Sustained Release Compositions Using Wax-like Materials

Chen; Andrew Xian ; et al.

U.S. patent application number 17/126748 was filed with the patent office on 2021-04-22 for sustained release compositions using wax-like materials. The applicant listed for this patent is Farnam Companies, Inc.. Invention is credited to Andrew Xian Chen, Patricia D. Kigin.

| Application Number | 20210113469 17/126748 |

| Document ID | / |

| Family ID | 1000005290188 |

| Filed Date | 2021-04-22 |

| United States Patent Application | 20210113469 |

| Kind Code | A1 |

| Chen; Andrew Xian ; et al. | April 22, 2021 |

SUSTAINED RELEASE COMPOSITIONS USING WAX-LIKE MATERIALS

Abstract

Sustained release spherical or non-spherical pellets comprising (a) an active ingredient (b) a wax-like agent, and (c) a spheronizing agent are provided. Oral dosage forms comprising said pellets and methods for preparing and using such pellets and dosage forms are also provided.

| Inventors: | Chen; Andrew Xian; (San Diego, CA) ; Kigin; Patricia D.; (Scottsdale, AZ) | ||||||||||

| Applicant: |

|

||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Family ID: | 1000005290188 | ||||||||||

| Appl. No.: | 17/126748 | ||||||||||

| Filed: | December 18, 2020 |

Related U.S. Patent Documents

| Application Number | Filing Date | Patent Number | ||

|---|---|---|---|---|

| 12040443 | Feb 29, 2008 | 10888521 | ||

| 17126748 | ||||

| 60904456 | Mar 2, 2007 | |||

| Current U.S. Class: | 1/1 |

| Current CPC Class: | A61K 31/135 20130101; A61K 31/7008 20130101; A61K 9/1652 20130101; A61K 31/522 20130101; A01N 43/90 20130101; A61K 9/1694 20130101; A61K 9/0095 20130101; A61K 9/1617 20130101 |

| International Class: | A61K 9/16 20060101 A61K009/16; A61K 31/7008 20060101 A61K031/7008; A61K 31/522 20060101 A61K031/522; A61K 31/135 20060101 A61K031/135 |

Claims

1. A composition comprising: (a) an active ingredient, which is an insect growth regulator (IGR); (b) a wax-like agent; and (c) a spheronizing agent, wherein the composition is in the form of pellets.

2. The composition of claim 1, wherein the IGR is a member selected from the group consisting of methoprene, kinoprene, hydroprene, diflubenzuron, and pyriproxifen.

3. The composition of claim 1, wherein the IGR is methoprene.

4. The composition of claim 1, wherein the IGR is diflubenzuron.

5. The composition of claim 1, wherein the IGR is pyriproxifen.

6. The composition of claim 1, comprising: (a) from about 0.1% to about 90% of the active ingredient; (b) from about 5% to about 40% of the wax-like agent; and (c) from about 5% to about 40% of the spheronizing agent.

7. The composition of claim 1, wherein the active ingredient is present in an amount of about 0.1% to about 5%.

8. The composition of claim 1, comprising: (a) from about 0.1% to about 5% of methoprene; (b) from about 5% to about 30% of hydrogenated vegetable oil; (c) from about 5% to about 30% of microcrystalline cellulose; and from about 1% to about 10% pregelatinized starch.

9. The composition of claim 1, wherein the pellets are coated.

10. The composition of claim 1, wherein the wax-like agent is selected from the group consisting of fatty alcohols, saturated and unsaturated fatty acid esters, saturated and unsaturated fatty acid glycerides, hydrogenated fats, hydrogenated vegetable oil, and cholesterol.

11. The composition of claim 1, wherein the wax-like agent is hydrogenated vegetable oil.

12. The composition of claim 1, wherein the spheronizing agent is microcrystalline cellulose.

13. The composition of claim 1, further comprising an inactive ingredient which is a member selected from the group consisting of a binder, an antioxidant, an a colorant.

14. The composition of claim 13, wherein the one or more inactive ingredients are present at the total concentration from about 0.01% to about 5.0% based on the pellet weight.

15. The composition of claim 1, wherein the average diameter of the spherical pellets are about 0.5 mm to about 1.5 mm.

16. A method for treating or preventing a pest infestation, comprising contacting a host with a composition comprising an effective amount of an insect growth regulator (IGR), a wax-like agent; and a spheronizing agent, wherein the composition is in the form of pellets.

17. The method of claim 16, wherein the IGR is a member selected from the group consisting of methoprene, kinoprene, hydroprene, diflubenzuron, and pyriproxifen.

18. The method of claim 16, wherein the IGR is methoprene.

19. The method of claim 16, wherein the IGR is diflubenzuron.

20. The method of claim 16, wherein the IGR is pyriproxifen.

Description

CROSS-REFERENCE TO RELATED APPLICATION

[0001] The present application is a continuation of U.S. patent application Ser. No. 12/040,443, filed Feb. 29, 2008, which claims priority to U.S. Provisional Patent Application No. 60/904,456, filed Mar. 2, 2007, the disclosures of which are hereby incorporated herein by reference in their entireties for all purposes.

BACKGROUND OF THE INVENTION

Field of the Invention

[0002] This invention relates to sustained release compositions and dosage forms and to methods of preparing and using such compositions and dosage forms.

Description of the Related Art

[0003] Oral pharmaceutical dosage forms usually come in single dosage unit forms, such as tablets or capsules. Each tablet or capsule unit contains a fixed amount of an active ingredient.

[0004] Many active ingredients require specific release kinetics or prolonged release. In such instances, use is made of so-called sustained or controlled release formulations. The term "sustained release" is often also used for formulations that show controlled release during a prolonged period of time. Controlled release formulations have been introduced for active ingredients that require a specific release pattern such as a constant release during a certain period of time, i.e., a release of an active ingredient that minimizes peaks and drops. Various controlled release formulations are now available that avoid temporary over- or under-dosing of the active ingredient. Sustained release formulations have been developed in which the release of the active ingredient is prolonged in some way in order to maintain therapeutic activity for a longer period of time. The terms of "sustained release" and "controlled release" are often interchangeable.

[0005] Sustained release formulations typically are applied to drugs that have a short half-life or for active ingredients that require active blood plasma levels for long periods of time. In the former instance, multiple daily dosing can be avoided such as b.i.d., t.i.d. or q.i.d regimens, which often lead to problems caused by lack of patient compliance. Sustained release formulations are more preferably applied for patients on chronic medication where one administration suffices to maintain active blood plasma levels for longer periods such as several days or even weeks.

[0006] Tablet and capsule dosage forms are convenient to use but suffer from limitations in delivering a drug that (1) requires a very high dose for its therapeutic benefits, (2) are for patients that do not take tablet/capsule voluntarily, or (3) are for those with swallowing difficulties.

[0007] For instance, one tablet that contains up to 0.75-1 gram of an active ingredient along with other inactive ingredients required for forming the tablets often ends up with rather bulky mass with a total weight up to 1.5-2 grams. Any further increase in active dose (e.g., more than 1 g) would render the tablet too big to swallow. Size of a capsule containing the same weight can be even greater because the capsule content is usually not compressed like a tablet.

[0008] A sustained release oral dosage form is intended to deliver a drug in one unit for a prolonged therapeutic duration such as 1/2, 1, 2, or even 3 days. A sustained release formulation is often not feasible as a tablet or capsule due to their unacceptably large size. For example, for a drug that is administered 3 times a day at 500 mg each time in a non-sustained release formulation, a once-a-day dose (i.e., 1500 mg) would result in a bulky tablet with a total weight of greater than 2-3 grams. Such a bulky tablet would be very difficult to swallow by a human or animal subject.

[0009] It is difficult to give tablets or capsules to animals such as horses, cats or dogs because they do not take tablets or capsules voluntarily, and poking down a tablet or capsule can be very cumbersome. Similarly, some human patients do not like to or unable to swallow tablets or capsules, especially the large ones.

[0010] Multiparticulate formulations are of particular use in overcoming the aforementioned shortcomings associated with tablet or capsule formulations.

[0011] Multiparticulates are well-known dosage forms that comprise a multiplicity of drug-containing particles whose totality represents the intended therapeutically useful dose of a drug. A multiparticulate dosage form can be made with a pure drug substance or formulated with other ingredients with typical particle size of 1-2 mm or less. When taken orally, multiparticulates generally disperse freely in the gastrointestinal tract, exit relatively rapidly and reproducibly from the stomach, and maximize absorption. See, for example, Multiparticulate Oral Drug Delivery (Marcel Dekker, 1994) and Pharmaceutical Pelletization Technology (Marcel Dekker, 1989).

[0012] A multiparticulate formulation may be represented by other terms such as powders, granules, pellets, microspheres, minispheres, beadlets, sachets etc. Because for each dose, multiple units of particles are given, the term multi-unit dosage form is used.

[0013] A multiparticuate formulation may be dosed as (1) dry powder which is placed in mouth and swallowed with liquid, (2) dispersed in a liquid and then swallowed, or (3) placed in a capsule. For the 1.sub.st and 2.sup.nd methods of administration, large amounts of particles can be given. For example, 5-10 grams of spherical pellets can be suspended in water and swallowed easily by a human patient. For animals such as horse, a multiparticulate formulation can be readily mixed with feed and be consumed by the animal voluntarily. Moreover, unlike humans, animals are usually dosed based on body weight. Animals have a tremendous variability in body weights. For example, dogs may have body weights ranging from 2 kg to 50 kg, requiring the dosage form be administered in very specific quantities adjusted according to body weight of the patient. In such instances, a multiparticulate formulation is of particular use because its dose can be adjusted easily by weighing or measuring by volume or counting the number of pellets to give a wide range of dose variation, e.g., from about 10 mg (1 pellet) to 100 g (10,000 pellets).

[0014] Numerous active ingredients require sustained release kinetics or prolonged release such as twice-a-day, preferably once-a-day, or ever more preferable once every 2-3 days. In such instances, use is made of so-called sustained release multiparticulate formulations. Because of the allowance for a high dosing volume, a sustained release multiparticulate formulation is particularly useful for drugs that are given at a high dose, e.g., more than 1000 mg per dose.

[0015] Unlike the tablets where a sustained release may be obtained by a matrix and/or coating system, known sustained release multiparticulate formulations rely almost exclusively on a coating system to provide a barrier to the drug release, i.e., "sustained release coating." This is due to the greatly increased surface area of a small pellet of 1-2 mm diameter compared to a tablet. For example, a tablet in disc shape of 10 mm diameter and 5 mm thickness contains the same volume as 750 spheres of 1 mm diameter. Given the same density, the 750 spheres combined have 30 times of the surface area of the tablet of the same weight. According to the Noyes-Whitney equation which was developed by Noyes and Whitney in 1897:

-dM/dt=KA(Cs-C)

where -dM/dt is the drug dissolution rate of a drug from a matrix, K is the diffusion constant, A is the surface area and (Cs-C) is the concentration differential between the unstirred surface layer adjacent to solid mass and bulk of the dissolution medium.

[0016] It is clear that the dissolution rate of a drug is directly proportional to the surface of the matrix mass, i.e., a matrix tablet or spheres. The overall drug dissolution rate of 750 spheres of 1 mm diameter is thus 30 times faster than a tablet of the same volume and density. In other words, a matrix tablet capable of releasing its drug in 24 hours would release the drug in about 0.8 hour should it be converted to spheres of 1 mm diameter of the same matrix mass. This dramatic increase in surface area and thus dissolution rate has made sustained release spheres almost impossible without a barrier coating, because most matrix-forming materials and the conventional matrix manufacturing processes are incapable of providing sufficiently prolonged drug dissolution. A barrier coating is required for almost all known sustained release pellets (see, U.S. Patent Application Publication No. 2006/0153908, U.S. Pat. Nos. 5,188,841, 6,699,506, 6,897,205, and 6,436,438).

BRIEF SUMMARY OF THE INVENTION

[0017] The present invention provides pharmaceutical compositions for sustained release of pharmaceutically active agents and methods for preparing and using such pharmaceutical compositions. The pharmaceutical compositions are in the form of pellets and may have one or more of the following characteristics: (1) providing sustained release that does not require a sustained release barrier coating, which lowers the cost associated with the barrier coating and decreases scale-up complexity; (2) providing the flexibility for dosing, especially for animal patients; (3) enabling slow release of active ingredients due to relatively large sizes of the pellets (e.g., at least about 0.5 mm or 1 mm in diameter for spherical pellets), which enables slow release of active ingredients; and (4) easier to administer pharmaceutically active agents of short half-lives and/or high doses compared to tablets or capsules.

[0018] In one aspect, the present invention provides a composition that comprises (a) an active ingredient, a wax-like agent, and a spheronizing agent, (b) is in the form of pellets, and (c) provides sustained release of the active ingredient. In certain embodiments, the composition provides such sustained release without the need for a sustained release barrier coating.

[0019] In certain embodiments, the pellets are uncoated. In certain other embodiments, the pellets are coated. The coating may be a sustained release barrier coating, a taste masking barrier, a moisture barrier, a color barrier, or an enteric-coating.

[0020] In certain embodiments, the pellets are spherical. In other embodiments, the pellets are non-spherical.

[0021] In certain embodiments, the composition has an in vitro dissolution rate measured by standard USP basket method according to Example 3 of at most about 50%, 60%, 70%, 80%, or 90% of the active ingredient released after 2 hours.

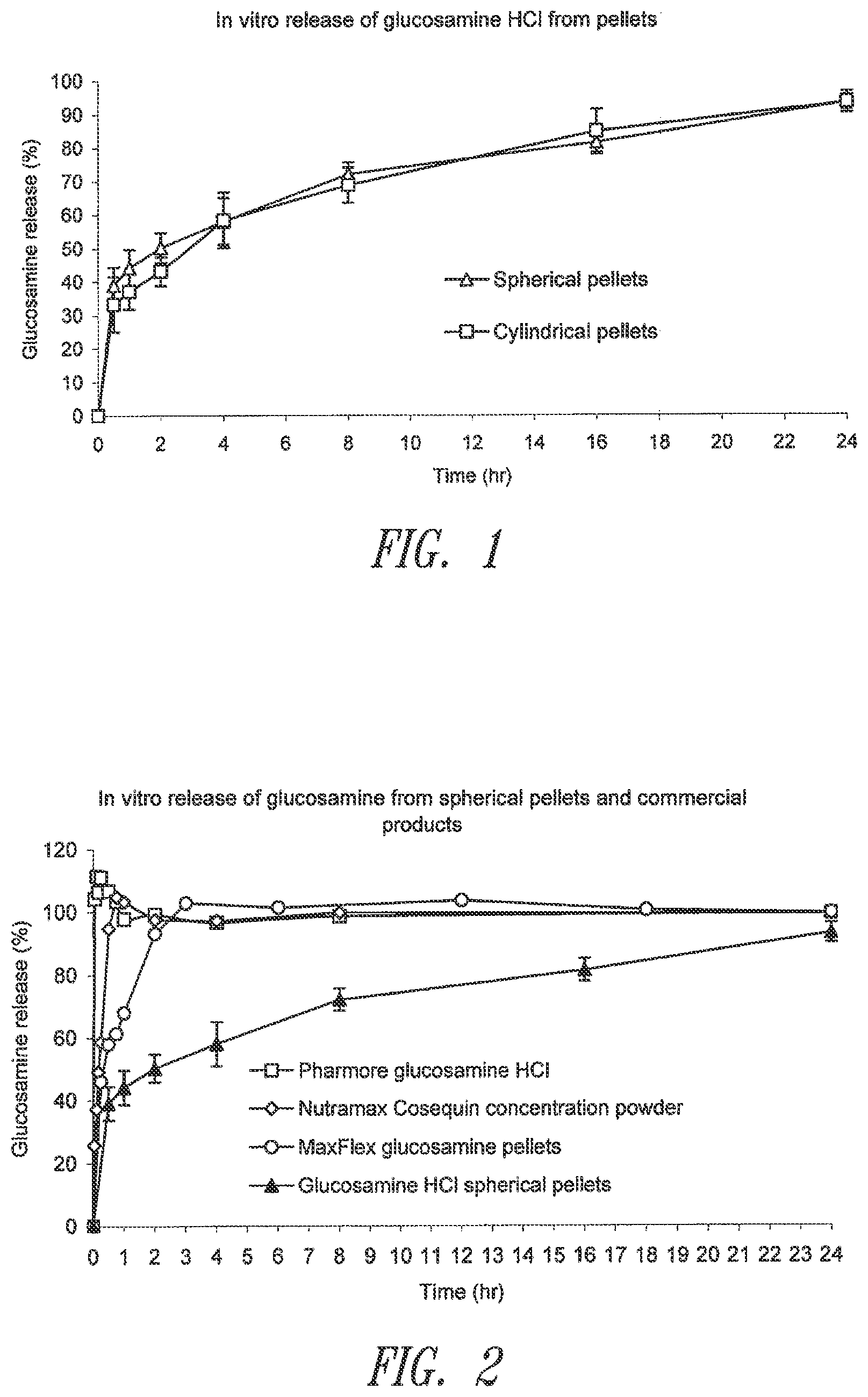

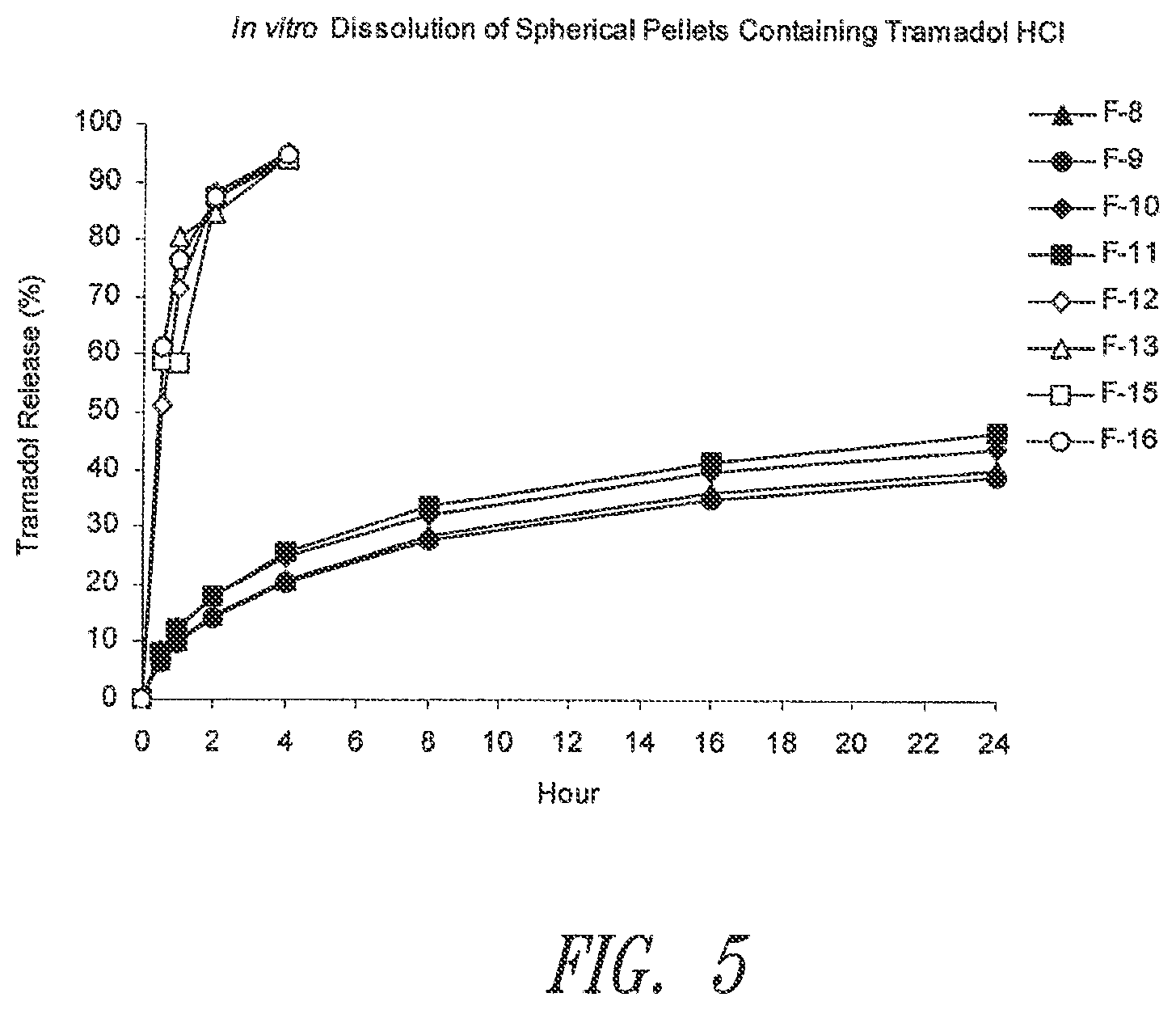

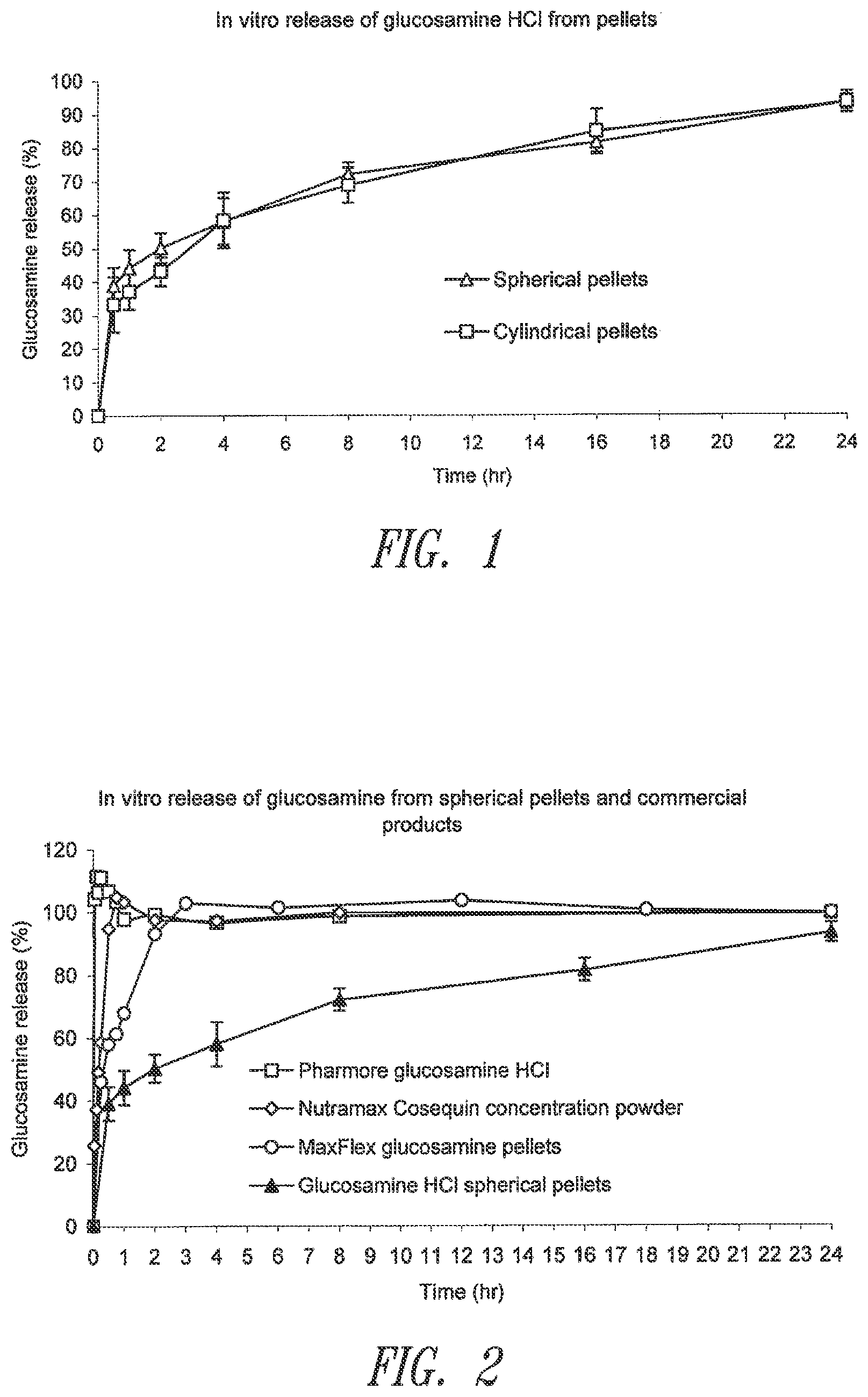

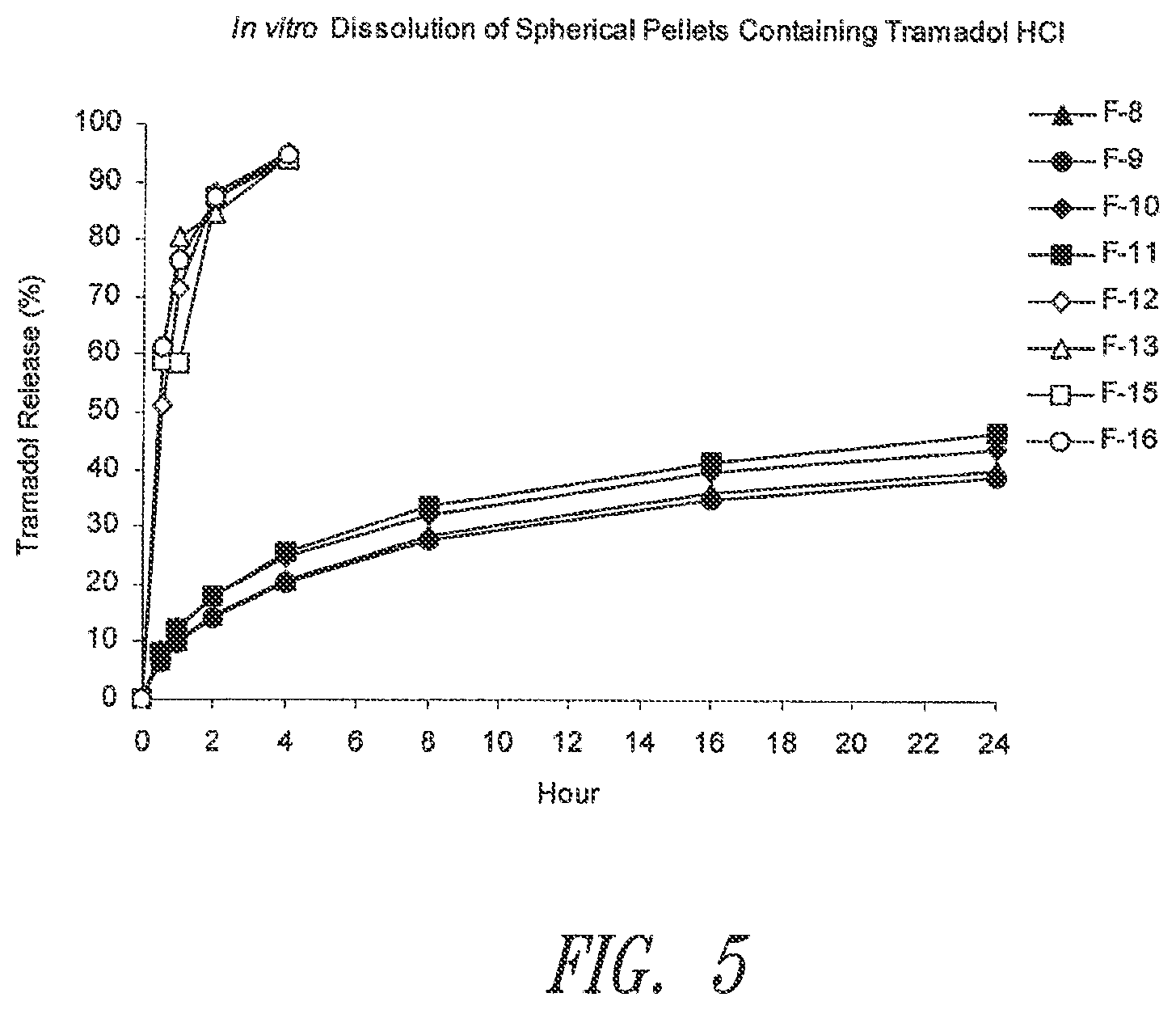

[0022] In certain embodiments, the composition has an in vitro dissolution rate measured by standard USP basket method according to Example 3 of: about 10% to about 60% of the active ingredient released after 1 hour; about 20% to about 70% of the active ingredient released after 2 hours; about 30% to about 80% of the active ingredient released after 4 hours; and about 40% to about 90% of the active ingredient release after 8 hours; and about 50% to about 100% of the active ingredient release after 12 hours. In certain embodiments, the active ingredient is glucosamine or a pharmaceutically acceptable salt thereof.

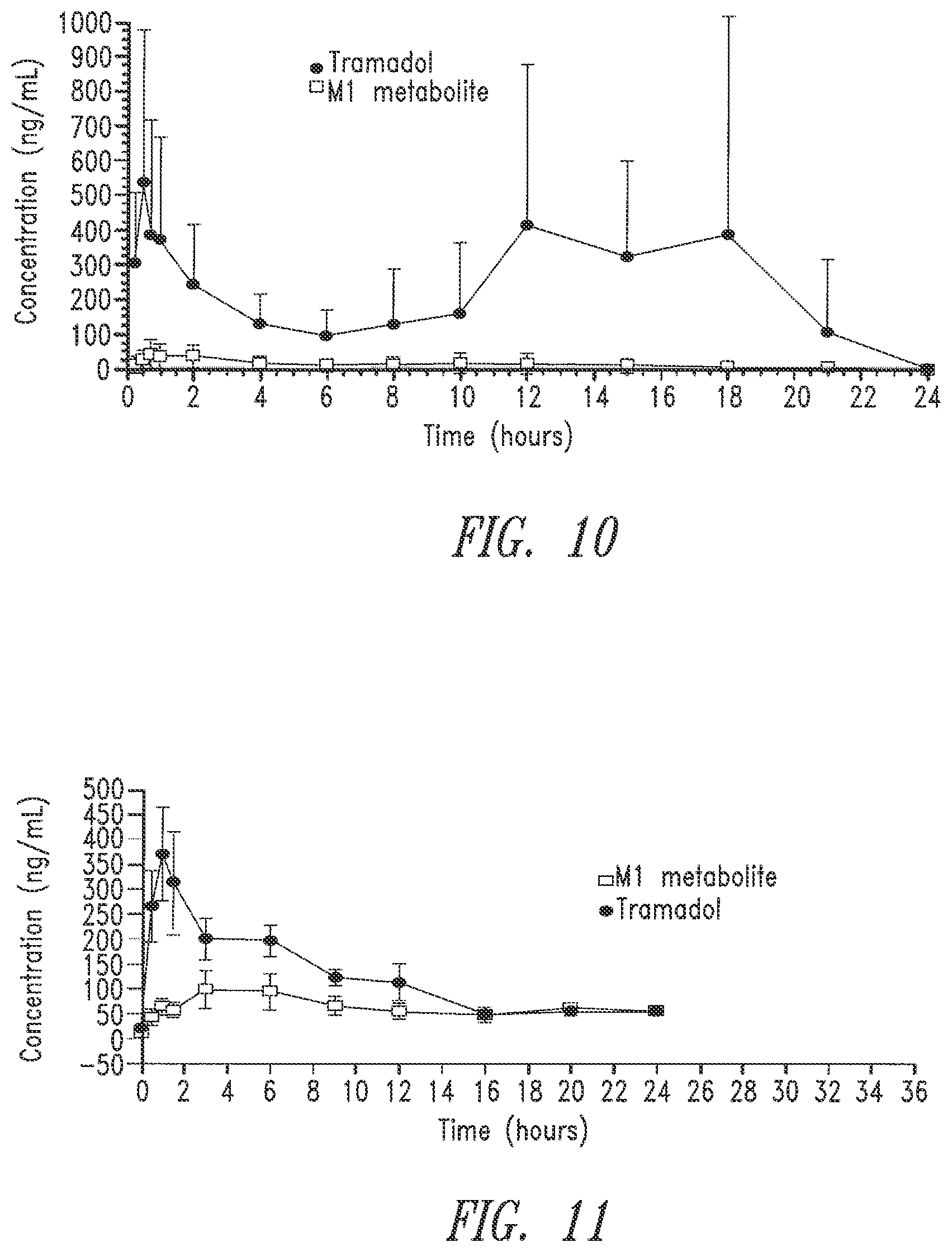

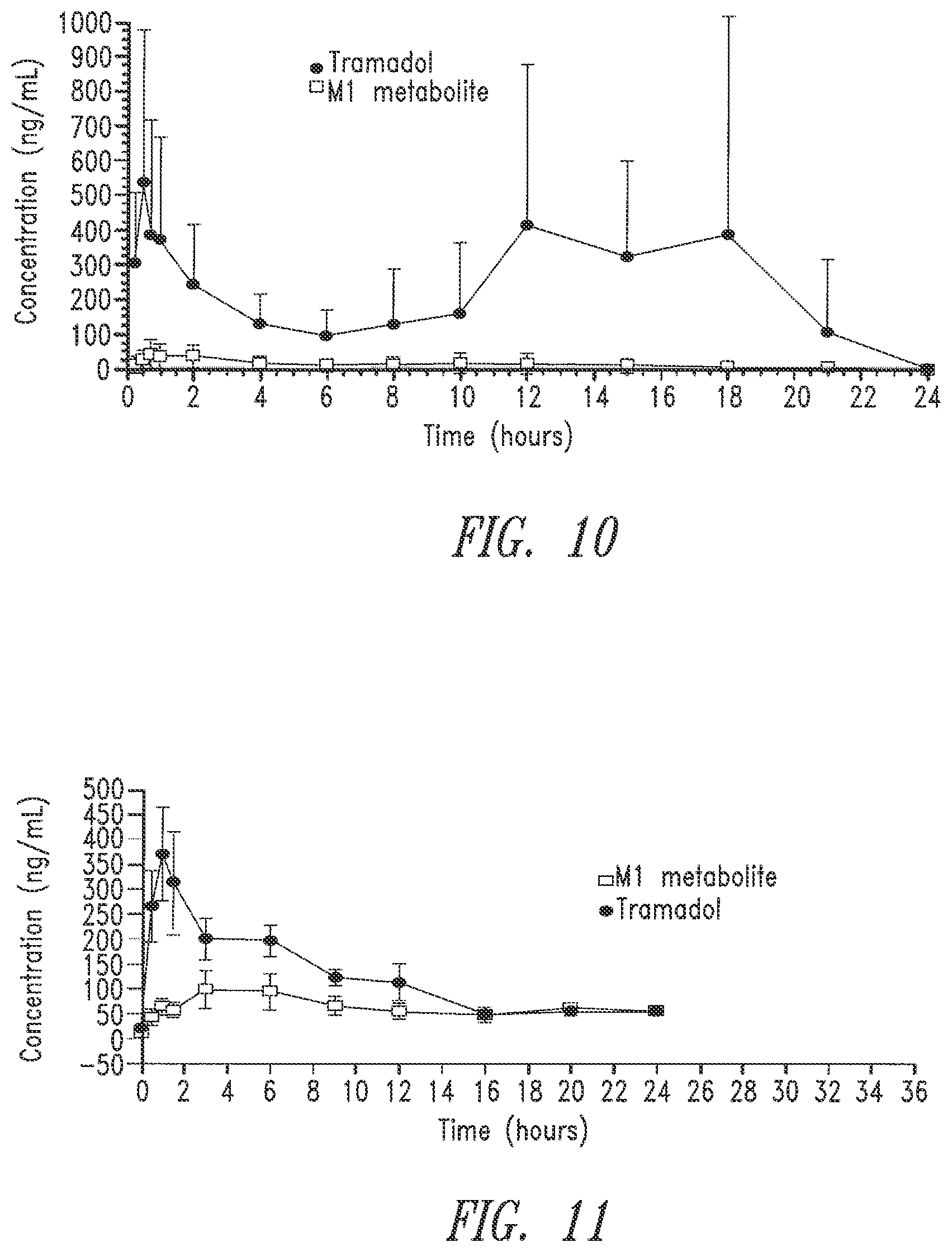

[0023] In certain embodiments, the composition has an in vitro dissolution rate measured by standard USP basket method according to Example 3 of: about 0% to about 30% after 2 hours; about 5% to about 35% after 4 hours, about 10% to about 40% after 8 hours; about 15% to about 45% after 16 hours; about 20% to about 50% after 24 hours. In certain embodiments, the active ingredient is tramadol or a pharmaceutically acceptable salt thereof.

[0024] In certain embodiments, upon or after oral administration, the composition provides a 2-phase release profile, where the first phase releases 10-60% of the active ingredient in about 1 hour and the second phase releases the rest of the active ingredient, in a nearly linear fashion, for at least about 2, 3, 4, 5, 6, 7, 8, 9, 10, 11, 12, 14, 16, 18, 20, 22, or 24 hours.

[0025] In certain embodiments, the composition comprises: (a) from about 5% to about 90% of the active ingredient; (b) from about 5% to about 40% of the wax-like agent; and (c) from about 5% to about 40% of the spheronizing agent.

[0026] In certain embodiments, the composition may further comprise one or more inactive ingredients. In certain embodiments, the inactive ingredients may be binders, antioxidants or colorants. In certain embodiments, the inactive ingredient(s) may be present at a total concentration from about 0.01% to about 5.0% based on the pellet weight.

[0027] In certain embodiments, the active agent may be an analgesic or a pharmaceutically acceptable salt thereof, such as acetaminophen, a centrally acting analgesic agent, opiate, narcotic, nonsteroidal anti-inflammatory drugs (NSAIDS), and salicylate. In certain embodiments, the analgesic is tramadol or a pharmaceutically acceptable salt thereof.

[0028] In certain embodiments, the composition comprises: (a) from about 45% to about 85% of an analgesic or a pharmaceutically acceptable salt thereof; (b) from about 5% to about 30% of hydrogenated vegetable oil (e.g., cottonseed oil); (c) from about 5% to about 20% of microcrystalline cellulose; and (d) from about 1% to about 10% pregelatinized starch.

[0029] In certain embodiments, the active ingredient is a dietary supplement, such as vitamins, minerals, herbs or other botanicals, amino acids, proteins, and other nutrient substances or their constituents. In certain embodiments, the dietary supplement is glucosamine or a pharmaceutically acceptable salt thereof.

[0030] In certain embodiments, the composition comprises: (a) from about 45% to about 85% of a dietary supplement or a pharmaceutically acceptable salt thereof; (b) from about 5% to about 30% of hydrogenated vegetable oil (e.g., cottonseed oil); (c) from about 5% to about 20% of microcrystalline cellulose; and (d) from about 1% to about 10% pregelatinized starch.

[0031] In certain embodiments, the active ingredient is an antiviral agent or a pharmaceutically acceptable salt thereof, such as abacavir, acyclovir, ganciclovir, lamivudine, nelfinavir, ritonavir, valacyclovir, foscarnet, and zidovudine, or a derivative, prodrug or pharmaceutically acceptable salt thereof.

[0032] In certain embodiments, the composition comprises: (a) from about 45% to about 85% of an antiviral agent or a pharmaceutically acceptable salt thereof; (b) from about 5% to about 30% of hydrogenated vegetable oil (e.g., cottonseed oil); (c) from about 5% to about 30% of microcrystalline cellulose; and (d) from about 1% to about 10% pregelatinized starch.

[0033] In certain embodiments, the active ingredient is an anti-infective agent or a pharmaceutically acceptable salt thereof, such as antibiotics (including .beta.-lactam antibiotics, aminoglycosides, cephalosporins, macrolides, penicillins, quinolones, sulfonamides, tetracyclines, antifungals, antimalarial agents, antituberculotics agents, and anti-parasitics). In certain embodiments, the anti-infective agent is azithromycin, clarithromycin, roxithromycin, erythromycin, ciprofloxcin, a combination of amoxicillin and clavulanate potassium, or a derivative, prodrug, a pharmaceutically acceptable salt thereof.

[0034] In certain embodiments, the composition comprises: (a) from about 45% to about 85% of an anti-infective agent or a pharmaceutically acceptable salt thereof, (b) from about 5% to about 30% of hydrogenated vegetable oil (e.g., cottonseed oil), (c) from about 5% to about 30% of microcrystalline cellulose, and (d) from about 1% to about 10% pregelatinized starch.

[0035] In certain embodiments, the active ingredient is an antacid, such as sodium antacid, calcium antacids, aluminum antacids, magnesium antacids, and combinations thereof. In certain embodiments, the antacid is aluminum hydroxide, magnesium hydroxide, trisodium phosphate (also referred to as "sodium phosphate tribase") or a combination of two or all of these three compounds. In certain embodiments, the antacid is a combination of aluminum hydroxide and magnesium hydroxide, or a combination of trisodium phosphate and magnesium hydroxide, at a weight ratio of about 1:3, 1:2, 1:1, 2:1, or 3:1.

[0036] In certain embodiments, the composition comprises: (a) from about 45% to about 85% of an antacid, (b) from about 1% to about 30% of hydrogenated vegetable oil (e.g., cottonseed oil), (c) from about 5% to about 30% of microcrystalline cellulose, and (d) from about 1% to about 10% pregelatinized starch.

[0037] In certain embodiments, the active ingredient is a high-dose drug, such as fenbendazole, albendazole, febantel, carprofen, ketoprofen, diclofenac, morphine, meperidine, buprenorphine, butorphanol, metronidazole, potassium bromide, gabapentin, zileuton, sucralfate, metformin, glipizide, nabumetone, niacin, procainamide, tolmetin sodium, choline magnesium trisalicylate, guaifenesin, eprosartan mesylate, etodolac, acarbose, ursodiol, polyene phosphatidylchoine, and a pharmaceutically acceptable salt thereof.

[0038] In certain embodiments, the composition comprises: (a) from about 45% to about 90% of a high-dose pharmaceutically active agent, (b) from about 5% to about 40% of hydrogenated vegetable oil (e.g., cottonseed oil), (c) from about 5% to about 40% of microcrystalline cellulose, and (d) from about 1% to about 10% pregelatinized starch.

[0039] In certain embodiments, the active ingredient is an insect growth regulator (IGR) or a pharmaceutically acceptable salt thereof, such as methoprene, kinoprene, hydroprene, diflubenzuron, or pyriproxifen.

[0040] In certain embodiments, the composition comprises: (a) from about 45% to about 85% of an insect growth regulator or a pharmaceutically acceptable salt thereof; (b) from about 5% to about 30% of hydrogenated vegetable oil (e.g., cottonseed oil); (c) from about 5% to about 30% of microcrystalline cellulose; and (d) from about 1% to about 10% pregelatinized starch.

[0041] In certain embodiments, the pellets are coated. The coating may or may not contribute to sustained release of the composition.

[0042] In certain embodiments where the pellets are spherical, their average diameter is about 0.1 mm to about 3 mm, about 0.5 mm to about 2 mm, or 0.5 mm to about 1.5 mm.

[0043] In certain embodiments, the wax-like agent is selected from the group consisting of fatty alcohols, saturated and unsaturated fatty acid esters, saturated and unsaturated fatty acid glycerides, hydrogenated fats, hydrogenated vegetable oil, and cholesterol. In certain embodiments, the wax-like agent is hydrogenated vegetable oil.

[0044] In certain embodiments, the wax-like sustained release agent has a melting point at least about 40.degree. C., or 60.degree. C.

[0045] In certain embodiments, the spheronizing agent is microcrystalline cellulose.

[0046] In another aspect, the present invention provides a dosage form that comprises the composition described herein.

[0047] In certain embodiments, the dosage form comprises the active ingredient at a dose of at least about 1, 2, 3, 4, 5, 6, 7, 8, 9, or 10 g per dose.

[0048] In certain embodiments, the dosage form further comprises one or more inactive ingredients, such as flavorants, suspending agents, anticaking agents, fillers, sweeteners, colorants, and lubricants.

[0049] In certain embodiments, the dosage form further comprises water and is in the form of an oral suspension.

[0050] In certain embodiments, the dosage form may be packaged in a bottle, packet, pouch, sachet, or capsule.

[0051] In certain embodiments, the dosage form, upon oral administration to a patient in need thereof, provides a plasma concentration of the active agent at or above its minimum effective concentration for at least about 2, 4, 6, 8, 10, 12, 14, 16, 18, 20, 24, 36, 48, 72, 96, 120, 144, or 168 hours.

[0052] In certain embodiments, the dosage form, upon oral administration to a patient in need thereof, provides a plasma concentration of the active agent at or above its minimum effective concentration for a period of time that is at least about 2, 3, 4, or 5 times of that of an immediate release formulation administered at a standard dose.

[0053] In certain embodiments, the dosage form is suitable for administration to a patient in need thereof at or no more than once or twice per day, once per two, three, four, five, six, seven days, once per one, two, three, or four weeks, or once per treatment.

[0054] In another aspect, the present application provides a method for making spherical or non-spherical pellets comprising (i) an active ingredient; (ii) a wax-like agent; and (iii) a spheronizing agent, the method comprising: (a) preparing a mixture of the active ingredient, the wax-like agent, the spheronizing agent, and a liquid; (b) extruding said mixture to obtain an extrudate; (c) spheronizing the extrudate to form spherical pellets or fragmenting the extrudate to form non-spherical pellets; (d) drying the spherical pellets; and (e) heating the dry pellets to a temperature higher than the melting point of the wax-like agent.

[0055] For example, in certain embodiments, the present application provides a method for making spherical pellets comprising (i) an active ingredient; (ii) a wax-like agent; and (iii) a spheronizing agent, the method comprising: (a) preparing a mixture of the active ingredient, the wax-like agent, the spheronizing agent, and a liquid; (b) extruding said mixture to obtain an extrudate; (c) spheronizing the extrudate to form spherical pellets; (d) drying the spherical pellets; and (e) heating the dry pellets to a temperature higher than the melting point of the wax-like agent.

[0056] In certain related embodiments, the present invention provides a method for making spherical pellets comprising above steps (a) to (d), but not above step (e).

[0057] In certain embodiments, the spherical pellets are subsequently mixed with a flavorant or a vehicle comprising one or more inactive ingredients, such as flavorants.

[0058] In certain embodiments, the liquid is water. In certain other embodiments, the liquid comprises water and an organic solvent (e.g., propylene glycol, ethanol, or isopropanol).

[0059] In certain other embodiments, the present application provides a method for making non-spherical pellets comprising (i) an active ingredient; (ii) a wax-like agent; and (iii) a spheronizing agent, the method comprising: (a) preparing a mixture of the active ingredient, the wax-like agent, the spheronizing agent, and a liquid; (b) extruding said mixture to obtain an extrudate; (c) fragmenting the extrudate to form non-spherical pellets: (d) drying the non-spherical pellets; and (e) heating the dry pellets to a temperature higher than the melting point of the wax-like agent.

[0060] In a related aspect, the present invention provides a method for making non-spherical pellets comprising above steps (a) to (d), but not above step (e).

[0061] In certain embodiments, the non-spherical pellets are subsequently mixed with a vehicle comprising one or more inactive ingredients, such as flavorants.

[0062] In certain embodiments, the liquid is water. In certain other embodiments, the liquid comprises water and an organic solvent (e.g., propylene glycol, ethanol, or isopropanol).

[0063] In another aspect, the present invention also provides spherical and non-spherical pellets produced according to the methods described herein.

[0064] In another aspect, the present invention further provides methods for making dosage forms that comprise the compositions disclosed herein.

[0065] In certain embodiments, the method for making a dosage form comprises filling the pellets disclosed herein in a suitable container, such as capsules, bottles, and pouches.

[0066] In certain embodiments, the method for making a dosage form comprises mixing the pellets disclosed herein with a vehicle, and suspending the resulting mixture in water or another solution to form oral suspension dosage form.

[0067] In certain embodiments, the method for making a dosage form comprises mixing the pellets with human food or animal feed.

[0068] In another aspect, the present invention provides a method of treating an animal in need thereof, comprising administering to the animal orally a composition or a dosage form containing an effective amount of the composition described herein.

[0069] For example, in one aspect, the present invention provides a method for reducing pain, comprising administering orally to a patient in need thereof a composition described herein that comprises an effective amount of an analgesic or a pharmaceutically acceptable salt thereof.

[0070] In another aspect, the present invention provides a method for treating or preventing dietary deficiency, comprising administering orally to a patient in need thereof a composition described herein that comprises an effective amount of a dietary supplement or a pharmaceutically acceptable salt thereof.

[0071] In another aspect, the present invention provides a method for treating or preventing viral infection, comprising administering orally to a patient in need thereof a composition described herein that comprises an effective amount of an anti-viral agent or a pharmaceutically acceptable salt thereof.

[0072] In another aspect, the present invention provides a method for treating or preventing bacterial infection, comprising administering orally to a patient in need thereof a composition described herein that comprises an effective amount of an anti-infective agent or a pharmaceutically acceptable salt thereof.

[0073] In another aspect, the present invention provides a method for treating or preventing gastrointestinal ulcer or disorder, comprising administering orally to a patient in need thereof a composition described herein that comprises an effective amount of an antacid or a pharmaceutically acceptable salt thereof.

[0074] In certain embodiments, the method for treating or preventing gastrointestinal ulcer or disorder comprises administering orally to a patient in need thereof a mixture of a composition that comprises aluminum hydroxide and magnesium hydroxide described herein and a composition that comprises sodium phosphate tribase described herein. In certain embodiments, the ratio of the total weight of aluminum hydroxide and magnesium hydroxide to sodium phosphate tribase is about 9:1.

[0075] In certain embodiments, the present invention provides a method for treating or preventing parasite or pest infestation that comprises administering orally to a patient in need thereof a composition described herein that comprises an effective amount of an insect growth regulator.

BRIEF DESCRIPTION OF THE DRAWINGS

[0076] FIG. 1. Representative dissolution profiles from spherical and non-spherical pellets prepared according to Examples 1 and 2.

[0077] FIG. 2. Comparison of glucosamine in vitro dissolution profiles between the pellets prepared according to Examples 1 and 2 and commercial products.

[0078] FIG. 3. Dissolution profiles from cylindrical pellets prepared according to Example 2 measured in two months apart.

[0079] FIG. 4. In vitro dissolution of glucosamine from sustained release spherical pellets containing glucosamine hydrochloride, chondroitin sulfate, calcium ascorbate and manganese sulfate prepared according to Example 5.

[0080] FIG. 5. In vitro dissolution of tramadol from spherical pellets prepared according to Example 6.

[0081] FIG. 6. In vitro dissolution of azithromycin pellets for oral suspension prepared according to Examples 7 and 8 and ZMAX.TM. by Pfizer performed according to the method described in U.S. Pat. No. 6,984,403.

[0082] FIG. 7. In vitro dissolution profiles of glucosamine from spherical pellets by different heating conditions prepared according to Example 17.

[0083] FIG. 8. In vitro dissolution profiles of glucosamine from spherical pellets prepared with various oil according to Example 18.

[0084] FIG. 9. In vitro dissolution profile of tramadol from spherical pellets prepared according to Example 19.

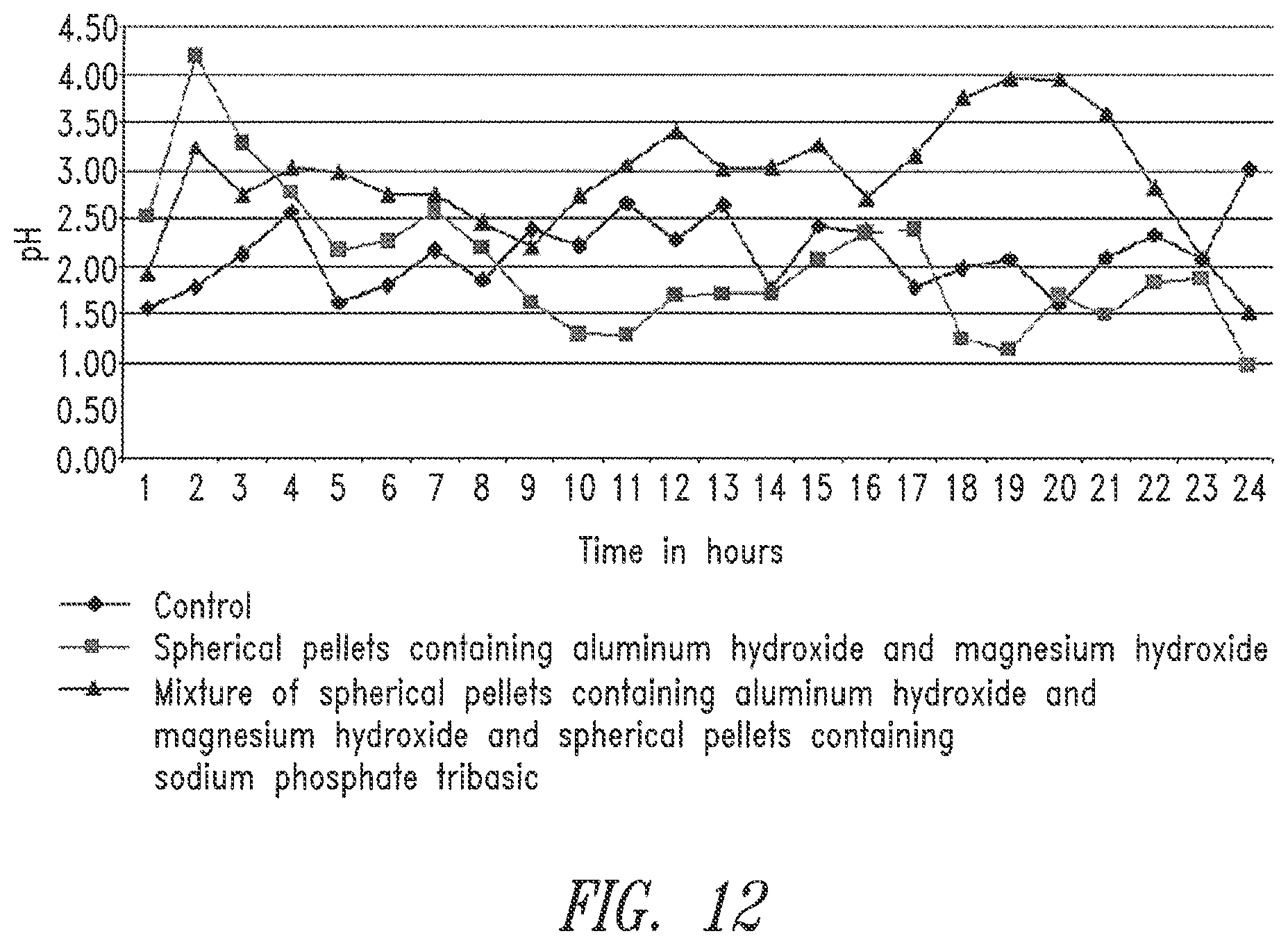

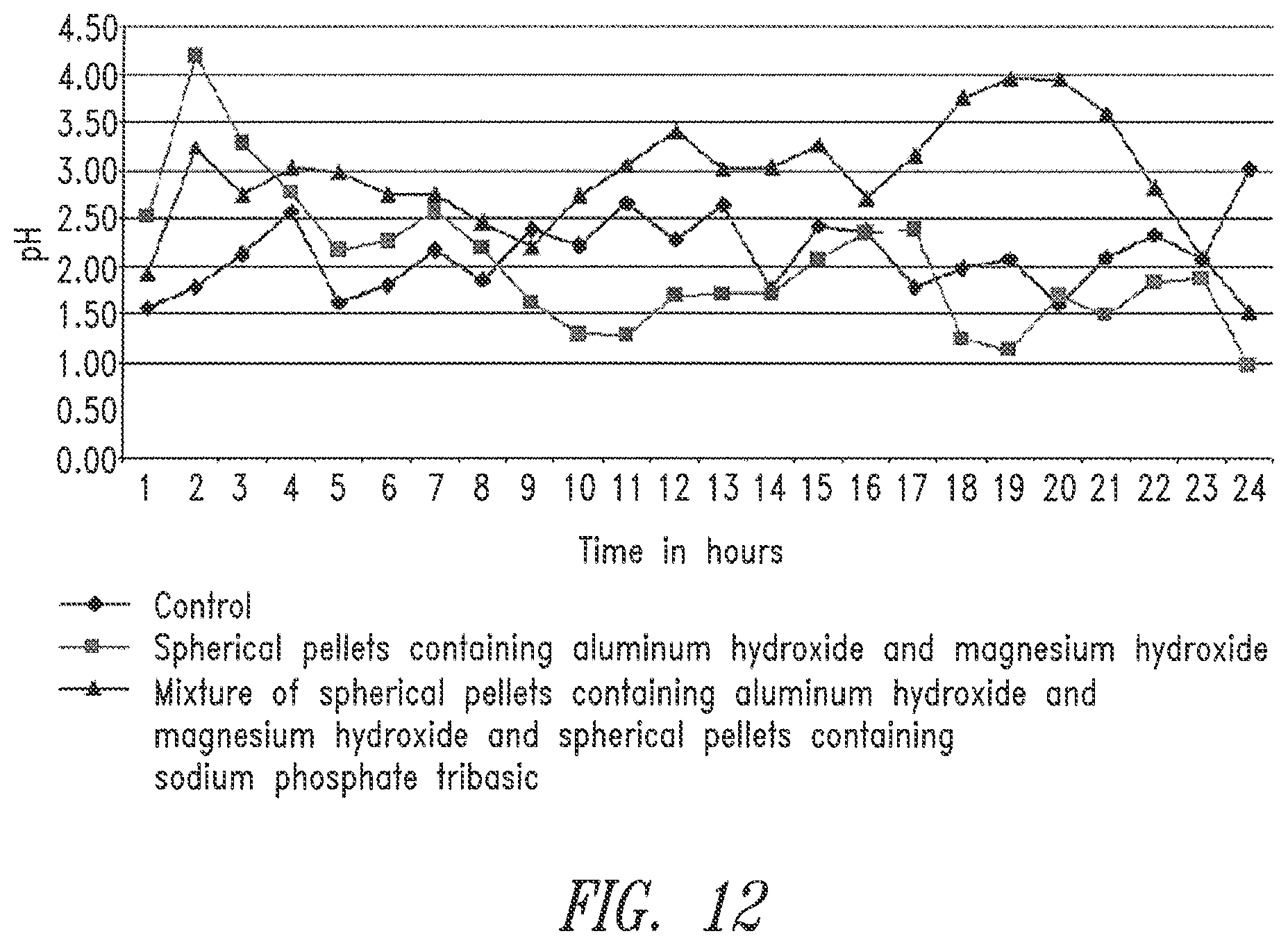

[0085] FIG. 10. Pharmacokinetic profiles of tramadol and its main active metabolite, M1, in horses following oral administration of tramadol hydrochloride sustained release spherical pellets.

[0086] FIG. 11. Pharmacokinetic profiles of tramadol and its main active metabolite, M1, in horses following oral administration of tramadol hydrochloride.

[0087] FIG. 12. Horse gastric pH following oral administration of two antacid sustained release spherical pellet formulations: (1) the formulation that contains aluminum hydroxide and magnesium hydroxide prepared according to Example 11, and (2) the 9:1 combination of spherical pellets that contain aluminum hydroxide and magnesium hydroxide and spherical pellets that contain sodium phosphate tribase also prepared according to Example 11.

DETAILED DESCRIPTION OF THE INVENTION

[0088] The present invention provides pharmaceutical compositions for sustained release of pharmaceutically active agents in the form of pellets, which do not require the presence of a sustained release barrier coating. In addition, the present invention provides dosage forms that comprise such compositions. It further provides methods for preparing and using the pharmaceutical compositions and dosage forms.

[0089] Unless indicated otherwise, any percentage is weight by weight (w/w) relative to the total weight of a composition or to the total weight of a dry pellet.

[0090] As used in the present invention, the term "about" refers to any value in the range of 90% to 110% of a specified value. For example about 40.degree. C. refers to any temperature from 36.degree. C. to 44.degree. C.

[0091] As used in the present invention, any numerical ranges recited herein are to be understood to include any integer within the range and, where applicable (e.g., concentrations), fractions thereof, such as one tenth and one hundredth of an integer (unless otherwise indicated).

I. Compositions

[0092] In one aspect, the present invention provides a composition that (a) comprises (i) an active ingredient, (ii) a wax-like agent, and (Iii) a spheronizing agent, (b) is in the form of pellets, and (c) provides sustained release of the active ingredient. In certain embodiments, the sustained release of the active ingredient does not require the presence of a sustained release barrier coating on the pellets.

[0093] A. Active Ingredient

[0094] The active ingredient in the composition may be any pharmaceutically active agent (i.e., a compound or a composition, such as a herb extract, with beneficial pharmaceutical, therapeutic, nutritional, or cosmetic effects).

[0095] In certain embodiments, the active agent may be an analgesic or a pharmaceutically acceptable salt thereof, such as acetaminophen, a centrally acting analgesic agent, opiate, narcotic, nonsteroidal anti-inflammatory drugs (NSAIDS), and salicylate. In certain embodiments, the active agent is a combination of two or more analgesics or their pharmaceutically acceptable salts thereof. In certain embodiments, the analgesic is tramadol or a pharmaceutically acceptable salt thereof (e.g., tramadol HCl).

[0096] In certain embodiments, the active ingredient is a dietary supplement, such as vitamins, minerals, herbs or other botanicals, amino acids, proteins, and other nutrient substances or their constituents. In certain embodiments, the active agent is a combination of two or more dietary supplements. In certain embodiments, the dietary supplement is glucosamine or a pharmaceutically acceptable salt thereof.

[0097] In certain embodiments, the active ingredient is an antiviral agent or a pharmaceutically acceptable salt thereof, such as abacavir, acyclovir, ganciclovir, lamivudine, nelfinavir, ritonavir, valacyclovir, and zidovudine. In certain embodiments, the active agent is a combination of two more antiviral agents or their pharmaceutically acceptable salts.

[0098] In certain embodiments, the active ingredient is an anti-infective agent or a pharmaceutically acceptable salt thereof, such as antibiotics (including .beta.-lactam antibiotics, aminoglycosides, cephalosporins, macrolides, ketolides, penicillins, quinolones, sulfonamides, tetracyclines, cycloserine, vancomycin, linezolid, oxazolidinone, pyrimethamine, atovaquone, tigecycline, glycylcyclines, anthelmintics, antifungals, antimalarial agents, antiprotozoal agents, leprostatics, antituberculosis agents, and anti-parasitics. In certain embodiments, the anti-infective agent is azithromycin, clarithromycin, roxithromycin, erythromycin, telithromycin, ciprofloxacin, a combination of amoxicillin and clavulanate potassium, or a pharmaceutically acceptable salt thereof. In certain embodiments, the active agent is a combination of two or more anti-infective agents or their pharmaceutically acceptable salts.

[0099] In certain embodiments, the active ingredient is an antacid, such as sodium antacids (e.g. trisodium phosphate, also referred to as "sodium phosphate tribase"), calcium antacids (e.g. calcium carbonate), aluminum antacids (e.g., aluminum hydroxide), magnesium antacids (e.g., magnesium hydroxide), and combinations thereof. In certain embodiments, the antacid is aluminum hydroxide, magnesium hydroxide, trisodium phosphate (also referred to as "sodium phosphate tribase") or a combination of two or all of these three compounds. In certain embodiments, the antacid is a combination of aluminum hydroxide and magnesium hydroxide, or a combination of trisodium phosphate and magnesium hydroxide at a weight ratio of about 1:3, 1:2, 1:1, 2:1, or 3:1.

[0100] In certain embodiments, the active ingredient is an insect growth regulator (IGR) or a pharmaceutically acceptable salt thereof, such as methoprene, kinoprene, hydroprene, diflubenzuron, or pyriproxifen. In certain embodiments, the active ingredient is a combination of two or more insect growth regulators or their pharmaceutically acceptable salts.

[0101] In certain embodiments, the composition comprises: (a) from about 45% to about 85% of an insect growth regulator or a pharmaceutically acceptable salt thereof; (b) from about 5% to about 30% of hydrogenated cottonseed oil; (c) from about 5% to about 30% of microcrystalline cellulose; and (d) from about 1% to about 10% pregelatinized starch.

[0102] In certain embodiments, the active ingredient is a high dose pharmaceutically active agent. A pharmaceutically active agent of "high dose" refers to a pharmaceutically active agent that is orally administered at a daily dose of about or greater than 1 mg/kg body weight to an adult human patient or an adult non-human subject (e.g., a dog, cat, horse, pig, etc.). In certain embodiments, the pharmaceutically active agent of the present invention has a daily dose about or greater than 2, 3, 4, 5, 6, 7, 8, 9, 10, 20, 30, 40, or 50 mg/kg body weight for an adult human or an adult non-human subject. In certain embodiments, the pharmaceutically active agent of the present invention has a daily dose about or greater than 100, 200, 250, 300, 350, 400, 450, 500, 600, 700, 800, 900, or 1000 mg for an adult human or an adult non-human subject. In certain embodiments, the active ingredients are those that must be given at at least about 200 mg, 300 mg, 400 mg, 500 mg, 600 mg, 700 mg, 800 mg, 900 mg, or 1 g per dose in a twice-a-day, once-a-day or once-per-treatment regimen.

[0103] Exemplary pharmaceutically active agents of high dose include tramadol (e.g., tramadol HCl) (100 mg/dose or more), acyclovir (200 mg/dose), acetaminophen (300 mg/dose), metformin (e.g., metformin HCl) (500 mg/dose), gabapentin (100-800 mg/dose), glucosamine, glucosamine sulfate, glucosamine HCl (500 mg/dose), etc.

[0104] Additional examples of the high-dose ingredients are niacin, azithromycin, valacyclovir, ursodiol, polyene phospholipids, cholestyramine, chitosan, fenbendazole, albendazole, febantel, carprofen, ketoprofen, diclofenac, morphine, meperidine, buprenorphine, butorphanol, metronidazole, potassium salts, zileuton, sucralfate, glipizide, nabumetone, procanamide, tolmetin sodium, choline magnesium trisalicylate, guaifenesin, eprosartan mesylate, etodolac, acarbose, ursodiol, polyene phosphatidylcholine, a pharmaceutically acceptable salt thereof, vitamins, minerals, irons, antacids, herbal extracts, and the like.

[0105] In certain embodiments, the active ingredient is a combination of two or more high dose pharmaceutically active agents or their pharmaceutically acceptable salts. The two or more high dose pharmaceutically active agents may or may not have similar pharmaceutical effects.

[0106] A"pharmaceutically acceptable salt" of a pharmaceutically active agent refers to a salt (including an acid addition salt) of the pharmaceutically active agent, within the scope of sound medical judgment, suitable for use in contact with the tissues of humans and lower animals without undue toxicity, irritation, allergic response, and the like, and effective for the intended use of the pharmaceutically active agent.

[0107] In certain embodiments, the active ingredient is therapeutically effective for a human (e.g., an adult human patient) or non-human subject (e.g., a dog, a cat, a horse, a pig, etc.) at a daily dose of at least about 5 mg/kg of the body weight of the subject, such as at least about 7.5, 10, 12, 14, 16, 18, 20, 25, 30, 35, 40, or 50 mg/kg of the body weight of the subject.

[0108] In certain embodiments, the active ingredient has a short half-life. A pharmaceutically active agent of "short half-life" refers to a pharmaceutically active agent that has a half-life about or less than 10 hours. In certain embodiments, the pharmaceutically active agent of the present invention has a half-life of about or less than about 9, 8, 7, 6, 5, 4, 3, or 2 hours in a human (e.g., an adult human patient) or non-human subject (e.g., a dog, cat, horse, pig, etc.). In general, a pharmaceutically active agent of a short half-life is required to be taken more than twice a day in its immediate release forms to maintain the efficacious blood concentration level through the day.

[0109] In certain embodiments, the active ingredient is of both short half-life and high dose. Such active ingredients include, but not limited to verapamil HCl, potassium chloride, cefdnir, propafenone HCl, hydroxyurea, hydrocodone bitartrate, delavirdine mesylate, nelfinavir mesylate, pentosan polysulfate sodium, tocainide HCl, quetiapine fumarate, fexofenadine HCl, carafate, rifampin, moxifloxacin HCl, praziquantel, ciprofloxacin, phosphate sodium potassium, methenamine mandelate, santalol HCl, cefprozil, cefadroxil, metformin HCl, irbesartan, nefazodone HCl, gatifloxacin, didanosine, modafinil, efavirenz, metaxalone, amantadine HCl, morphine sulfate, mefenamic acid, diltiazem HCl, sevelamer HCl, albendazole, amoxicillin, clavulanate potassium, lithium carbonate, lamivudine, sumatriptan succinate, nabumetone, zidovudine, cimetidine, chlorpromazine HCl, valacyclovir HCl, bupropion HCl, ranitidine, abacavir sulfate, acyclovir, aminobenzoate potassium, pyridostigmine bromide, potassium chloride, isosorbide mononitrate, nicin, demeclocycline HCl, cefixime, naproxen sodium, tetratcycline HCl, cefuroxime axetil, propoxyphene napsylate, pyrazinamide, flecaimide acetate, simethicone, mebendazole, methdopa, chlorothiazide, indinavir, penicillamine, meyyrosine, losartan potassium, thiobendazole, norfloxacin, hydroxyurea, procainamide, entacapone, valsartan, terbinafine HCl, metoprolol tartrate, ofloxacin, levofloxacin, chlorzoxazone, tolmetin sodium, tramadol HCl, bepridil HCl, phenytoin sodium, atorvastatin calcium, gabapentine, celecoxib, fluconazole, doxepine HCl, trovafloxacin mesylate, azithromycin, sertraline HCl, rifabutin, cefpodoxime proxetil, mesalamine, etidronate disodium, nitrofurantoin, choline magnesium trisalicylate, theophylline, nizatidine, pancreatin, quinidine sulfate, methocarbamol, mycophenolate mefetil, gancicovir, saquinavir mesylate, tolcapone, ticlopidine HCl, valganciclovir HCl, capecitabine, orlistat, colsevelam HCl, irbesartan, succimer, meperidine HCl, hydroxychloroquine sulfate, guaifenesine, eprosartan mesylate, amiodarone HCl, felbamate, pseudoephedrine sulfate, carisoprodol, venlafaxine, propanolol HC, etodolac, acebutolol, chondroitin, pyruvate, water soluble vitamins, creatine, Isoflavone, betaine HCl, psyllium, pantothenic Acid, zinc chloride, zinc gluconate, zinc sulfate, hytoestrogen, pycnogenol, proanthocyanidin, suntheanine, methylsulfonyl-methane, L-glutamine, colostrums, biotin, acetyl-L-carnitine, inositol, L-tyrosine, s-adenosyl methionine, bromelain, 2-dimethylaminoethanol, chromium picolinate, and combinations thereof.

[0110] In certain embodiments, the active ingredient may be insoluble, slightly soluble, sparingly soluble, soluble, freely soluble or very soluble in water. These terms are defined in the following table from Remington's Pharmaceutical Sciences, Mack Publishing Co., Easton, Pa., the latest edition.

TABLE-US-00001 Parts of solvent needed Descriptive terms for 1 part solute Very soluble <1 Freely soluble 1-10 Soluble 10-30 Sparingly soluble 30-100 Slightly soluble 100-1000 Very slightly soluble 1000-10,000 Practically insoluble or insoluble >10,000

[0111] In certain embodiments, the active ingredient is present in an amount of at least about 0.1%, 1%, 5%, 10%, 15%, 20%, 25%, 30%, 35%, 40%, 45%, or 50%, 55%, or 60% of the total weight of the composition. In certain embodiments, the active ingredient is present in an amount of at most about 65%, 70%, 75%, 80%, 85%, 90%, or 95% of the total weight of the composition. In certain embodiments, the active ingredient is present in the range of from about 0.1% to about 95%, such as from about 40% to about 85%, from about 50% to about 75%, from about 55% to about 70%, or from about 60% to about 65%, or any other range between any one of the above-noted minimum amount and any one of the above-noted maximum amount, w/w relative to the total weight of the composition.

[0112] In certain embodiments, the composition may further comprise a second pharmaceutically active agent. In certain embodiments, the second pharmaceutically active agent may be of high dose and/or short half-life. For example, in certain embodiments, the active ingredient may comprise glucosamine hydrochloride and chondroitin sulfate, tramadol hydrochloride and glucosamine hydrochloride, or tramadol hydrochloride and acetaminophen.

[0113] In certain embodiments, the other pharmaceutically active agent may have a same or similar pharmaceutical effect as the first pharmaceutically active agent in a pharmaceutical composition. For instance, a pharmaceutical composition of the present invention may comprise tramadol and another analgesic agent, in certain embodiments, the second pharmaceutically active agent may have a pharmaceutical effect different from the first pharmaceutically active agent. For instance, a pharmaceutical composition of the present invention may comprise glucosamine, chondroitin, manganese sulfate and calcium ascorbate.

[0114] In the embodiments where a pharmaceutical composition comprises two or more pharmaceutically active agents that produce an additive pharmaceutical effect, the amount of each agent is generally lower than that used for each agent in monotherapy (i.e., when the agents are given alone). For example, in one embodiment, the dose of each agent in the composition may be from 0.1 to 0.75 of the dose used in monotherapy, such as from 0.25 to 0.75 of the dose used in monotherapy. In another embodiment, the dose of one agent is one quarter of its normal dose used in monotherapy, and the dose of the other agent is three quarters of its normal dose used in monotherapy. In another embodiment, the dose of each agent is approximately one half of its normal dose when used in monotherapy.

[0115] In the embodiments where a pharmaceutical composition comprises two or more pharmaceutically active agents that produce a synergistic pharmaceutical effect, the combined dose of the agents is lower than that if the two agents produce only an additive pharmaceutical effect. For example, in one embodiment, the dose of one agent is one quarter of its normal dose used in monotherapy, and the dose of the other agent is also quarter of its normal dose used in monotherapy.

[0116] In the embodiments where a pharmaceutical composition comprises two or more agents that produce different pharmaceutical effects, the amount of each agent should be sufficient to produce the intended effect of the agent. In most of embodiments, the dose of each agent is similar to that used in monotherapy. In certain other embodiments, the dose of each agent may be higher or lower than that used in monotherapy.

[0117] The weight ratio of the first agent to the second agent in a pharmaceutical composition of the present invention depends on both agents and their dosages used in monotherapy. In certain embodiments, the weight ratio of the first agent to the second agent in a pharmaceutical composition is from about 1:1000 to 1000:1, such as 1:100 to 100:1, 1:50 to 50:1, 1:10 to 10:1, 1:5 to 5:1, 1:2 to 2:1.1:1 to 1:10, 1:1 to 1:50, 1:1 to 1:100, 100:1 to 1:1, 50:1 to 1:1, or 10:1 to 1:1.

[0118] In certain embodiments, the pharmaceutical composition comprises tramadol and another analgesic agent. For example, in certain embodiments, the pharmaceutical composition comprises tramadol and an opioid analgesic. In certain other embodiments, the pharmaceutical composition comprises tramadol and a non-steroidal anti-inflammatory drug (NSAID).

[0119] Exemplary opioid analgesics that may be included in tramadol-containing pharmaceutical compositions include, but are not limited to, alfentanil, alphaprodine, anileridine, apomorphine, betaprodine, buprenorphine, butorphanol, carfentanil, codeine, codeine, cyclorphan, cyclazocine, dextromethorphan, dextropropoxyphene, diamorphine (heroin), dihydrocodeine, diphenoxylate, ethoheptazine, etorphine, fentanyl, hydrocodone, hydromorphone, isomethadone, levallorphan, levorphanol, loperamide, meperidine, methadone, metopon, morphine, morphinone, nalbuphine, normorphine, N-(2-phenylethyl)-normorphine, oxycodone, oxymorphone, pentazocine, pethidine (meperidine), phenazocine, piminodine, propoxyphene, racemorphan, remifentanil, and sufentanil.

[0120] Exemplary NSAIDs that may be included in tramadol-containing pharmaceutical compositions include, but are not limited to, aspirin, carprofen, deracoxib, etodolac, firocoxib, celecoxib, diclofenac, diflunisal, fluriprofen, ibuprofen, indomethacin, ketoprofen, kietorolac, mefenamic acid, meloxicam, naproxen, phenylbutazone, piroxicam, rofecoxib, sulindac, and valdecoxib.

[0121] In certain embodiments, the pharmaceutical compositions of the present invention comprise both tramadol and acetaminophen. In a certain embodiment, the weight ratio of tramadol to acetaminophen in the composition is from about 1:10 to about 1:5.

[0122] In certain embodiments, the pharmaceutical compositions of the present invention comprise both tramadol and diclofenac. In a certain embodiment, the weight ratio of tramadol to diclofenac is about 1:4 to 4:1, such as 1:2 to 3:1, and 1:1 to 2.5:1.

[0123] In certain embodiments, the pharmaceutical compositions of the present invention comprise both tramadol and aspirin. In a certain embodiment, the weight ratio of tramadol to aspirin is about 1:4 and 4:1, such as between 1:2 and 2:1. In certain embodiments, the pharmaceutical compositions of the present invention comprise both tramadol and carprofen. In a certain embodiment, the weight ratio of tramadol to carprofen is about 3:1 to 10:1.

[0124] In certain embodiments, the pharmaceutical compositions of the present invention comprise both tramadol and flupirtine. In a certain embodiment, the weight ratio of tramadol to flupirtine is about 1:1 to 1:5.

[0125] In certain embodiments, the pharmaceutical compositions of the present invention comprise both tramadol and codeine or oxycodone. In a certain embodiment, the weight ratio of tramadol to codeine or oxycodone is about 1:20 to about 20:1, such as about 1:2 to about 2:1 and about 1:1 to 2:1.

[0126] In certain embodiments, the pharmaceutical compositions of the present invention comprise both tramadol and a NSAID, wherein the weight ratio of tramadol to the NSAID is about 1:1 to about 1:200, from about 1:2 to about 1:200, and about 1:2 to about 1:20.

[0127] In certain embodiments, the pharmaceutical compositions of the present invention comprise both tramadol and a calcium channel antagonist (e.g., nimodipine, nicardipine, nifedipine, diltiazem, verapamil, gallopamil, flunarizine, and cinnarizine). In a certain embodiment, the weight ration of tramadol to the calcium channel antagonist is about 200:1 to about 5:1.

[0128] In certain embodiments, the tramadol-containing pharmaceutical compositions of the present invention further comprise ketoprofen, cyproheptadine (serotonin antagonist), prozosin (.alpha.-1-adrenoceptor antagonist), clonidine (.alpha.-2-adrenoceptor agonist), clomipramine (selective inhibitor of serotonin neuronal uptake), or xylamine (selective irreversible inhibitor of norepinephrine uptake).

[0129] In certain embodiments, the pharmaceutical compositions of the present invention comprise glucosamine and an analgesic, such as a NSAID. Exemplary NSAIDs include, but are not limited to, aspirin; phenylbutazone, oxyphenbutazone, antipyrine, aminopyrine, dipyrone and apazone; indomethacin; sulindac; fenamates such as mefenamic, meclofenamic, flufenamic, tolfenamic and etofenamice acids; aryl acetic acid and propionic acid compounds such as 2-(p-isobutylphenyl)propionic acid (ibuprofen); alphamethyl-4-(2-thienylc-arbonyl) benzene acetic acid (suprofen); 4,5-diphenyl-2-oxazole propionic acid (oxprozin); rac-6-chloro-alphamethyl-carbazole-2-acetic acid (carprofen); 2-(3-phenyloxyphenyl)-propionic acid, particularly the calcium salt dihydrate thereof (fenoprofen and fenoprofen calcium); 2-(6-methoxy-2-naphthyl) propionic acid (naproxen); 4-(1,3-dihydro-1-oxo-2H-isoindol-2-yl)-.alpha.-methylbenzene acetic acid (indoprofen); 2-(3-benzoylphenyl)propionic acid (ketoprofen); and 2-(2-fluoro-4-biphenylyl) propionic acid (flurbiprofen) and 1-5-(4-methylbenzoyl)-1H-pyrrole-2-acetic acid (tolmetin). Additional exemplary NSAIDs are compounds within the class including sodium 5-(4-chlorobenzoyl)-1,4-dimethyl-1H-pyrrole-2-acetate dihydrate (zomepirac sodium); 4-hydroxy-2-methyl-N-(2-pyridyl-2H-1,2-benzothiazine-3-carboxamide-1,1-di- oxide (piroxicam); 2',4'-difluoro-4-hydroxy-3-biphen-ylcarboxylic acid (diflunisal) or 1-isopropyl-7-methyl-4-phenyl-2(1H)-quin-ozolinone (proquazone), and Cox-2 inhibitors such as rofecoxib and celecoxib.

[0130] In certain embodiments, the weight ratio of glucosamine to the analgesic in the above pharmaceutical compositions is from about 1:10 to about 100:1, such as from about 1:1 to about 20:1, and about 1:2 to about 10:1.

[0131] In certain embodiments, the glucosamine-containing pharmaceutical compositions of the present invention further comprise ibuprofen, diclofenac, tramadol, or acetaminophen. In certain embodiments, the weight ratio of glucosamine to ibuprofen, diclofenac, tramadol, or acetaminophen is from about 1:10 to about 100:1, such as from about 1:1 to about 20:1, and about 1:2 to about 10:1.

[0132] In certain embodiments, the pharmaceutical composition of the present invention comprises glucosamine (e.g., glucosamine hydrochloride and glucosamine sulfate), hydrolyzed collagen, and a bioflavanol (e.g., proanthocyanidin, leucocyanidin, pcynogenol, and those extracted from grape seeds, pine bark or turmeric root).

[0133] B. Wax-Like Agents

[0134] The compositions of the present invention also comprise a wax-like agent that is a pharmaceutically acceptable material capable of forming, together with the active ingredient and spheronizing agent, spherical or non-spherical pellets, and providing sustained release of the active ingredient.

[0135] A "wax-like agent," as used herein, refers to a natural, semi-synthetic or synthetic material that is plastic (i.e., malleable) at normal ambient temperatures (i.e., 20-25.degree. C.), has a melting point above 40.degree. C., is very slightly soluble, practically Insoluble, or insoluble in water (e.g., having a water-solubility lower than about 1:5000 (w/w)), and is composed of an ester of a fatty alcohol and saturated and unsaturated fatty acid(s), saturated and unsaturated fatty acid glyceride (mono-, di- or triglyceride), hydrogenated fat, hydrogenated vegetable oil, cholesterol, hydrocarbon, hydrophobic polymer having a hydrocarbon backbone, hydrophilic polymer having a hydrocarbon backbone, or a combination of one or more of the above-listed compounds.

[0136] A wax-like agent, as used herein, includes commonly known wax, such as animal and insect waxes (e.g., beeswax, Chinese wax, shellac wax, spermaceti wax, lanolin wax), vegetable waxes (e.g., bayberry wax, candelilla wax, camauba wax, castor wax, esparto wax, Japan was, jojoba oil, ouricury wax, rice bran wax), mineral waxes (e.g., ceresin waxes, montan wax extracted from lignite and brown coal, ozocerite, peat waxes), petroleum waxes (e.g., paraffin wax, microcrystalline wax), and synthetic waxes (e.g., polyethylene waxes, Fischer-Tropsch waxes, chemically modified waxes (e.g., esterified or saponified waxes), substituted amide waxes, and polymerized .alpha.-olefins). In certain embodiments, the wax is an ester of ethylene glycol and two fatty acids.

[0137] The term "pharmaceutically acceptable," as used herein, refers to being compatible with other ingredients of the composition and not deleterious to the recipient thereof.

[0138] In certain embodiments, the wax-like agent is thermoplastic with a melting point above 40.degree. C. (e.g., above 45.degree. C.), and below 120.degree. C. (e.g., below 110.degree. C.), including any value between 40.degree. C. and 120.degree. C. in certain embodiments, the wax-like agent has a melting point in a range formed by any two values between 40.degree. C. and 120.degree. C., such as between 50.degree. and 100.degree. C.,

[0139] To meet the desire for sustained release, the wax-like agent should be substantially non-degradable and insoluble in gastrointestinal fluids under the relevant time frame (e.g., for 10-12 hours when used in composition that provides sustained release for twice per day administration) and at least under the initial release phase (e.g., the first hour, the first two hours, or the first three hours).

[0140] In certain embodiments, the wax-like agent is hydrogenated vegetable oils, such as hydrogenated cottonseed oil, partially hydrogenated cottonseed oil, hydrogenated soybean oil, partially hydrogenated soybean oil, and stearyl alcohol.

[0141] In certain embodiments, the wax-like agent is present in the composition in an amount of at least about 1%, 2%, 3%, 4%, 5%, 6%, 7%, 8%, 9%, or 10% of the total weight of the composition. In certain embodiments, the wax-like agent is present in an amount of at most about 15%, 20%, 25%, 30%, 35%, 40%, 45%, or 50% of the total weight of the composition. In certain embodiments, the wax-like agent is present in the range of from about 1% to about 40%, such as from about 1% to about 30%, from about 5% to about 40%, from about 5% to about 40%, or any other range between any one of the above-noted minimum amount and any one of the above-noted maximum amount, w/w relative to the total weight of the composition.

[0142] C. Spheronizing Agent

[0143] The compositions of the present invention further comprise a spheronizing agent that is a pharmaceutically acceptable material capable of forming, together with the wax-like sustained release agent and active ingredient, spherical and non-spherical pellets.

[0144] A "spheronizing agent," as used herein, refers to an agent that together with an active ingredient and a wax-like agent, forms a cohesive plastic mass that may be subsequently spheronized to produce spherical pellets or fragmented to form non-spherical pellets.

[0145] In certain embodiments, the spheronizing agent is microcrystalline cellulose, such as the product sold under the tradename "AVICEL.TM.." Other exemplary spheronizing agents include sodium carboxymethylcellulose, pregelatinized starch (e.g., pregelatinized corn starch). In certain embodiment, the spheronizing agent is a combination of microcrystalline cellulose and pregelatinized starch.

[0146] In certain embodiments, the spheronizing agent (e.g., microcrystalline cellulose or a combination of microcrystalline cellulose and pregelatinized starch) is present in the composition in an amount of at least about 1%, 2%, 3%, 4%, 5%, 6%, 7%, 8%, 9%, or 10% of the total weight of the composition. In certain embodiments, the spheronizing agent is present in an amount of at most about 11%, 12%, 13%, 14%, 16%, 18%, 20%, 25%, 30%, 35%, 40%, 45%, or 50% of the total weight of the composition. In certain embodiments, the spheronizing agent is present in the range from about 5% to about 40%, such as about 5% to about 20%, from about 8% to about 15%, or from about 9% to about 12%, or any other range between any one of the above-noted minimum amount and any one of the above-noted maximum amount, w/w relative to the total weight of the composition.

[0147] D. Sustained Release

[0148] The composition of the present invention provides sustained release of the active ingredient.

[0149] The term "sustained release," as used in describing the present invention, refers to the release of the active ingredient more slowly than that from an immediate release dosage form. The term may be used interchangeably with "slow-release," "controlled release," or "extended release." The sustained release property of a composition is typically measured by an in vitro dissolution method and confirmed by an in vivo blood concentration-time profile (i.e., a pharmacokinetic profile).

[0150] The term "Immediate release dosage forms" refers to release forms wherein at least 75% of the active ingredient is released or dissolved within about one-half hour after administration. Such immediate release dosage forms include tablets, capsules, multiparticulates, powders for oral suspension and sachets of an active ingredient. Examples of immediate release dosage forms include, but are not limited to, commercially available various glucosamine tablet and capsule products as described herein in Example 3.

[0151] In certain embodiments, the pharmaceutical compositions of the present invention a 2-phase release profile, where the first phase releases 10-60% of the active ingredient in about 1 hour and the second phase releases the rest of the active ingredient, in a nearly linear fashion, for at least about 2, 3, 4, 5, 6, 7, 8, 9, 10, 11, 12, 14, 16, 18, 20, 22, or 24 hours. A pharmaceutically active agent is released in a "nearly linear" fashion for a specified period of time if the release rate of the agent does not change more than 20% during any hour within the specified period of time.

[0152] In certain embodiments, the composition has an in vitro dissolution rate measured by standard USP basket method according to Example 3 of: about 10% to about 60% of the active ingredient released after 1 hour; about 20% to about 70% of the active ingredient released after 2 hours; about 30% to about 80% of the active ingredient released after 4 hours; about 40% to about 90% of the active ingredient release after 8 hours; and about 50% to about 100% of the active ingredient release after 12 hours. In certain embodiments, the active ingredient is glucosamine or a pharmaceutically acceptable salt thereof.

[0153] In certain embodiments, the composition has an in vitro dissolution rate measured by standard USP basket method according to Example 3 of: about 0% to about 30% after 2 hours; about 5% to about 35% after 4 hours, about 10% to about 40% after 8 hours; about 15% to about 45% after 16 hours; about 20% to about 50% after 24 hours. In certain embodiments, the active ingredient is tramadol or a pharmaceutically acceptable salt thereof.

[0154] In certain embodiments, the composition has an in vitro dissolution rate measured by standard USP basket method according to Example 3 of at most about 20%, 30%, 40%, 50%, 60%, 70%, 80%, or 90% of the active ingredient released after 2, 3, 4, 5, 6, 7, 8, 9, 10, 12, 14, 16, 18, 20, 22, or 24 hours.

[0155] In certain embodiments, the pharmaceutical composition of the present invention, upon oral administration to a human or non-human patient in need thereof, provides release of its active ingredient at such a rate that the blood level of the active ingredient in the patient is maintained within the therapeutic range (i.e., at or above minimum effective concentration (MEC) but below toxic levels) for at least about 8, 9, 10, 11, 12, 13, 14, 15, 16, 17, 18, 19, 20, 21, 22, 23, 24, 36, 48, 72, 96, 120, 144, or 168 hours.

[0156] The MEC of a pharmaceutically active agent of interest in a human or non-human patient may be determined using appropriate techniques known in the art (see, e.g., Grond et al., British Journal of Clinical Pharmacology 48: 254-7, 1999; and Lehmann et al Clinical Journal of Pain 6: 212-20, 1990 for determining the MEC of tramadol in humans).

[0157] In certain embodiments, the composition of the present invention, when administered orally to a patient in need thereof at the equivalent daily dose of an immediate release formulation, provides a plasma concentration of its active ingredient at or above its minimum effective concentration for a period of time at least about the same as, or about 2, 3, 4, or 5 times of, that of the immediate release formulation administered at a daily standard dose (i.e., the daily dose according to the official product description for the formulation or the dose approved by a regulatory authority (e.g., the U.S. FDA) for the formulation).

[0158] E. Physical Form-Pellets

[0159] In certain embodiments, the composition of the present invention is in the form of pellets.

[0160] The term "pellets" refers to small particles with approximately uniform shapes and sizes. A "small particle" refers to a particle of which diameter, length, height, width, or the like is at most 10 mm (e.g., at most 2, 3, 4, 5, 6, 7, 8, or 9 mm). Small particles have approximately uniform sizes if the diameter, length, height, width, or the like of the smallest particle is at least about one half of the average diameter, length, height, width, or the like of the particles and if the diameter, length, height, width, or the like of the largest particle is at most about twice the average diameter, length, height, width, or the like of the particles.

[0161] In certain embodiments, the composition of the present invention is in the form of spherical pellets. The term "spherical pellet" refers to pellets, beads, particles, spheroids or the like that are of round or about round shape (i.e., having or approaching the shape of a small sphere).

[0162] In certain embodiments, the spherical pellets have a smooth surface texture. Such physical characteristics lead to excellent flow properties, improved "mouth feel," ease of swallowing and ease of uniform coating, if required.

[0163] In certain embodiments, the average size (i.e., the average diameter) of the spherical pellets according to this invention may be about 0.1 mm to about 3 mm, including any range formed by any two values between about 0.1 mm and about 3 mm, such as from about 0.5 mm to about 2 mm, or from 0.5 mm to about 1.5 mm. In certain embodiments, the average size of the spherical pellets is about 1 mm. In certain embodiments, the average size of the spherical pellets is at least about 0.2, 0.4, 0.5, 0.6, 0.8, 1, 1.2, 1.4, or 1.5 mm.

[0164] In certain embodiments, the sizes of the spherical pellets according to this invention vary within a range of at most about 5%, 10%, 15%, or 20%, In other words, in certain embodiments, the diameters of the spherical pellets according to this invention vary within a range of at most about 5%, 10%, 15%, or 20%. Narrow size variations provide pellets with sufficient spherical homogeneity so that they can conveniently be coated for identification, stability, taste masking, delayed release or sustained or controlled release applications. Additionally, the narrow size variations allow such pellets to have a coating of homogeneous thickness.

[0165] In certain embodiments, the size distribution of the spherical pellets may vary in a statistical manner. For example, the size distribution may be in a bell-shaped curve wherein about 90% or about 95% of the number of pellets are within a size range that varies between about 10% to about 20% of the average sizes mentioned above.

[0166] In certain embodiments, the composition of the present invention may be in the form of non-spherical pellets (i.e., in the form other than spherical pellets), such as cylindrical pellets. In certain embodiments, the cylindrical pellets may a height from about the same to about 2-3 times of the cylinder diameter. In certain embodiments, the average cylinder diameter is about 0.1 mm to about 3 mm, including any range formed by any two values between about 0.1 mm and about 3 mm, such as from about 0.5 mm to about 2 mm, or from 0.5 mm to about 1.5 mm. In certain embodiments, the average cylinder diameter of the cylindrical pellets is about 1 mm. In certain embodiments, the heights of the non-spherical pellets are about the same.

[0167] The pellets according to the invention have low water content. In particular embodiments, the water contents in the pellets is lower than about 5%, 4%, 3%, or 2% of the total weight of the dry pellets.

[0168] F. Additional Ingredients and Coating

[0169] Optionally, the composition of the present invention may comprise one or more pharmaceutically acceptable inactive ingredients, including binders, antioxidants, and colorants.

[0170] Suitable binders include water-soluble hydroxyalkyl celluloses such as hydroxypropyl cellulose, hydroxypropyl methylcellulose (HPMC), sodium carboxymethylcellulose sodium (CMC), or water insoluble polymers, such as pre-gelatinized starch (e.g., STARCH 1500M by Colorcon), acrylic polymers or copolymers, or alkyl celluloses such as ethyl cellulose.

[0171] Suitable antioxidants include butylated hydroxyanisole (BHA), butylated hydroxytoluene (BHT), vitamin E or ascorbyl palmitate.

[0172] Suitable colorants may be selected from any FD&C pigments, dyes or lakes.

[0173] In certain embodiments, these other ingredients may be present in the pellets at most about 30%, 20%, 10%, or 5% of the total weight of the dry pellets.

[0174] In certain embodiments, the composition of the present invention provides sustained release of an active ingredient without the need of a sustained release barrier coating. In other words, the matrix of the pellets alone is sufficient in providing sustained release of the active ingredient.

[0175] The term "sustained release barrier coating" refers to a coating on a dosage form (e.g., spherical or non-spherical pellets) that substantially slows the release of the active ingredient of the dosage form. More specifically, the presence of a sustained release barrier coating on a dosage form reduces the in vitro dissolution rate of the active ingredient within the first two hours (measured by the method disclosed herein) at least by about 50%.

[0176] Uncoated sustained release pellets are preferred over coated pellets for lower manufacturing cost and scale-up complexity. A typical sustained release barrier coating for pellets comprises water-insoluble polymers such as ethylcellulose, which is usually applied in an organic solvent or in a proprietary aqueous dispersion (e.g. SURELEASE.RTM. by Colorcon). The organic coating system requires expensive fireproof or explosion-proof equipment and facility and environmental protection measures. The proprietary aqueous dispersion systems are of generally high cost, and because of the greatly increased surface area, pellets need a much high amount of coating on a weight basis compared to tablets. For example, a typical sustained release coating weight for a tablet is about 1-5% of the total weight of the coated tablets whereas pellets would need as high as 20-50% of the total weight of the coated pellets to achieve the same sustained release property (again due to the greater surface area for the pellets). The cost of a proprietary aqueous coating dispersion can therefore become a serious limitation of manufacturing feasibility of a sustained release pellet products. Moreover, pellet coating is normally performed using a fluid bed coater, which is more costly to purchase and to operate than pan coaters conventionally used for tablets.

[0177] Another reason to prefer sustained release matrix pellets over coated pellets is the risk of dose dumping. This phenomenon occurs when there are undesired openings or defects in the coating, which may be caused during manufacturing or by the patient while handling the dosage form, or by non-voluntary chewing on it. Small openings or cracks in the coating mantle causes contact of the interior with body fluids setting a catastrophic release of the active causing a serious safety concern.

[0178] In certain embodiments, the composition of the present invention is not coated with a sustained release barrier coating. Nevertheless, other functional coatings such as taste masking, color barrier (such as for identification), or moisture barrier (such as for improving stability or shelf life) may be applied to the sustained release pellets of this invention. In another example where a non-sustained release coating may be needed is the active ingredient may be too aggressive to the stomach or other parts of the gastro-intestinal system or may be prone to decomposition by gastric juices. In such instances, the active ingredient needs to be kept separated from environmental factors by a suitable technique such as enteric-coating, e.g., by coating the pellets with a layer of polymers that is insoluble at the acidic gastric environment and dissolves only in intestines.

[0179] In certain embodiments, although not required, a sustained release barrier coating may be applied to the pellets of the present invention. The presence of the sustained release barrier coating further slows the release of the active ingredient in the pellets.

[0180] Suitable sustained release coating materials include water-insoluble waxes and polymers such as polymethacrylates (e.g., the EUDRAGIT.TM., polymers) or water insoluble celluloses, such as alkyl celluloses (e.g., ethylcellulose). Optionally, water-soluble polymers such as polyvinylpyrrolidone or water-soluble celluloses such as hydroxypropylmethyl-cellulose or hydroxypropylcellulose may be included. Further components that may be added are water-soluble agents such as polysorbate. In certain embodiment, a suitable plasticizer may also be added. In certain embodiment, the coating material sold under the trade name SURELEASE.TM. (Colorcon), which is a dispersion of ethylcellulose, may be used to form a coating on the pellets of the present invention.

[0181] G. Exemplary Formulations

[0182] Unless otherwise provided, the exemplary formulations described in this subsection may comprise any active ingredient, especially one or more of those specifically described above. In addition, such exemplary formulations are in the form of pellets and provide sustained release of the active ingredient (e.g., having an in vitro dissolution rate of the active ingredient measured by standard USP basket method of at most about 90% of the active ingredient released after 2 hours) without requiring the presence of a sustained release barrier coating on the pellets.

[0183] In certain embodiments, the composition of the present invention in the form of pellets comprises: (a) from about 5% to about 90% of an active ingredient; (b) from about 5% to about 40% of a wax-like agent; and (c) from about 5% to about 40% of a spheronizing agent.

[0184] In certain embodiments, the composition of the present invention in the form of pellets comprises: (a) from about 45% to about 85% of an active ingredient; (b) from about 5% to about 30% of a wax-like agent; and (c) from about 5% to about 30% of a spheronizing agent.

[0185] In certain embodiments, the composition of the present invention in the form of pellets comprises: (a) from about 50% to about 75% of an active ingredient; (b) from about 10% to about 30% of a wax-like agent; and (c) from about 5% to about 20% of a spheronizing agent.

[0186] In certain embodiments, the composition of the present invention in the form of pellets comprises: (a) from about 60% to about 65% of an active ingredient; (b) from about 10% to about 30% of a wax-like agent; and (c) from about 5% to about 20% of a spheronizing agent, in certain embodiments, the composition comprises: (a) from about 45% to about 85% of an analgesic or a pharmaceutically acceptable salt thereof; (b) from about 5% to about 30% of hydrogenated vegetable oil (e.g., hydrogenated cottonseed oil); (c) from about 5% to about 20% of microcrystalline cellulose; and (d) from about 1% to about 10% pregelatinized starch.

[0187] In certain embodiments, the composition comprises: (a) from about 45% to about 85% of a dietary supplement or a pharmaceutically acceptable salt thereof; (b) from about 5% to about 30% of hydrogenated vegetable oil (e.g., hydrogenated cottonseed oil); (c) from about 5% to about 20% of microcrystalline cellulose; and (d) from about 1% to about 10% pregelatinized starch.