Fermentation Methods For Producing Steviol Glycoside Using High Ph And Compositions Obtained Therefrom

Anderson; James C. ; et al.

U.S. patent application number 17/029348 was filed with the patent office on 2021-04-08 for fermentation methods for producing steviol glycoside using high ph and compositions obtained therefrom. The applicant listed for this patent is CARGILL, INCORPORATED, EVOLVA, S.A.. Invention is credited to James C. Anderson, Manuel Quiros Asensio, Simon Carlsen, Ting Liu Carlson, Veronique Douchin, Ariene M. Fosmer, Hans Peter Smits.

| Application Number | 20210102229 17/029348 |

| Document ID | / |

| Family ID | 1000005277927 |

| Filed Date | 2021-04-08 |

View All Diagrams

| United States Patent Application | 20210102229 |

| Kind Code | A1 |

| Anderson; James C. ; et al. | April 8, 2021 |

FERMENTATION METHODS FOR PRODUCING STEVIOL GLYCOSIDE USING HIGH PH AND COMPOSITIONS OBTAINED THEREFROM

Abstract

Disclosed are methods for producing steviol glycosides, such as rebaudioside D and rebaudioside M, using engineered yeast. In some embodiments, the methods include fermenting with a yeast at a high pH such as of about 5.8 or greater. In some embodiments, the methods can be carried out by first growing the yeast at a lower first pH, and then adjusting the pH to a higher pH.

| Inventors: | Anderson; James C.; (Eden Prairie, MN) ; Asensio; Manuel Quiros; (Soborg, DK) ; Carlsen; Simon; (Copenhagen, DK) ; Carlson; Ting Liu; (Marietta, SC) ; Douchin; Veronique; (Birkerod, DK) ; Fosmer; Ariene M.; (Eden Prairie, MN) ; Smits; Hans Peter; (Holte, DK) | ||||||||||

| Applicant: |

|

||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Family ID: | 1000005277927 | ||||||||||

| Appl. No.: | 17/029348 | ||||||||||

| Filed: | September 23, 2020 |

Related U.S. Patent Documents

| Application Number | Filing Date | Patent Number | ||

|---|---|---|---|---|

| 15578125 | Nov 29, 2017 | 10815513 | ||

| PCT/US2016/034728 | May 27, 2016 | |||

| 17029348 | ||||

| 62168345 | May 29, 2015 | |||

| Current U.S. Class: | 1/1 |

| Current CPC Class: | A23L 27/36 20160801; A23V 2002/00 20130101; C07H 15/256 20130101; C12P 19/56 20130101 |

| International Class: | C12P 19/56 20060101 C12P019/56; C07H 15/256 20060101 C07H015/256; A23L 27/30 20060101 A23L027/30 |

Claims

1. A method for increasing the production of a first, lower molecular weight steviol glycoside, relative to a second, higher molecular weight steviol glycoside, in an engineered yeast, comprising fermenting the engineered yeast capable of producing the first steviol glycoside and the second steviol glycoside at a pH of 5.8 or greater in a fermentation medium.

2. The method of claim 1, wherein the pH is in the range of 5.8 to 8.

3. The method of claim 1, wherein the pH is in the range of 6.0 to 7.5.

4. The method of claim 1, wherein the pH is in the range of 6.5 to 7.5.

5. The method of claim 1, wherein the pH is in the range of 5.8 to 6.5.

6. The method of claim 1, wherein the pH is in the range of 5.8 to 6.2.

7. The method of claim 1, wherein the fermentation medium comprises a nitrogen source selected from the group consisting of ammonium hydroxide, yeast extract, urea, and ammonium sulfate.

8. The method of claim 7, wherein the nitrogen source comprises 90% (wt) or greater ammonium hydroxide or urea.

9. The method of claim 1, further comprising continuous or batch addition of additional fermentation material to the medium comprising the engineered yeast.

10. The method of claim 1 performed for a period of time of up to 150 hours.

11. The method of claim 10 performed for a period of time in the range of 8 to 88 hours.

12. The method of claim 11 performed for a period of time in the range of 22 to 48 hours.

13. The method of claim 1, wherein the fermentation medium has a biomass in the range of 20-120 g dcw/L.

14. The method of claim 1, wherein the engineered yeast produces a ratio of the first steviol glycoside to the second steviol glycoside at the pH of 5.8 or greater that is increased by 10% or greater than a ratio of the first steviol glycoside to the second steviol glycoside when the engineered yeast are fermented at a pH of 5.0.

15. The method of claim 1, wherein the first steviol glycoside is rebaudioside D, and the second steviol glycoside is rebaudioside M.

16. The method of claim 15, wherein the ratio of rebaudioside D to rebaudioside M is in the range of 1:20 to 1:1.

17. The method of claim 1, further comprising growing the engineered yeast in a first medium at a first pH, wherein the first pH is the same as the pH of the fermentation medium.

18. The method of claim 1, further comprising growing the engineered yeast in a first medium at a first pH, wherein the first pH is lower than the pH of the fermentation medium.

19. The method of claim 18, wherein the first pH is a pH less than 5.8.

20. The method of claim 18, wherein the first pH is a pH less than 5.5.

21. A method for increasing the production of a first, lower molecular weight steviol glycoside relative to a second, higher molecular weight steviol glycoside in an engineered yeast, the method comprising a step of fermenting engineered yeast capable of producing one or more steviol glycoside(s) at a pH of 5.8 or greater in a fermentation medium, wherein the engineered yeast produces a ratio of the first and second steviol glycosides at pH of 5.8 or greater that is greater than a ratio of the first and second steviol glycosides produced at a pH that is less than 5.8.

22. The method of claim 21 wherein the ratio of the first and second steviol glycosides at pH of 5.8 or greater is 10% or greater than the ratio of the first and second steviol glycosides produced at a pH that is less than 5.8.

23. The method of claim 22 wherein the ratio of the first and second steviol glycosides at pH of 5.8 or greater is 25% or greater than the ratio of the first and second steviol glycosides produced at a pH that is less than 5.8.

Description

CROSS-REFERENCE TO RELATED APPLICATIONS

[0001] This application claims priority to U.S. Provisional Application No. 62/168,345 filed May 29, 2015, which is herein incorporated by reference in its entirety.

REFERENCE TO SEQUENCE LISTING

[0002] This application contains references to amino acid sequences and/or nucleic acid sequences which have been submitted concurrently herewith as an ASCII text file entitled "CAR0210WO_Sequence_Listing.txt," created on May 27, 2016, and having a size of 92 KB. The sequence listing is hereby incorporated by reference in its entirety pursuant to 37 C.F.R. .sctn. 1.52(e)(5).

FIELD

[0003] The present invention relates fermentation methods for producing steviol glycosides, fermentation compositions, and steviol glycoside compositions produced by fermentation.

BACKGROUND

[0004] Sugars, such as sucrose, fructose and glucose, are utilized to provide a pleasant taste to beverages, foods, pharmaceuticals, and oral hygienic/cosmetic products. Sucrose, in particular, imparts a taste preferred by consumers. Although sucrose provides superior sweetness characteristics, it is caloric. Non-caloric or lower caloric sweeteners have been introduced to satisfy consumer demand, and there is desire for these types of sweeteners that have favorable taste characteristics.

[0005] Stevia is a genus of about 240 species of herbs and shrubs in the sunflower family (Asteraceae), native to subtropical and tropical regions from western North America to South America. The species Stevia rebaudiana, commonly known as sweetleaf, sweet leaf, sugarleaf, or simply stevia, is widely grown for its sweet leaves. Stevia-based sweeteners may be obtained by extracting one or more sweet compounds from the leaves. Many of these compounds are steviol glycosides, which are glycosides of steviol, a diterpene compound. These diterpene glycosides are about 150 to 450 times sweeter than sugar. Steviol glycosides differ from each other by sweetness power as well as other sensory features contributing to taste quality such as bitterness, lingering aftertaste and the like. See Kinghorn, A. D., Stevia: The genus Stevia, Taylor & Francis, London (2002).

[0006] Examples of steviol glycosides are described in WO 2013/096420 (see, e.g., listing in FIG. 1); and in Ohta et. al., "Characterization of Novel Steviol Glycosides from Leaves of Stevia rebaudiana Morita," J. Appl. Glycosi., 57, 199-209 (2010) (See, e.g., Table 4 at p. 204). Structurally, the diterpene glycosides are characterized by a single base, steviol, and differ by the presence of carbohydrate residues at positions C13 and C19, as presented in FIGS. 2a-2k. See also PCT Patent Publication WO 2013/096420.

[0007] Typically, on a dry weight basis, the four major steviol glycosides found in the leaves of Stevia are dulcoside A (0.3%), rebaudioside C (0.6-1.0%), rebaudioside A (3.8%) and stevioside (9.1%). Other glycosides identified in Stevia extract include one or more of rebaudioside B, D, E, F, G, H, I, J, K, L, M, N, O, steviolbioside and rubusoside.

[0008] While the major steviol glycoside Reb A is commonly used as sweetener in beverage applications it has off-taste issues. More recently, there has been focus on certain minor steviol glycosides which have better taste properties. For example, rebaudioside M has higher sweetness intensity and is more potent than other steviol glycosides (e.g., see Prakash, I., et al. (2013) Nat. Prod. Commun., 8: 1523-1526, and WO 2013/096420). Rebaudioside D tastes about 200-220 times sweeter than sucrose and in a sensory evaluation it had a slow onset of sweetness and was very clean, namely sweeter overall than sucrose, less sweet lingering aftertaste compared to sucrose (e.g., see Prakash, I., et al. (2012) Int. J. Mol. Sci., 13:15126-15136).

[0009] Molecular techniques have been used to prepare recombinant organisms capable of synthesizing steviol glycosides via fermentation. For example, recombinant strains of S. cerevisiae having multiple transgenes encoding enzymes involved in steviol glycoside synthesis have been used for the production of rebaudioside M and rebaudioside D (see, for example, WO2014/122227).

SUMMARY

[0010] The present invention generally relates to methods for producing steviol glycosides using engineered yeast, as well as fermentation compositions, and fermentation products that include one or more steviol glycosides. Fermentation conditions of the disclosure can promote increased production of steviol glycosides from the engineered yeast, and can also provide desirable steviol glycoside ratios, such as fermentation compositions that have high rebaudioside D to rebaudioside M ratios. For example, in some embodiments of the invention, a fermentation composition may include a ratio of rebaudioside D to rebaudioside M of 1:20 or greater. In still other embodiments, the ratio of rebaudioside D to rebaudioside M is in the range of 1:20 to 1:1. In other embodiments, the ratio of rebaudioside D to rebaudioside M at a second pH is greater than a ratio of rebaudioside D to rebaudioside M produced when an engineered yeast is maintained at the first pH throughout fermentation.

[0011] In one embodiment, the invention provides a method for producing steviol glycoside which involves changing the medium to a higher pH condition during fermentation for production of the steviol glycoside(s).

[0012] The method includes a step of growing engineered yeast in a first medium at a first pH, wherein the engineered yeast are capable of producing one or more steviol glycoside(s). An "engineered yeast" refers to yeast cells having at least one exogenous DNA sequence that is introduced into the cell, either integrated into the cell's genome or present on an extrachromosomal construct, such as a plasmid or episome. Next, a composition is added to the first medium to provide a second medium having a second pH that is greater than the first pH. In the second medium the engineered yeast is fermented to produce the one or more steviol glycoside(s). The composition added to the medium can include a nitrogen-containing compound, such as one selected from ammonium hydroxide, urea, ammonium sulfate. The composition added to the medium can be used to control the pH. The pH can also be controlled by a non-nitrogen containing base, such as potassium hydroxide or sodium hydroxide or calcium hydroxide and supplementing the nitrogen in the medium with a yeast nitrogenous base, ammonium sulfate, urea, yeast extract or other nitrogen containing nutrients.

[0013] In the second medium, the pH can be adjusted to greater than about 5, greater than about 5.5, or greater than about 5.8, such as in the range of about 5.8 to 7.5 or 5.8 to 6.2. The nitrogen-containing compound added to the medium can be a base, such as ammonium hydroxide, and be used to form the second, higher, pH condition. Alternatively, a nitrogen-containing compound can be used with a non-nitrogen base to provide the higher pH. The nitrogen-containing compound, such as yeast extract, ammonium hydroxide, urea, ammonium sulfate, or combinations thereof, can be the predominant nitrogen component in the second medium during fermentation conditions. The non-nitrogen bases can include potassium hydroxide, sodium hydroxide, and calcium hydroxide.

[0014] An exemplary method involves (a) growing the engineered yeast in a medium having a carbohydrate (e.g., glucose) at a lower pH, such as below 5.8, and then (b) adding a composition with a nitrogen-containing compound, such as ammonium hydroxide, urea, ammonium sulfate, or combinations thereof, and optionally a non-nitrogen containing base, to the medium, along with additional carbohydrate, and optionally other fermentation compounds, to provide a medium having a pH of 5.8 or greater, and then fermenting the medium with the engineered yeast to produce steviol glycoside(s).

[0015] In another embodiment, the invention provides a method for producing steviol glycosides wherein a pH shift is not required, but rather optional. Accordingly, another embodiment is a method for producing steviol glycoside, where the method comprises a step of growing and fermenting a medium with an engineered yeast at a pH of 5.8 or greater in medium comprising a nitrogen source. The nitrogen source is selected from ammonium hydroxide, urea, and ammonium sulfate, yeast extract and one or a combination of these compounds is the primary nitrogen source during fermenting. During fermenting the engineered yeast produces one or more steviol glycoside(s). For example, the steviol glycosides include rebaudioside D, rebaudioside M or rebaudioside D and rebaudioside M. In some embodiments, the molar ratio of rebaudioside D to rebaudioside M is 1:20 or greater.

[0016] In another embodiment, the invention provides a method for increasing the production of a first, lower molecular weight steviol glycoside relative to a second, higher molecular weight steviol glycoside in an engineered yeast. The method includes a step of fermenting engineered yeast capable of producing one or more steviol glycoside(s) at a pH of 5.8 or greater in a fermentation medium, wherein the engineered yeast produces a ratio of the first and second steviol glycosides at pH of 5.8 or greater that is greater than a ratio of the first and second steviol glycosides produced at a pH that is less than 5.8. For example, the method can increase the ratio of the first and second steviol glycosides at pH of 5.8 or greater by about 10% or greater over the ratio when then engineered yeast are grown at the lower pH.

[0017] In another embodiment, the invention also provides compositions comprising steviol glycosides produced by a fermentation process. Accordingly, in another embodiment, the invention provides a composition obtained from a fermentation process comprising rebaudioside D and rebaudioside M, wherein the molar ratio rebaudioside D to rebaudioside M is 1:20 or greater.

DESCRIPTION OF THE DRAWINGS

[0018] FIG. 1 shows a representative mevalonate pathway.

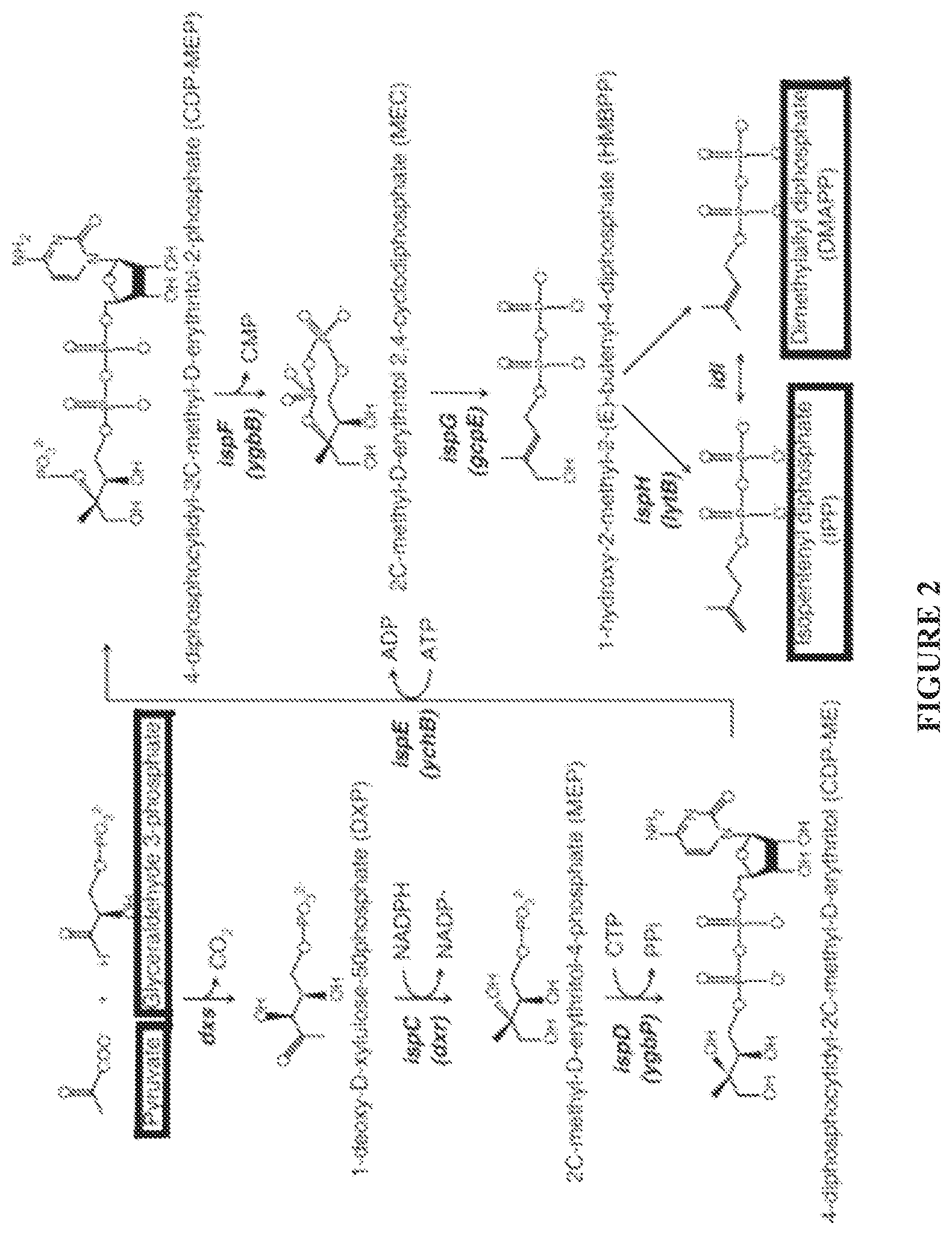

[0019] FIG. 2 shows a representative non-mevalonate pathway.

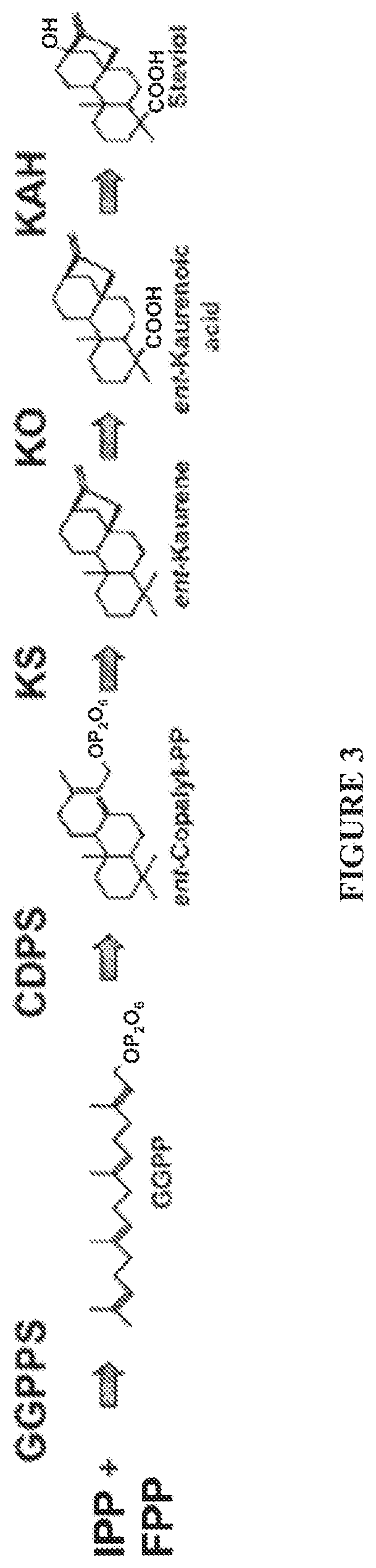

[0020] FIG. 3 shows a representative pathway for steviol production.

[0021] FIG. 4 shows representative pathways for the biosynthesis of steviol glycosides from steviol.

DETAILED DESCRIPTION

[0022] Embodiments of the disclosure described herein are not intended to be exhaustive or to limit the invention to the precise forms disclosed in the following detailed description. Rather a purpose of the embodiments chosen and described is so that the appreciation and understanding by others skilled in the art of the principles and practices of the present invention can be facilitated.

[0023] Fermentation methods of the disclosure use engineered yeast capable of producing steviol glycosides. The engineered yeast capable of producing steviol glycosides can include one or more exogenous nucleic acids that encode enzyme(s) that promote formation of one or more steviol glycosides in the cell. For example, the engineered yeast can have a set of enzymes that provide a pathway for the synthesis of the steviol glycosides RebM and RebD.

[0024] As used herein, the term "steviol glycoside(s)" refers to glycosides of steviol. Exemplary steviol glycoside, include, but not are not limited to, rebaudioside A, rebaudioside B, rebaudioside C, rebaudioside D, rebaudioside E, rebaudioside F, rebaudioside G, rebaudioside H, rebaudioside I, rebaudioside J, rebaudioside K, rebaudioside L, rebaudioside M, rebaudioside N, rebaudioside O, stevioside, steviolbioside, dulcoside A, rubusoside. Engineered yeast can produce steviol glycosides that are the same as steviol glycosides found in nature ("naturally occurring") as well as steviol glycosides that are not found in nature. Steviol glycosides can be formed in engineered yeast by enzymatic processes.

[0025] Structurally, steviol glycosides have a central molecular moiety, which is a single steviol base, and glucopyranosyl residues attached to the C13 and/or C19 atoms of the steviol base, according to the atom numbering on the base shown below. That is, glucopyranosyl residues represent groups R.sub.1 and R.sub.2 in the following formula:

##STR00001##

[0026] Table A below shows the various steviol glycosides and the corresponding R.sub.1 and R.sub.2 groups:

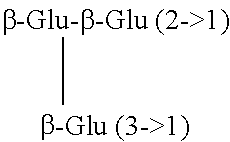

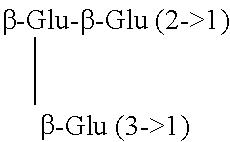

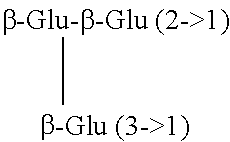

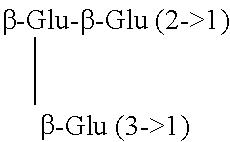

TABLE-US-00001 TABLE A Compound name R.sub.1 (C-19) R.sub.2 (C-13) Steviol H H Stevioside .beta.-Glu .beta.-Glu-.beta.-Glu (2->1) Rebaudioside A .beta.-Glu ##STR00002## Rebaudioside B H ##STR00003## Rebaudioside C .beta.-Glu ##STR00004## Rebaudioside D .beta.-Glu-.beta.-Glu (2->1) ##STR00005## Rebaudioside E .beta.-Glu-.beta.-Glu (2->1) .beta.-Glu-.beta.-Glu (2->1) Rebaudioside G .beta.-Glu .beta.-Glu-.beta.-Glu (3->1) Rebaudioside M ##STR00006## ##STR00007## Rebaudioside N ##STR00008## ##STR00009## Rebaudioside O ##STR00010## ##STR00011## Glu: glucose Rha: rhamnose

[0027] According to the current disclosure, steviol glycosides are produced in a process that includes fermenting the engineered yeast at a pH that is higher than typical yeast fermentation conditions. By comparison, the yeast Saccharomyces cerevisiae is typically fermented at a pH in the range of 4 to 5.

[0028] The method of the disclosure can use various yeast host cells engineered to provide a pathway to one or more steviol glycosides. Such cells used in the methods of the disclosure can be transformed with one or more DNA construct(s) encoding enzymes for steviol glycoside synthesis. Exemplary yeast that can be used for hosts for exogenous DNA constructs encoding steviol glycoside pathway enzymes, include, but are not limited to species of Candida, Kloeckera (Hanseniaspora), Kluyveromyces, Lipomyces, Pichia (Hansenula), Rhodotorula, Saccharomycete, Saccharomyces, Schizosaccharomyces, Torulopsis, Torulaspora, Yarrowia, and Zygosaccharomyces. Exemplary species are Candida albicans, Pichia pastoris, Saccharomyces cerevisiae, and Schizosaccharomyces pombe, and Yarrowia lipolytica. Further, host cells can also include genetic modifications other than those of the steviol glycoside pathway that may provide improved performance during fermentation.

[0029] The term "exogenous" refers to a molecule, such as a nucleic acid, or an activity, such as an enzyme activity, that is introduced into the host yeast. An exogenous nucleic acid can be introduced into the yeast host by well-known techniques and can be maintained external to the hosts chromosomal material (e.g., maintained on a non-integrating vector), or can be integrated into the yeast's chromosome, such as by a recombination event. Generally, the genome of an engineered yeast is augmented through the stable introduction of one or more recombinant genes. An exogenous nucleic acid can encode an enzyme, or portion thereof, that is either homologous or heterologous to the yeast. An exogenous nucleic acid can be in the form of a "recombinant gene or DNA construct" referring to a nucleic acid that is in one or more ways manipulated through molecular techniques to be in a form that does not naturally exist.

[0030] The term "heterologous" (e.g., "non-native") refers to a molecule or activity that is from a source that is different than the referenced molecule or organism. Accordingly, a gene or protein that is heterologous to a referenced organism is a gene or protein not found in that organism. In the context of the disclosure, a "heterologous glycosyltransferase" refers to a glycosyltransferase polypeptide that is different from any glycosyltransferase polypeptide that may be native to the host organism. For example, a specific glycosyltransferase gene found in a first species and exogenously introduced into a host yeast organism that is different than the first species is "heterologous" to the host yeast.

[0031] The engineered yeast can use an auxotrophic marker suitable for selecting for a transformant having a nucleic acid encoding a steviol glycoside pathway enzyme. The host yeast can include modifications (deletions, etc.) in one or more genes that control auxotrophies, such as LYS2, LEU2, HIS3, URA3, URA5, and TRP1. Using a host cell having a desired genetic background for introduction of one or more exogenous genes, one or more gene construct(s) is introduced into a cell to integrate into the genome, or to be stably maintained and allow for expression. Methods for introducing a gene construct into a host cell include transformation, transduction, transfection, co-transfection, and electroporation. In particular, yeast transformation can be carried out using the lithium acetate method, the protoplast method, and the like. The gene construct to be introduced may be incorporated into a chromosome in the form of a plasmid, or by insertion into the gene of a host, or through homologous recombination with the gene of a host. The transformed yeast into which the gene construct has been introduced can be selected with a selectable marker (for example, an auxotrophic marker as mentioned above). Further confirmation can be made by measuring the activity of the expressed protein, or the production of a bioproduct associated with the introduced gene(s) such as a steviol glycoside.

[0032] The transformation of exogenous nucleic acid sequences including the steviol pathway genes can be confirmed using methods well known in the art. Such methods include, for example, nucleic acid analysis such as Northern blots or polymerase chain reaction (PCR) amplification of mRNA, or immunoblotting for expression of gene products, or other suitable analytical methods to test the expression of the introduced nucleic acid sequences or their corresponding gene product. It is understood by those skilled in the art that the exogenous nucleic acid is expressed in a sufficient amount to produce the desired product, and it is further understood that expression levels can be optimized to obtain sufficient expression using methods well known in the art and as disclosed herein.

[0033] The terpenoid compounds isopentenyl diphosphate (IPP) and dimethylallyl diphosphate (DMAPP) can serve as chemical precursors to steviol glycosides in an engineered yeast. Some organisms, including plants, insect, and some microbial species, have a mevalonate (MVA) pathway that converts acetyl-CoA through a series of chemical intermediates to IPP and DMAPP. Some organisms produce IPP and DMAPP through the non-mevalonate pathway (also known as the methyl D-erythritol 4-phosphate or MEP pathway) starting with glyceraldehyde-3-phosphate (G3P) and pyruvate (PYR).

[0034] The yeast Saccharomyces cerevisiae naturally expresses genes of the mevalonate pathway. Mevalonate pathway genes that encode enzymes that include: (a1) acetoacetyl CoA thiolase (EC 2.3.1.9), (b1) 3-hydroxy-3-methylglutaryl-coenzyme A (HMG-CoA) synthase (EC 4.1.3.5); (c1) HMG-CoA reductase (EC 1.1.1.34); (d1) mevalonate kinase (EC 2.7.1.36); (e1) phosphomevalonate kinase (EC 2.7.4.2); and (f1) mevalonate diphosphate decarboxylase (EC 4.1.1.33). Enzymes of the mevalonate pathway converts acetyl-CoA to IPP as follows: acetyl-CoA.fwdarw.acetoacetyl-CoA.fwdarw.3-hydroxy-3-methylglutaryl-CoA.f- wdarw.mevalonate.fwdarw.mevalonate-5-phosphate.fwdarw.mevalonate-5-pyropho- sphate.fwdarw.IPP. See also FIG. 1

[0035] In some embodiments, the engineered yeast can include one or more modifications to increase the flux from acetyl-CoA to IPP and/or DMAPP, thereby providing an increased pool of IPP and/or DMAPP for use in a pathway to steviol. The modifications can include, for example, increasing expression or activity of one or more mevalonate pathway enzymes (a1)-(f1), such as by placing a nucleic acid encoding an enzyme that is homologous or heterologous to the yeast cell under the control of a promoter that provides increased expression, using multiple copies of the nucleic acid, and/or using a heterologous enzyme, a variant enzyme (e.g., one including one or more amino acid substitutions), or a variant heterologous enzyme that provides a higher level of enzymatic activity as compared to the native enzyme.

[0036] Alternatively, the non-mevalonate (MEP) pathway can be used to provide IPP and DMAPP as precursors to steviol glycoside production. The yeast Saccharomyces cerevisiae do not naturally express genes of the MEP pathway, but can optionally be engineered to provide MEP pathway genes. Theoretically, the MEP pathway is more energetically efficient generally because it loses less carbon as CO2 as compared to the MVA pathway (MEP pathway: 1 CO2/IPP; MVA pathway: 4 CO2/IPP; sugar as carbon source).

[0037] In particular, in the non-mevalonate (MEP) pathway compounds isopentenyl diphosphate (IPP), dimethylallyl diphosphate (DMAPP) are generated through a series of intermediates leading from glyceraldehydes-3-phosphate (G3P) and pyruvate (PYR), and a number of enzymes are responsible for this conversion. Enzymes involved in a biosynthetic pathway from G3P and PYR to IPP and DMAPP include (a2) 1-deoxy-D-xylulose-5-phosphate synthase (DXS), (b2) 1-Deoxy-D-xylulose-5-phosphate reductoisomerase (ispC)-, (c2) 4-diphosphocytidyl-2C-methyl-D-erythritol synthase (IspD), (d2) 4-diphosphocytidyl-2-C-methyl-D-erythritol kinase (IspE), (e2) 2C-Methyl-D-erythritol-2,4-cyclodiphosphate Synthase (IspF), (f2) 1-hydroxy-2-methyl-2-(E)-butenyl-4-diphosphate synthase (IspG), (g2) 4-hydroxy-3-methyl-2-(E)-butenyl-4-diphosphate reductase (IspH), and (h2) isopentenyl-diphosphate isomerase (IDI), see FIG. 2.

[0038] The methods of the disclosure for producing steviol glycoside(s) by fermentation can use engineered yeast that have one or more genetic modifications to increase the flux from G3P and PYR to IPP and/or DMAPP, thereby providing an increased pool of IPP and/or DMAPP for use in a pathway to steviol. The modifications can include, for example, increasing expression or activity of one or more enzymes (a2)-(h2), such as by placing a nucleic acid encoding an enzyme that is heterologous to the yeast cell under the control of a promoter that provides increased expression, using multiple copies of the nucleic acid, and/or using a heterologous enzyme, a variant enzyme (e.g., one including one or more amino acid substitutions), or a variant heterologous enzyme that provides a high levels of enzymatic activity.

[0039] The methods of the disclosure for producing steviol glycoside(s) by fermentation can use engineered yeast can also include a pathway to convert IPP and/or DMAPP to steviol. For example, in some aspects the engineered yeast can include exogenous nucleic acids expressing the following enzymes: (a3) geranyl geranyldiphosphate synthase (GGPPS), (b3) copalyl diphosphate synthase (CDPS), (c3) kaurene synthase (KS), (d3) kaurene oxidase (KO), and (e3) kaurenoic acid 13-hydroxylase (KAH). Enzymes of the mevalonate pathway convert IPP and/or DMAPP to steviol as follows: IPP/ DMAPP.fwdarw.geranyl geranyldiphosphate.fwdarw.copalyl diphosphate.fwdarw.kaurene.fwdarw.kaurenoic acid.fwdarw.steviol. (See FIG. 3) Exogenous nucleic acids encoding enzymes (a3)-(e3) that are heterologous to the yeast cell can be placed under the control of a promoter that provides increased expression, using multiple copies of the nucleic acid, and/or using a variant enzyme (e.g., one including one or more amino acid substitutions), or a variant heterologous enzyme that provides a high levels of enzymatic activity.

[0040] The methods of the disclosure for producing steviol glycoside(s) by fermentation can use engineered yeast having any pathway to convert steviol to a steviol glycoside. If more than one steviol glycoside pathway enzyme is present in the engineered yeast, the yeast may be able to produce different steviol glycosides. For example, the yeast may be able to produce two, three, four, five, six, seven, eight, nine, ten, or more than ten different steviol glycoside species.

[0041] The steviol glycoside pathway can include one or more uridine diphosphate (UDP) glycosyltransferases (UGTs) that mediate the transfer of glycosyl residues from activated nucleotide sugars to acceptor molecules. In the case of a steviol glycoside pathway, a monosaccharide unit can be transferred to a hydroxyl or carboxyl moiety on a steviol or steviol glycoside molecule, or to a hydroxyl group on a glucose group that is attached to the steviol base. See FIG. 4 UGTs have been classified into families and subfamilies based on sequence homology. See Li, et al., 2001, J. Biol. Chem. 276:4338-4343. A superfamily of over 100 genes encoding UGTs, each containing a 42 amino acid consensus sequence, has been identified in the model plant Arabidopsis thaliana, and genes encoding UGTs have also been identified in several other higher plant species.

[0042] Exemplary UDP-glucosyltransferase can be any UDP-glucosyltransferase capable of adding at least one glucose unit to the steviol and or steviol glycoside substrate to provide the target steviol glycoside. In one embodiment, the engineered yeast can include one or more UDP-glucosyltransferase selected from group UGT74G1 (SEQ ID NO: 1), UGT85C2 (SEQ ID NO: 2), UGT76G1 (SEQ ID NO: 3), UGT91D2 (SEQ ID NO: 4), and also UGTs having substantial identity (e.g. >85%, >75%, >65%, >55%, >45% and >35%) to these polypeptides. An engineered yeast can include one or more exogenous nucleic acid molecule(s) that code for these UGTs.

[0043] The engineered yeast can also include one or more UGT and UDP-glucose recycling enzyme(s). An exemplary UDP-glucosyltransferase capable of adding at least one glucose unit to rubusoside to form stevioside is UGT91D2 (SEQ ID NO: 4). An exemplary UDP-glucosyltransferase capable of adding at least one glucose unit to stevioside to form rebaudioside A is UGT76G1 (SEQ ID NO: 3). An exemplary UDP-glucosyltransferase capable of adding at least one glucose unit to rebaudioside A to form rebaudioside D is UGT91D2 (SEQ ID NO: 4). An exemplary UDP-glucosyltransferase capable of adding at least one glucose unit to rebaudioside D to form rebaudioside M is UGT76G1 (SEQ ID NO: 3).

[0044] Exemplary publications that describe engineered microorganisms for steviol glycoside production and steviol glycoside pathway enzymes include, for example, US2014/0357588, WO2014/193934, WO2014/193888, and WO2014/122227, each of which is incorporated herein by reference in their entirety.

[0045] In one embodiment, an engineered yeast useful for the production of steviol glycosides expresses the following enzymes: geranylgeranyl diphosphate synthase (GGPPS), ent-copalyl diphosphate synthase (CDPS), kaurene oxidase (KO), kaurene synthase (KS); steviol synthase (KAH), cytochrome P450 reductase (CPR), UGT74G1, UGT76G1, UGT91D2, UGT85C2 and a EUGT11. WO2014/122227 describes an engineered yeast strain that express these enzymes. The UDP-glucosyltransferases can be a gene encoding a polypeptide for example, UGT74G1 (SEQ ID NO: 1), UGT85C2 (SEQ ID NO: 2), UGT76G1 (SEQ ID NO: 3), UGT91D2 (SEQ ID NO: 4), and a EUGT11 (SEQ ID NO: 13); these genes encode polypeptides capable of carrying out a number of reactions such as a) a gene encoding a polypeptide capable of beta 1,2 glucosylation of the C2' of the 19-O glucose of a steviol glycoside; (b) a gene encoding a polypeptide capable of beta 1,2 glucosylation of the C2' of the 13-O-glucose of a steviol glycoside; (c) a gene encoding a polypeptide capable of beta 1,3 glucosylation of the C3' of the 19-O-glucose of a steviol glycoside; (d) a gene encoding a polypeptide capable of beta 1,3 glucosylation of the C3' of the 13-O-glucose of a steviol glycoside; (i) a gene encoding a polypeptide capable of glucosylation of the 13-OH of steviol or a steviol glycoside; (j) a gene encoding a polypeptide capable of glucosylation of the C-19 carboxyl of steviol or a steviol glycoside. For example, UGT85C2 carries out reaction (i); UGT74G1 carries out reaction (j); UGT91D2 carries out reactions (a; weakly), (b); UGT76G1 carries out reactions (c) and (d) EUGT11 carries out reactions (a), (b; less well).

[0046] Aspects of the disclosure can be described with reference to stages of cell culture. For example, the process may include one or more "stages" or "phases" of culturing the engineered yeast. For example, the process can include a "seed/growth phase". As used herein "seed phase" refers to a period during which the cells are grown in a medium to become acclimated to the medium components (carbohydrates, nitrogen source, salts, vitamins, trace metals) that will be used in the subsequent growth phase and to increase cell numbers. "Growth phase" as used herein refers to the period during which the cells multiply (e.g. exponentially). During the seed/growth phase, the engineered yeast can begin to multiply by budding, referred to as yeast division.

[0047] The seed/growth phase can be characterized by rapid multiplication of the engineered yeast. The seed/growth phase can be described in terms of the doubling times of the engineered yeast. In some embodiments of the disclosure, growth of the engineered yeast can be performed at a lower (first) pH (e.g., about 5.8 or below or about 5.0 or below), and then at a time later in the growth phase, or at time in the subsequent fermentation phase, the pH can be increased to a higher (second) pH (e.g., about 5.8 or greater or about 6.0 or greater). In other embodiments of the disclosure, growth of the engineered yeast can be performed at the higher (second) pH, and therefore an adjustment to a higher pH during the growth and fermentation phases is not required.

[0048] After the growth phase, the engineered yeast can enter a "fermentation phase" in which growth has at least slowed and the engineered yeast are actively assimilating carbohydrate and producing the desired product, e.g. steviol glycoside(s). As used herein "fermentation," "fermenting," or variants therefor is used to describe the phase of significant production of steviol glycoside(s) by converting a substrate with a yeast, which can occur in partially aerobic, aerobic or anaerobic conditions. In partially aerobic conditions, both fermentative and respiratory pathways can be active, and some cell growth may occur. In partially aerobic conditions the amount of oxygen consumed can be less than during the seed/growth phase. As used herein, the phrase "throughout the process" or "throughout" when used in reference to the various phases or treatments means from growth phase through formation of product.

[0049] In some modes of practice, the pH of the medium during the fermentation phase can be at the higher pH if the pH of the medium was increased during, or at the beginning of the growth phase. In other modes of practice, the pH can be adjusted to the higher pH at a predetermined point during the fermentation phase. If the pH is increased during fermentation, it is preferably increased closer to the beginning of the fermentation phase than the end of the fermentation phase, and more preferably at the beginning or very close to the beginning of the fermentation phase.

[0050] In some modes of practice, the pH of the medium during the growth phase is carried out at the same pH as the fermentation phase. For example, the growth phase is carried out at the higher (second) pH. For example, the higher (second) pH is from about 5.8 or greater.

[0051] In some embodiments, the method of the disclosure for producing steviol glycoside(s) involves altering the medium in which the engineered cells are in to a higher pH for fermentation and production of steviol glycoside(s). Therefore, a step in the method can involve growing the engineered yeast in a first medium at a first, lower pH (e.g., pH 5.8 or less or pH 5.0 or less) and then after a period of time at the first, lower, pH the engineered yeast are fermented in a medium at a second pH that is higher than the first pH. The engineered yeast are fermented at the second, higher, pH (e.g., pH 5.8 or greater, or pH 6.0 or greater) to produce the one or more steviol glycoside(s), and the higher pH conditions can result in increased amounts of steviol glycosides, as well as a shift to more desirable ratios of steviol glycosides among those produced.

[0052] The term "medium" refers to a liquid composition in which the engineered yeast can be maintained, can grow, can be fermented, or combinations thereof. A "medium" may also be referred to as a "broth" or "cell culture," and terms such as "starting" or "fermentation" may be used to more specifically define the medium and the cellular activity that is occurring therein. A medium can be defined with regards to the components present in the medium, and amounts thereof, such as carbon sources, including (a) carbohydrates such as glucose and starch products such as maltodextrin; (b) nitrogen sources, such as yeast nitrogen base, ammonium hydroxide, urea, ammonium sulfate, yeast extract or any combination thereof; (c) salts, such as potassium phosphate (monobasic, dibasic), magnesium sulfate, sodium chloride, and calcium chloride; (d) vitamins, such as biotin, calcium pantothenate, folic acid, (myo)-inositol, nicotinic acid, p-aminobenzoic acid, pyridoxine HCl, riboflavin, thiamine HCl, and citric acid; (e) trace metals such as boric acid, copper sulfate, cobalt chloride, calcium chloride, potassium iodide, ferric chloride, magnesium sulfate, manganese chloride, sodium molybdate, and zinc sulfate. Components in the medium can be defined on a dry weight basis. Further, the medium is water-based, or an "aqueous" composition. The medium can also be defined with regards to its pH, and biocompatible acids, bases, and buffers that are used to control the pH in the medium.

[0053] Fermentation of the engineered yeast can be performed using a medium that has a starch and/or sugar containing plant material derivable from any plant and plant part, such as tubers, roots, stems, leaves and seeds. Starch and/or sugar-containing plant materials can be obtained from cereal, such as barley, wheat, maize, rye, sorghum, millet, barley, potatoes, cassava, or rice, and any combination thereof. The starch-and/or sugar-containing plant material can be processed, such as by methods such as milling, malting, or partially malting. In some embodiments, medium (with higher pH or lower pH) includes a treated starch. For example, the medium for growth and/or fermentation can include a partially hydrolyzed starch. The partially hydrolyzed starch can include high molecular weight dextrins and high molecular weight maltodextrins. A partially hydrolyzed starch product can be used that has amounts of starch and starch degradation products within desired ranges beneficial for steviol glycoside production.

[0054] Optionally, a starch degrading enzyme can be added to the medium that includes a starch material in order to increase the concentration of monomeric sugars such as glucose that can be utilized by the engineered yeast. Exemplary starch-degrading enzymes include amylolytic enzymes such as glycoamylase and amylase.

[0055] In some modes of practice, fermentation can be carried out in medium that includes steviol-containing compounds. Such compounds can be directly used by the glucosyltransferases in the engineered yeast. For example, optionally, fermentation can be carried out in medium containing steviol, steviol-13-O-glucoside or steviol-19-O-glucoside. Using this medium, the microorganism may contain and express genes encoding a functional EUGT11 (SEQ ID NO: 13), a functional UGT74G1 (SEQ ID NO: 1), a functional UGT85C2 (SEQ ID NO: 2), a functional UGT76G1 (SEQ ID NO: 3), and a functional UGT91D2 (SEQ ID NO: 4). Compounds such as rebaudioside A, rebaudioside D, and rebaudioside M may be obtained from the fermentation medium. As another option, fermentation can be carried out in medium containing rubusoside. Using this medium, the microorganism may contain and express genes encoding a functional EUGT11 (SEQ ID NO: 13), a functional UGT76G1 (SEQ ID NO: 3), and a functional UGT91D2 (SEQ ID NO: 4). Compounds such as rebaudioside A, D, and M may be obtained from the medium following fermentation. The terms "rebaudioside DM", "Reb DM", and variations thereof, as used herein, refer to glycosides that are primarily rebaudioside D and rebaudioside M (hence, the "DM"), their related isomers (e.g. natural or synthetic), and/or salts thereof. This terminology format may be used for glycosides having any other combination of glycosides, for example, but not limited to Reb DA, Reb MA, Reb DMA and the like.

[0056] In some cases fermentation is carried out in industrial capacity fermenters in order to achieve commercial scale economic benefits and control. In an embodiment, the fermentation is carried out in a fermenter that has a capacity of about 10,000 liters or more.

[0057] The terms "first medium" and "second medium" (and optionally, "third," "fourth," fifth," etc., if necessary) may be used to describe aspects of the method of producing steviol glycosides. In one mode of practice, a first medium at a lower pH (e.g., less than 5.8 or less than 5.0) and containing the engineered cells is provided and engineered yeast therein are cultured for a period of time. Subsequently, a liquid composition free of cells (e.g., a "feed composition") is added to the first medium to provide a second medium having the same or a higher pH, which can be used for fermentation of the engineered yeast. The feed composition can be added to the first medium in a continuous or batch process. In a preferred mode of practice, the feed composition is added in a continuous process to more precisely control fermentation conditions in the medium. In some embodiments, the feed composition is the same composition of feed added to the first medium and added to the second medium.

[0058] As another example, a first medium at the low pH (e.g., less than 5.8 or less than 5.0) and including the engineered yeast can be cultured for a period of time. The first medium can then be added to a predetermined volume of a liquid composition free of cells in a batch or bulk step to create a second medium which has a higher pH (e.g., 5.8 or greater or 6.0 or greater), which can be used for fermentation of the engineered yeast and steviol glycoside production. It is understood that there are a variety of ways a second medium having a higher pH can be prepared starting with a first medium with a lower pH. Therefore, formation of the second medium can be by a process of "adding to," "adding into," or "mixing," using bulk or continuous addition of one or more feed components. The feed components can be in liquid or in solid form. In some cases formation of the second medium can be by a multi-step process. In other cases the formation of the first medium and the second medium has the higher pH of the second medium.

[0059] In some modes of practice, the first medium is present is a vessel, and then the pH of the medium is adjusted to provide a second medium at a higher pH, which is formed in the same vessel. In other modes of practice, the first medium is formed in a first vessel and then it is transferred to a second vessel wherein the second medium having a higher pH is formed by combining the first medium with other components or materials.

[0060] The first medium having a lower pH can be formed by adding a seed culture to a liquid composition that includes a carbohydrate(s), a nitrogen source, such as yeast nitrogen base, ammonium hydroxide, urea, ammonium sulfate, yeast extract or any combination thereof; salts, vitamins, and trace metals. In some modes of practice the first medium includes ammonium hydroxide, urea, ammonium sulfate, or combinations thereof, as the sole nitrogen source in the medium. An "initial" concentration of components in the first medium may be described, with an understanding that the concentration of components may decrease in the first medium over time as the engineered cells consume the components. When the second medium with the higher pH (e.g., 5.8 or greater, or 6.0 or greater) is formed, the ammonium hydroxide, urea, or ammonium sulfate can be the sole nitrogen source in the medium.

[0061] In some modes of practice, the first medium, such as the medium where yeast growth takes place, can have a pH less than about 6.0, less than about 5.9, less than about 5.8, less than about 5.7, less than about 5.6, less than about 5.5, less than about 5.4, less than about 5.3, less than about 5.2, less than about 5.1, less than about 5.0, such as in the range of about 3.0 to about 5.5, about 3.5 to about 5.3, or about 4.0 to about 5.0. An exemplary pH in the first medium is about 5.0. During the period of growth in the first medium, the pH may fluctuate. For example, growth of the yeast cells may cause the first medium to become more acidic after a period of time. Optionally, the pH in the first medium can be controlled by monitoring the pH over time, and, if necessary, adjusting the pH such as with a base or a buffer so it remains within a desired range during growth in the first medium. For example, the pH of the first medium can be controlled using a nitrogen-containing base, such as ammonium hydroxide so the pH is maintained in the range of about 4.8 to about 5.2. A nitrogen-containing base used in the first medium can be the same as a nitrogen-containing base used in the second medium (e.g., ammonium hydroxide), with a difference being that the base used in the second medium is at a higher concentration to provide a higher pH.

[0062] In some modes of practice, the first medium can have an initial concentration of glucose that is less than about 50 g/L, less than 25 g/L, such as in the range of about 5 g/L to about 50 g/L, or about 10 g/L to about 35 g/L. The glucose concentration in the first medium may also be defined relative to the glucose concentration in the second medium.

[0063] In exemplary modes of practice, growth in the first medium is performed at a temperature in the range of about 25-35.degree. C., or 28-32.degree. C., and most preferably at about 30.degree. C.

[0064] Also, growth of the engineered yeast can be performed with aeration, and with agitation.

[0065] For example, in the first medium and during the growth phase, aeration can be performed. Aeration may be described in terms of dissolved oxygen transfer rate to the medium in units of mg min.sup.-1 liter.sup.-1. (For example, see Anderlei, T., and Buchs, J. (2000) Biochem. Engin. J. 3478:1-6). A sparging technique that promotes the formation of fine gas bubbles can be performed to provide desired aeration. In some modes of practice, during the growth phase in the first medium, agitation and aeration is increased, such as in a stepwise manner. Aeration conditions can have an effect on the amount of oxygen dissolved in the medium, and therefore the oxygen available to the engineered yeast. The amount of oxygen uptake by the engineered yeast can be controlled by the rate at which oxygen is supplied and the formation of small oxygen bubbles in the medium, which can be achieved through agitation and/or sparging. Limited aeration can also be performed during the fermentation phase.

[0066] Growth of the engineered yeast in the first medium can be carried out for a desired period of time before adjusting to the second medium at the higher pH. In some modes of practice, growth of the engineered yeast in the first medium can be carried out for a desired period of time before adjusting to the second medium, where the first medium and second medium have the higher pH. For example, growth in the first medium can be carried out for a time of about two hours or greater, or about 10 hours or greater, such as a period of time in the range of about two hours to about 30 hours, or about 10 hours to about 24 hours. The time in the first medium may encompass all or part of the lag phase of growth, and all or part of the log (exponential) phase of growth of the engineered yeast. Further, during the time in the first medium at the lower pH, the engineered yeast can have a predetermined growth rate. For example, in the first medium the engineered yeast can have a doubling time in the range of about 2.31 hours to about 13.86 hours, or about 2.77 hours to about 7.3 hours. Alternatively, growth rate can be expressed as the dilution rate, which can be in the range of about 0.05-0.31/h, or about 0.095-0.251/h.

[0067] Growth of the engineered yeast can be performed to provide a desired amount of biomass. As used herein "biomass" refers to the weight of the engineered yeast, which can be measured in grams of dried cell weight per liter of medium (DCW/L). In some mode of practice, the engineered yeast are grown to a biomass amount of about 20 g dcw/L or greater, about 30 g dcw/L or greater, such as in the range of about 20 g dcw/L to about 120 g dcw/L, or about 40 g dcw/L to about 80 g dcw/L.

[0068] In forming the second medium, a base can be added to the first medium, which causes an increase from the lower pH to the higher pH. The time at which the base is added can be chosen based on aspects such as the time the engineered yeast have spent in the first medium, the concentration of components in the first medium at a particular time point, or the growth characteristics of the engineered yeast at a particular time point, or combinations of these aspects. In some modes of practice, the pH of the first medium is increased at a time at least halfway through the exponential (growth) phase of the engineered yeast in the first medium. For example, the pH of the first medium can be increased to about 5.8 or greater, or to about 6.0 or greater as the engineered yeast are coming out of the exponential phase, and their growth is slowing. Therefore, addition of base to raise the pH can be performed prior to the engineered yeast entering the fermentation phase with lower growth rates. Therefore, the pH of the medium can be increased following any significant production of steviol glycoside(s) from the engineered yeast in a fermentation period. However, the high pH conditions preferably encompass a period of fermentation that provides production of steviol glycoside(s) from the engineered yeast. Alternatively, addition of base to raise the pH can be performed after the engineered yeast enter the fermentation phase.

[0069] The base can be a nitrogen-containing base, such as ammonium hydroxide, or a non-nitrogen base suitable for use in a fermentation medium. A composition that includes a mixture of a nitrogen-containing base and a non-nitrogen-containing base can optionally be used. Other optional nitrogen-containing bases that can be used in the second medium can be anhydrous ammonia or an ammonium hydroxide/potassium hydroxide blend. Other optional non-nitrogen-containing bases that can be used in the second medium can be potassium hydroxide, sodium hydroxide, and calcium hydroxide. A composition that includes a nitrogen containing base in concentrated form (e.g., ammonium hydroxide up to about 15% (w/v) or greater) can be used to change the pH.

[0070] The base can be added to the first composition as a liquid composition, or can be added as a solid, for formation of the second medium. The base can be added to the first composition in a bulk method or a continuous process. In some modes of practice, the base is added in a continuous process to achieve a desired pH over a desired period of time. For example the change from the first pH to the second pH can be carried out over a short period of time (minutes), or longer times (hours), or any time in between. For example, the change can occur for a period of time in the range of about two minutes to about four hours, about five minutes to about four hours, or about 30 minutes to about three hours. In an exemplary mode of practice, a change from about pH 5.0 to about pH 7.0 can occur in a period of time in the range of about 30 minutes to about 180 minutes.

[0071] Formation of the second medium can also include providing a feed medium to the first medium. In some modes of practice, a base is added to the first medium to increase the pH from a lower to a higher pH, and then a feed composition is added to the medium at the higher pH. In other modes of practice, the feed medium includes a base and has a higher pH, and then when the feed medium is added to the first medium it increases the pH to provide the second medium. The feed medium, with or without base, can be the same or different than the first medium in which the engineered yeast are grown. In some embodiments, the feed medium added to the first medium is the same as the feed medium added to the second medium.

[0072] The feed medium can include a carbohydrate(s), a nitrogen source, such as yeast extract, ammonium hydroxide, urea, ammonium sulfate, or any combination thereof; salts, vitamins, and trace metals such. The concentration of the components in the feed medium can be greater than the concentration of components in the first medium so that when the feed medium is added it provides desired amounts of components in the second medium suitable for fermentation of the engineered yeast. In exemplary embodiments, the concentration of glucose in the feed medium or during fermentation(e.g. second medium) is kept in the range of about 0 g/L to about 5 g/L, or 0 g/L to about 2 g/L. In exemplary embodiments, the concentration of a nitrogen source (total amount) in the feed medium such as yeast extract, nitrogen base, ammonium hydroxide, urea, ammonium sulfate, is kept in the range of about 5 g/L to about 40 g/L. In exemplary embodiments, the concentration of salts (total amount) in the feed medium such as salts including magnesium sulfate in the range of about 0 g/L to about 12 g/L, and potassium phosphate in the range of about 0 g/L to about 22 g/L. In exemplary embodiments, the concentration of trace metals (total amount) in the feed medium is kept in the range of about 0 g/L to about 0.4 g/L, or 0 g/L to about 0.2 g/L.

[0073] During the period the engineered yeast are in the second medium, such as during a period of fermentation, the pH may fluctuate. However, the pH is preferably kept at about pH 5.8 or greater, or about pH 6.0 or greater, such as in the range of about pH 5.8 to about pH 8.0, pH 5.8 to about pH 7.5 or greater, about pH 6.0 to about pH 7.0, about 5.8 to about 6.5 or about 5.8 to about 6.2. During the period in the second medium, the pH can be monitored (e.g., periodically or continuously) and adjustments to the second medium can be made if the pH falls outside a desired range. For example, additional ammonium hydroxide can be added to the second medium if the pH drops below 5.8, so as to adjust the pH to about 5.8 or greater. In exemplary embodiments, approximately 0.17 kg to about 0.2 kg of 12% NH4OH is added during fermentation to maintain the pH at 5.0 and approximately 0.20 kg to about 0.24 kg of 12% NH4OH is added during fermentation to maintain the pH at 6.0. Approximately 1.18 kg to about 1.21 kg of feed medium is added during the feeding phase in a typical fermentation.

[0074] In exemplary embodiments, the glucose concentration was kept limiting by controlling flow rates of feed medium. A two-phase feeding strategy can include an initial exponential phase beginning at 10 hours with a growth rate for example of u=0.12 1/h while second feeding (or feed phase II) can start at 33 hours with a constant flow rate for example of 0.180 mls/minute. Feeding can continue until a final volume of about 1.95 liters can be obtained by about 120 hours. Other methods of feeding rates for producing the desired steviol glycosides are described in the application titled "Fermentation Methods for Producing Steviol Glycosides with Multi-phase Feeding," U.S. patent application Ser. No. 62/168,372, and International PCT application titled "Fermentation Methods for Producing Steviol Glycosides with Multi-phase Feeding," Attorney Docket No. N00293USP1 (CAR0212/WO) and filed concurrently with the present application, each application which are hereby incorporated by reference in their entirety.

[0075] The period of time the engineered yeast are present in the second medium can include a fermentation period carried out for an amount of time sufficient to produce a desired amount of steviol glycosides. For example, the second medium with higher pH can be formed at a time of 2 hours or later, 10 hours or later, or 24 hours or later, from an initial culturing of the engineered yeast, and can extend to up to a time of 150 hours, up to 96 hours, or up to 72 hours, from the initial culturing of the engineered yeast. Fermentation of the engineered yeast and production of the steviol glycoside(s) can begin at a point during residence of the engineered yeast in the second medium. Preferably most of the steviol glycoside (i.e., greater than 50%) is produced by the engineered yeast while in the in the second medium at the higher pH.

[0076] In exemplary modes of practice, fermentation and optionally growth in the second medium is performed at a temperature in the range of about 25-35.degree. C., or 28-32.degree. C., and most preferably at about 30.degree. C. Also, fermentation and optionally growth of the engineered yeast in the second medium can be performed with aeration, and with agitation.

[0077] Optionally, the pH in the second medium can be controlled by monitoring the pH over time, and, if necessary, adjusting the pH in the second medium such as with a base or a buffer so it remains within a desired range during fermentation. For example, the pH of the second medium can also be controlled using a nitrogen-containing base, such as ammonium hydroxide so the pH is maintained in at about 5.8 or greater, such as in the range of about pH 5.8 to about pH 7.5 or greater, about pH 6.0 to about pH 7.0, about 5.8 to about 6.5 or 5.8 to about 6.2. A nitrogen-containing base used in the second medium can be the same as the nitrogen-containing base used in the first medium (e.g., ammonium hydroxide).

[0078] The engineered yeast can be maintained in the second medium for a period of time sufficient to produce one or more steviol glycosides. For example, the engineered yeast can be present in the second medium for a period up to about 150 hours which can include growth and fermentation phases of the process. Exemplary periods in the second medium are in the range of about 20 hours to about 150 hours, about 30 hours to about 120 hours, or about 40 hours to about 90 hours. The period in the second medium can be most of the growth phase and all of the fermentation phase, a part of the growth phase and all of the fermentation phase, all of the fermentation phase, or most of the fermentation phase.

[0079] In another embodiment, the disclosure provides a method for producing a steviol glycoside using engineered yeast in which a higher pH condition is present at an early point in the process, such as at the outset of the growth phase. For example, both the growth and fermentation phases of the process can be in a medium having a pH of 5.8 or greater, about pH 6.0 or greater, such as in the range of about pH 5.8 to about pH 8.0, pH 5.8 to about pH 7.5 greater, about pH 6.0 to about pH 7.0, about 5.8 to about 6.5 or about 5.8 to about 6.2. The medium can include a nitrogen source selected from ammonium hydroxide, urea, and ammonium sulfate. One or a combination of these compounds can be the primary nitrogen source during the growth and fermenting stages of the process.

[0080] In a process that starts with a high pH, during the periods the engineered yeast are growing and fermenting, the pH may fluctuate. However, the pH is preferably kept at about pH 5.8 or greater, or about pH 6.0 or greater, such as in the range of about pH 5.8 to about 8.0, pH 5.8 to about pH 7.5 or greater, or about pH 6.0 to about pH 7.0 during the growth and fermentation period. During these periods, the pH can be monitored (e.g., periodically or continuously) and adjustments to the medium can be made if the pH falls outside a desired range. For example, additional ammonium hydroxide can be added to the medium if the pH drops below 5.8 or 6.0, so as to adjust the pH to about 5.8 or greater.

[0081] In some modes of practice wherein the engineered yeast are present in a higher pH medium at the outset or early into the growth phase, the engineered yeast can be maintained in the medium for a period of time sufficient to produce one or more steviol glycosides. For example, the engineered yeast can be present in the higher pH medium for a period of about 150 hours, or even greater. Exemplary periods in the second medium are in the range of about 40 hours to about 150 hours, about 50 hours to about 130 hours, or about 60 hours to about 110 hours.

[0082] During fermentation, the medium at the higher pH can be monitored for the production of steviol glycosides. Fermentation can be stopped at a point where there is a desired steviol glycoside total amount and profile.

[0083] The "total steviol glycosides" (TSG) refers all the steviol glycosides present in the medium after a period of fermentation, which includes the amount of steviol glycosides in the liquid medium and obtainable from the engineered yeast. The steviol glycoside content can be expressed with regards to a total steviol glycosides amount in the medium, or the amount of one or more, but not all, steviol glycosides, in the medium. The amounts of steviol glycosides in the composition can be expressed in relation to one another, or to the total amount of steviol glycosides, such as by a weight percentage of the total amount of steviol glycosides, or a ratio, or range of ratios, expressed as weight percent, or molar percent. The sum of the content of all steviol glycosides in a composition it typically carried out on a dry (anhydrous) basis.

[0084] The amount of steviol glycosides can also be expressed relative to a control sample, such as a control sample fermented at a lower pH. An exemplary comparison is engineered yeast grown at a pH of about 5.0, and then adjusted to a pH in the range of 5.8 to 7.5 for fermentation, compared to engineered yeast grown and fermented at a pH of about 5.0, without adjusting to a higher pH. Another exemplary comparison is engineered yeast grown and fermented at pH in the range of 5.8 to 7.5 for fermentation, compared to engineered yeast grown and fermented at a pH of about 5.0.

[0085] For example, engineered yeast that are fermented at the higher pH condition, or both grown and fermented at the higher pH condition, can exhibit an increase in total steviol glycoside amount of about 1.2.times. or greater, about 1.3.times. or greater, about 1.4.times. or greater, about 1.5.times. or greater, about 1.6.times. or greater, about 1.7.times. or greater, about 1.8.times. or greater, about 1.9.times. or greater, or about 2.0.times. or greater, relative to the engineered yeast strain that is grown at a lower pH condition (e.g., pH 5.0).

[0086] The production of certain steviol glycosides, such as rebaudioside D and rebaudioside M, at higher pH conditions can also be described relative to engineered yeast grown at a lower pH condition. For example, engineered yeast that are fermented at the higher pH condition, or both grown and fermented at the higher pH condition, can exhibit an increase in rebaudioside D amount of about 1.4.times. or greater, about 1.5.times. or greater, about 1.6.times. or greater, about 1.7.times. or greater, about 1.8.times. or greater, about 1.9.times. or greater, about 2.0.times. or greater, about 2.1.times. or greater, relative to the engineered yeast strain that is grown at a lower pH condition (e.g., pH 5.0). Exemplary titers of rebaudioside D in the fermentation medium are about 1 g/L or greater, about 1.25 g/L or greater, about 1.5 g/L or greater, about 1.75 g/L or greater, or about 2.0 g/L or greater.

[0087] As another example, engineered yeast that are fermented at the higher pH condition, or both grown and fermented at the higher pH condition, can exhibit an increase in rebaudioside M amount of about 1.1.times. or greater, about 1.2.times. or greater, about 1.3.times. or greater, about 1.4.times. or greater, about 1.5.times. or greater, or about 1.6.times. or greater, relative to the engineered yeast strain that is grown at a lower pH condition (e.g., pH 5.0).

[0088] Engineered yeast fermented at the high pH conditions may also exhibit a change in the relative amounts of steviol glycosides produced. For example, at a lower pH, the engineered yeast may exhibit production of first and second steviol glycosides at a certain ratio (e.g., X:Y). Upon change to a higher pH fermentation condition, the engineered yeast may not only be able to produce a greater amount of the glycosides, including first and second glycosides, but may also able to produce the first and second glycosides at a ratio that is different than their production at the lower pH. In some modes of practice, the first steviol glycoside has a lower molecular weight than the second steviol glycoside. For example, with reference to rebaudioside D and rebaudioside M, fermentation at a higher pH (e.g., in the range of 5.8 to 7.5) can increase the reb D:reb M ratio as compared to the reb D:reb M ratio grown at a lower pH (e.g., pH 5.0).

[0089] In some modes of practice, the method provides a fermentation composition wherein the ratio of rebaudioside D to rebaudioside M in step (b) is about 1:20 or greater, such as in the range

[0090] of about 1:20 to about 1:1, about 1:5 to about 1:1, about 1:2 to about 1:1, about 1:1.75 to about 1:1, or about 1:1.5 to about 1:1. For example, engineered yeast that are fermented at the higher pH condition, or both grown and fermented at the higher pH condition, can exhibit ratios of rebaudioside D to rebaudioside M as about 1:20 or greater, such as in the range of about 1:20 to about 1:1, about 1:10 to about 1:1, about 1:7.5 to about 1:1, about 1:5 to about 1:1, about 1:3 to about 1:1, about 1:2 to about 1:1, about 1:1.75 to about 1:1, or about 1:1.5 to about 1:1.

[0091] For example, engineered yeast that are fermented at the higher pH condition, or both grown and fermented at the higher pH condition, can exhibit an increase in the reb D:reb M ratio of about 10% or greater, about 20% or greater, about 30% or greater, or about 40% or greater, relative to the reb D:reb M ratio when the engineered yeast strain are grown at a lower pH condition (e.g., pH 5.8 or less, or pH 5.0 or less).

[0092] Following the period of fermentation at the higher pH, a composition containing one or more steviol glycoside(s) can be obtained from the medium using various techniques. In some embodiments, a compound such as permeabilizing agent can be added to the medium to enhance removal of the steviol glycosides from the cell and into the medium.

[0093] The medium can then be centrifuged or filtered to remove the engineered cells. The medium can optionally be treated to remove low molecular weight components (glucose, basic nutrients, and salts), such as by membrane dialysis. Depending on a desired use, a composition comprising one or more steviol glycoside compound(s) can be used.

[0094] After fermentation the engineered yeast can optionally be treated using a heat treatment method to enhance the recovery of steviol glycosides. After fermentation, but before any heat treatment, the medium may contain a suboptimal amount of the steviol glycosides, with a portion of the desired steviol glycosides within the engineered yeast. To increase the recovery of steviol glycosides, in some modes of practice a composition, such as the medium at the higher pH in which the engineered yeast have been fermented, is heated to a temperature in the range from 50.degree. C. to 95.degree. C., or 70.degree. C. to 95.degree. C., for a period of time in the range of 5 minutes to 48 hours.

[0095] If it is desired to provide a composition with steviol glycosides in enriched or purified form, or where certain steviol glycosides are separated from one another, further purification can be carried out. Such enrichment or purification of steviol glycoside components can be carried out on the medium in which fermentation took place, or the medium can then be dried down prior to purification. For example, medium can be dried down using lyophilization to form a dry composition (e.g., powder or flakes) including steviol glycosides that can be subsequently processed.

[0096] In some modes of practice, dried fermentation broth enriched for steviol glycosides is used as the starting material for purification. For example, a solvent or solvent combination can be added to the dried fermentation broth to dissolve or suspend material that includes the steviol glycosides. An exemplary combination for dissolving the steviol glycosides is a mixture of water and an alcohol (e.g., 50:50 ethanol:water). To facilitate dissolving or suspending, the dried broth materials can be heated at a temperature above room temperature, such as in the range of 40.degree. C.-60.degree. C. Mechanical disruption of the dried broth materials can also be performed, such as by sonication. The dissolved or suspended broth materials can be filtered using a micron or sub-micron prior to further purification, such as by preparative chromatography.

[0097] Dried fermentation broth enriched for steviol glycoside compounds can be subjected to purification, such as by reverse phase liquid chromatography. A suitable resin can be used to retain steviol glycoside compounds in the column, with removal of hydrophilic compounds which get washed through the column with a liquid such as water. Elution of steviol glycosides from the column can be accomplished a suitable solvent or solvent combination such as acetonitrile or methanol.

[0098] Elution of steviol glycosides from a reverse phase column can yield a composition which can be useful for any one of a variety of purposes. For example, a purified steviol glycoside composition can be used as a sweetener composition for oral ingestion or oral use. The composition can be defined with regards to the steviol glycosides in the composition.

[0099] Steviol glycoside-producing S. cerevisiae strains were constructed using methods as described in WO 2011/153378, WO 2013/022989, WO 2014/122227, and WO 2014/122328, each of which is incorporated by reference in their entirety. The following sequences were used for construction of a parent strain (Strain A): a recombinant gene encoding a Synechococcus sp GGPPS polypeptide (SEQ ID NO:6), a recombinant gene encoding a truncated Zea mays CDPS polypeptide (SEQ ID NO:7), a recombinant gene encoding an Arabidopsis thaliana KS polypeptide (SEQ ID NO:8), a recombinant gene encoding a recombinant Stevia rebaudiana KO polypeptide (SEQ ID NO:9, SEQ ID NO:10), a recombinant gene encoding an A. thaliana ATR2 polypeptide (SEQ ID NO:11, SEQ ID NO:12), a recombinant gene encoding an Oryza saliva EUGT 11 polypeptide (SEQ ID NO:13), a recombinant gene encoding an SrKAHe1 polypeptide (SEQ ID NO:14, SEQ ID NO:15), a recombinant gene encoding an Stevia rebaudiana CPR8 polypeptide (SEQ ID NO:16, SEQ ID NO:17), a recombinant gene encoding an Stevia rebaudiana UGT85C2 polypeptide (SEQ ID NO:2), a recombinant gene encoding an Stevia rebaudiana UGT74G1 polypeptide (SEQ ID NO:1), a recombinant gene encoding an Stevia rebaudiana UGT76G1 polypeptide (SEQ ID NO:3), and a recombinant gene encoding an Stevia rebaudiana UGT91D2 variant (or functional homolog), UGT91D2e-b, (SEQ ID NO:4) polypeptide produced steviol glycosides.

[0100] The UGT91D2e-b variant of UGT91D2 (SEQ ID NO:5 from PCT/US2012/050021) includes a substitution of a methionine for leucine at position 211 and a substitution of an alanine for valine at position 286. (Additional variants, except T144S, M152L, L213F, S364P, and G384C variants, described in Table 12 and Example 11 of PCT/US2012/050021 could be used.) GeneArt codon-optimized sequence encoding a Stevia rebaudiana UGT91D2e-b with the amino acid modifications L211M and V286A (SEQ ID NO:4 for amino acid sequence; codon optimized nucleotide sequence is set forth in SEQ ID NO:5).

[0101] Strain B is derived from the parent strain described above and additionally includes a codon-optimized CPR1 from Stevia rebaudiana (SEQ ID NO:18 corresponding to amino acid SEQ ID NO:19).

[0102] Strain C is derived from strain B and additionally includes a gene encoding a KO polypeptide according to SEQ ID NO: 20.

[0103] Strain D is derived from strain C and additionally includes a gene encoding a KAH polypeptide according to SEQ ID NO: 21.

[0104] Strain E is derived from strain C and additionally includes a gene encoding a CPR4497 polypeptide according to SEQ ID NO: 22

[0105] Some additional non-limiting embodiments are provided below to further exemplify the present disclosure:

1. A method for producing steviol glycoside, the method comprising steps of:

[0106] (a) growing engineered yeast in a first medium at a first pH, wherein the engineered yeast are capable of producing one or more steviol glycoside(s);

[0107] (b) adding a composition to the first medium to provide a second medium with a second pH that is greater than the first pH; and

[0108] (c) fermenting the engineered yeast to produce the one or more steviol glycoside(s) in the second medium at the second pH.