Makeup Article

SCHENA; Cecilia Elena ; et al.

U.S. patent application number 17/065677 was filed with the patent office on 2021-04-22 for makeup article. The applicant listed for this patent is CHROMAVIS S.p.A.. Invention is credited to Andrea Rubens SANGALLI, Cecilia Elena SCHENA.

| Application Number | 20210112943 17/065677 |

| Document ID | / |

| Family ID | 1000005146082 |

| Filed Date | 2021-04-22 |

| United States Patent Application | 20210112943 |

| Kind Code | A1 |

| SCHENA; Cecilia Elena ; et al. | April 22, 2021 |

MAKEUP ARTICLE

Abstract

A make-up article (1) comprising a primary terracotta container (2) which directly holds at least one make-up product (3), the area of the primary terracotta container (2), when seen in a plan view, being greater than the area of the make-up product 3 when seen in a plan view, so that the primary container can be easily handled by a user without touching the make-up product.

| Inventors: | SCHENA; Cecilia Elena; (Cesano Boscone (MI), IT) ; SANGALLI; Andrea Rubens; (Crema, IT) | ||||||||||

| Applicant: |

|

||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Family ID: | 1000005146082 | ||||||||||

| Appl. No.: | 17/065677 | ||||||||||

| Filed: | October 8, 2020 |

| Current U.S. Class: | 1/1 |

| Current CPC Class: | A45D 33/006 20130101; A45D 33/20 20130101; A45D 40/22 20130101 |

| International Class: | A45D 33/00 20060101 A45D033/00; A45D 33/20 20060101 A45D033/20; A45D 40/22 20060101 A45D040/22 |

Foreign Application Data

| Date | Code | Application Number |

|---|---|---|

| Oct 17, 2019 | IT | 102019000019202 |

Claims

1. Make-up article (1) comprising a primary terracotta container (2) that directly supports at least one makeup product (3), the area of the primary terracotta container (2), seen in plan view, being greater than the area of the makeup product (3) seen in plan view, so that the primary container can be easily handled by a user without touching the makeup product.

2. The article according to claim 1, further comprising a secondary container (4) made entirely of cardboard, the secondary container (4) being configured to protect the makeup product (3) and presenting at least one part in direct contact with the primary container in terracotta, at least when the secondary container (4) is coupled to the primary container (2).

3. The article according to the claim 1, wherein the secondary container (4) comprises a first foldable flap (6A) and a second foldable flap (6B).

4. Make-up article according to the claim 3, wherein the secondary container (4) comprises a box-shaped element (5) made by folding and gluing the cardboard, the box-shaped element comprising at least a first (5A), a second (5B), a third (5C) and a fourth wall (5D), and/or in which the first (6A) and the second flap (6B) are configured to define a fifth openable wall of the box-shaped element (5).

5. An article according to the claim 4, in which the first (6A) and the second flap (6B) are made in one piece with the box-shaped element (5), and optionally a further flap made in one piece with the box-shaped element is provided (5) which defines a sixth wall (20) of the container.

6. The article according to claim 4, wherein the secondary container (4) comprises a shaped element (7A, 7B) permanently fixed to the primary container (2), the first (6A) and the second flap (6B) being made in one piece with the shaped element (7A, 7B).

7. The article according to claim 1, in which the primary container (2) is slidably housed in the box-shaped element (5) and the box-shaped element comprises a retainer (6F) folded and fixed to the primary container (2) which cooperates with a corresponding counter-stop (5F) of the box-shaped element (5), so as to limit the sliding of the primary container (2) with respect to the box-shaped element (5).

8. The article according to claim 3, wherein the shaped element (7B) comprises a first part (6C) at least partially fixed to the primary container (2) and a cover (6E) hinged (6C) to the first part (6C), the first (6A) and the second flap (6B) extending from said cover (6E).

9. An article according to claim 5, wherein the primary container (2) is slidably housed in the box-shaped element (5), and the primary container has at least one step (2A, 2B, 2C) made in one piece, which cooperates with a part of the box-shaped element (5) to limit the sliding of the primary container with respect to the box-shaped element (5).

10. The article according to claim 1, in which the primary container (2) is a rotating solid, and the secondary container (4) has a tubular conformation, with a first end (10) open and a second end (9) closed.

11. The article according to claim 1, wherein the primary container (2) has a cavity (8) in which the makeup product (3) is housed at least partially.

12. The article according to claim 1, wherein the primary container (2) has a surface decoration made by means of recesses and crests, the surface decoration of the primary container optionally integrating itself with a corresponding decoration made by means of recesses and crests on the cosmetic product (3).

13. The article according to claim 1, wherein the primary container (2) has on its surface at least two distinct cosmetic products (3, 3A), respectively separated by at least a part (2A) of the primary container (2), each cosmetic product being optionally housed in its own cavity (8, 8A).

Description

[0001] This application claims priority to Italian Patent Application No. 102019000019202 filed on Oct. 17, 2019, which is incorporated herein by reference.

FIELD OF THE INVENTION

[0002] The present invention relates to a make-up article.

[0003] More specifically, it relates to a make-up article, such as foundation, eye shadow, blusher, highlighter, face powder, lipstick, bronzer, eyebrow pencil, eyeliner, and mascara.

BACKGROUND ART

[0004] Commonly known make-up articles have a decidedly attractive appearance. However, part of the aesthetics of a make-up product originates from its packaging, which is often very sumptuous and elaborate.

[0005] The disadvantage is that, at present, almost all cosmetic product packaging is made of plastic, which, as is known, is an enemy of the environment.

SUMMARY OF THE INVENTION

[0006] The object of the present invention is to provide a make-up article which is an improvement on the prior art.

[0007] A further object of the invention is to provide a make-up article that is more environmentally friendly than conventional ones.

[0008] This and other objects are achieved by means of a make-up article produced according to the technical teachings of the claims annexed hereto.

BRIEF DESCRIPTION OF THE FIGURES

[0009] Further characteristics and advantages of the invention will become clearer in the description of a preferred but not exclusive embodiment of the device, illustrated--by way of a non-limiting example--in the drawings annexed hereto, in which:

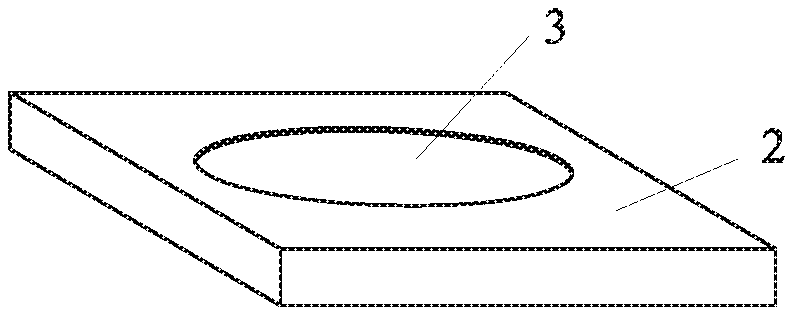

[0010] FIG. 1 is a perspective view of a primary container for the make-up article, according to the present invention;

[0011] FIG. 1A is a partial section of the container in FIG. 1.

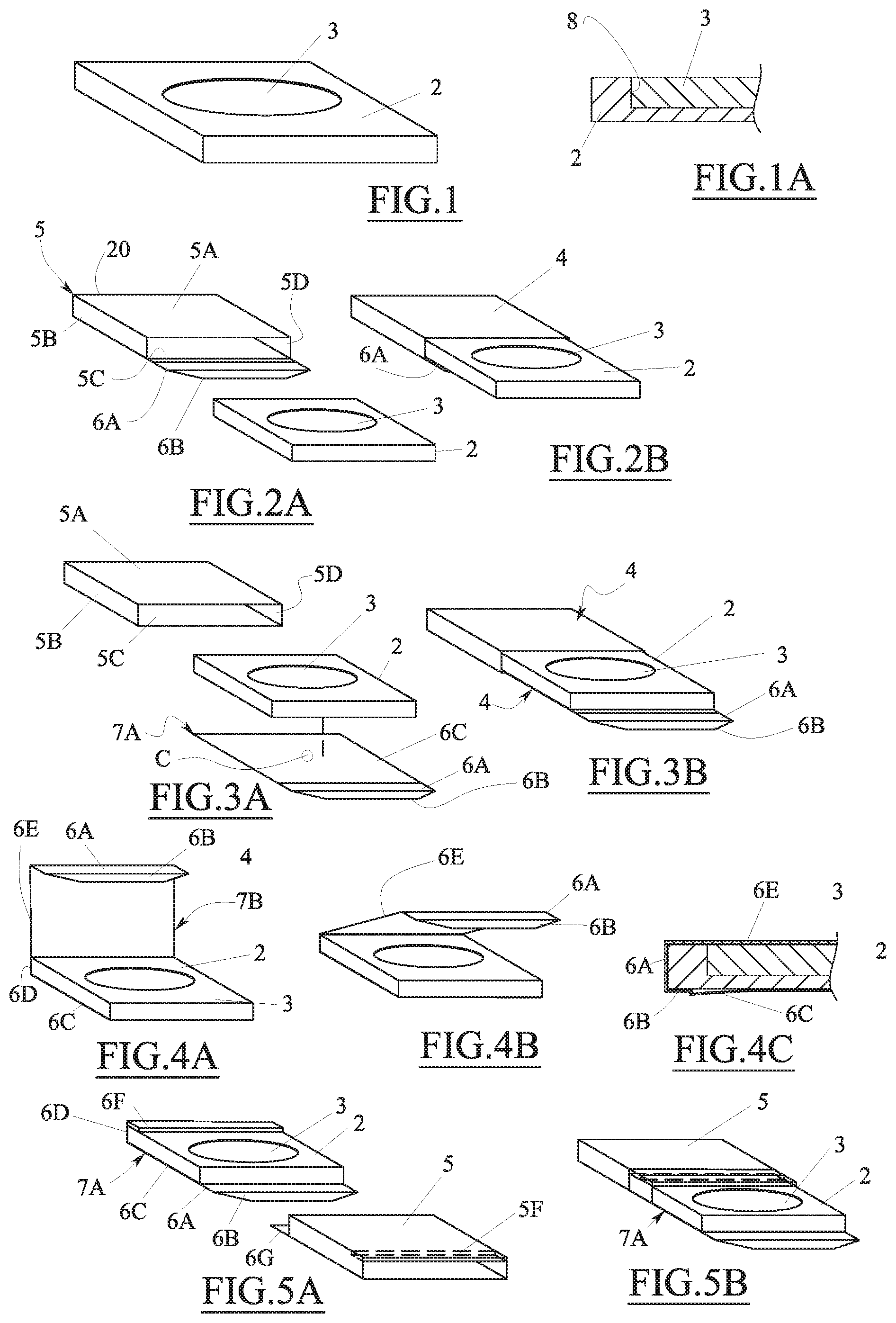

[0012] FIG. 2A is a perspective view of a first embodiment of an article according to the present invention, in a disassembled configuration;

[0013] FIG. 2B is a perspective view of the article in FIG. 2A when partially assembled, before the closure thereof.

[0014] FIG. 3A is an exploded perspective view of a second embodiment of the invention;

[0015] FIG. 3B is a perspective view of the article in FIG. 3A when partially assembled, before the closure thereof;

[0016] FIG. 4A is a perspective view of a third embodiment of the invention, in the use configuration;

[0017] FIG. 4B is a perspective view of the article in FIG. 4A in a partially open configuration;

[0018] FIG. 4C is a partial section view of the article in FIG. 4A in the closed position;

[0019] FIG. 5A is a partially exploded perspective view of a fourth embodiment of the invention;

[0020] FIG. 5B shows the article in FIG. 5A in a use configuration;

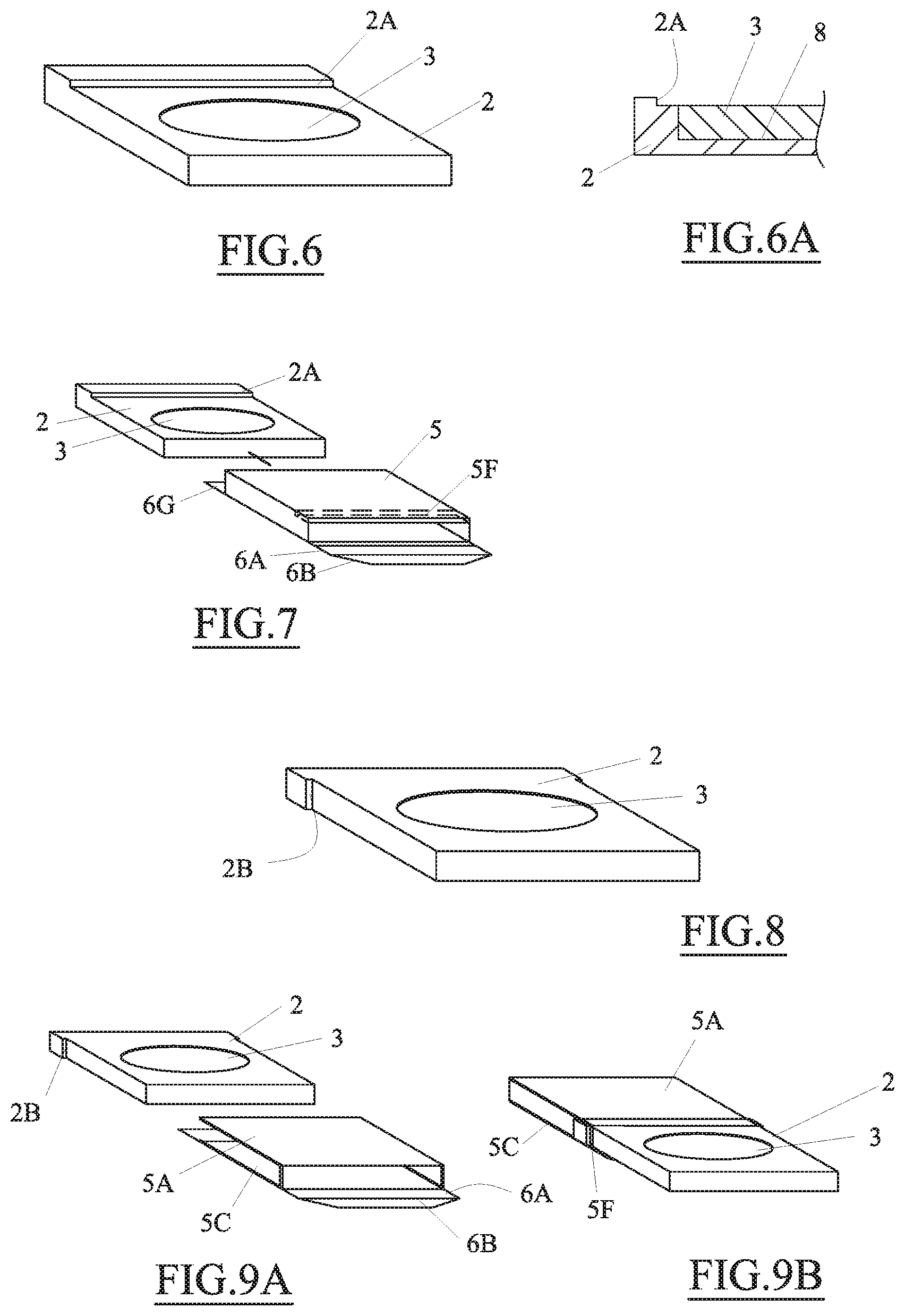

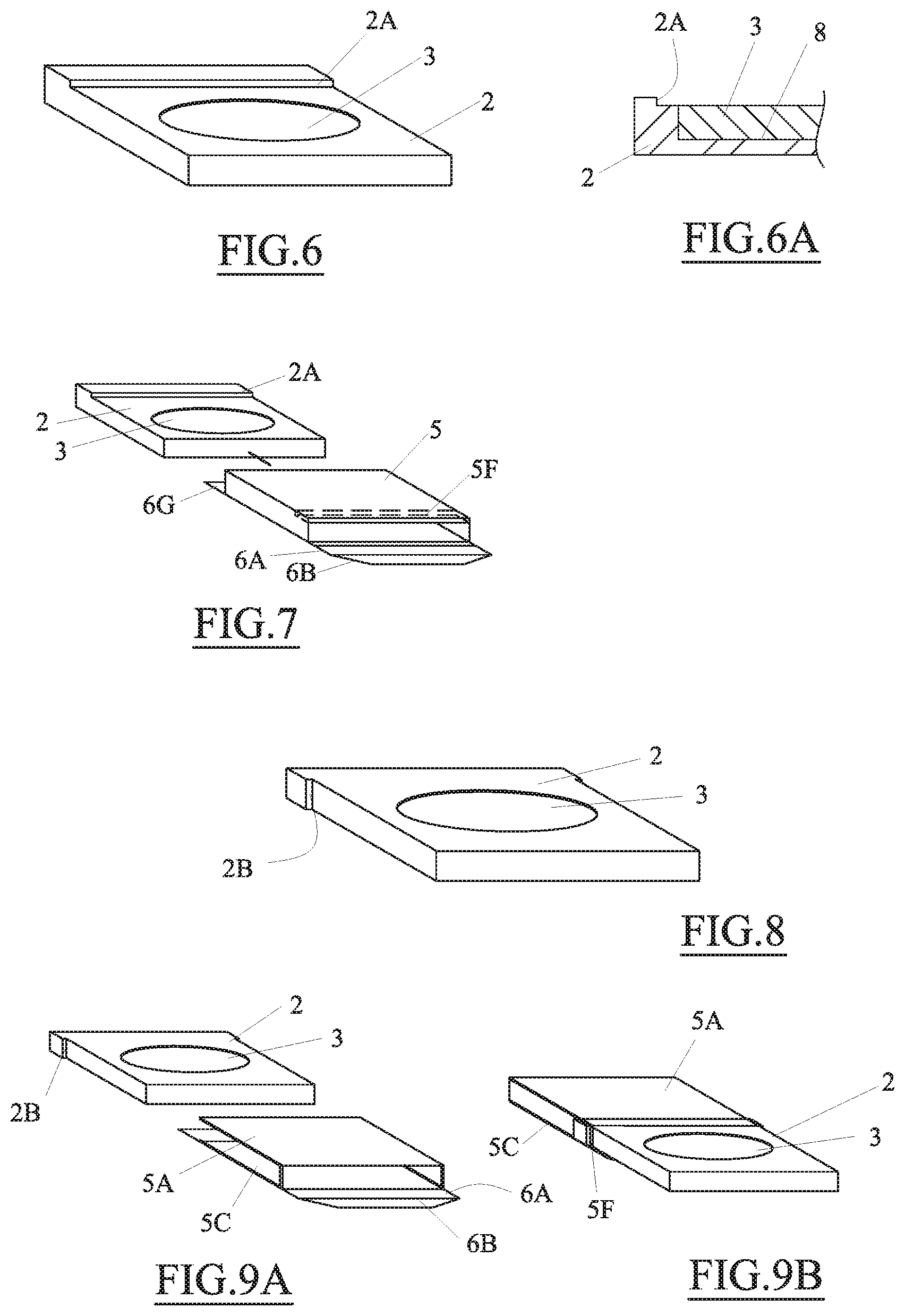

[0021] FIG. 6 shows, in a perspective view, a fifth embodiment of the primary container for the make-up article, according to the present invention;

[0022] FIG. 6A is a partial section view of the container in FIG. 6;

[0023] FIG. 7 is a perspective view of the fifth embodiment of an article according to the present invention, in a disassembled configuration;

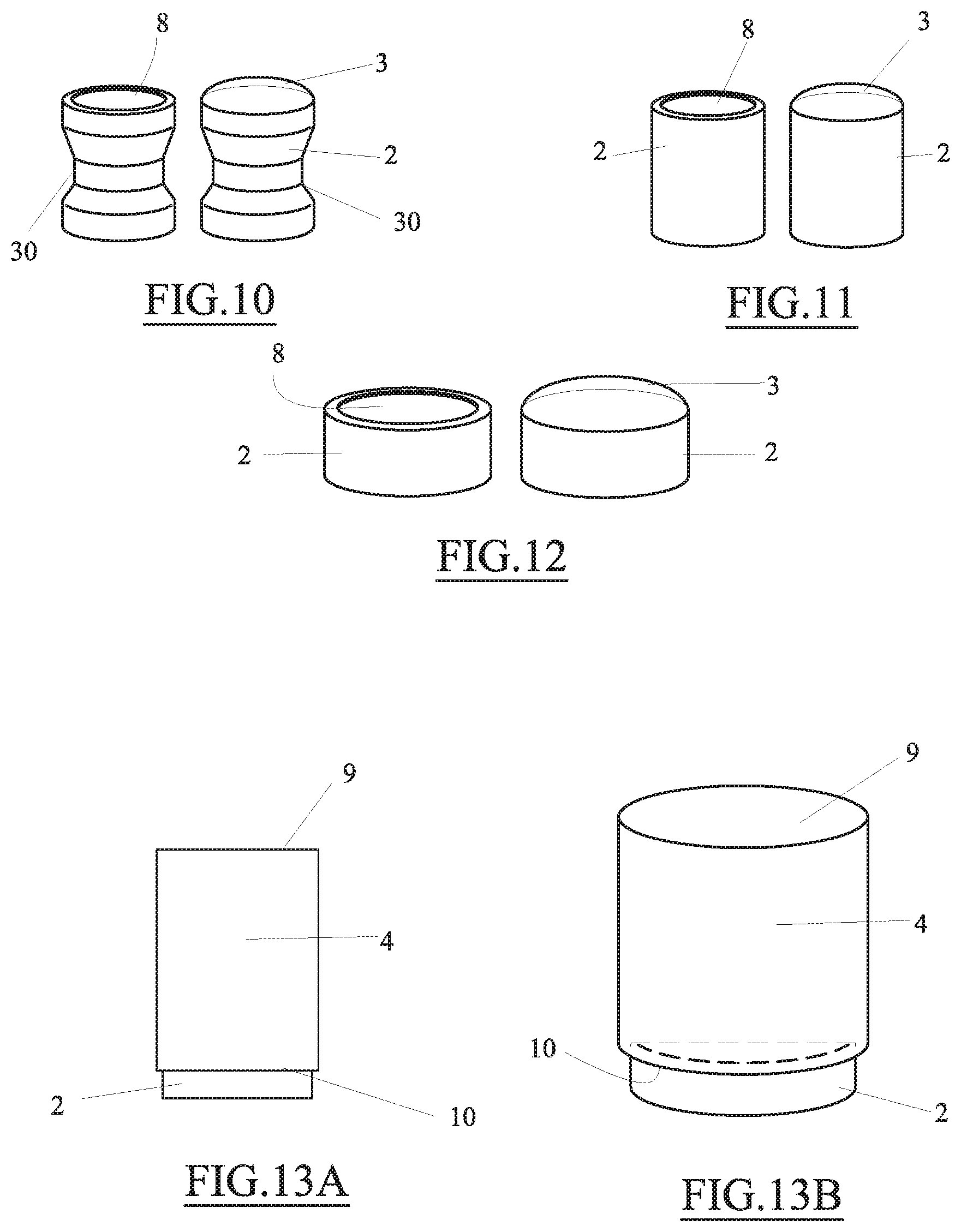

[0024] FIG. 8 shows a perspective view of a sixth embodiment of the primary container for the make-up article, according to the present invention;

[0025] FIG. 9A is a perspective view of the sixth embodiment of an article according to the present invention, in a disassembled configuration;

[0026] FIG. 9B is a perspective view of the sixth embodiment of an article according to the present invention, in the use configuration;

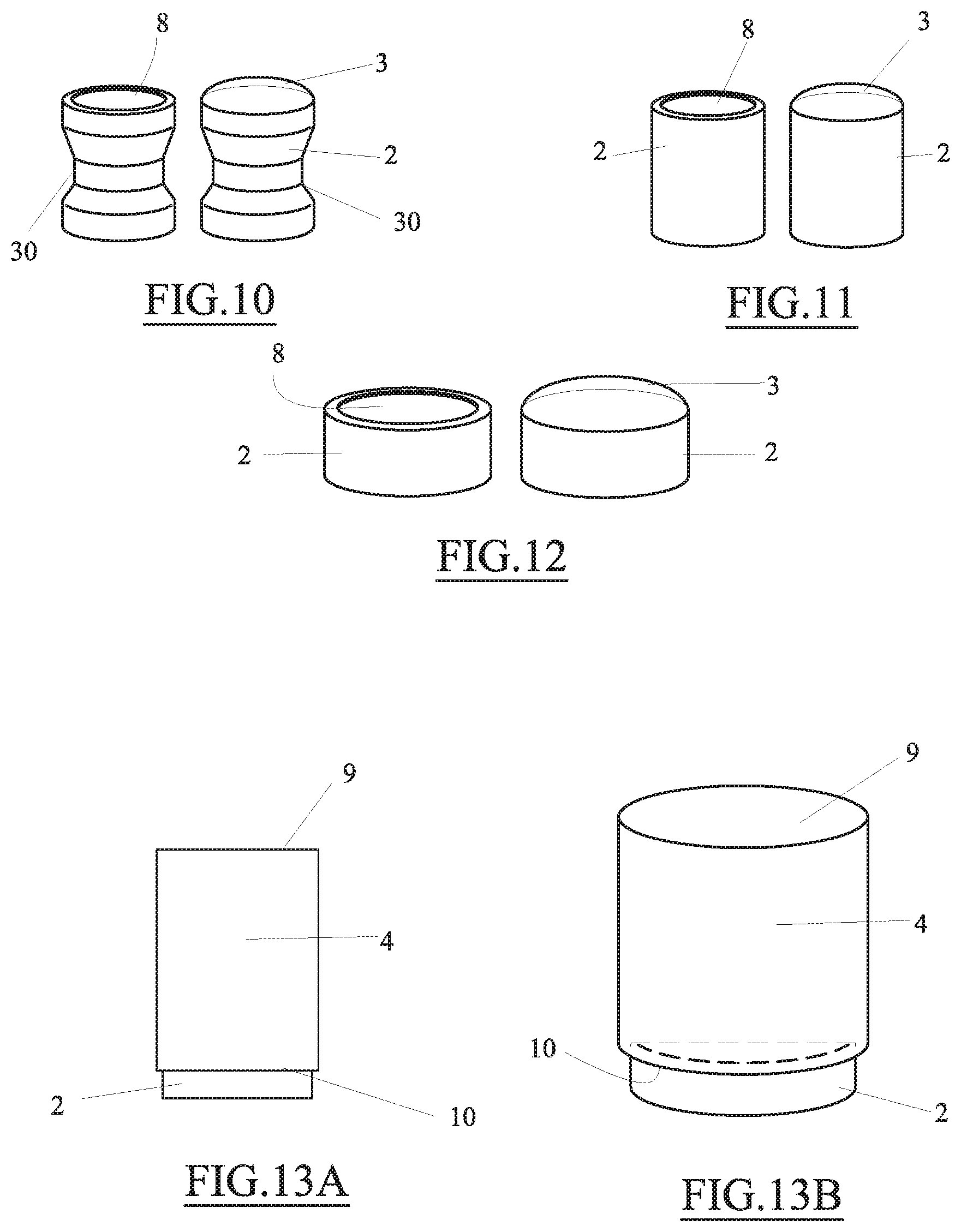

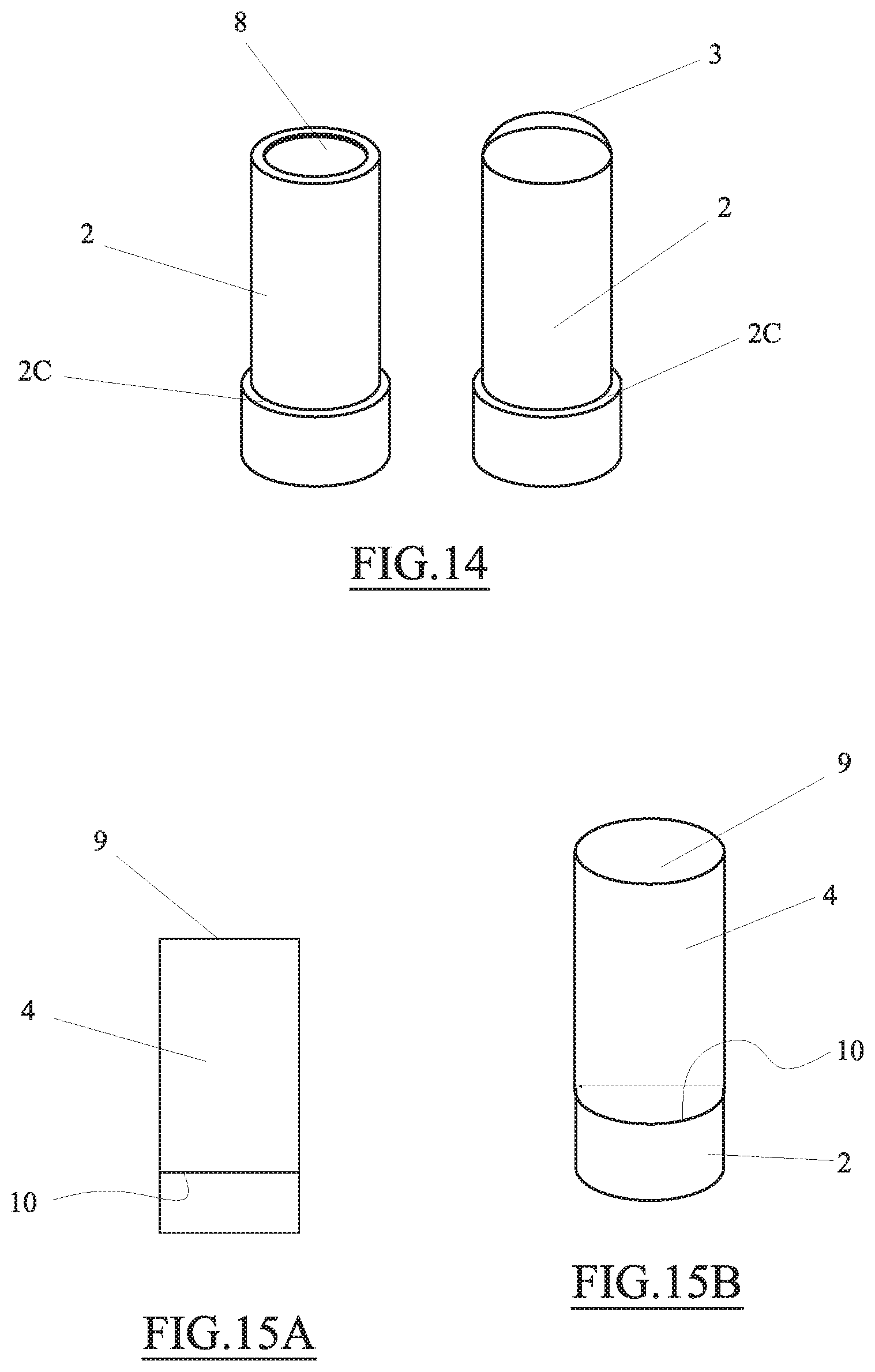

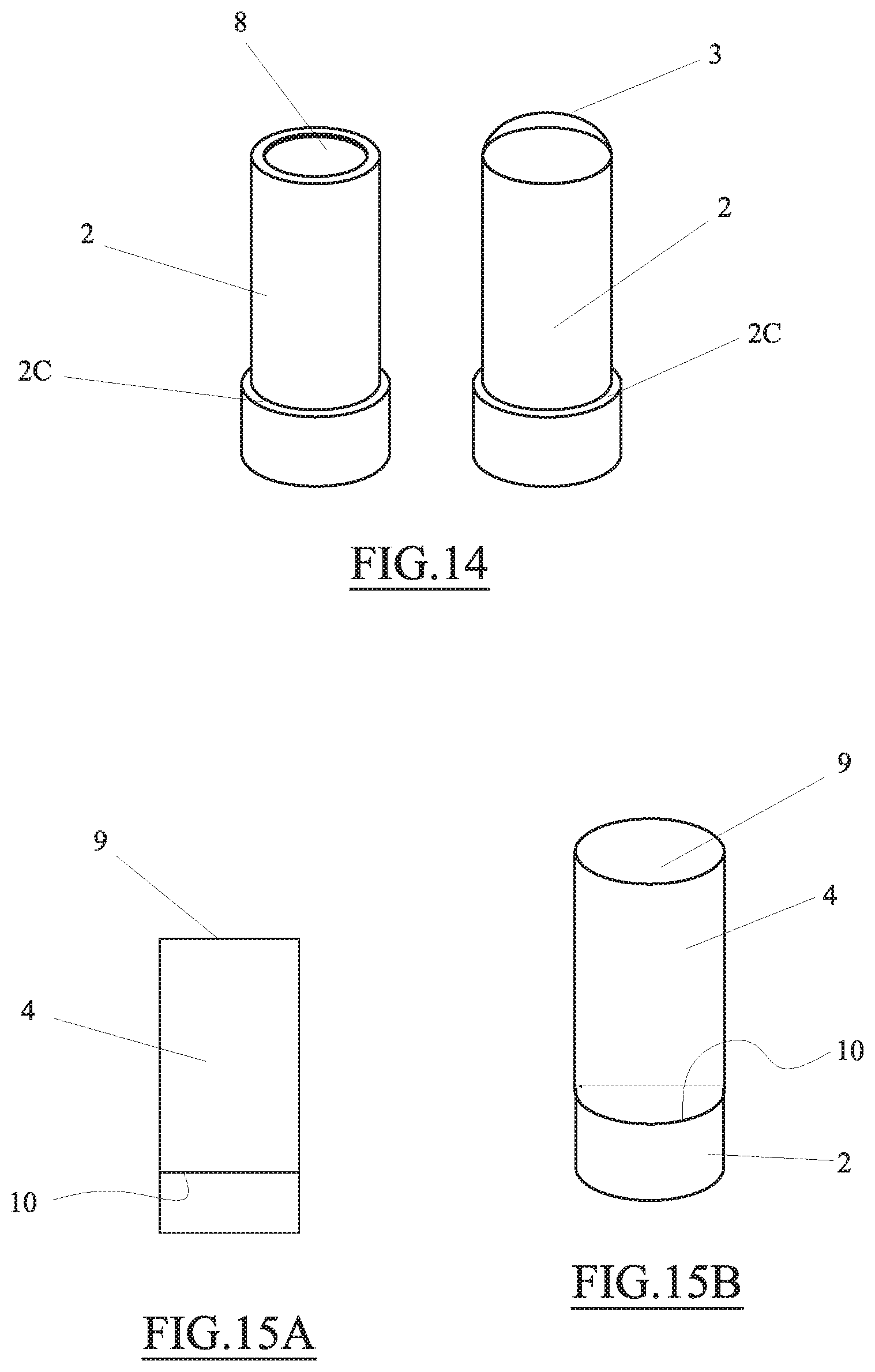

[0027] FIGS. 10 to 12 and FIG. 14 show, in a perspective view, further embodiments of the primary container for the makeup article, according to the present invention;

[0028] FIGS. 13A and 13B show a front and perspective view of the primary containers in FIG. 10 or 11 coupled to the respective secondary container; and

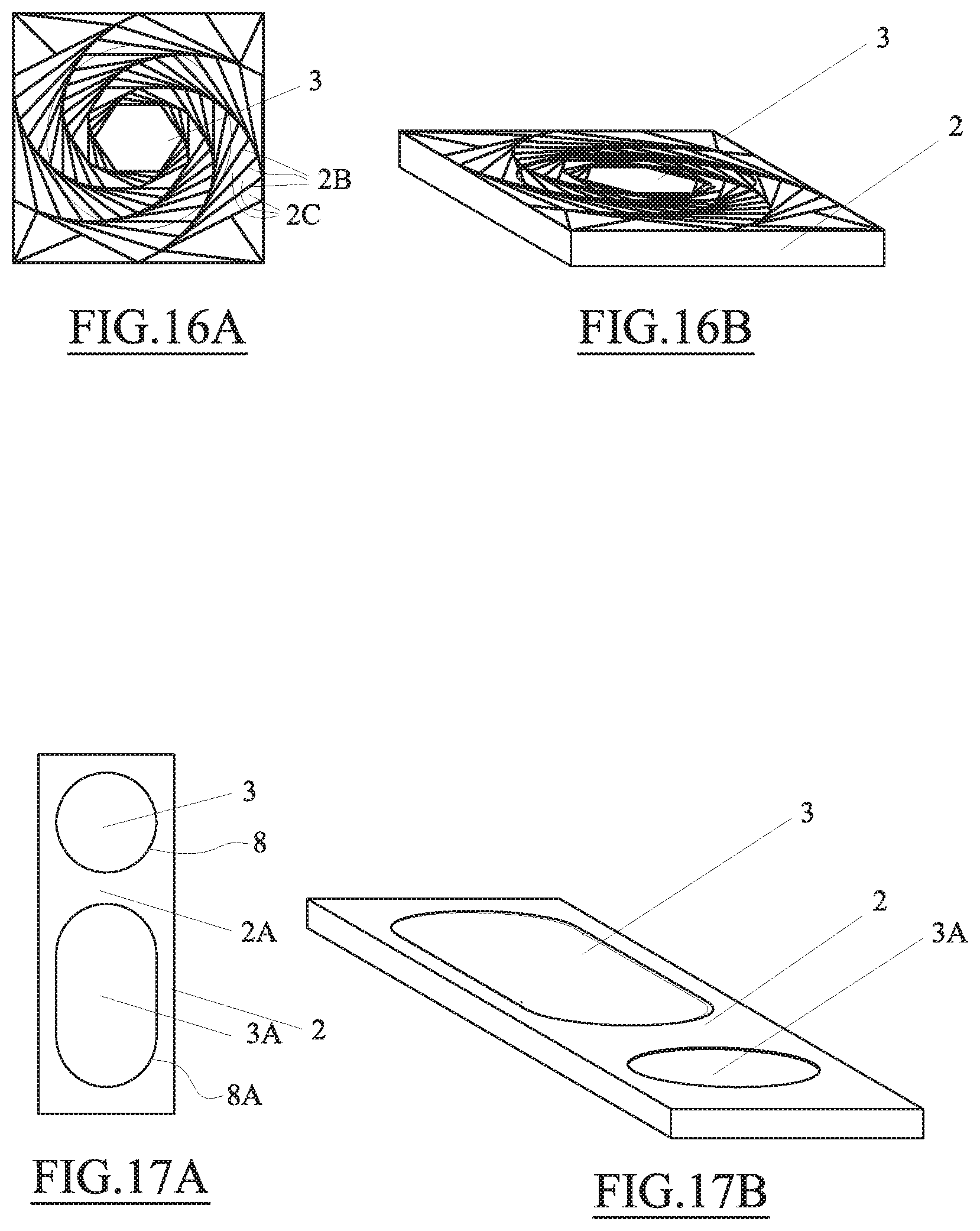

[0029] FIGS. 15A and 15B show a front and perspective view of the primary containers in FIG. 14 coupled to the respective secondary container;

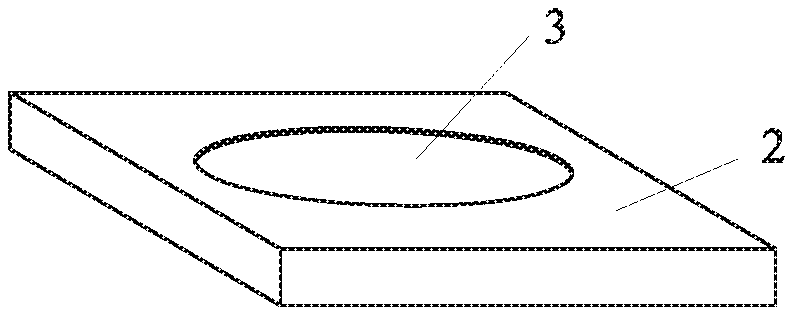

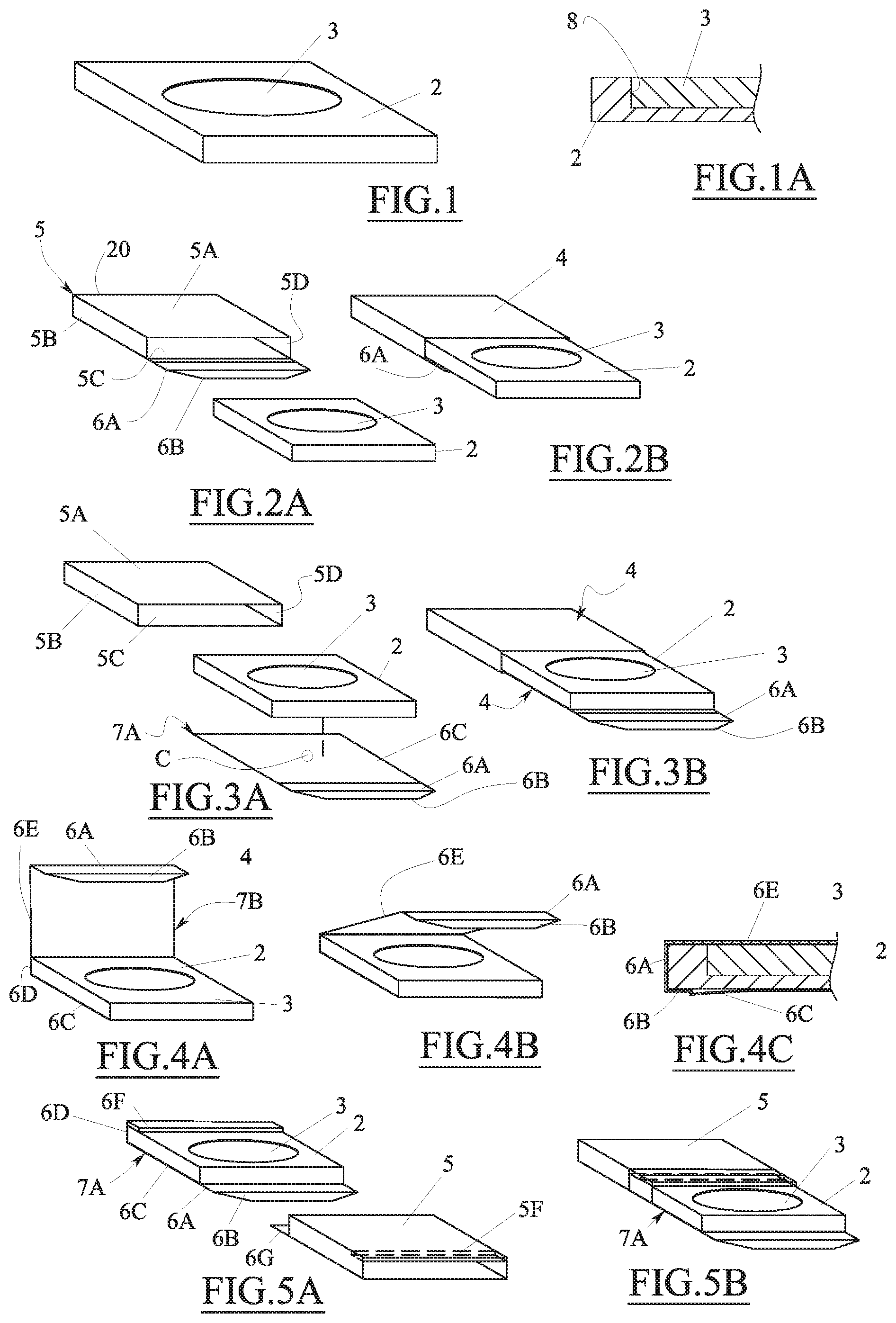

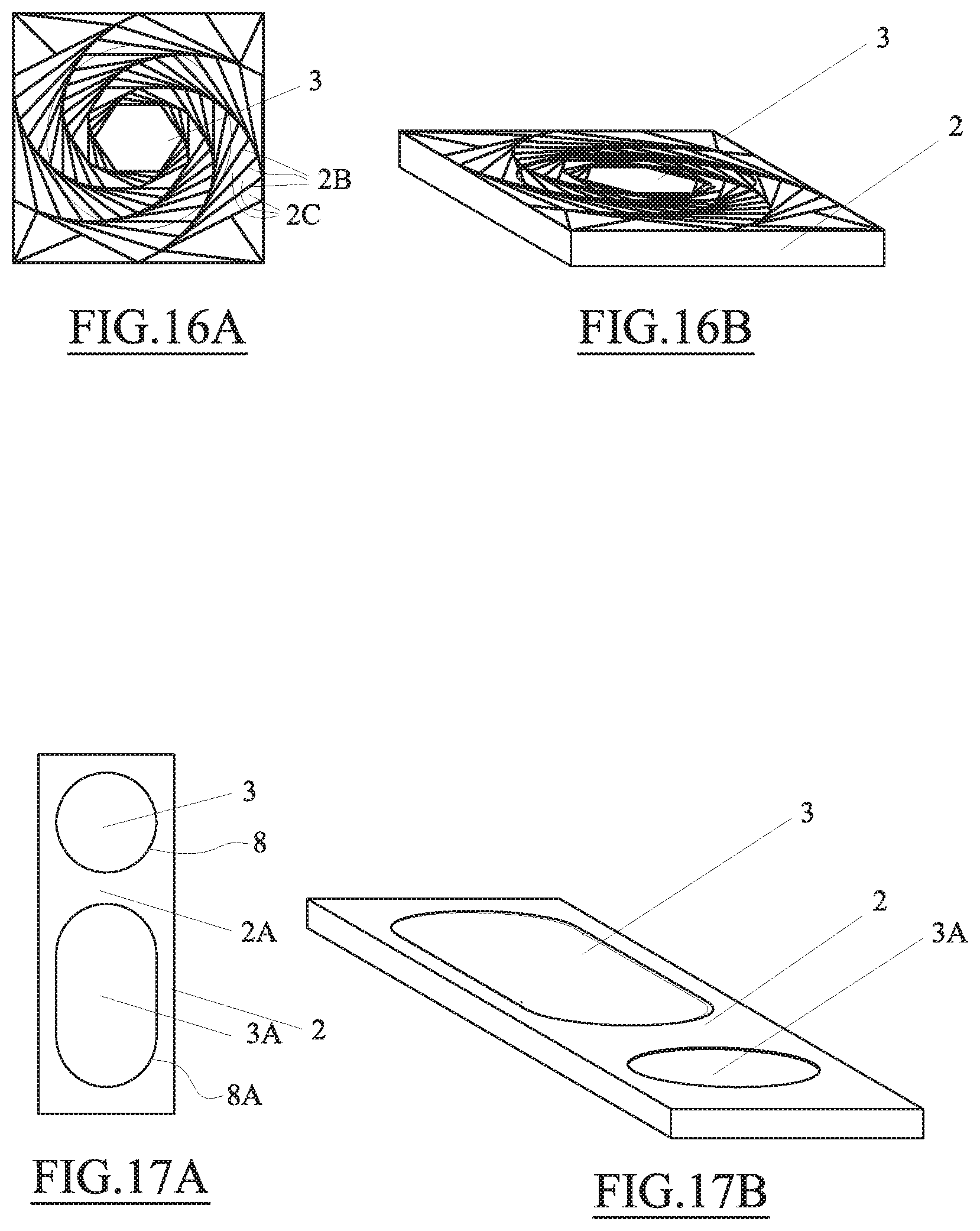

[0030] FIGS. 16A, 16B, 17A and 17B show possible variants of the primary container in FIG. 1.

DETAILED DESCRIPTION OF THE INVENTION

[0031] With reference to the figures stated, reference number 1 is used to denote, as a whole, a make-up article.

[0032] The make-up article 1 comprises a primary terracotta container 2, which directly supports at least one make-up product 3.

[0033] From a plan view, the area of the primary terracotta container 2 is greater than the area of the makeup product 3.

[0034] More specifically, the primary terracotta container 2 has a greater footprint, seen from above, than the make-up product 3.

[0035] In practice, when seen from a top-down plan view, the primary container has greater dimensions than the cosmetic product placed directly thereupon.

[0036] In other words, the primary container 2 extends beyond the perimeter of the make-up product (in the plan view).

[0037] Furthermore, from a plan view, the external perimeter of the primary container is greater and is located outside the perimeter (also from a plan view) of the make-up article.

[0038] In this way, the primary container can be handled easily by a user, who can hold it directly without the risk of touching the make-up product.

[0039] This is possible, for example, by sandwiching the primary container between two fingers (typically the thumb and index finger) which are placed as follows: one on the surface of the primary container in which the make-up product is housed (in the part where the make-up product is not present) and the other on the opposite surface.

[0040] Preferably the make-up product 3 is a cosmetic paste which is poured or placed (depending on the density thereof) directly onto the primary terracotta container 2 while still wet.

[0041] In this document, the term `still wet` means the amount of solvent (which may be for example water, isododecane, alcohol, etc.) present in the cosmetic paste forms a weight percentage of between 10% and 80%, preferably 50%.

[0042] Advantageously, the cosmetic paste is obtained by extrusion, dispensing, or injection.

[0043] The paste can be obtained by mixing at least fats for cosmetic use (for example emulsified fats), powder dyes, and at least one solvent for cosmetic use.

[0044] Preparation of the paste can include the following steps:

[0045] a) preparing components in two different phases, referred to herein as "powder dyes" and "fat emulsion";

[0046] b) mixing the said components;

[0047] c) extruding/dispensing/injecting the paste obtained;

[0048] The "fat emulsion" according to the present invention can be obtained by treating fats for cosmetic use with at least one solvent, for example water or a solvent suitable for cosmetic use, including mixtures thereof; the essential characteristic of the solvent used is that it can be eliminated by drying, after extrusion/dispensing/injection, at temperatures that do not alter the end product, advantageously at temperatures not exceeding 60.degree. C.

[0049] The solvent can be neutral or coloured, the latter case either as a result of specific properties thereof of due to the addition of dyes.

[0050] According to the present invention, the expression "fats for cosmetic use" means any fatty material suitable for the preparation of cosmetics, such as esters of fatty acids, triglycerides, waxes, fruit and seed oil derivatives and extracts, etc.

[0051] The fats for cosmetic use which are useful according to the invention include, for example, sorbitan stearate, isopropyl stearate, caprylic capric triglycerides, dipentacrythrityl hexahydroxystearate/rosinate, stearate (sold under the trade name Cosmol 168AR), magnesium myristate and oil, silicones, etc.

[0052] According to the present invention, the expression "powder dyes" means any powder, or mixture of powders, containing dyeing pigments suitable for cosmetic use.

[0053] Suitable powder dyes include, for example, those obtained by synthesis and/or natural pigments, which may be opaque or pearlescent, with inert powders used as diluents, such as mica or talc, mixed in variable proportions depending on the powder effect and desired dyeing power.

[0054] The dyes (or pearlescent substances) which can be used include the following substances (either alone or in combination):

[0055] TiO2 (Cl 77891)+mica (Cl 77019)

[0056] bismuth oxychloride Cl 77163

[0057] mica Cl 77019

[0058] copper and bronze powder Cl 7740

[0059] iron oxide Cl 77491-2-9

[0060] ultramarine blue Cl 77007

[0061] manganese violet Cl 77.742

[0062] chromium oxide hydrate of Cl 77289

[0063] anhydrous chromium oxide Cl 77288

[0064] ferric ferrocyanide Cl 77510

[0065] titanium dioxide Cl 77891

[0066] D & C red n. 7 lake Ca Cl 15850: 1

[0067] D & C red n. 19 Al lake C145170: 3

[0068] D & C red n. 6 Ba lake Cl 15850: 2

[0069] D & C red n. 3 Al lake C145430: 1

[0070] D & C red n. 9 Ba lake Cl 15585: 1

[0071] D & C red n. 21 Al lake Cl 45380: 3

[0072] D & C red n. 22 Al lake C145380

[0073] D & C red n. 28 Al lake C145410

[0074] D & C yellow n. 5 Al lake Cl 19140: 1

[0075] D & C red n.30 Al lake Cl 73360

[0076] D & C red n.27 Al lake Cl 45410: 2

[0077] D & C yellow n. 5 Al lake Cl 19140: 1

[0078] D & C orange 5 Cl 45370: 1

[0079] FD & C yellow n. 6 Al lake Cl 15985: 1

[0080] FD & C blu n. 1 Al lake Cl 42090: 2

[0081] D & C red n. 36 Cl 12085

Carmine Cl 75470

[0082] Obviously, the paste to be extruded/dispensed/injected can be obtained, for example, either by mixing in each individual component, one after the other, using a mixer, or by first preparing the components in two different phases, namely the "fat emulsion" and the "powder dyes", and then mixing them together.

[0083] The proportions of the individual components may vary considerably depending on the type of product required.

[0084] The "fat emulsion" and the "powder dyes" are preferably mixed in different ratios.

[0085] The extrusion/dispensing/injection can be performed by processing the (neutral or coloured) paste obtained in step (b) with a normal extruder/dispenser/injector to obtain a still wet product of the desired shape but, preferably, with a liquid consistency which therefore renders it highly malleable and pourable.

[0086] The semi-finished product produced following the steps described above is subsequently dried. In particular, the drying step is carried out by placing the cosmetic paste and the primary container in the oven at a temperature of between 30 and 65.degree. C. and for a time between 6 and 24 hours.

[0087] In any case, regardless of the drying technique utilised, it is advantageous for the drying step to continue until the solvent contained in the semi-finished product (i.e. the solvent present in the base paste, preferably water) reaches a residual amount of below 1.5 wt %.

[0088] In this way the cosmetic paste "solidifies", losing moisture, and forms the make-up product.

[0089] The drying step may result in the formation of a light surface crust on the make-up product, which can be removed mechanically using standard techniques.

[0090] It should be stressed that the cosmetic paste is placed directly into the primary container 2, without the interposition of any base, cloth, or other intermediate material.

[0091] Therefore, the cosmetic paste (which will become the make-up product 3 once dry) is in direct contact with the primary container.

[0092] Advantageously, the intrinsic `porosity` of the terracotta allows the cosmetic product to bind to the primary container in a very stable manner

[0093] Furthermore, the fact that the primary container is made of terracotta (which is a porous material) is very important. In practice, during the drying step, the porosity of the said terracotta ensures optimal evaporation of the solvent present in the cosmetic paste, even close to the interface between the makeup product and the primary container 2, thereby resulting in homogeneous evaporation of the solvent in any area of the make-up product 3.

[0094] According to the present invention, the make-up product 3 may simply be placed on top of the primary container, or be partially contained within the primary container, which may have a cavity 8 in which the make-up product 3 is at least partially housed.

[0095] Advantageously, the perimeter of the cavity 8 can have any form, such as that shown in FIG. 1, which has a circular, square, rectangular, star, heart-shaped footprint etc.

[0096] If the primary container 2 has a cavity 8, 8A, the make-up product 3 may be something other than a dried paste, for example, a powder pressed in a conventional way directly into the cavity of the primary container. And therefore, even in this case, the make-up product is in direct contact with the primary container.

[0097] In one configuration of the present invention, the make-up article may comprise a secondary container 4 made of cardboard.

[0098] In this document, the term `cardboard` refers to any material akin to or derived from paper which is thick enough to form a pack with the desired features, such as cardboard proper, paper pulp or cellulose-based materials (e.g. Caudex), etc. These materials may be completely natural, or appropriately treated to take on particular physical characteristics (such as resistance to humidity, etc.) or they can be decorated and coloured in any way. Advantageously, the cardboard used in the present cosmetic article is 100% recyclable.

[0099] The secondary container 4 is configured to protect the make-up product 3 and has at least one part thereof in direct contact with the terracotta primary container 2 when, at least, the secondary container 4 is coupled to the primary container 2.

[0100] The secondary container 4 may comprise a first flap 6A and a second flap 6B, which may be folded.

[0101] As shown in FIG. 2A, the secondary container 4 may comprise a box element 5 made by folding and gluing the cardboard.

[0102] The box element may have an internal volume corresponding in shape and size to that of the primary container 2.

[0103] The box element 5 may comprise at least a first wall 5A, a second wall 5B, a third wall 5C, and a fourth wall 5D.

[0104] The first fin 6A and the second fin 6B may be made integrally with the box element 5, and configured to define a fifth wall, which may be opened, of the box element 5.

[0105] Optionally, the box element may feature a sixth wall 20 which is open. In this way, when the primary container 2 is housed in the box element 5, a wall of the primary container is visible through the open wall 20.

[0106] Alternatively, the box element may have a sixth wall 20, which is closed and is also formed from a folded part of the cardboard (flap) of which the box element is formed.

[0107] In the previous embodiment, as in some of the others which follow, the primary container 2 has a parallelepiped shape. The cavity 8 is not a through cavity.

[0108] Obviously, however, the primary container may be any shape. For example, it may be disk-shaped or similar.

[0109] In the embodiment shown in FIGS. 3A and 3B, in addition to the box element 5, the secondary container 4 comprises a shaped element 7A which is permanently fixed to the primary container 2. The first flap 6A and the second flap 6B are made integrally with the shaped element 7A, 7B.

[0110] The shaped element 7A is made from a single piece of cardboard (preferably of the same type as the box element) and comprises a wall 6C which is fixed (for example by means of glue C) to the lower side (i.e. the side opposite where the makeup product is positioned) of the primary container 2.

[0111] Therefore, the primary container 2 (together with the shaped element 7A) is housed in the box element 5 in a slidable fashion.

[0112] The wall 6C may have a configuration corresponding (in a plan view) to the primary container and the first fin 6A and the second fin 6B may protrude therefrom as part thereof.

[0113] The first flap and the second flap may be folded to form a wall of the box element (when the primary container 2 is completely housed within the box element 5); in the open configuration, the first flap and the second flap also act as a grip (like a tab) to facilitate extraction of the primary container from the box element 5.

[0114] A possible variant of the invention in FIGS. 3A and 3B is shown in FIGS. 5A and 5B.

[0115] Here, the shaped element 7A includes a folded stop 6F fixed (for example again with glue) to the primary container 2.

[0116] For example, a further first wall 6D and the stop 6F (which in practice covers a wall or edge of the primary container 2) may protrude from the part 6C (as a single piece).

[0117] When the primary container 2 is partially extracted from the box element 5, the stop 6F comes into contact with a corresponding counter-stop 5F on the box element 5, which limits how far the primary container 2 slides within the box element 5.

[0118] The counter-stop 5F may be made by folding and gluing (towards the inside of the box element) a flap made integrally with the said box element 5 (for example, protruding from the upper wall 5C.

[0119] A simplified embodiment of the secondary container 4 is shown in FIGS. 4A, 4B, and 4C.

[0120] As previously, the shaped element 7B comprises a first part 6C, which is at least partially fixed to the primary container 2, and a lid 6E hinged 6D to the first part 6C, the first flap 6A and the second flap 6B extending from the said lid 6E.

[0121] Advantageously, the hinging between the first part 6C and the lid 6E is located at a folded portion 6D of the first part 6C, near the primary container 2. It is possible that the folded portion 6D is glued (or fixed in another way) to the primary container.

[0122] FIG. 4C shows, as a detail, how the secondary container 4 in this configuration may be easily closed to protect (through the lid 6E) the make-up product 3.

[0123] More specifically, in the closed configuration, one end of the second flap 6B is wedged between the bottom of the primary container and a free edge of the first part 6C of the secondary container 4. It should be remembered that the first part 6C is fixed to the primary container 2, and exploits the flexibility of the free end thereof to keep the second fin 6B fastened.

[0124] FIGS. 6 and 7 show an improved embodiment of the configuration in FIG. 2A.

[0125] In this case, the secondary terracotta container is shaped in such a way as to also feature a stop (in practice a step 2A), which comes into contact with a part 5F of the box element 5 to limit the sliding of the primary container with respect to the box element 5 (and therefore prevent total extraction of the primary container 2).

[0126] A closure wall 6G may also be featured.

[0127] FIGS. 8, 9A and 9B show an alternative positioning of the step 2B, on the sides of the primary container 2, also housed in the box element 5 in a slidable manner

[0128] In this case, the stop 5F on the box element may be configured to cooperate with the step 2B.

[0129] In FIGS. 10 to 15B, the primary container 2 is a solid of rotation, and the secondary container 4 has a tubular conformation, with a first end 10 open and a second end 9 closed.

[0130] In the closed configuration (as shown in FIGS. 13A and 13B), the secondary container 4 is fitted onto the primary container.

[0131] The primary container 2 may have a cavity 8 in which the make-up product 3 is positioned, which may also have a dome configuration, as shown in FIG. 10, on the right-hand side. The cavity or the make-up product are positioned within a substantially flat surface of the primary container.

[0132] The external shape of the primary container 2 (on the lateral surface) may feature depressions 30 provided for aesthetic purposes, or may be simply cylindrical, as in FIG. 11 (elongated cylinder) or as in FIG. 12 (more squat cylinder).

[0133] FIG. 14 shows a still further different configuration of the primary container 2, which features a stop 2C--on the lateral surface thereof, which comes into contact with a free edge of the secondary container 4, which also has a cylindrical conformation, when the secondary container 4 is fitted onto the primary container (FIGS. 15A and 15B).

[0134] In FIG. 14, one can also see the cavity 8 produced in a flat surface of the primary container 2. Obviously, the conformation of the make-up product 3 can be rounded as in the cases described earlier.

[0135] As shown in FIGS. 16A and 16B, the primary container 2 may have a surface decoration formed of recesses 2B and ridges 2C. In fact, the recesses may simply be grooves 2B made in the flat surface 2C of the primary container. From this point of view, the ridges correspond to the flat non-etched surface (or rather, with grooves).

[0136] In the aforesaid figure, the decoration is a design featuring the sun's rays. This way, the surface decoration (like an etching) on the primary container integrates with the make-up product 3 present, providing a aesthetically pleasing effect (in this case a sun design consisting of the cosmetic product with `rays` extending outwards therefrom `etched` into the terracotta).

[0137] The result is very pleasant from an aesthetic point of view.

[0138] Obviously, the surface decoration (in relief) of the primary container can be integrated with a corresponding decoration, also formed of recesses and ridges (and therefore by etching) in the cosmetic product 3.

[0139] Obviously the decoration of the terracotta or make-up product may be implemented in all the embodiments already described and likewise those described hereafter.

[0140] In FIGS. 17A and 17B it can be seen that the primary container 2 has at least two distinct cosmetic products 3, 3A on its surface, which are separated by at least one part 2A of the primary container.

[0141] Optionally, each cosmetic product may be housed in its own cavity 8, 8A.

[0142] Obviously, the primary container may be housed in any secondary container of those described above (suitably adapted to the shape of the primary container), or others which may easily be derived by a person skilled in the art based on the present invention.

[0143] Various embodiments of the innovation have been described, but others may be conceived using the same innovative concept.

[0144] All the materials used to implement the invention are environmentally sound and recyclable. In fact, the terracotta used for the primary container is natural, while the cardboard of which the secondary container 4 is made (whether it is made as a single piece or in two pieces that cooperate with each other) is environmentally sound and entirely recyclable.

[0145] The glue used (in some embodiments) to fix the primary container to the secondary container may also be an environmentally sound glue.

[0146] Finally it must be again stressed, that in the described embodiments the primary container can be entirely made of terracotta.

* * * * *

D00000

D00001

D00002

D00003

D00004

D00005

XML

uspto.report is an independent third-party trademark research tool that is not affiliated, endorsed, or sponsored by the United States Patent and Trademark Office (USPTO) or any other governmental organization. The information provided by uspto.report is based on publicly available data at the time of writing and is intended for informational purposes only.

While we strive to provide accurate and up-to-date information, we do not guarantee the accuracy, completeness, reliability, or suitability of the information displayed on this site. The use of this site is at your own risk. Any reliance you place on such information is therefore strictly at your own risk.

All official trademark data, including owner information, should be verified by visiting the official USPTO website at www.uspto.gov. This site is not intended to replace professional legal advice and should not be used as a substitute for consulting with a legal professional who is knowledgeable about trademark law.