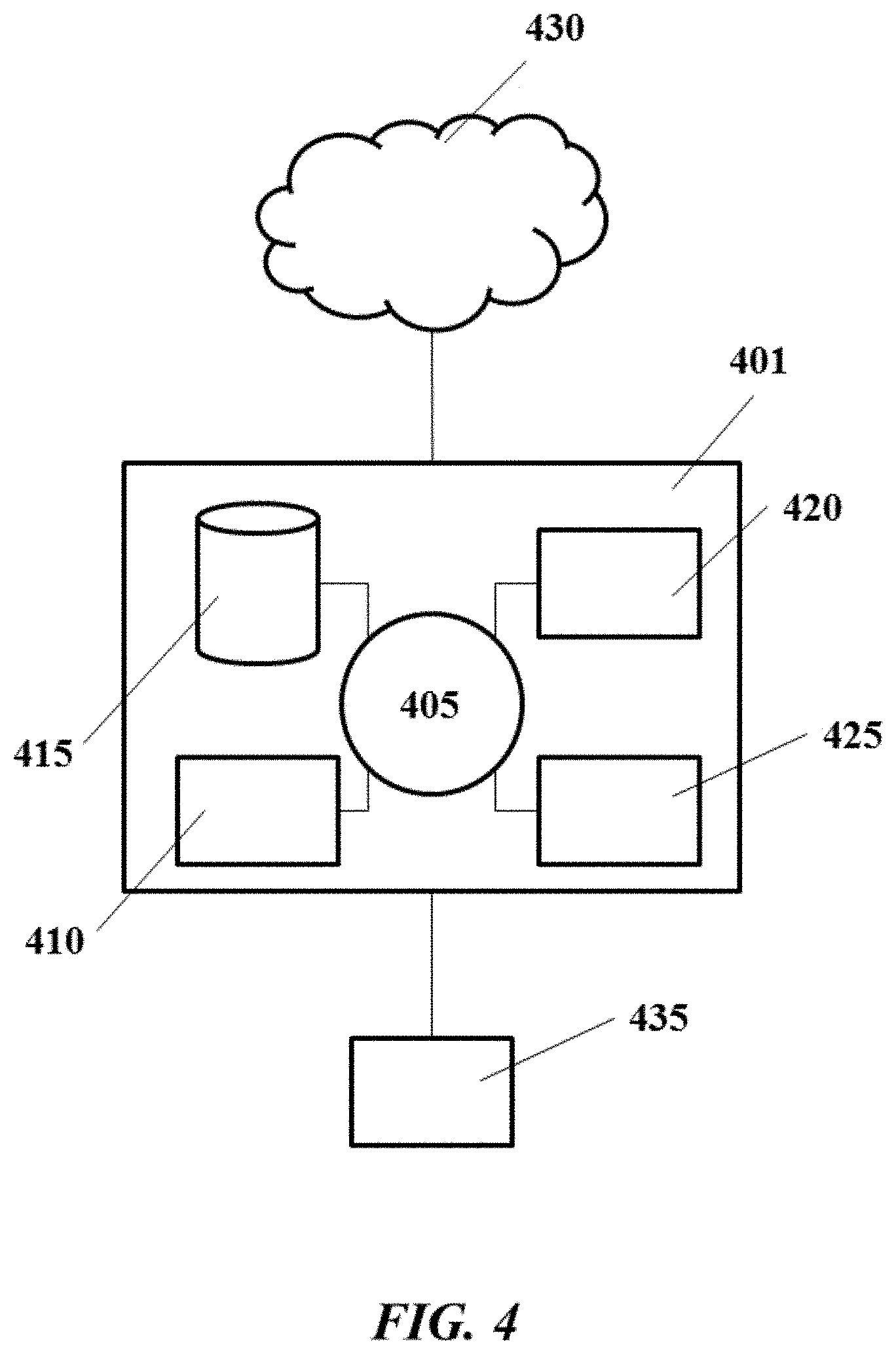

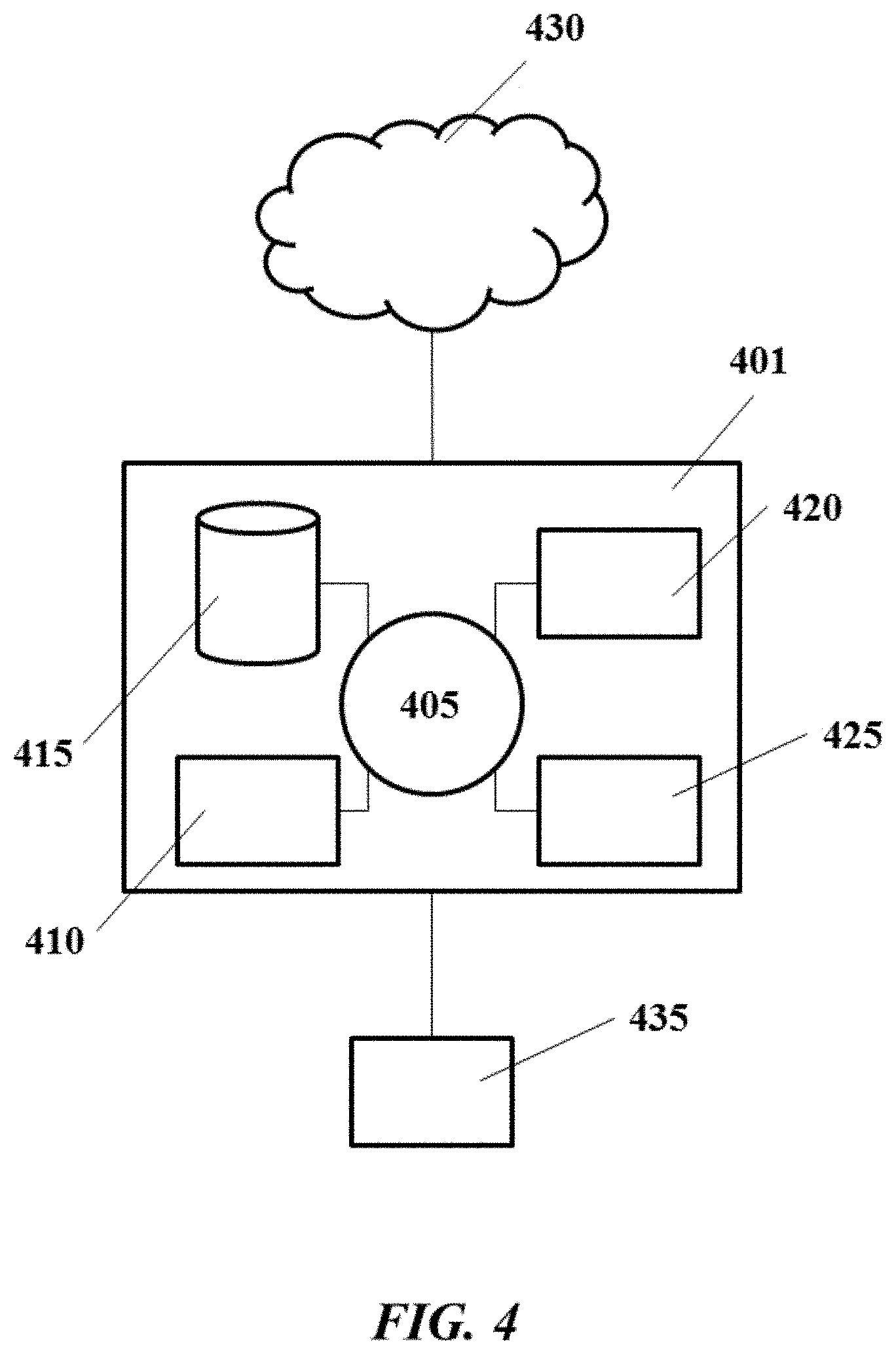

FIG. 4 shows an example computer system that is programmed or otherwise configured to control, regulate or implement devices, systems and methods described herein;

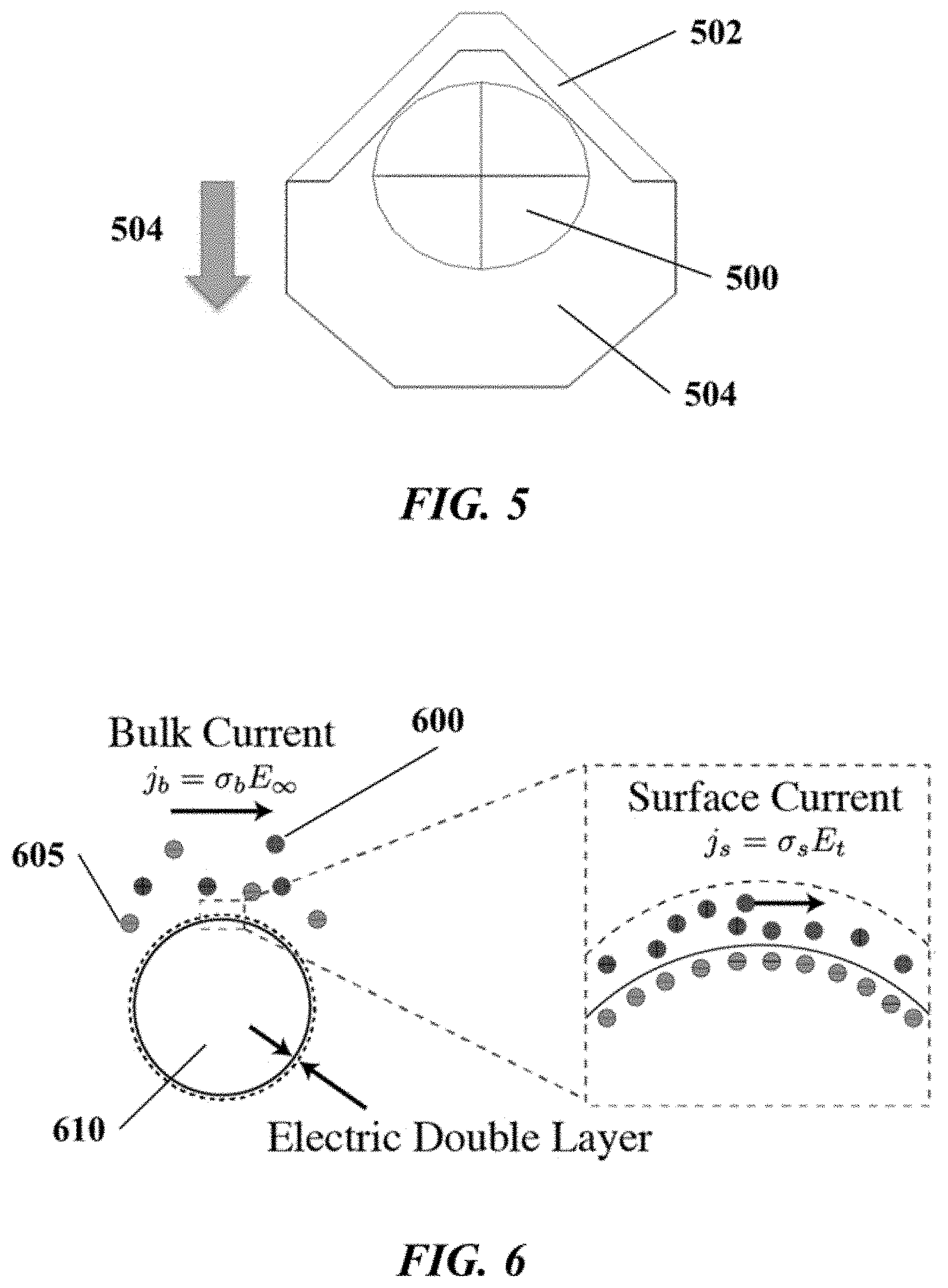

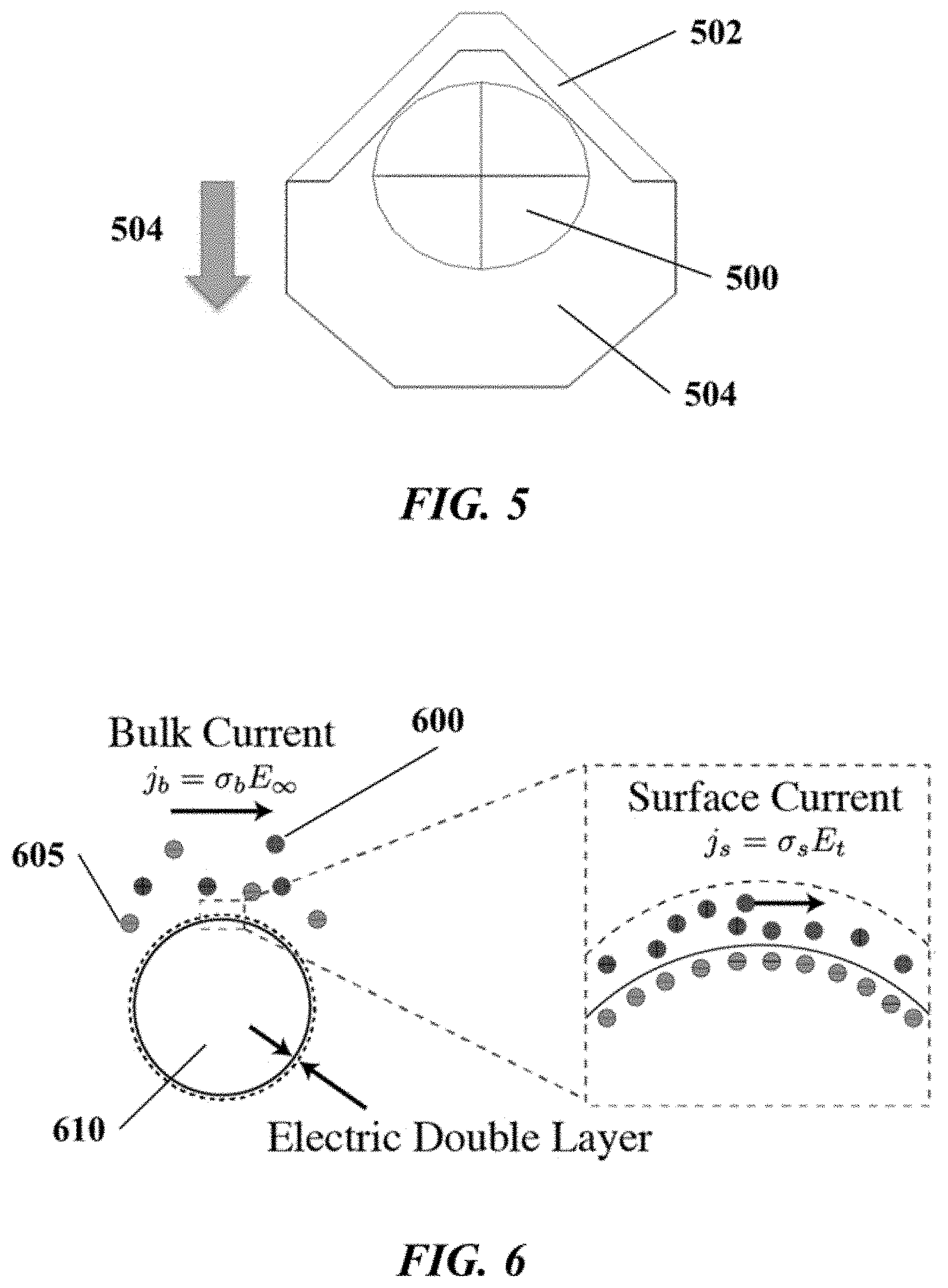

FIG. 5 schematically depicts an example bead-sensor structural configuration;

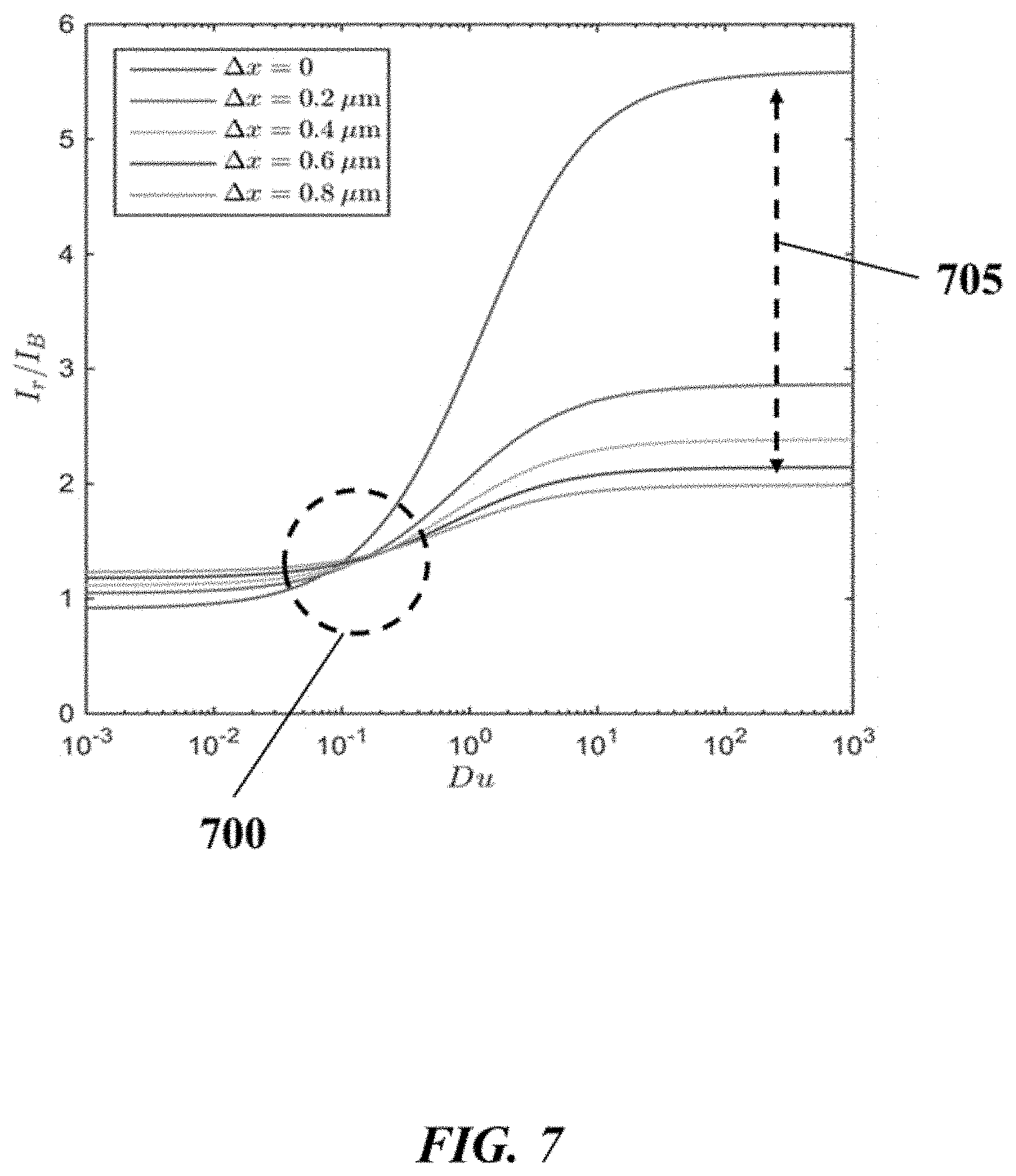

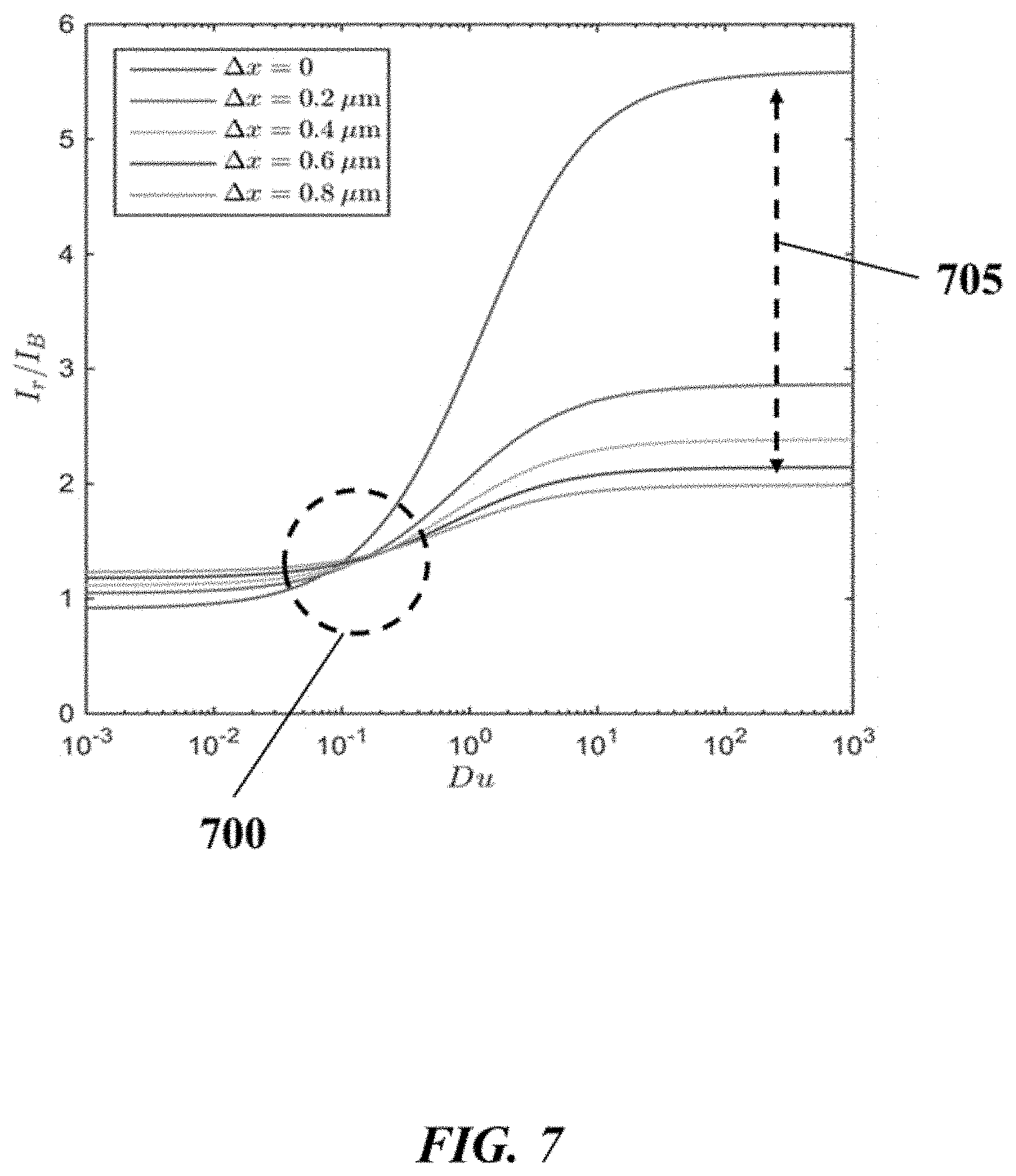

FIG. 6 schematically depicts an example of conductivity at a bead surface and in a bulk fluid adjacent to the bead surface;

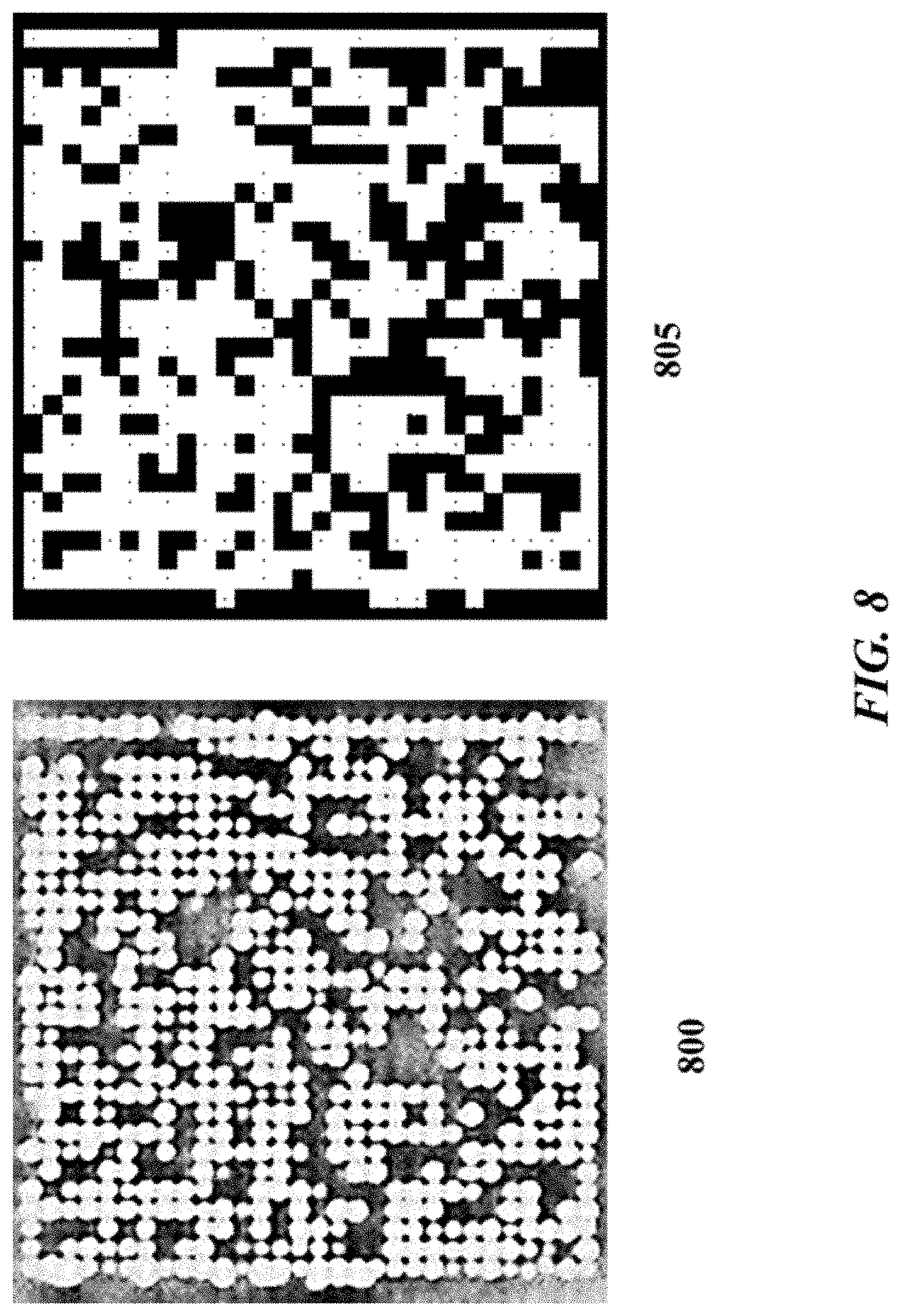

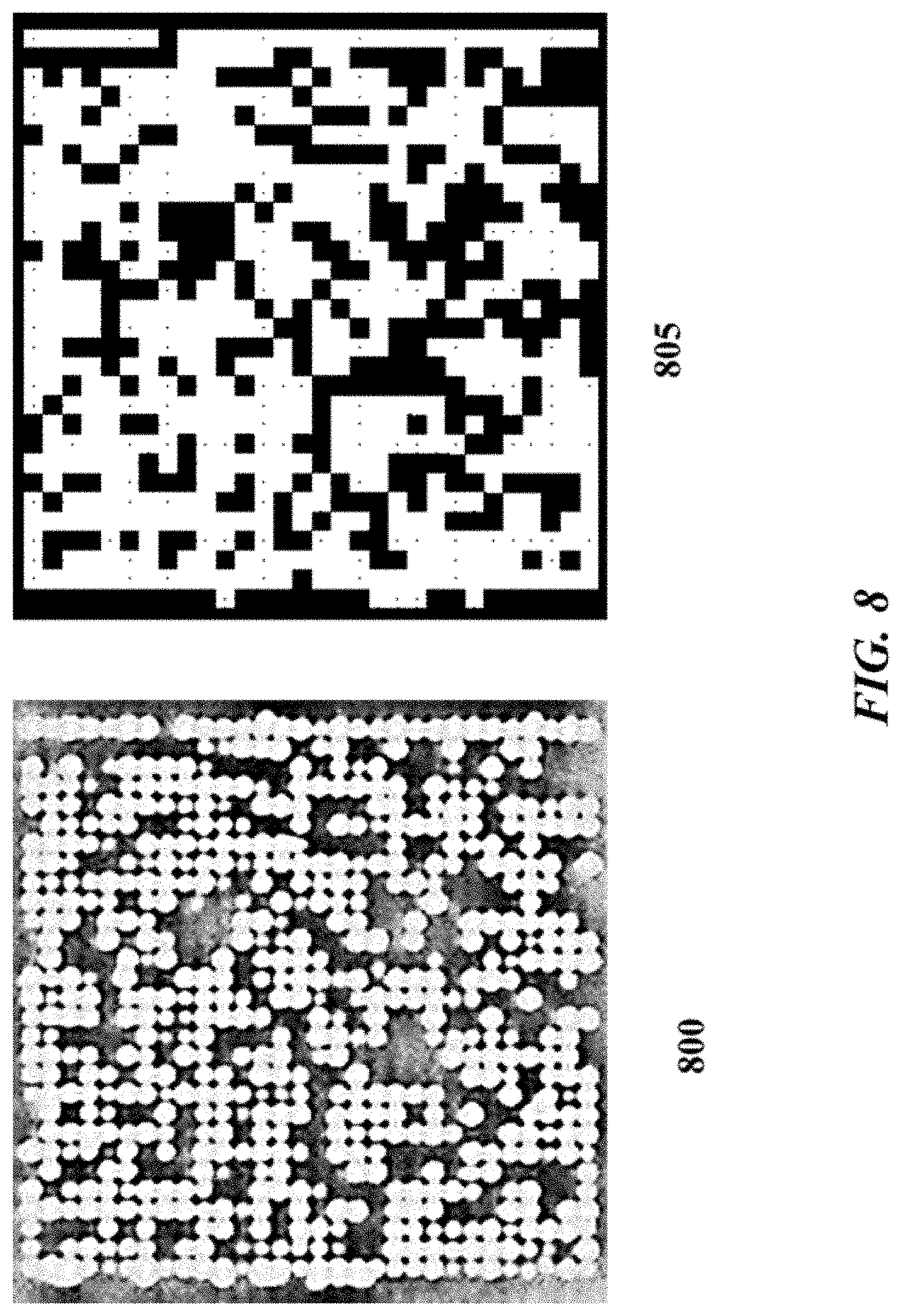

FIG. 7 graphically depicts an example of the effect of buffer concentration on the sensitivity of observed current to movement of a bead associated with a sensor;

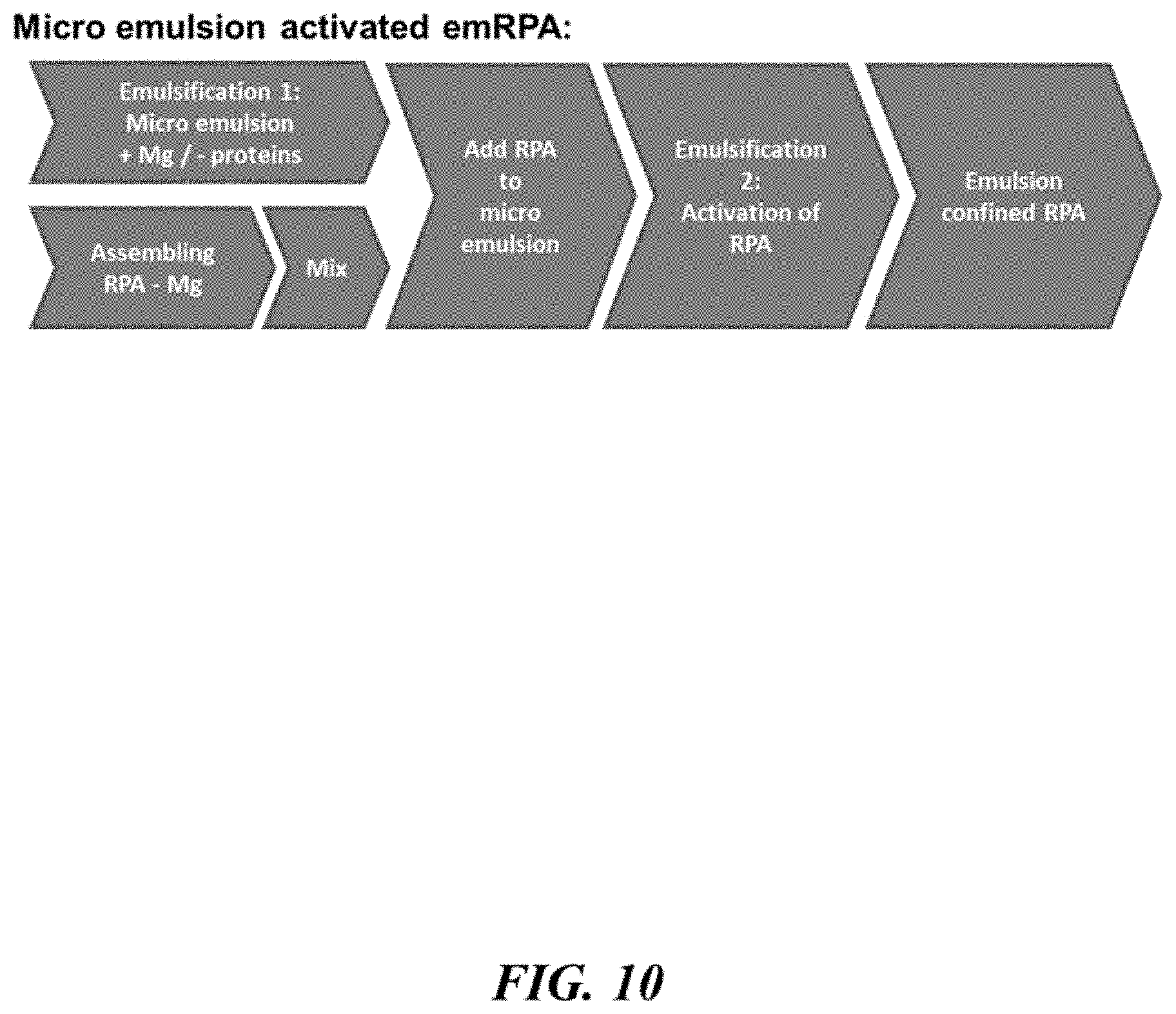

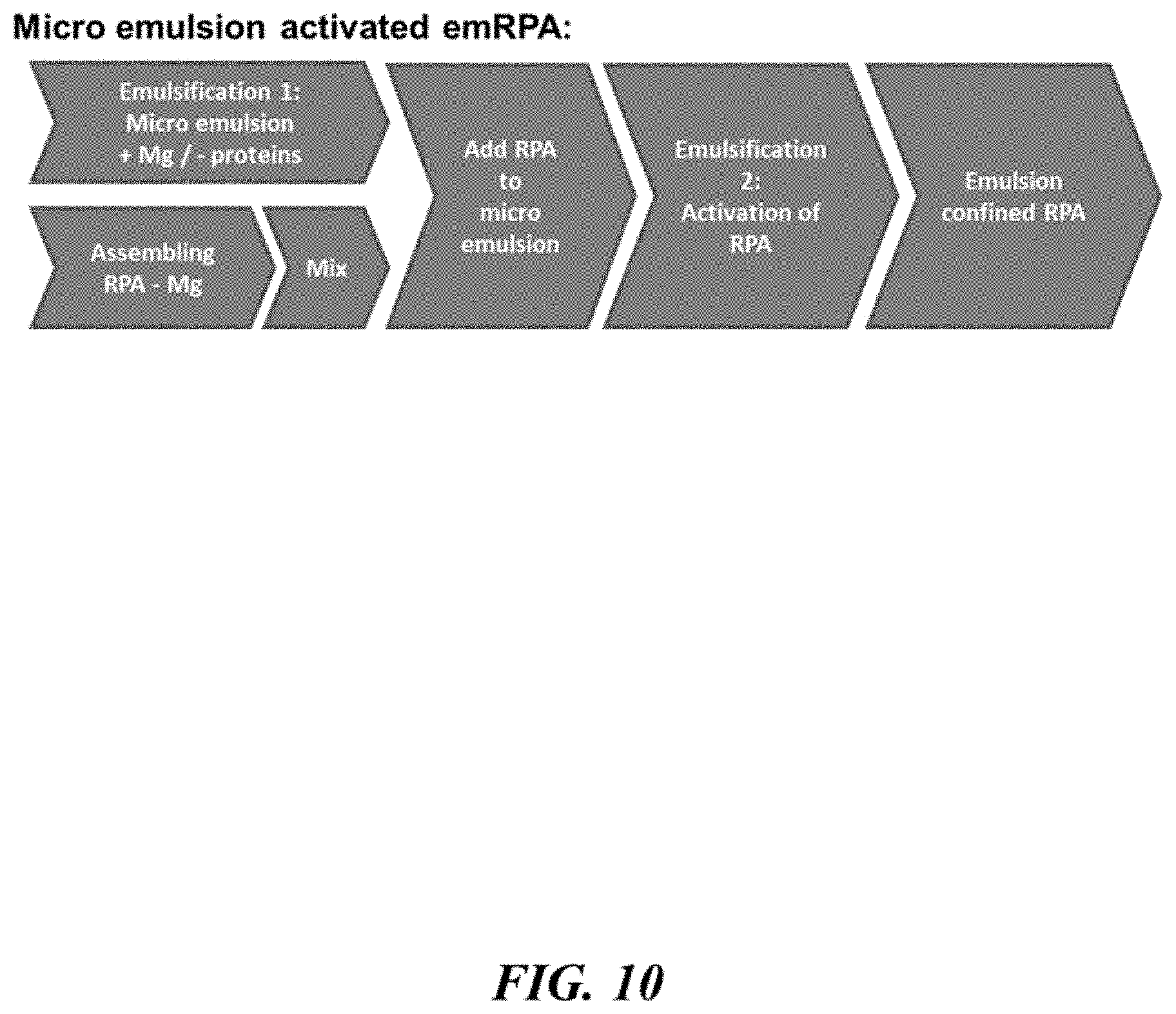

FIG. 8 graphically depicts an example of bead occupancy on an example sensor array;

FIG. 9 graphically depicts example data relating to bead occupancy on example sensor arrays;

FIG. 10 schematically illustrates a method for processing a nucleic acid sample;

FIGS. 11A-11F schematically illustrate obstacle based emulsification and arrays thereof.

FIG. 11A shows droplets flowing towards an obstacle; FIG. 11B shows droplet distorting around the object due to shear forces; FIG. 11C shows a droplet splitting around the obstacle; FIG. 11D shows obstacles may have an arbitrary shape; FIG. 11E shows obstacles may be confined in a flow cell; and FIG. 11F shows and array of obstacles;

FIGS. 12A-12E schematically illustrate integration of an obstacle array into a microfluidic fluidic device for emulsion generation; FIG. 12A shows an obstacle array within a microfluidic channel; FIG. 12B shows a multiplexing of arrays; FIG. 12C shows an example of an on-chip amplification; FIG. 12D shows using membrane valves and pumps to move liquid; FIG. 12E shows a closed version of a membrane pump;

FIG. 13 schematically illustrates the breaking and deactivating of an emulsion in two steps;

FIGS. 14A-14D schematically illustrate obstacle based bead sorting; FIG. 14A shows unamplified beads appearing amplified; FIG. 14B shows separation of amplified beads from unamplified beads by use of obstacles; FIG. 14C shows a different implementation of the separation approach; FIG. 14D shows a further implementation of the separation approach;

FIG. 15 schematically illustrates integration of an enrichment module into a microfluidic fluidic device;

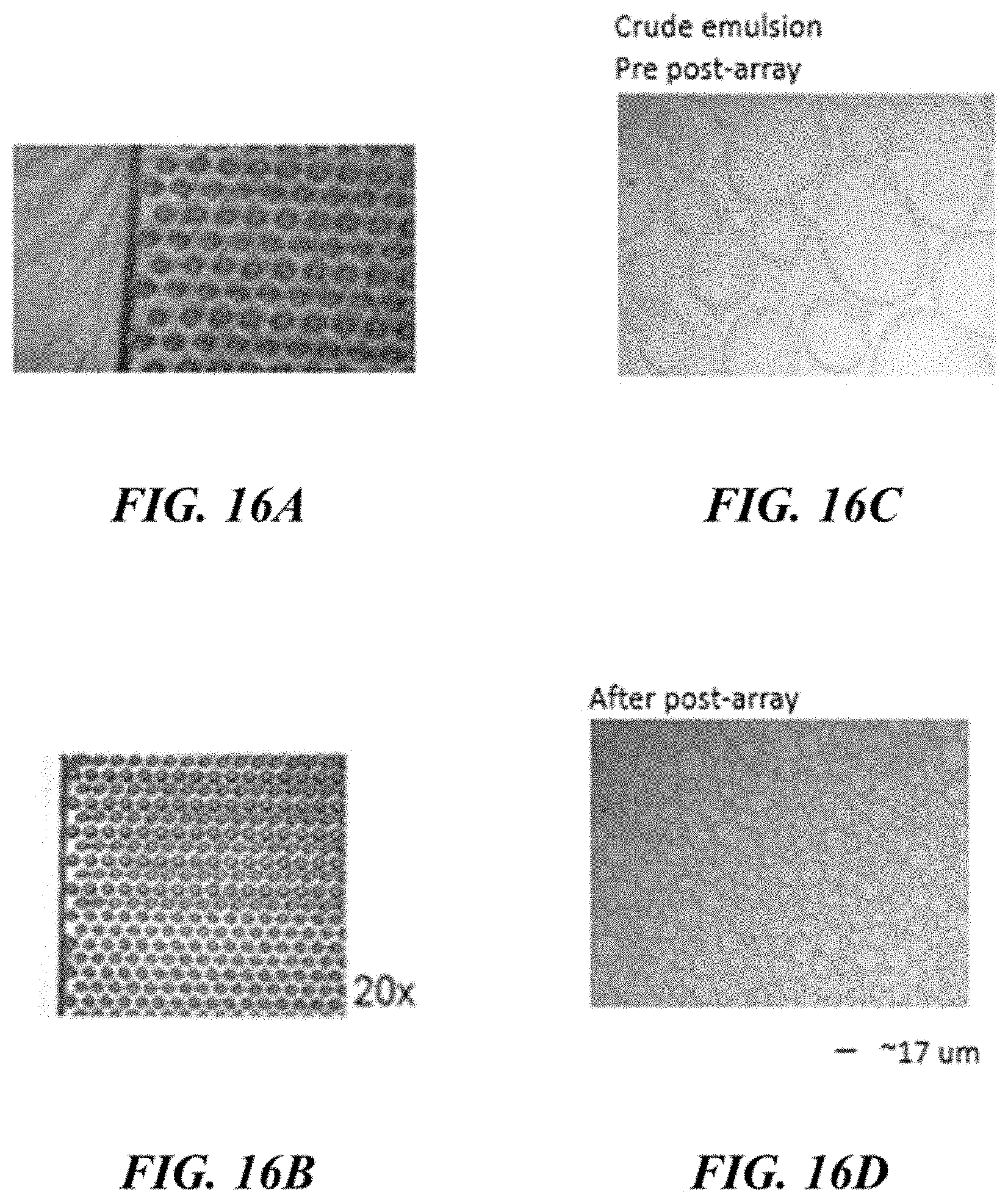

FIGS. 16A-16D schematically illustrate emulsification using obstacle arrays. FIG. 16A shows an obstacle array; FIG. 16B shows another obstacle array; FIG. 16C shows a crude emulsion prior to the fluid being directed through an obstacle array; FIG. 16D shows an emulsion after the fluid is directed through an array;

FIG. 17 schematically illustrates systems for bead and bead free nucleic acid sequencing;

FIG. 18 schematically illustrates thermodynamic movement of linear polymer chains in solution;

FIG. 19 schematically illustrates an entangled polymer network coupled to a solid support and primers;

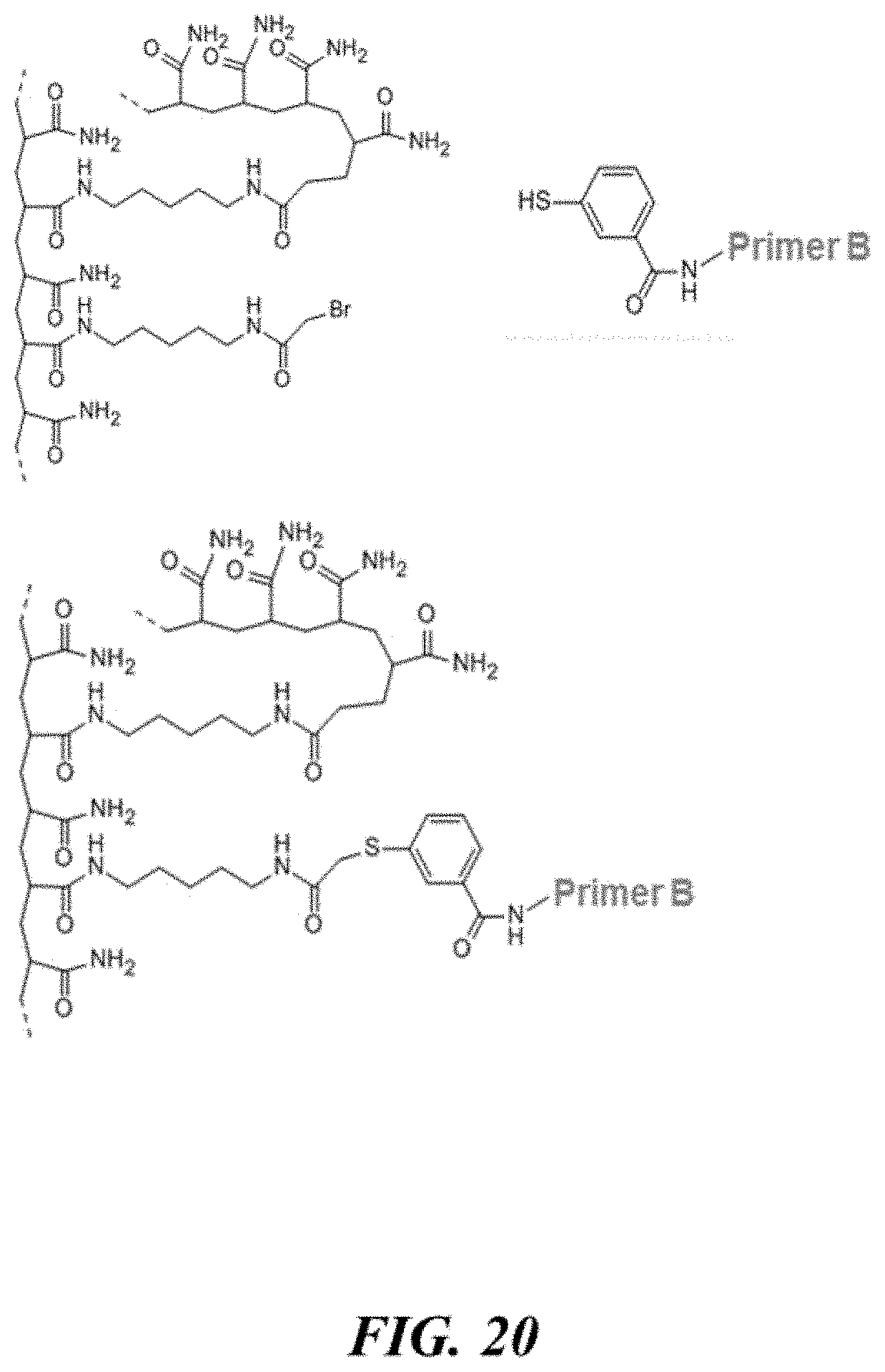

FIG. 20 schematically illustrates a reaction between a benzthiolated primer and Bromoacetamidepentylacrylamide (BRAPA);

FIGS. 21A-21D schematically illustrate preparation of a porous polymer monolith (PPM) thin film; FIG. 21A shows a support surface to be modified; FIG. 21B shows the surface modification with a polymerizable silane group; FIG. 21C shows the system before polymerization; FIG. 21D shows the system after polymerization;

FIG. 22 schematically illustrates a polymerization chemistry for PPM thin film preparation;

FIG. 23 schematically illustrates a hybridization-dehybridization (Hyb-DeHyb) assay performed with a primer conjugated to the PPM thin film;

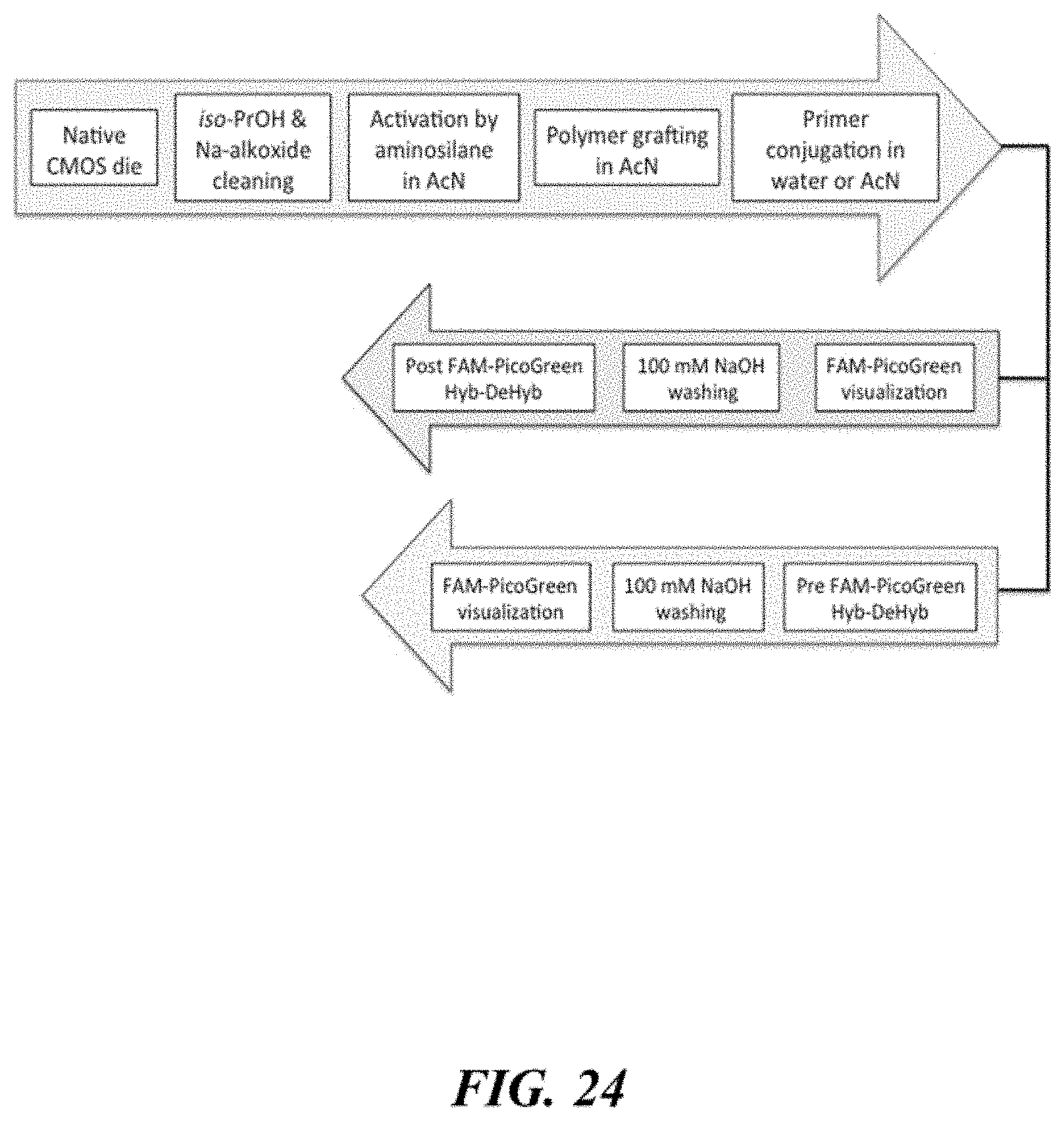

FIG. 24 schematically illustrates procedure for preparing primer conjugated polymer coated supports and visualization of primer density;

FIG. 25 schematically illustrates primer density of primer conjugated supports both with and without silane activation;

FIGS. 26A-26C schematically illustrate immobilized primer arrangements with regard to the polymer coated support and method of building confinement into the amplification reaction; FIG. 26A schematically illustrates immobilization of primers to the polymer coated support; FIG. 26B schematically illustrates a surface confined amplification method; FIG. 26C shows template density after amplification as a function of starting template concentration;

FIG. 27 shows visualization of the primer density before and after an amplification reaction;

FIG. 28 shows electronic detection of primer extension and nucleic acid incorporation for templates amplified on a support surface;

FIG. 29 shows capillary electrophoresis readout of extension of FAM-labeled primers during a sequencing experiment;

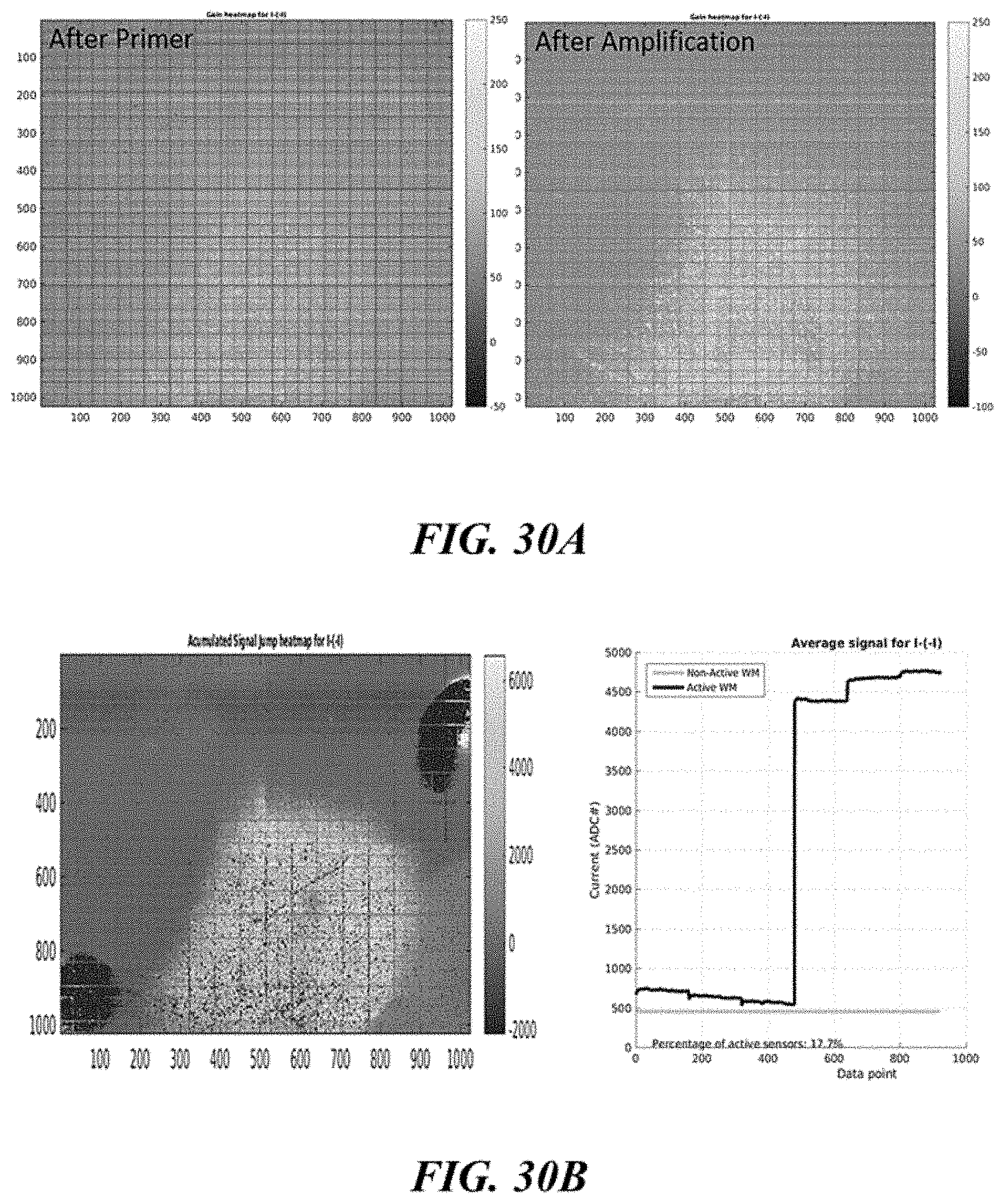

FIGS. 30A and 30B show visualization of primer density and electronic detection of nucleic acid incorporation on a support surface; FIG. 30A shows visualization of primer density before and after a amplification reaction; FIG. 30B shows visualization of accumulated nucleic acid incorporation and electronic detection of nucleic acid incorporation;

FIGS. 31A and 31B show the density of primers conjugated to polymer coated supports before and after rinsing with an alkaline solution; FIG. 31A shows primer density before rinsing with an alkaline solution; FIG. 31B shows primer density after rinsing with an alkaline solution;

FIG. 32 shows a thin-layer cell used for conjugation of primers to a PPM thin film;

FIG. 33 shows detection of primer oligos surface conjugated to the PPM thin film;

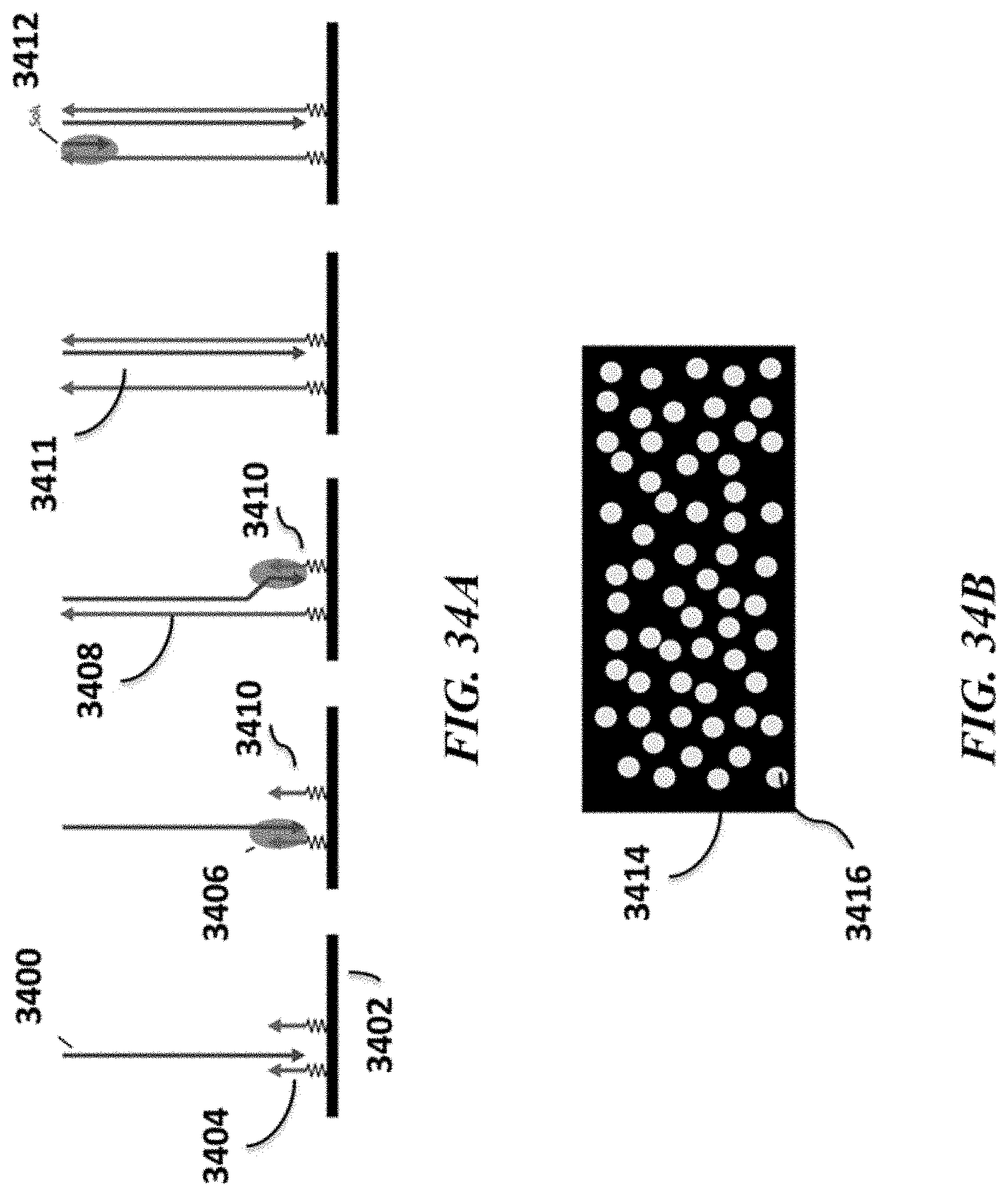

FIGS. 34A and 34B show an example clonal amplification method; FIG. 34A schematically depicts an example method for producing clonal colonies of nucleic acid molecules; FIG. 34B schematically depicts an example surface on which colonies of nucleic acids are present; and

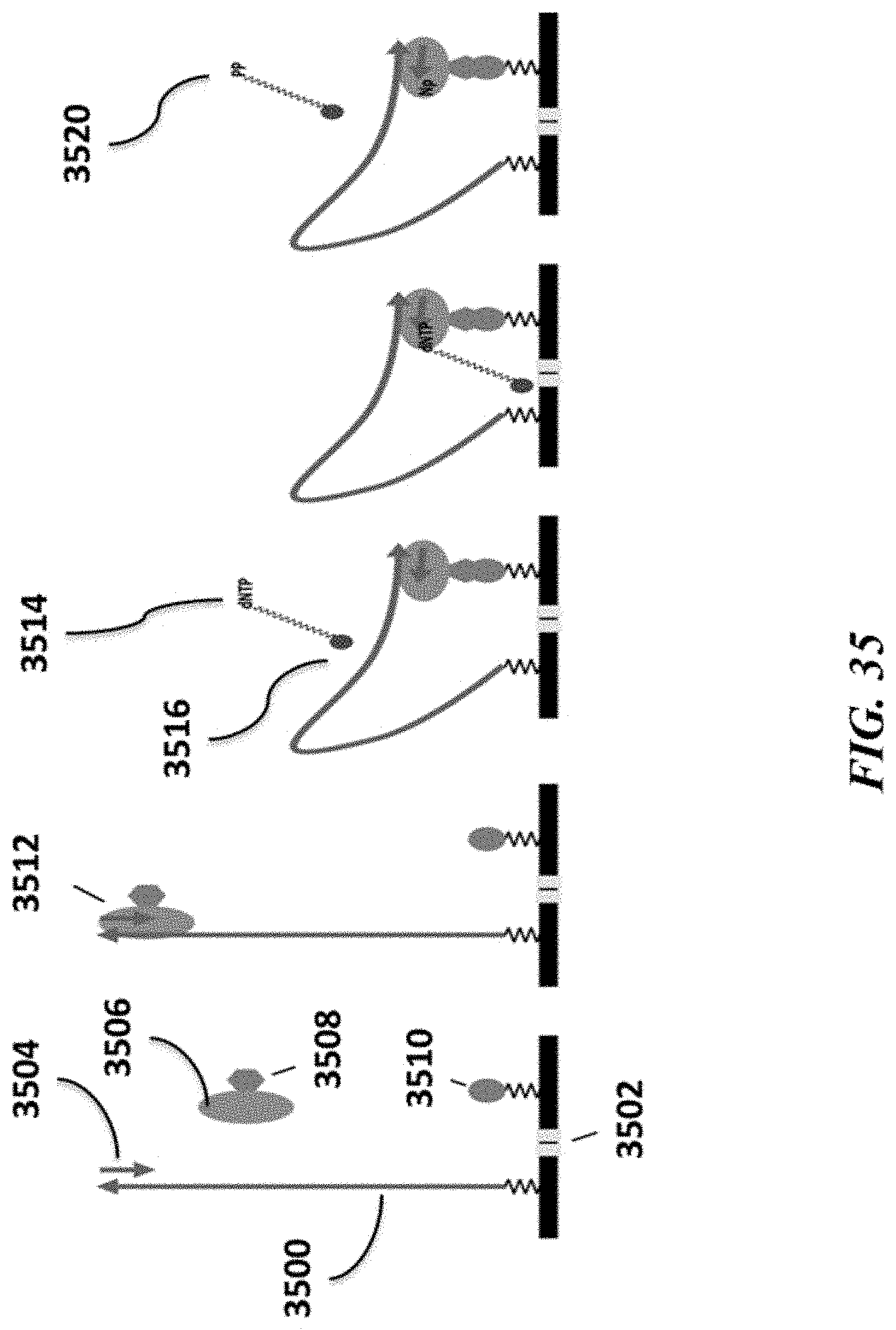

FIG. 35 schematically depicts an example method for sequencing a nucleic acid molecule using redox mediators.

DETAILED DESCRIPTION

While various embodiments of the invention have been shown and described herein, it will be obvious to those skilled in the art that such embodiments are provided by way of example only. Numerous variations, changes, and substitutions may occur to those skilled in the art without departing from the invention. It should be understood that various alternatives to the embodiments of the invention described herein may be employed.

The term "adjacent to," as used herein, generally refers to next to, in proximity to, or in sensing or electronic vicinity (or proximity) of. For example, a first object adjacent to a second object can be in contact with the second object, or may not be in contact with the second object but may be in proximity to the second object. An object adjacent to another object may have one or more intervening objects (e.g., layers). In some examples, a first object adjacent to a second object is within about 0 micrometers (.mu.m), 0.001 .mu.m, 0.01 .mu.m, 0.1 .mu.m, 0.2 .mu.m, 0.3 .mu.m, 0.4 .mu.m, 0.5 .mu.m, 1 .mu.m, 2 .mu.m, 3 .mu.m, 4 .mu.m, 5 .mu.m, 10 .mu.m, or 100 .mu.m of the second object.

As used herein, the terms "amplifying", "amplification" and "nucleic acid amplification" are used interchangeably and generally refer to generating one or more copies or "amplified product" or "amplicons" of a nucleic acid. Amplification of a nucleic acid may be linear, exponential, or a combination thereof. Non-limiting examples of nucleic acid amplification methods include reverse transcription, primer extension, polymerase chain reaction, ligase chain reaction, helicase-dependent amplification, asymmetric amplification, rolling circle amplification, recombinase polymerase amplification (RPA), and multiple displacement amplification (MDA). In some embodiments, the amplified product may be DNA. In cases where a target RNA is amplified, DNA can be obtained by reverse transcription of the RNA and subsequent amplification of the DNA can be used to generate an amplified DNA product. In cases where DNA is amplified, DNA amplification may be employed. Non-limiting examples of DNA amplification methods include polymerase chain reaction (PCR), variants of PCR (e.g., real-time PCR, allele-specific PCR, assembly PCR, asymmetric PCR, digital PCR, emulsion PCR, dial-out PCR, helicase-dependent PCR, nested PCR, hot start PCR, inverse PCR, methylation-specific PCR, miniprimer PCR, multiplex PCR, nested PCR, overlap-extension PCR, thermal asymmetric interlaced PCR, touchdown PCR), and ligase chain reaction (LCR). In some cases, nucleic acid amplification is dependent upon thermal cycling conditions. In other cases, nucleic acid amplification is isothermal.

The term "bead," as used herein, generally refers to any type of particle suitable for association with a nucleic acid or other biological molecule. A bead may have a regular shape, including spherical and non-spherical shapes and 1:1 aspect ratio and non 1:1 aspect ratios. In some cases, a bead has a regular shape (e.g., a spherical bead) or may have an irregular shape (e.g., a globular-bead comprising multiple domains of magnetic material). A bead may comprise any type of suitable material(s) with non-limiting examples that include metals, ceramics, magnetic materials, a polymer(s) and combinations thereof. In some cases, a bead is magnetic and, with a magnetic force applied to the bead, can be manipulated/immobilized. Non-limiting examples of beads include nanobeads (e.g., nanorods, nanospheres, nanoshells, nanotubes, nucleic acid nanoballs, etc.), microbeads (e.g., microspheres, microbeads, etc.), quantum dots, cells, polymeric scaffolds and combinations thereof.

The terms "nucleic acid," "nucleic acid molecule," "nucleic acid fragment," "oligonucleotide" or "polynucleotide," are used herein interchangeably, and generally refer to a molecule comprising one or more nucleic acid subunits, or nucleotides. A nucleic acid may include one or more nucleotides selected from adenosine (A), cytosine (C), guanine (G), thymine (T) and uracil (U), or variants thereof. A nucleotide generally includes a nucleoside and at least 1, 2, 3, 4, 5, 6, 7, 8, 9, 10, or more phosphate (PO.sub.3) groups. A nucleotide can include a nucleobase, a five-carbon sugar (either ribose or deoxyribose), and one or more phosphate groups. Ribonucleotides are nucleotides in which the sugar is ribose. Deoxyribonucleotides are nucleotides in which the sugar is deoxyribose. A nucleotide can be a nucleoside monophosphate or a nucleoside polyphosphate. A nucleotide can be a deoxyribonucleoside polyphosphate, such as, e.g., a deoxyribonucleoside triphosphate (dNTP), which can be selected from deoxyadenosine triphosphate (dATP), deoxycytidine triphosphate (dCTP), deoxyguanosine triphosphate (dGTP), uridine triphosphate (dUTP) and deoxythymidine triphosphate (dTTP) dNTPs, that include detectable tags, such as luminescent tags or markers (e.g., fluorophores). A nucleotide can include any subunit that can be incorporated into a growing nucleic acid strand. Such subunit can be an A, C, G, T, or U, or any other subunit that is specific to one or more complementary A, C, G, T or U, or complementary to a purine (i.e., A or G, or variant thereof) or a pyrimidine (i.e., C, T or U, or variant thereof). In some examples, a nucleic acid is deoxyribonucleic acid (DNA), ribonucleic acid (RNA), or derivatives or variants thereof. A nucleic acid may be single-stranded or double stranded. In some cases, a nucleic acid molecule is circular. Moreover, a nucleic acid can have any suitable length, such as a length of at least about 100 bases, 200 bases, 300 bases, 400 bases, 500 bases, 1 kilobase (kb), 2 kb, 3, kb, 4 kb, 5 kb, 10 kb, or 50 kb.