Woven Stretchable Fitted Sheet

Fischer; Jane

U.S. patent application number 17/071281 was filed with the patent office on 2022-04-21 for woven stretchable fitted sheet. The applicant listed for this patent is American Textile Company, Inc.. Invention is credited to Jane Fischer.

| Application Number | 20220117416 17/071281 |

| Document ID | / |

| Family ID | 1000005224366 |

| Filed Date | 2022-04-21 |

| United States Patent Application | 20220117416 |

| Kind Code | A1 |

| Fischer; Jane | April 21, 2022 |

WOVEN STRETCHABLE FITTED SHEET

Abstract

A woven stretchable fitted sheet is made of a woven material but is stretchable in one dimension. The fitted sheet is made of a single such material comprising the top wall and side walls combined together to form a skirt. The edges of the skirt have an elastic band attached thereto which bunches up the material slightly to allow it to be stretched over a mattress and to accommodate to mattresses of differing heights. The fabric preferably used to manufacture the fitted sheet includes a blend of a material such as cotton or cotton/polyester blend blended with SPANDEX.RTM. elastic yarn. These materials are made into a yarn using a core spinning technique. In the preferred embodiment, the blend of cotton or other fabric and SPANDEX.RTM. is from 2 to 20% SPANDEX.RTM. and the remainder cotton or other material, such as, for example, a cotton/polyester blend.

| Inventors: | Fischer; Jane; (Mooresville, NC) | ||||||||||

| Applicant: |

|

||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Family ID: | 1000005224366 | ||||||||||

| Appl. No.: | 17/071281 | ||||||||||

| Filed: | October 15, 2020 |

| Current U.S. Class: | 1/1 |

| Current CPC Class: | D10B 2331/04 20130101; D10B 2201/02 20130101; A47G 9/0246 20130101; D10B 2503/06 20130101; D03D 15/56 20210101; D10B 2401/061 20130101 |

| International Class: | A47G 9/02 20060101 A47G009/02; D03D 15/08 20060101 D03D015/08 |

Claims

1. A fitted sheet comprising: a) a woven fabric made of a first set of yarns extending along a length dimension and a second set of yarns extending along a width dimension and woven into said first set of yarns to create said woven fabric; b) one of said first or said second set of yarns being made of a material chosen from the group consisting of cotton, a cotton/polyester blend, and polyester; c) another of said first or said second set of yarns being made of a blended material consisting of (1) one of cotton, a cotton/polyester blend or polyester, blended with (2) an elastic yarn; d) said woven fabric being employed for a top wall of said fitted sheet and side walls of said fitted sheet, said side walls combining together to form a skirt; e) an elastic strip attached to a bottom open edge of said skirt; and f) said woven fabric being stretchable in a direction of one of said dimensions.

2. The fitted sheet of claim 1, wherein said one of said dimensions comprises said width dimension.

3. The fitted sheet of claim 1, wherein said elastic yarn comprises 2-20%, by weight, of said another of said first or said second set of yarns.

4. The fitted sheet of claim 3, wherein said woven fabric has a stretch ratio of 3 to 13%.

5. The fitted sheet of claim 1, wherein said woven fabric has a thread count of 200 to 1500 threads per inch.

6. The fitted sheet of claim 5, wherein said thread count is 300 threads per inch.

7. The fitted sheet of claim 1, wherein said top wall and skirt are made of a single piece of fabric.

8. The fitted sheet of claim 1, wherein said second set of yarns includes said elastic yarn.

9. The fitted sheet of claim 8, wherein said elastic yarn is made of two pre-polymers reacted together to produce elastic fibers made into said elastic yarn.

10. The fitted sheet of claim 9, wherein one of said pre-polymers comprises a flexible macro-glycol and another of said pre-polymers comprises a stiff di-isocyanate.

11. The fitted sheet of claim 10, wherein said stiff di-isocyanate contains at least 85% polyurethane.

12. The fitted sheet of claim 1, wherein said elastic strip is attached to said bottom edge of said skirt in a stretched configuration.

13. The fitted sheet of claim 1, wherein said first set of yarns comprise cotton yarns and said second set of yarns comprise a blend of 80-98% cotton and 2 to 20% elastic yarn.

14. The fitted sheet of claim 13, wherein said fabric has a thread count of 200-1500 threads per inch.

15. The fitted sheet of claim 8, wherein said second set of yarns are core spun with elastic fiber comprising a core thereof.

16. A fitted sheet comprising: a) a woven fabric made of a first set of yarns extending along a length dimension and a second set of yarns extending along a width dimension and woven into said first set of yarns to create said woven fabric; b) said first set of yarns being made of a material chosen from the group consisting of cotton, a cotton/polyester blend, and polyester; c) said second set of yarns being made of a blended material consisting of (1) one of cotton, a cotton/polyester blend or polyester, blended with (2) an elastic yarn, said second set of yarns being core spun with elastic fiber comprising a core thereof; d) said woven fabric being employed for a top wall of said fitted sheet and side walls of said fitted sheet, said side walls combining together to form a skirt, and said top wall and skirt being made of a single piece of fabric; e) an elastic strip attached to a bottom edge of said skirt; and f) said woven fabric being stretchable along said width direction.

17. The fitted sheet of claim 16, wherein said elastic yarn comprises 5-12%, by weight, of said second set of yarns.

18. The fitted sheet of claim 16, wherein said woven fabric has a stretch ratio of 1.5 to 3.0.

19. The fitted sheet of claim 16, wherein said woven fabric has a thread count of 100 to 800 threads per inch.

20. The fitted sheet of claim 16, wherein said elastic yarn is made of two pre-polymers reacted together to produce elastic fibers, one of said pre-polymers comprising a flexible macro glycol and another of said pre-polymers comprising a stiff di-isocyanate.

Description

BACKGROUND OF THE INVENTION

[0001] The present invention relates to a woven stretchable fitted sheet. In the prior art, fitted sheets have a top wall, side walls, and a periphery which includes some form of elastic allowing the periphery to be stretched to fit over a mattress and extend under the mattress to hold the fitted sheet in place. In all fitted sheets known to Applicant, while the top wall is woven it is not stretchable.

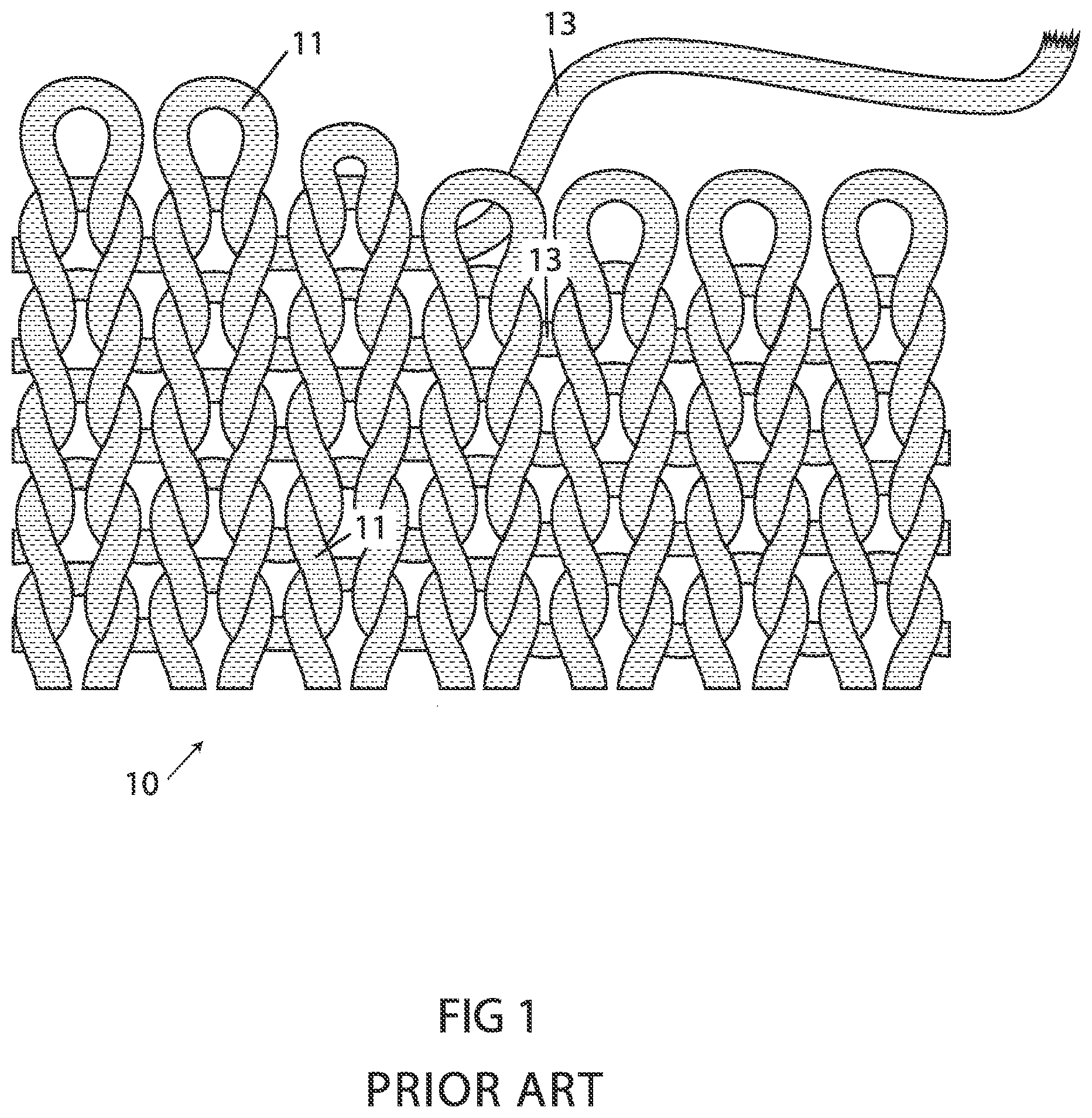

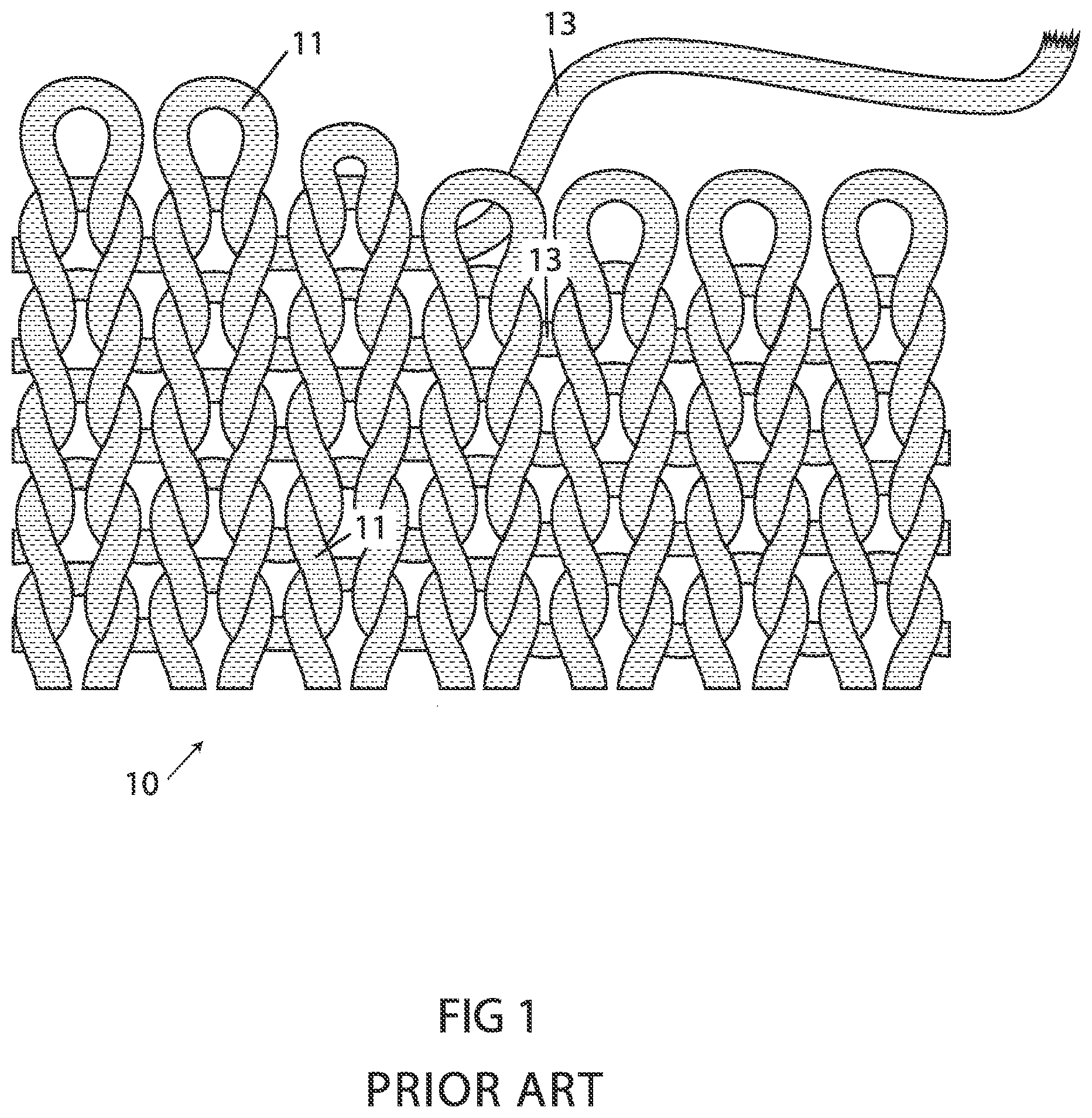

[0002] There are two typical ways in which fabric is created. A first way is to knit the yarn into a fabric. FIG. 1 shows an enlarged view of a portion of a fabric that has been knitted. As is seen, the fabric 10 includes a plurality of yarns 11 that have been formed into loops. Other yarns 13 interlace or interloop with the looped yarns 11 to form a knitted fabric. Due to their construction, as shown in FIG. 1, knitted fabrics are stretchable. They are typically used for articles of apparel such as sweaters.

[0003] By contrast, typically, woven fabrics are not stretchable. FIG. 2 shows three examples of weave patterns, plain weave, twill weave, and satin weave. Each one has horizontal yarns 21 and vertical yarns 23.

[0004] FIG. 3 shows another type of woven fabric designated by the reference numeral 30. In the fabric 30, a series of parallel yarns 31 are woven with an undulating piece of yarn 33 to create the weave. In FIG. 3, the yarn 33 is shown much thicker than the yarn 31 but it is certainly well known for the various yarn pieces to be of equal thickness. The fabric 30 typically defines the yarn pieces 31 as the "warp" and the yarn pieces 33 to be the "weft."

[0005] While there are general standards in the bedding industry for the dimensions of mattresses, slight variations do exist in the dimensions of the top surface of a mattress and the thickness of its side walls. As such, fitted sheets must be constructed with at least some degree of flexibility to facilitate fitting on mattresses of various sizes. Typically, variability is provided by making the side walls, comprising a skirt, longer than necessary to cover the side walls of a typical mattress and the periphery of the fitted sheet is elasticized and the elasticity is relatively large to allow the periphery to be stretched over most, if not all, mattresses of a single class such as twin, full, queen or king as the case may be. As such, it would be advantageous to develop a fitted sheet which includes sufficient flexibility to accommodate to mattresses in each size class with slight variations in size.

[0006] In the prior art, it is known to blend cotton yarns with yarns sold under the trademark SPANDEX.RTM. or LYCRA.RTM. to add flexibility to a finished fabric. However, to date, Applicant is unaware of any such fabric being utilized in a woven fabric-based fitted sheet. As is known to those of ordinary skill in the art, SPANDEX.RTM. or LYCRA.RTM. are trademarks used to describe a long-chain polyglycol substance combined with a short di-isocyanate and which contains at least 85% polyurethane. The unique elastic property of this material, when made into fibers or yarns, results from this chemical composition.

[0007] There are two ways to create a fabric made out of cotton or other material blended with SPANDEX.RTM. or LYCRA.RTM. fibers. A first way is shown in FIG. 4 which depicts a two-ply yarn 40 which is made up of a fiber of, for example, cotton 41 and an elastic fiber 43 of, for example, SPANDEX.RTM. fiber. The finished yarn 40 is made by twisting the fibers 41 and 43 together. Variations of this yarn 40 can be, as also shown in FIG. 4, a S-twist version 45 and a Z-twist version 47. In either case, flexibility is somewhat limited.

[0008] The following prior art is known to Applicant.

[0009] U.S. Pat. No. 6,883,193 B2 to Brooks et al. discloses an elastic fitted cover. This patent contemplates a quilted top that is designed to be stretchable in the width direction and the length direction. The quilted composite fabric comprises at least two fibrous layers that are quilted together and the elastic layer is disclosed as being woven, knitted or non-woven and may include up to 10% by weight elastic thread such as SPANDEX.RTM.. The present invention differs from the teachings of Brooks et al. as contemplating a fitted sheet made of a single material not multiple materials stitched together and which is not quilted but consists of a smooth fitted sheet that may be stretched preferably in the width direction only and made of a woven material.

[0010] U.S. Pat. No. 8,671,476 B2 to Stewart et al. discloses a non-core spun yarn such as illustrated in FIG. 4 herein and wherein the warp and fill yarns are disclosed as being made of a "non-spandex, non-core spun elastomeric yarn . . . ". The disclosed sheet is not stretchable, made of 65% cotton/35% polyester. This differs from the teachings of the present invention which contemplates use of a core spun yarn and a yarn which has a SPANDEX.RTM. core.

SUMMARY OF THE INVENTION

[0011] The present invention relates to a woven stretchable fitted sheet. The present invention includes the following interrelated objects, aspects and features:

[0012] (1) In a first aspect, the present invention contemplates a fitted sheet that is made of a woven material but is stretchable in one dimension. The fitted sheet is made of a single such material comprising the top wall and side walls combined together to form a skirt. The edges of the skirt have an elastic band attached thereto which bunches up the material slightly to allow it to be stretched over a mattress and to accommodate to mattresses of differing heights. By "stretchable" Applicant means the sheet may be stretched in at least one direction, width or length, preferably width, by a stretch factor greater than 2% meaning the fabric can stretch in one direction greater than 2% longer than its unstretched length in that direction.

[0013] (2) The fabric that is used to manufacture the inventive fitted sheet is a combination of a material such as, for example, cotton combined with SPANDEX.RTM. or LYCRA.RTM. elastic yarn. These materials are made into a yarn using a core spinning technique in which the core is made of the SPANDEX.RTM. or LYCRA.RTM. material and yarn pieces of cotton or other fabric are wound around the SPANDEX.RTM. or LYCRA.RTM. core.

[0014] (3) The core spun yarns are then woven into a fabric which is utilized to manufacture the fitted sheet. In the preferred embodiment, the blend of cotton or other fabric on the one hand and SPANDEX.RTM. or LYCRA.RTM. on the other hand is from 2 to 20% SPANDEX.RTM. or LYCRA.RTM. and the remainder cotton or other material, such as, for example, a cotton/polyester blend. 2 to 20% SPANDEX.RTM. or LYCRA.RTM. in the yarn results in a stretch factor of 3% to 13% meaning the fabric can stretch in one direction corresponding to the direction of extent of the yarns blended with SPANDEX.RTM. or LYCRA.RTM. by from 3% to 13% as compared to the unstretched length of the fabric in that direction.

[0015] (4) In the preferred embodiment, the fabric used to manufacture the fitted sheet is woven with the yarn in the width direction being the core spun yarn comprising a blend including SPANDEX.RTM. or LYCRA.RTM. and the yarn in the lengthwise direction is devoid of SPANDEX.RTM. or LYCRA.RTM. and merely comprises the other material whether cotton or other material. In this way, the fitted sheet can stretch in the width direction but is substantially non-stretchable in the length direction. Applicant has found that making the fabric stretchable in both the length and width directions results in bunching up and non-uniformity of the fabric when the fitted sheet is installed over a mattress which makes the fitted sheet uncomfortable for the sleeper. As such, in the preferred embodiment, the fabric is only stretchable in one direction, length or width, preferably width.

[0016] (5) In the preferred embodiment of the present invention, the thread count for the woven fabric is in the range of 300 threads per inch. However, this thread count may suitably be varied from anywhere from 200 to 1500 depending upon the desired price point and other relevant factors, including desired comfort.

[0017] (6) If desired, instead of cotton, other materials may suitably be used to be blended with SPANDEX.RTM. or LYCRA.RTM. including, if desired, Lyocell, polyester and polyester blended with cotton. The determining factor is mainly the marketing for comfort and the price point.

[0018] Accordingly, it is a first object of the present invention to provide a woven stretchable fitted sheet.

[0019] It is a further object of the present invention to provide such a sheet in which the sheet is woven but is stretchable in one direction.

[0020] It is a still further object of the present invention to provide such a fitted sheet in which stretchability is provided by blending cotton or a cotton/polyester blend or a cotton/Lyocell blend with a SPANDEX.RTM. or LYCRA.RTM. thread in a core-spun process.

[0021] It is a still further object of the present invention to provide such a fitted sheet of woven fabric that is stretchable in the width direction.

[0022] It is a still further object of the present invention to provide such a fitted sheet made of a fabric consisting of 2 to 20% SPANDEX.RTM. in the yarn utilized to weave the fabric to yield a stretch factor of 3 to 13%.

[0023] It is a still further object of the present invention to provide such a fitted sheet in which the top wall and side walls comprising the skirt are made of one piece.

[0024] It is a yet further object of the present invention to provide such a fitted sheet in which the bottom edges of the skirt have an elastic material attached thereto in a bunched configuration to allow it to stretch over the periphery and bottom of a mattress.

[0025] These and other objects, aspects and features of the present invention will be better understood from the following detailed description of the preferred embodiment when read in conjunction with the appended drawing figures.

BRIEF DESCRIPTION OF THE DRAWINGS

[0026] FIG. 1 shows a prior art drawing showing the manner by which knitted fabrics are created.

[0027] FIG. 2 shows three alternative prior art woven fabric patterns.

[0028] FIG. 3 shows a prior art image of another view of a woven fabric having warp threads and weft threads.

[0029] FIG. 4 shows a prior art yarn made of non-core spun threads.

[0030] FIG. 5 shows a yarn made of core spun threads.

[0031] FIG. 6 shows a portion of a woven fabric.

[0032] FIG. 7 shows a perspective view of the fitted sheet covering a mattress.

[0033] FIG. 8 shows a bottom view of the mattress with the fitted sheet covering it.

[0034] FIG. 9 shows a perspective view the mattress and fitted sheet of FIGS. 7 and 8 from a different perspective.

SPECIFIC DESCRIPTION OF THE PREFERRED EMBODIMENT

[0035] With reference first to FIG. 5, a core spun yarn 50 is shown with the core designated by the reference numeral 51 and the surrounding fibers designated by the reference numerals 53 and 55. The core 51 in accordance with the teachings of the present invention is made of an elastic material such as that which is sold under the trademark SPANDEX.RTM. or LYCRA.RTM.. Such materials consist of two types of pre-polymers reacted together to produce the fiber. One pre-polymer is a flexible macro-glycol while the other is a stiff di-isocyanate. Of course, the chemical composition and manner of manufacturing SPANDEX.RTM. or LYCRA.RTM. fibers is well known to those of ordinary skill in the art.

[0036] Applicant has found that creating the fabric using the core spun technique for creating a blend with SPANDEX.RTM. or LYCRA.RTM. is the superior manner of manufacture because it provides the desired degree of resiliency and elasticity for the application that forms the heart of the present invention.

[0037] In the preferred embodiment of the present invention, the blend of SPANDEX.RTM. or LYCRA.RTM. on the one hand and cotton, cotton/Lyocell blends, polyester or cotton/polyester blends on the other hand has a mixture from 2 to 20%, by weight, SPANDEX.RTM. or LYCRA.RTM. with the remainder being the cotton or cotton/polyester blend. This range of proportions provides stretch characteristic ratios of from 3 to 13% with the greater number corresponding to the higher percentage of SPANDEX.RTM. or LYCRA.RTM.. Applicant has found that a blend of 93% BCI cotton and 7% SPANDEX.RTM. or LYCRA.RTM. yields a stretch ratio of about 4%. Again, as the SPANDEX.RTM. or LYCRA.RTM. percentage in the blend increases, the stretch ratio increases to the point where 12% SPANDEX.RTM. in the blend yields a stretch characteristic of approximately 8.5%.

TABLE-US-00001 TABLE 1 Blend Fiber 1 Fiber 2 Structural Yarn in Warp Cotton/Bamboo Ranges From Ranges From Fiber 1 + Fiber 2 to create (40% to 99%) (1% to 60%) a one structural yarn. Cotton/Tencel* Ranges From Ranges From Fiber 1 + Fiber 2 to create (40% to 99%) (1% to 60%) a one structural yarn. Cotton/Modal* Ranges From Ranges From Fiber 1 + Fiber 2 to create (40% to 99%) (1% to 60%) a one structural yarn. Cotton/ Ranges From Ranges From Fiber 1 + Fiber 2 to create Other Fiber Blends (40% to 99%) (1% to 60%) a one structural yarn. Cotton/Polyester Ranges From Ranges From Fiber 1 + Fiber 2 to create or synthetic blend (40% to 99%) (1% to 60%) a one structural yarn. Cotton/Lyocell Ranges From Ranges From Fiber 1 + Fiber 2 to create (40% to 99%) (1% to 60%) a one structural yarn. Cotton Alone 100% N/A N/A Polyester Alone 100% N/A N/A *a wood-based fiber

[0038] Table 1 shows a variety of yarn blends that may be used to weave the fabric used to manufacture the fitted sheet of the present invention. Based upon their respective properties that are known to those of ordinary skill in the art, the fabric may be made from cotton, cotton/Lyocell blends, polyester, cotton/polyester blends and/or any of the blends listed in Table 1. If desired, the horizontal yarns may be made of any of these materials blended with 2-20%, by weight, elastic yarn such as is sold under the trademark SPANDEX.RTM. or LYCRA.RTM. and the vertical yarns may be made of any of these materials. In Table 1, "Fiber 1" is cotton and "Fiber 2" is the other listed material. Preferred ratios of Fiber 1 and Fiber 2 include: (1) all cotton; (2) 51% cotton, 49% Lyocell; (3) all polyester; (4) 35% cotton, 65% polyester. Fabric made of cotton/Lyocell blend combined with SPANDEX.RTM. or LYCRA.RTM. preferably comprises 54% cotton, 41% Lyocell, and 5% SPANDEX.RTM. or LYCRA.RTM..

[0039] FIG. 6 shows a portion of the fabric 60 utilized in making the fitted sheet of the present invention. FIG. 6 shows the width direction and the length direction. As shown, yarns 61 extend in the width direction and yarns 63 extend in the length direction. In the preferred embodiment of the present invention, the yarns 61 comprise a blend of SPANDEX.RTM. and cotton or cotton/polyester blends. The yarns 63 comprise a cotton or cotton/polyester blend without any SPANDEX.RTM. fibers therein. As such, the fabric 60 stretches in the width direction with a stretch ratio of 3 to 13% when the percentage of SPANDEX.RTM. or LYCRA.RTM. fiber in the yarn is from 2 to 20%. As is the case for woven fabrics, in the length direction, since the yarns 63 are devoid of SPANDEX.RTM., the fabric 60 does not stretch. Applicant has found that creating a fabric with stretchability in the width and length dimensions causes the fabric to bunch up and become irregular when installed over a mattress. As a result, it is disadvantageous to create a fitted sheet which stretches in the width and length dimensions.

[0040] FIGS. 7-9 show a fitted sheet 70 installed over a mattress 1. As shown, the fitted sheet 70 has a top wall 71 and side walls 73, 75, 77 and 79 which together form a skirt which depends downwardly from the top wall 71.

[0041] As particularly shown in FIG. 8, the fitted sheet 70 has an elasticized band 81 that is attached on the lower edges of the skirt and, as shown, the elastic band 81 is stretched before it is affixed to the edges of the skirt so that bunching of the skirt is created as shown in FIG. 8 so that the elastic 81 can be stretched to extend over the mattress 1 and down its sides and to its underside which is shown by the reference numeral 3 in FIG. 8 to secure the fitted sheet 70 onto the mattress 1.

[0042] As is well known, while the sizes twin, full, queen and king as well as the "California" king have similar dimensions, it is also true that slight variations in those dimensions are found in the marketplace. Thus, the length and width dimensions of the top surface of the mattress sometimes slightly differ and, more commonly, the actual height of the mattress differs, often in the range of 10 to 16 inches or higher or lower. The stretchability of the fabric 60 utilized to create the fitted sheet 70 allows the fitted sheet 70 to accommodate to mattresses of dramatically differing dimensions. In doing so, the particular weave of the fabrics allows a smooth, snug fit on all types of mattresses in a manner never before demonstrated in the prior art.

[0043] In the preferred embodiment of the present invention, the thread count for the fabric 60 is about 250 threads per inch. Thread counts from 200 to 1500 may also be contemplated based upon the desired level of comfort and the desired price point for the fitted sheet. Additionally, the price point may be altered by making the sheet including pure cotton combined with SPANDEX.RTM. in the width direction or cotton combined with polyester in desired ratios as well known by those of ordinary skill in the art. If desired, the yarns used to weave the fabric may have a diameter of 40 to 60 microns but these dimensions may be altered depending upon the desired thread count, comfort level, and price point.

[0044] As such, an invention has been disclosed in terms of a preferred embodiment thereof which fulfills each and every one of the objects of the invention as set forth hereinabove and provides a new and useful woven stretchable fitted sheet of great novelty and utility.

[0045] Of course, various changes, modifications and alterations in the teachings of the present invention may be contemplated by those of ordinary skill in the art without departing from the intended spirit and scope thereof.

[0046] As such, it is intended that the present invention only be limited by the terms of the appended claims.

* * * * *

D00000

D00001

D00002

D00003

D00004

D00005

XML

uspto.report is an independent third-party trademark research tool that is not affiliated, endorsed, or sponsored by the United States Patent and Trademark Office (USPTO) or any other governmental organization. The information provided by uspto.report is based on publicly available data at the time of writing and is intended for informational purposes only.

While we strive to provide accurate and up-to-date information, we do not guarantee the accuracy, completeness, reliability, or suitability of the information displayed on this site. The use of this site is at your own risk. Any reliance you place on such information is therefore strictly at your own risk.

All official trademark data, including owner information, should be verified by visiting the official USPTO website at www.uspto.gov. This site is not intended to replace professional legal advice and should not be used as a substitute for consulting with a legal professional who is knowledgeable about trademark law.