Functional Toothbrush Stick And Method For Manufacturing Same

PARK; Mi Ra

U.S. patent application number 16/764145 was filed with the patent office on 2020-12-24 for functional toothbrush stick and method for manufacturing same. The applicant listed for this patent is Mi Ra PARK. Invention is credited to Mi Ra PARK.

| Application Number | 20200397133 16/764145 |

| Document ID | / |

| Family ID | 1000005072844 |

| Filed Date | 2020-12-24 |

| United States Patent Application | 20200397133 |

| Kind Code | A1 |

| PARK; Mi Ra | December 24, 2020 |

FUNCTIONAL TOOTHBRUSH STICK AND METHOD FOR MANUFACTURING SAME

Abstract

A functional toothbrush shaft and a method of manufacturing the same are proposed. The functional toothbrush shaft includes: a toothbrush body including a handle, a bristle head support neck, and a bristle head; and at least one finger support protrusion that forms a stable resultant force by forming at least three support points on the handle of the toothbrush body, prevents slipping of a user's fingers to increase friction, and allows free gripping throughout 360.degree. at any point of a cylindrical surface of the toothbrush body.

| Inventors: | PARK; Mi Ra; (Seoul, KR) | ||||||||||

| Applicant: |

|

||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Family ID: | 1000005072844 | ||||||||||

| Appl. No.: | 16/764145 | ||||||||||

| Filed: | November 12, 2018 | ||||||||||

| PCT Filed: | November 12, 2018 | ||||||||||

| PCT NO: | PCT/KR2018/013703 | ||||||||||

| 371 Date: | July 21, 2020 |

| Current U.S. Class: | 1/1 |

| Current CPC Class: | A46B 5/026 20130101; A46B 5/021 20130101; A46B 9/028 20130101; A46B 9/04 20130101; A46B 15/0069 20130101; A46B 2200/108 20130101 |

| International Class: | A46B 9/04 20060101 A46B009/04; A46B 5/02 20060101 A46B005/02 |

Foreign Application Data

| Date | Code | Application Number |

|---|---|---|

| Nov 15, 2017 | KR | 10-2017-0152489 |

Claims

1. A functional toothbrush shaft, comprising: a toothbrush body including a handle, a bristle head support neck, and a bristle head; and at least one finger support protrusion that forms a stable resultant force by forming at least three support points on the handle of the toothbrush body, prevents slipping of a user's fingers to increase friction, and allows free gripping throughout 360.degree. at any point of a cylindrical surface of the toothbrush body.

2. The functional toothbrush shaft of claim 1, wherein the finger support protrusion comprises: a first finger support protrusion protruding from an outer circumferential surface of the handle, and determining upper positions of a user's thumb and a user's index finger; a second finger support protrusion protruding determining lower positions of the user's thumb and the user's index finger; and a third finger support protrusion determining a position of a user's middle finger, wherein first and second support grooves allowing the user's fingers to be seated therein are provided between the first, second, and third finger support protrusions.

3. The functional toothbrush shaft of claim 1, further comprising: a rear round grip provided at a rear end of the handle, and allowing a user's ring finger, and a user's little finger, and a user's palm to be placed and supported thereon.

4. The functional toothbrush shaft of claim 2, further comprising: a shoulder grip provided between a front end of the first finger support protrusion and the bristle head support neck, and allowing the user's thumb and the user's index finger to be placed thereon and prevented from slipping.

5. The functional toothbrush shaft of claim 1, wherein a center of gravity of the toothbrush body is placed at a rear end of the handle so that even if a toothbrush is dropped on a floor, the handle is first brought into contact with the floor; and the finger support protrusions form a predetermined angle with respect to bristles and the bristle head support neck is formed inclinedly so that the bristles of the bristle head are prevented from contact with the floor and thus prevented from contamination due to a contact surface.

6. The functional toothbrush shaft of claim 1, wherein the handle and the finger support protrusion protruding outward from the handle are formed in a circular shape to facilitate rotation.

7. The functional toothbrush shaft of claim 1, wherein the toothbrush body further comprises a month indicator on which each month from January to December is marked as numbers or twelve colors are displayed, so that the toothbrush shaft is replaced every month and used in a state in which dental plaque removing efficiency of bristles is high, thereby providing a psychological and educational effect to increase oral hygiene awareness.

8. The functional toothbrush shaft of claim 1, wherein the bristle head is one selected from a daily brush head, an advanced brush head, an interdental brush head, and an infant brush head.

9. A method of manufacturing a functional toothbrush shaft of claim 1, the method being capable of maximizing personalized motion suitability in accordance with an anatomical structure of a hand of a user and further increasing personalized anatomical suitability by three-dimensional (3D) scanning and printing in manufacturing the functional toothbrush shaft, the method comprising: inputting anatomical structure data of the hand of the user including a person with disability, into a computer; generating toothbrush shaft design data conforming to the anatomical structure of the hand of the user including the person with disability; transmitting, by the computer, three-dimensional (3D) data to a three-dimensional (3D) printer; and producing, by the 3D printer, a three-dimensional toothbrush shaft on the basis of on the 3D data, thereby manufacturing a personalized toothbrush shaft.

10. The functional toothbrush shaft of claim 2, further comprising: a rear round grip provided at a rear end of the handle, and allowing a user's ring finger, and a user's little finger, and a user's palm to be placed and supported thereon.

Description

TECHNICAL FIELD

[0001] The present invention relates generally to a functional toothbrush shaft and a method of manufacturing the same. More particularly, the present invention relates to a functional toothbrush shaft and a method of manufacturing the same, wherein a finger support protrusion forms at least three support points by a finger support structure to form a stable resultant force; slipping of a user's fingers is prevented to increase friction thereby enabling stable gripping; and the toothbrush shaft is designed to rotate 360.degree. to enable free gripping in any direction, thereby ensuring that bristles reach any area in a user's oral cavity stably to accurately and efficiently remove dental plaque from all surfaces (tooth surfaces, mucosal surfaces, and the tongue) in a user's oral cavity. Further, a toothbrush is replaced at an appropriate time so that the toothbrush is used in a state in which dental plaque removing efficiency of bristles is high. Further, a personalized toothbrush shaft is manufactured and provided.

BACKGROUND ART

[0002] As well known in the art, a toothbrush is an oral hygiene instrument used with toothpaste.

[0003] A teeth cleaning method with a wooden toothpick is described in Italy's health booklet around 1450. A toothbrush made of bristles attached to a handle appeared in the 1600s and was made in England in 1780. After World War II, a toothbrush made of nylon bristles and an acrylic resin handle has been developed and is in use.

[0004] There are various types of bristled portions are attached, such as bombay type and straight type, but for oral hygiene, a straight type is currently common. As a method of brushing teeth, a rotation method is recognized worldwide, and an ergonomic angle is given to a toothbrush handle to facilitate this method.

[0005] However, the conventional toothbrush as described above has many problems as follows.

[0006] First, in a conventional toothbrush shaft, only one support point for thumb force exists on the same surface as the surface on which the bristles are located. This limits rotational displacement in the up and down direction and induces a user to perform standardized brushing.

[0007] Second, in the conventional toothbrush shaft, due to the fact that only one support point for thumb force exists on the same surface as the bristles, in order to reach the bristles in a correct position when brushing in various directions, a user has to lift up his/her elbow, bend his/her wrist, or tilt his/her head at an angle, leading to low positional stability. Thus, during brushing, the bristles deviate from a brushing area of target teeth, which makes it difficult to accurately brush a user's teeth, or causing mucosal damage.

[0008] Third, the conventional toothbrush shaft is used by forcibly gripping a toothbrush handle with a user's all five fingers, and thus the degree of freedom of movement is limited during brushing. Additionally, excessive force is concentrated on the bristles, which makes it difficult to accurately brush the target teeth, or causing mucosal damage.

[0009] Fourth, in the conventional toothbrush shaft, the support point for thumb force is formed, and two support points are formed on the opposite side at upper and lower positions. Due to this fact, during movement in the longitudinal axis direction of the toothbrush, rotational force is created around the support points, resulting that the bristles are shaken up and down relative to the longitudinal axis of the toothbrush, which makes it difficult to accurately brush the target teeth, or causing mucosal damage.

[0010] Fifth, in the conventional toothbrush shaft, due to the fact that the support point for thumb force is formed, and two support points are formed on the opposite side at upper and lower positions, during movement in the transverse axis direction of the toothbrush, rotational force is created around the support points, resulting that the bristles are shaken up and down relative to the longitudinal axis of the toothbrush, which makes it difficult to accurately brush the target teeth, or causing mucosal damage.

[0011] Sixth, in the conventional toothbrush shaft, due to the fact that the support point for thumb force is formed, and two support points are formed on the opposite side at upper and lower positions, during rotational movement of the toothbrush, another rotational force is created around the support points, resulting that the bristles are shaken up and down relative to the longitudinal axis of the toothbrush, which makes it difficult to accurately brush the target teeth, or causing mucosal damage.

[0012] Seventh, in the conventional toothbrush shaft, due to the structure thereof, when the toothbrush shaft is placed on a sink, the bristles are brought into contact with a sink or bathtub surface, and when the toothbrush shaft is dropped on a floor, the bristles are brought into contact with contaminants on the floor.

[0013] Eighth, the conventional toothbrush shaft customarily provides a handle structure in which the upper and lower surfaces exist with respect to the bristles. This induces the user to perform standardized brushing.

[0014] Ninth, in the conventional toothbrush shaft, two opposed support points formed by a user's thumb and other four fingers mean two vectors, and thus stability cannot be achieved by adjusting the length of the vectors, and rotational force is continuously generated.

[0015] Tenth, in the conventional toothbrush shaft, during brushing a user's anterior teeth, there is less fixation by a user's cheeks compared to a user's posterior teeth. In particular, the position of the bristles is unstable due to rotational force generated by fixing front and rear surfaces at two points, resulting that the bristles are shaken up and down, which makes it difficult to accurately brush the target teeth, or causing mucosal damage.

[0016] Eleventh, the conventional toothbrush shaft is designed for people with normal body functions. This forces a user who has a different arm length, hand length, and finger length (including a person with disability) compared to a normal person to use the toothbrush with inconvenience, or to use a special toothbrush for a person with disability.

[0017] Twelfth, in the conventional toothbrush shaft, it is difficult to exactly recognize a replacement time, so the use period may be recognized by discoloration of the bristles containing a material that changes color when replacement is necessary, or by discoloration of the toothbrush handle, but the effect is negligible.

[0018] In an effort to solve the above-mentioned problems, the following related art documents have been applied, but there still remains a problem in that not all of the above-mentioned problems of the related art can be solved.

[0019] [Documents of Related Art]

[0020] (Patent Document 1) Korean Patent Application Publication No. 10-1999-0071809 (1999, Sep. 27)

[0021] (Patent Document 2) Korean Patent Application Publication No. 10-2013-0106734 (2013, Sep. 30).

[0022] (Patent Document 3) Korean Patent No. 10-1253594 (2013, Apr. 5)

[0023] (Patent Document 4) Korean Patent Application Publication No. 10-2015-0138294 (2015, Dec. 9)

[0024] (Patent Document 5) Korean Utility Model Registration No. 20-0374520 (2005, Jan. 20)

DISCLOSURE

Technical Problem

[0025] In the present invention, a user's thumb (hereinafter referred to as finger 1), a user's index finger (hereinafter referred to as finger 2), a user's middle finger (hereinafter referred to as finger 3), a user's ring finger (hereinafter referred to as finger 4), a user's little finger (Hereinafter referred to as finger 5) will be referred to as the above numbers for convenience of explanation.

[0026] The present invention has been made keeping in mind the above problems occurring in the related art, and a first objective of the present invention is to provide a functional toothbrush shaft including first, second, third finger support protrusions, first and second support grooves, a rear round grip, a shoulder grip, a bristle head support neck, and a bristle head. A second objective of the present invention according to the above-described technical configuration is to provide a functional toothbrush shaft, wherein finger 1 is used as a support point through first and second finger support protrusions (hereinafter, the finger support protrusions will also be referred to as `structures`) at any point of a toothbrush body throughout 360.degree. so that there is no restriction of rotational displacement, and a third finger support protrusion is additionally provided to allow fingers 1, 2, and 3 to support a cylindrical surface of the toothbrush body at two or three points. A third objective is to provide a functional toothbrush shaft, wherein by supporting the cylindrical surface of the toothbrush body at two or three points, displacement of bristles during brushing is minimized, deviation from the range of a target teeth brushing motion expected by a user is minimized, and the amount of force applied to the bristles is appropriately controlled thereby maximizing brushing efficiency while minimizing side effects such as mucosal damage. A fourth objective of the present invention is to provide a functional toothbrush shaft, wherein three fingers 1, 2, and 3 form two or three support points through the first and second finger support protrusions at a position near the bristles, and fingers 4 and 5 and a user's palm form one support point through a rear round grip, thereby forming a total of at least three support points. A fifth objective of the present invention is to provide a functional toothbrush shaft, wherein by forming a triangular vector sum by three support points or a quadrangular vector sum by four support points, it is possible to obtain static stability with a zero resultant force, thereby stably forming vibrations during movement in the longitudinal axis direction of a toothbrush when brushing with the Bass technique, without creating rotational force with respect to the direction of movement. A sixth objective of the present invention is to provide a functional toothbrush shaft, wherein when a vector sum of a small three-point triangle or a four-point quadrangle is formed in a user's hand to obtain positional stability, and then the toothbrush shaft is held by the hand and placed on a user's teeth with a user's armpit closed, it is easy to form a vector sum of a large three-point triangle of the user's armpit, the user's hand, and the user's teeth, which reduces displacement of brushing to brush target teeth, thereby enabling stable and efficient brushing of the target teeth with effective force, and minimizing a possibility that bristles become splayed or interdental brush bristles become bent or distorted. A seventh objective of the present invention is to provide a functional toothbrush shaft, wherein positional stability of the toothbrush shaft is maximized, thereby minimizing mucosal damage in a user's oral cavity caused by the toothbrush during brushing. An eight objective of the present invention is to provide a functional toothbrush shaft, wherein by three structures (finger support protrusions) for determining support point positions, the center of gravity is placed at a rear end of the toothbrush shaft thereby ensuring that even if the toothbrush shaft is dropped on a floor, a handle is first brought into contact with the floor; and the first structure always form a predetermined angle with respect to the bristles to prevent the bristles from contact with the floor, thereby implementing a function to prevent contamination due to a contact surface. A ninth objective of the present invention is to provide a functional toothbrush shaft, wherein personalized motion suitability is maximized in accordance with an anatomical structure of the user's hand, and personalized anatomical suitability is further increased three-dimensional (3D) scanning and printing thereby further increasing motion suitability. A tenth objective of the present invention is to provide a functional toothbrush shaft, wherein a toothbrush made of the toothbrush shaft according to the present invention forms three or four vectors, and thus even if the lengths of the three or four vectors are controlled, a resultant force is zero thereby forming and maintaining a stable structure, which ensures that if there are three vectors, anyone (including a person with disability) who has a different arm length, hand length, and finger length is able to reliably brush his/her teeth. An eleventh objective of the present invention is to provide a functional toothbrush shaft, wherein during brushing of a user's anterior teeth, a first node of finger 2 is placed on the first and second structures, while left and right sides of second and fourth structures are gripped by fingers 1 and 3 and fingers 4 and 5 and the user's palm are placed over a third structure, thereby enabling stable brushing; during brushing of a user's mandibular anterior teeth, with the toothbrush gripped upside down, fingers 1 and 3 are placed between the first and second structures while finger 2 is placed between the second and fourth structures to form a three-point vector triangle, thereby enabling stable brushing; and other various brushing methods are calculated for each 360.degree.. A twelfth objective of the present invention is to provide a functional toothbrush shaft, wherein the toothbrush shaft enables brushing for users of various arm lengths, hand lengths, and finger lengths (including people with disabilities), and the toothbrush shaft is personalized in accordance with a user's arm length, hand length, and finger length, by three dimensional (3D) scanning and printing, thereby increasing brushing efficiency. A thirteenth objective of the present invention is to provide a functional toothbrush shaft, wherein the toothbrush shaft is limited to a one-month use period (when used once a day) by marking each month from January to December on the toothbrush body as numbers or displaying twelve colors thereon, so that the toothbrush shaft is replaced every month and used in a state in which dental plaque removing efficiency of the bristles is high, thereby providing a psychological and educational effect to increase oral hygiene awareness.

Technical Solution

[0027] In order to accomplish the above objectives, the present invention provides a functional toothbrush shaft including a toothbrush body including: handle, a bristle head support neck, and a bristle head; and at least one finger support protrusion that forms a stable resultant force by forming at least three support points on the handle of the toothbrush body, prevents slipping of a user's fingers to increase friction, and allows free gripping throughout 360.degree. at any point of a cylindrical surface of the toothbrush body.

[0028] Further, the present invention provides a method of manufacturing a functional toothbrush shaft, the method being capable of maximizing personalized motion suitability in accordance with an anatomical structure of a hand of a user and further increasing personalized anatomical suitability by three-dimensional (3D) scanning and printing in manufacturing the functional toothbrush shaft, the method including: inputting anatomical structure data of the hand of the user including a person with disability, into a computer; generating toothbrush shaft design data conforming to the anatomical structure of the hand of the user including the person with disability; transmitting, by the computer, three-dimensional (3D) data to a three-dimensional (3D) printer; and producing, by the 3D printer, a three-dimensional toothbrush shaft on the basis of on the 3D data, thereby manufacturing a personalized toothbrush shaft.

Advantageous Effects

[0029] According to the present invention as described above, the toothbrush shaft includes first, second, third finger support protrusions, first and second support grooves, a rear round grip, a shoulder grip, a bristle head support neck, and a bristle head.

[0030] In the toothbrush shaft according to the present invention, finger 1 is used as a support point through first and second finger support protrusions (hereinafter, the finger support protrusions will also be referred to as `structures`) at any point of the toothbrush body throughout 360.degree. so that there is no restriction of rotational displacement, and a third finger support protrusion is additionally provided to allow all fingers 1, 2, and 3 to support a cylindrical surface of the toothbrush body at two or three points.

[0031] Further, in the toothbrush shaft, by supporting the cylindrical surface at two or three points that allow free movement of all fingers, displacement of bristles during brushing is minimized, deviation from the range of a target teeth brushing motion expected by a user is minimized, and the amount of force applied to the bristles is appropriately controlled thereby maximizing brushing efficiency while minimizing side effects such as mucosal damage.

[0032] Further, in the toothbrush shaft according to the present invention, three fingers 1, 2, and 3 form two or three support points through the first and second finger support protrusions at a position near the bristles, and fingers 4 and 5 and a user's palm form one support point through a rear round grip, thereby forming a total of at least three support points.

[0033] Further, in the toothbrush shaft according to the present invention, by forming a triangular vector sum by three support points or a quadrangular vector sum by four support points, it is possible to obtain static stability with a zero resultant force, thereby stably forming vibrations during movement in the longitudinal axis direction of a toothbrush when brushing with the Bass technique, without creating rotational force with respect to the direction of movement.

[0034] Further, in the toothbrush shaft according to the present invention, when a vector sum of a small three-point triangle or a four-point quadrangle is formed in a user's hand to obtain positional stability, and then the toothbrush shaft is held by the hand and placed on a user's teeth with a user's armpit closed, it is easy to form a vector sum of a large three-point triangle of the user's armpit, the user's hand, and the user's teeth, which reduces displacement of brushing to brush target teeth, thereby enabling stable and efficient brushing of the target teeth with effective force, and minimizing a possibility that bristles become splayed or interdental brush bristles become bent or distorted.

[0035] Further, in the toothbrush shaft according to the present invention, positional stability of the toothbrush shaft is maximized, thereby minimizing mucosal damage in a user's oral cavity caused by the toothbrush during brushing.

[0036] Further, in the toothbrush shaft according to the present invention, by three structures (finger support protrusions) for determining support point positions, the center of gravity is placed at the rear end of the toothbrush shaft thereby ensuring that even if the toothbrush shaft is dropped on a floor, a handle is first brought into contact with the floor; and the first structure always form a predetermined angle with respect to the bristles to prevent the bristles from contact with the floor, thereby implementing a function to prevent contamination due to a contact surface.

[0037] Further, in the toothbrush shaft according to the present invention, personalized motion suitability is maximized in accordance with an anatomical structure of the user's hand, and personalized anatomical suitability is further increased by three-dimensional (3D) scanning and printing thereby further increasing motion suitability.

[0038] In particular, a toothbrush made of the toothbrush shaft according to the present invention forms three or four vectors, and thus even if the lengths of the three or four vectors are controlled, a resultant force is zero thereby forming and maintaining a stable structure, which ensures that if there are three vectors, anyone (including a person with disability) who has a different arm length, hand length, and finger length is able to reliably brush his/her teeth.

[0039] Further, in the functional toothbrush shaft according to the present invention, during brushing of a user's anterior teeth, a first node of finger 2 is placed on the first and second structures, while left and right sides of second and fourth structures are gripped by fingers 1 and 3 and fingers 4 and 5 and the user's palm are placed over a third structure, thereby enabling stable brushing; during brushing of a user's mandibular anterior teeth, with the toothbrush gripped upside down, fingers 1 and 3 are placed between the first and second structures while finger 2 is placed between the second and fourth structures to form a three-point vector triangle, thereby enabling stable brushing; and other various brushing methods are calculated for each 360.degree..

[0040] Further, the toothbrush shaft according to the present invention enables brushing for users of various arm lengths, hand lengths, and finger lengths (including people with disabilities), and the toothbrush shaft is personalized in accordance with a user's arm length, hand length, and finger length, by three dimensional (3D) scanning and printing, thereby increasing brushing efficiency.

[0041] Lastly, in the toothbrush shaft according to the present invention, the toothbrush shaft is limited to a one-month use period (when used once a day) by marking each month from January to December on the toothbrush body as numbers or displaying twelve colors thereon, so that the toothbrush shaft is replaced every month and used in a state in which dental plaque removing efficiency of the bristles is high, thereby providing a psychological and educational effect to increase oral hygiene awareness.

[0042] Hereinafter, exemplary embodiments of the present invention for achieving these effects will be described in detail with reference to the accompanying drawings.

DESCRIPTION OF DRAWINGS

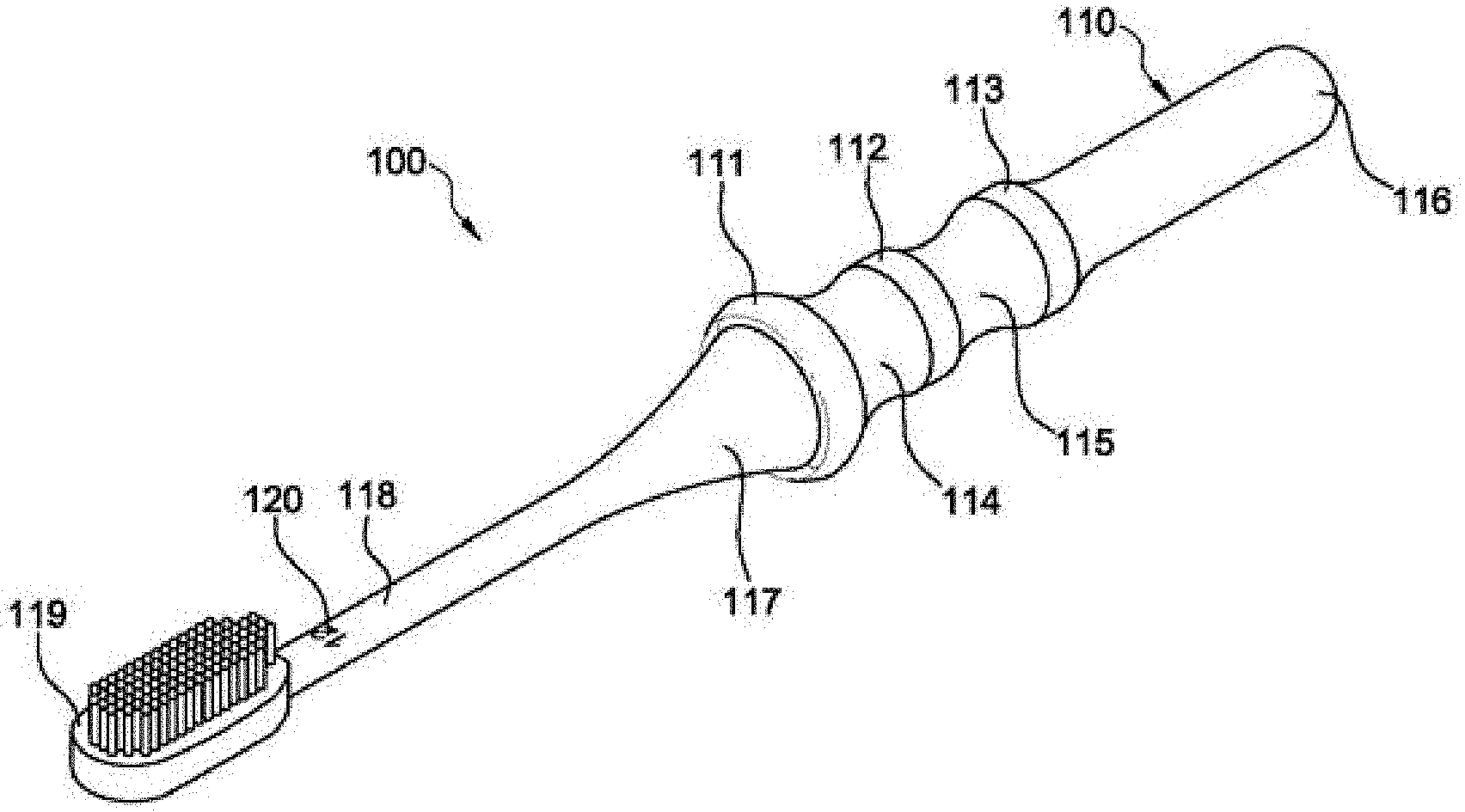

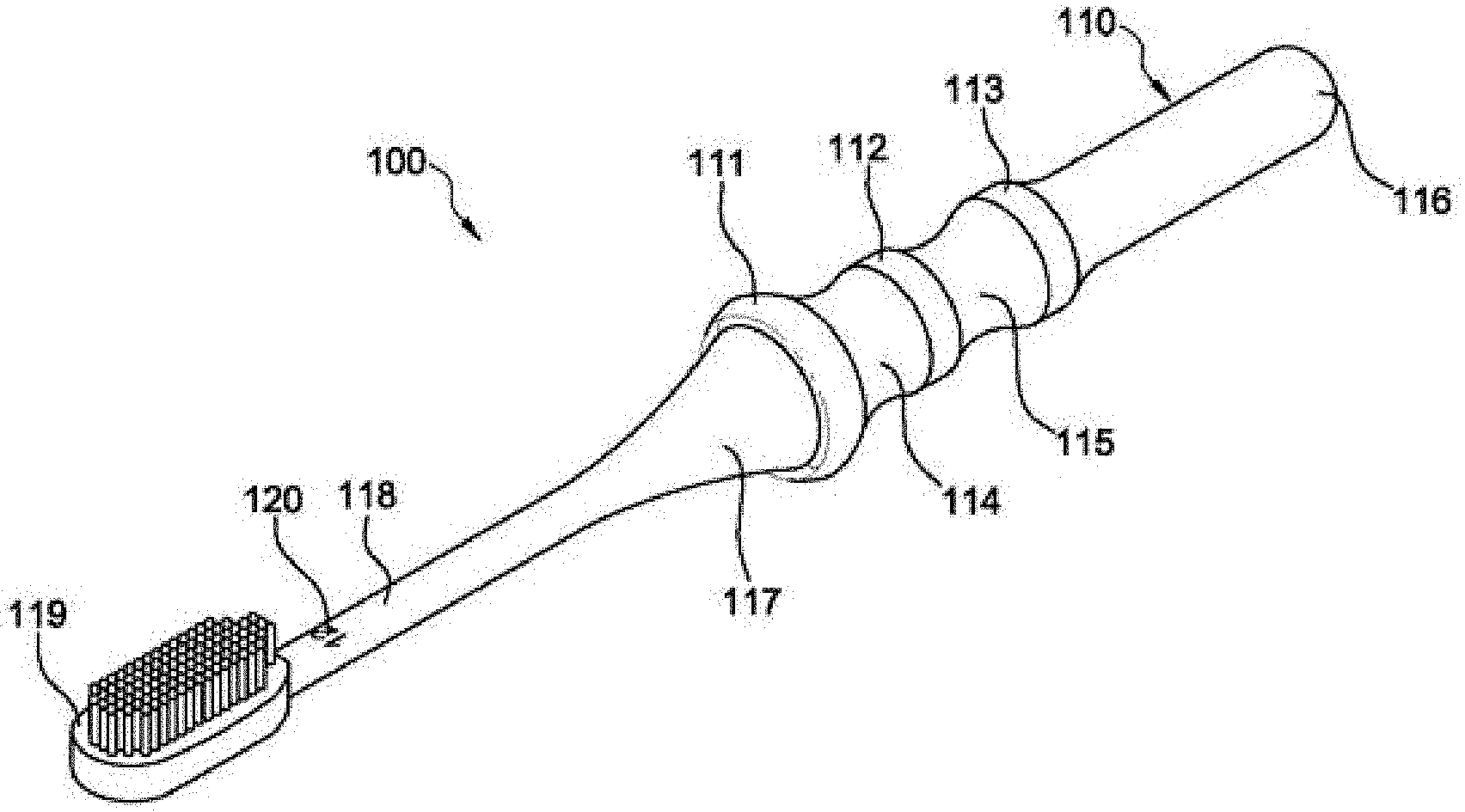

[0043] FIG. 1 is a perspective view illustrating a functional toothbrush shaft according to the present invention.

[0044] FIG. 2 is a front view illustrating the functional toothbrush shaft according to the present invention.

[0045] FIG. 3 is a plan view illustrating the functional toothbrush shaft according to the present invention.

[0046] FIG. 4 is a view illustrating photographs illustrating a grip method of gripping a handle of a daily toothbrush according to the present invention.

[0047] FIG. 5 is a view illustrating photographs illustrating a grip method of gripping the handle of the daily toothbrush according to the present invention (anterior teeth).

[0048] FIG. 6 is a view illustrating photographs illustrating a grip method of gripping a handle of an interdental toothbrush according to the present invention.

[0049] FIG. 7 is a view illustrating photographs illustrating a grip method of gripping a handle of an advanced toothbrush according to the present invention.

[0050] FIG. 8 is a view illustrating photographs illustrating a basic method of using the daily toothbrush according to the present invention.

[0051] FIG. 9 is a view illustrating photographs illustrating various methods of using the daily toothbrush according to the present invention.

[0052] FIG. 10 is a view illustrating photographs illustrating a use state of the daily toothbrush according to the present invention.

DESCRIPTION OF THE REFERENCE NUMERALS IN THE DRAWINGS

[0053] 100: toothbrush body [0054] 111, 112, 113: first, second, third finger support protrusions [0055] 114, 115: first and second support grooves [0056] 116: rear round grip [0057] 117: shoulder grip [0058] 118: bristle head support neck [0059] 119: bristle head [0060] 120: month indicator

BEST MODE

[0061] A functional toothbrush shaft according to the present invention and a method of manufacturing the same are configured as illustrated in FIGS. 1 to 10.

[0062] In the following description of the present invention, detailed descriptions of known functions and components incorporated herein will be omitted when it may make the subject matter of the present invention unclear.

[0063] Further, technical terms, as will be mentioned hereinafter, are terms defined in consideration of their function in the present invention, which may be varied according to the intention of a user, practice, or the like, so that the terms should be defined based on the contents of this specification.

[0064] In the drawings, the size or and thickness of each component is expressed arbitrarily for clarity of illustration, but due to this, the protective scope of the present invention should not be interpreted narrowly.

[0065] First, a toothbrush body 100 includes a handle 110, a bristle head support neck 118, and a bristle head 119.

[0066] The present invention provides a functional toothbrush shaft characterized by including at least one finger support protrusion that forms a stable resultant force by forming at least three support points on the handle 110 of the toothbrush body 100, prevents slipping of a user's fingers to increase friction, and allows free gripping throughout 360.degree. at any point of a cylindrical surface of the toothbrush body.

[0067] In particular, a first finger support protrusion 111 protruding from an outer circumferential surface of the handle 110, and

[0068] determining upper positions of a user's thumb and a user's index finger is provided.

[0069] Further, a second finger support protrusion 112 determining lower positions of the user's thumb and the user's index finger is provided.

[0070] Further, a third finger support protrusion 113 determining a position of a user's middle finger.

[0071] First and second support grooves 114 and 115 allowing a user's fingers to be seated therein are provided between the first, second, and third finger support protrusions 111, 112, and 113.

[0072] Further, a rear round grip 116 is provided at a rear end of the handle 110 and allows a user's ring finger, a user's little finger, and the user's palm to be placed and supported thereon.

[0073] Further, a shoulder grip 117 is provided between a front end of the first finger support protrusion 111 and the bristle head support neck 118 and allows the user's thumb and the user's index finger to be placed thereon and prevented from slipping.

[0074] In particular, in the present invention, the center of gravity of the toothbrush body 100 is placed at the rear end of the handle 110 so that even if a toothbrush is dropped on a floor, the handle is first brought into contact with the floor. Additionally, the finger support protrusions form a predetermined angle with respect to bristles and the bristle head support neck 118 is formed inclinedly so that the bristles of the bristle head 119 are prevented from contact with the floor and thus prevented from contamination due to a contact surface.

[0075] Further, it is preferable that the handle 110 and the finger support protrusion protruding outward from the handle are formed in a circular shape to facilitate rotation.

[0076] Further, the toothbrush body 100 further includes a month indicator 120 on which each month from January to December is marked as numbers or twelve colors are displayed, so that the toothbrush shaft is replaced every month and used in a state in which dental plaque removing efficiency of the bristles is high, thereby providing a psychological and educational effect to increase oral hygiene awareness.

[0077] Lastly, the bristle head 119 may be made of various types of brush heads, such as a daily brush head, advanced brush head, interdental brush head, and infant brush head.

[0078] The present invention may be variously modified and have various forms in applying the above-described components.

[0079] It should be understood that the present invention is not limited to the particular forms mentioned in the detailed description above, but rather includes all modifications, equivalents, and substitutes within the spirit and scope of the invention as defined by the appended claims.

[0080] Operational effects of the functional toothbrush shaft according to the present invention configured as described above will be described as follows.

[0081] First, according to the present invention, the finger support protrusions of the toothbrush shaft form at three support points by a finger support structure to form a stable resultant force, and also prevents slipping of the user's fingers to increase friction thereby enabling stable gripping. Additionally, the finger support protrusions allows free gripping throughout 360.degree. at any point of the cylindrical surface of the toothbrush body thereby ensuring that the bristles reach any area in a user's oral cavity stably.

[0082] To this end, FIG. 1 is a perspective view illustrating the functional toothbrush shaft according to the present invention, wherein the bristle head is a daily brush head.

[0083] FIG. 2 is a front view illustrating the functional toothbrush shaft according to the present invention. By three structures (finger support protrusions) for determining support point positions of the toothbrush shaft, the center of gravity is placed at the rear end of the toothbrush shaft thereby ensuring that even if the toothbrush shaft is dropped on a floor, the handle is first brought into contact with the floor. Additionally, a first structure always form a predetermined angle with respect to the bristles to prevent the bristles from contact with the floor, thereby implementing a function to prevent contamination due to a contact surface.

[0084] FIG. 3 is a plan view illustrating the functional toothbrush shaft according to the present invention.

[0085] FIG. 4 illustrates photographs illustrating a grip method of gripping a handle of the daily toothbrush according to the present invention, illustrating the position of the user's thumb, a front side of a bristle head, a left side of the bristle head, a right side of the bristle head, and a rear side of the bristle head.

[0086] FIG. 5 illustrates photographs illustrating a grip method of gripping the handle of the daily toothbrush according to the present invention (anterior teeth), illustrating a method of using the daily toothbrush upside down or upright.

[0087] FIG. 6 illustrates photographs illustrating a grip method of gripping a handle of an interdental toothbrush according to the present invention, illustrating sequentially, from the left, a rear side of a bristle head when gripping by rear support of finger 3, a front side of the bristle head upon gripping by rear support of the finger 3 and left and right gripping of fingers 1 and 2 of different heights, the front side of the bristle head upon gripping by rear support of finger 3 and left and right gripping of fingers 1 and 2 of different heights, and a left buccal side and a right lingual side of the front side of the bristle head upon gripping by rear support of finger 3 and left and right gripping of fingers 1 and 2 of different heights.

[0088] FIG. 7 illustrates photographs illustrating a grip method of gripping a handle of an advanced toothbrush according to the present invention, illustrating sequentially, from the left, a right lingual side and a left buccal side of a rear side of a bristle head upon gripping by rear support of finger 2 and left and right gripping of fingers 1 and 3, a right lingual side and a left buccal side of a front side of the bristle head upon gripping by rear support of finger 2 and left and right gripping of fingers 1 and 3, and a right side of the bristle head upon gripping by rear support of finger 2 and left and right gripping of fingers 1 and 3.

[0089] The toothbrush shaft according to the present invention ensures that the user's thumb is placed at any point of a cylindrical surface of the handle 110 throughout 360.degree., thereby obtaining stable support.

[0090] That is, for example, when brushing lingual surfaces of a user's mandibular teeth located in the rear of the oral cavity,

[0091] the user may brush his/her teeth and gums reliably, conveniently, and efficiently without bending his/her wrist, lifting his/her arm, or tilting his/her head.

[0092] In particular, a first point for keeping a user's armpit closed by the user's arm being held against a user's body, a second point for gripping a toothbrush handle, and a third point for contact with a user's teeth are fixed to realize a stable closed vector system with a short arm length from a user's elbow to a user's wrist.

[0093] A method of using the toothbrush shaft according to the present invention will be described in more detail as follows.

[0094] FIG. 8 is a view illustrating photographs illustrating a basic method of using the daily toothbrush. This method allows the user's thumb to support the toothbrush at any angle, and allows the user's remaining fingers to be stably fixed in position by the first, second, and third finger support protrusions 111, 112, and 113 and the first and second support grooves 114 and 115.

[0095] FIG. 9 is a view illustrating photographs illustrating various methods of using the daily toothbrush according to the present invention, and FIG. 10 is a view illustrating photographs illustrating a use state of the daily toothbrush according to the present invention.

[0096] The toothbrush shaft according to the present invention has no rotational displacement limitation by allowing the user's thumb to be used as a support point for first and second structures at any point throughout 360.degree.. Further, by adding structure 4, fingers 1, 2, and 3 may support both upper and lower surfaces of the toothbrush during brushing.

[0097] Further, the toothbrush shaft according to the present invention minimizes unnecessary displacement during brushing by limiting the positions of the support points of a user's all fingers, thereby minimizing deviation from the range of a brushing motion expected by the user, resulting in maximized dental plaque removing efficiency, which is the goal of brushing.

[0098] Further, in the toothbrush shaft according to the present invention, three fingers 1, 2, and 3 form two upper and lower support points through the first and second structures at a position near the bristles, and fingers 4 and 5 and the user's palm form one support point through a third structure, whereby a vector triangle consisting of three sides in three-dimensional space.

[0099] Further, in the toothbrush shaft according to the present invention, by forming a triangular vector sum by three support points, it is possible to obtain static stability with a zero resultant force, thereby forming vibration in the longitudinal axis direction of the toothbrush and rotation in the transverse axis direction of the toothbrush, without creating rotational force with respect to each direction of movement.

[0100] Further, in the toothbrush shaft according to the present invention, when a vector sum of a small three-point triangle of fingers 1, 2, and 3, fingers 4 and 5, and the user's palm is formed in a user's hand to obtain positional stability, and then the toothbrush shaft is held by the hand and placed on the user's teeth with the user's armpit closed, it is easy to form a vector sum of a large three-point triangle of the user's armpit, the user's hand, and the user's teeth. Thus, it is possible to reduce displacement of brushing of target teeth, thereby enabling stable and efficient brushing of the target teeth, resulting in maximized dental plaque removal efficiency.

[0101] Further, positional stability of the toothbrush shaft according to the present invention is maximized thereby minimizing mucosal damage in the oral cavity caused by the toothbrush during brushing.

[0102] Further, by the first structure for determining a support point position of the toothbrush shaft according to the present invention, the center of gravity is placed at the rear end of the handle of the toothbrush shaft thereby ensuring that even if the toothbrush shaft is dropped on a floor, the handle is first brought into contact with the floor. Additionally, the first structure always form a predetermined angle with respect to the bristles to prevent the bristles from contact with the floor, thereby implementing a function to prevent contamination due to a contact surface.

[0103] Further, the toothbrush shaft according to the present invention may be manufactured by three-dimensional (3D) scanning and printing in accordance with an anatomical structure of the user's hand, thereby further maximizing motion suitability.

[0104] Further, in the toothbrush shaft according to the present invention, three vectors are formed, and thus even if the lengths of the three vectors are controlled, a resultant force may be zero thereby forming and maintaining a stable structure. This means that if there are three vectors, anyone (including a person with disability) who has a different arm length, hand length, and finger length is able to reliably brush his/her teeth.

[0105] Lastly, in the toothbrush shaft according to the present invention, during brushing of the user's anterior teeth, a first node of finger 2 is placed on the first and second structures, while left and right sides of the second and fourth structures are gripped by fingers 1 and 3 and fingers 4 and 5 and the user's palm are placed over the third structure, thereby enabling stable brushing. Further, during brushing of a user's mandibular anterior teeth, with the toothbrush gripped upside down, fingers 1 and 3 are placed between the first and second structures while finger 2 is placed between the second and fourth structures to form a three-point vector triangle, thereby enabling stable brushing. Other various brushing methods may be calculated for each 360.degree..

[0106] Further, the present invention provides a method of manufacturing a functional toothbrush shaft, the method being capable of maximizing personalized motion suitability in accordance with the anatomical structure of the user's hand and further increasing personalized anatomical suitability by three-dimensional (3D) scanning and printing in manufacturing the functional toothbrush shaft, the method including: inputting anatomical structure data of the hand of the user including a person with disability, into a computer; generating toothbrush shaft design data conforming to the anatomical structure of the hand of the user including the person with disability; transmitting, by the computer, three-dimensional (3D) data to a three-dimensional (3D) printer; and producing, by the 3D printer, a three-dimensional toothbrush shaft on the basis of on the 3D data, thereby manufacturing a personalized toothbrush shaft.

INDUSTRIAL APPLICABILITY

[0107] The technical idea of a functional toothbrush shaft according to the present invention is that the same repeated results can be achieved in practice. In particular, the present invention can promote technological development, which contributes to industrial development, and thus the present invention is worth protecting.

* * * * *

D00000

D00001

D00002

D00003

D00004

D00005

D00006

XML

uspto.report is an independent third-party trademark research tool that is not affiliated, endorsed, or sponsored by the United States Patent and Trademark Office (USPTO) or any other governmental organization. The information provided by uspto.report is based on publicly available data at the time of writing and is intended for informational purposes only.

While we strive to provide accurate and up-to-date information, we do not guarantee the accuracy, completeness, reliability, or suitability of the information displayed on this site. The use of this site is at your own risk. Any reliance you place on such information is therefore strictly at your own risk.

All official trademark data, including owner information, should be verified by visiting the official USPTO website at www.uspto.gov. This site is not intended to replace professional legal advice and should not be used as a substitute for consulting with a legal professional who is knowledgeable about trademark law.