Refill For Liquid Makeup Case And Assembly Comprising A Case And Such A Refill

MILESI; Frederic

U.S. patent application number 16/765403 was filed with the patent office on 2020-10-22 for refill for liquid makeup case and assembly comprising a case and such a refill. This patent application is currently assigned to CHANEL PARFUMS BEAUTE. The applicant listed for this patent is CHANEL PARFUMS BEAUTE. Invention is credited to Frederic MILESI.

| Application Number | 20200329843 16/765403 |

| Document ID | / |

| Family ID | 1000004930860 |

| Filed Date | 2020-10-22 |

| United States Patent Application | 20200329843 |

| Kind Code | A1 |

| MILESI; Frederic | October 22, 2020 |

REFILL FOR LIQUID MAKEUP CASE AND ASSEMBLY COMPRISING A CASE AND SUCH A REFILL

Abstract

The invention concerns a refill (2) intended to be inserted into a makeup case (1). The refill (2) comprises a vessel containing a liquid makeup, the vessel comprising a tank (6) comprising an open top face forming an opening for dispensing the makeup. The tank (6) is delimited by a side wall (18) in line with the opening and a bottom (22) of the tank. The refill (2) comprises an absorbent complex (7) in the tank (6). The vessel further comprises at least one additional volume (13) outside the tank (6), in fluid communication with the inside of said tank (6). This helps optimise the volume available for containing a liquid make-up, while allowing the latter to be effectively retained in the refill. The invention also concerns an assembly comprising a case (1) and such a refill (2).

| Inventors: | MILESI; Frederic; (Paris, FR) | ||||||||||

| Applicant: |

|

||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Assignee: | CHANEL PARFUMS BEAUTE Neuilly-Sur-Seine FR |

||||||||||

| Family ID: | 1000004930860 | ||||||||||

| Appl. No.: | 16/765403 | ||||||||||

| Filed: | November 27, 2018 | ||||||||||

| PCT Filed: | November 27, 2018 | ||||||||||

| PCT NO: | PCT/FR2018/052989 | ||||||||||

| 371 Date: | May 19, 2020 |

| Current U.S. Class: | 1/1 |

| Current CPC Class: | A45D 34/00 20130101; A45D 42/04 20130101; A45D 2034/005 20130101 |

| International Class: | A45D 34/00 20060101 A45D034/00; A45D 42/04 20060101 A45D042/04 |

Foreign Application Data

| Date | Code | Application Number |

|---|---|---|

| Nov 30, 2017 | FR | 1761419 |

Claims

1-14. (canceled)

15. A refill configured to be inserted into a makeup case, said refill comprising: a vessel containing a liquid makeup, the vessel comprising a container comprising an open upper face forming an opening for the delivery of the makeup, the container being delimited by a lateral wall aligned with the opening and a bottom of the container, an absorbent complex within the container; and the vessel further comprising at least one additional volume outside the container in fluidic communication with the inside of the container.

16. A refill according to claim 15, wherein: the refill has a six-sided shape with a four-sided base and a height less than half of one side of its base.

17. A refill according to claim 15, wherein: the container has a round cross-sectional shape.

18. A refill according to claim 15, wherein: the vessel comprises a first part forming outside walls of the vessel and of the refill, and a bottom of the vessel and of the refill; and the vessel comprises a second part forming the lateral wall of the container and an upper wall of the vessel comprising the opening for delivery of the makeup.

19. A refill according to claim 18, wherein: the second part furthermore forms the bottom of the container.

20. A refill according to claim 18, wherein: the first part forms the bottom of the container.

21. A refill according to claim 18, wherein: the second part forms a hinge; and the refill further comprising a flap connected to the hinge, the flap being configured to be tiltable between a closed position obturating the opening for delivery of the makeup and an open position freeing the opening for delivery of the makeup.

22. A refill according to claim 15, further comprising: passages formed in the lateral wall of the container providing the fluidic communication.

23. A refill according to claim 20, further comprising: a space between the lateral wall of the container and the bottom of the container providing the fluidic communication.

24. A refill according to claim 15, further comprising: a film configured to tightly obturate the delivery opening formed by the open face of the container in a fluid-tight manner prior to a first use of the refill.

25. A refill according to claim 24, wherein: the film is fastened to a rigid ring connected to an upper edge of the lateral wall of the container.

26. A refill according to claim 24, wherein: the film is fastened to a rim formed on an upper edge of the lateral wall of the container.

27. An assembly comprising; a refill configured to be inserted into a makeup case, said refill comprising: a vessel containing a liquid makeup, the vessel comprising a container comprising an open upper face forming an opening for the delivery of the makeup, the container being delimited by a lateral wall aligned with the opening and a bottom of the container, an absorbent complex within the container; the vessel further comprising at least one additional volume outside the container in fluidic communication with the inside of the container; and a makeup case comprising a main body forming an inside volume for receiving the refill having a shape matching the inside volume of the makeup case, and the refill inserted and fastened inside the receiving volume of the makeup case.

28. An assembly according to claim 27, further comprising: a pad configured to enable recovery of liquid makeup by an application of pressure on the absorbent complex of the refill; and the makeup case further comprising a lid forming a reception space for the pad when the makeup case is closed by the lid.

Description

[0001] The present invention concerns the field of containers for liquid makeup. It relates in particular to the field of liquid makeup refills for cases for makeup, and of cases for liquid makeup.

[0002] It concerns for example cases configured to contain and deliver makeup in liquid form enabling the user to transport his or her makeup in a handbag or a pocket in order to apply makeup to himself or herself throughout the day. Below in the present document the male or female user will be designated by the female.

[0003] Similarly, the term "liquid makeup" must be understood broadly, and may designate for example a fluid foundation, eye contour makeup commonly referred to as "eyeliner", eye shadow, or a fluid lipstick The term makeup can also designate a liquid care formula, a liquid cream for the face or eyes, a lotion.

[0004] Such cases are of small size in order to be easily transportable. They must be fully fluid-tight in relation to the product they contain when they are closed, and must be simple to use, in particular by allowing easy delivery and application of liquid makeup.

[0005] The cases also have an important aesthetic function. They may be configured so that they can be re-used when they are empty.

[0006] To that end, the cases known in the state of the art contain a refill. This refill clips into the bottom of the case and makes it possible to provide the protection, sealing, and dispensing of the product for the user.

[0007] Such a refill is produced with materials compatible with the products it contains. It comprises a container which contains the liquid makeup and a lid enabling the fluid-tight obturation of the container.

[0008] A device enables the dispensing or delivery of makeup.

[0009] Various types of devices enabling the delivery of makeup which is in liquid form have been envisioned in the state of the art.

[0010] Some refills comprise an absorbent complex, which is a sponge. In these refills, the product, that is to say the liquid makeup, is imbibed in a sponge which is held in the bottom of the refill using a holding ring.

[0011] This ring supports a protective label which is removed by the user at the time of first use. The sealing is then provided by the lid of the refill. The dispensing of the product is made by imbibing an applicator such as a pad or a finger of the user by pressing on the sponge, in order for it to release the product it contains in its alveolae.

[0012] This first solution makes it possible to contain and deliver products that are very fluid.

[0013] Nevertheless, the sponge occupies a certain volume within the refill, to the detriment of the storage capacity for the contained product. For a given volume of product that can be released, the refill and the case must be larger than in the absence of a sponge. This goes against the transportability of the product.

[0014] A refill for liquid makeup comprising a sponge is in particular disclosed in document JP2008178463.

[0015] According to this same principle, the case for makeup may comprise, in addition to the refill container, secondary raceptacles or refills to contain other cosmetic compositions. This is described in document KR20120045146. This does not solve, or only imperfectly solves, the issue of the releasable amount contained by the refill of liquid makeup.

[0016] According to a second solution, the refills may present a mesh stretched above the container containing the makeup. The mesh is constituted by an extensible mesh or by a perforated silicone membrane. This solution makes it possible to pass the product through the loops of the fabric forming the mesh or through the perforations of the silicone when it is stretched by pressing upon it. Alternatively, the delivery of the product may be carried out through pressurization of the interior volume of the refill, by pressing on a deformable bottom it comprises. This is described in document FR2744602. According to this same solution, as there is no sponge or other member in the container, its entire volume is available to contain the product. Nevertheless, the product cannot be very fluid since the mesh provides imperfect holding of a very fluid product in the container, and the product must not pass through the mesh in the absence of pressure on the latter.

[0017] According to a third solution, the product is dispensed by a so-called "airless" pump (that is to say which does not use any propulsive gas) through a plate, either by a central hole, or by multiple orifices disposed on the upper surface of the plate. According to this solution, the bottom of the refill is constituted by a piston which comes to push the product under the action of the pump, or else a flexible packet which is squashed under the action of the pump. This solution is adapted to the storage and release of liquid products, even the most fluid products, but has a high cost and has a high bulk on account of the system comprising a piston and a pump.

[0018] Nevertheless, in the state of the art there is no refill for a liquid makeup case, nor corresponding case, that maximizes the storage volume for liquid makeup, which is potentially very fluid, while enabling easy delivery and being cheap to manufacture and of low bulk in order to enable easy transport by a user.

[0019] The invention is thus directed to a refill solving all or part of the aforesaid issues, as well as to an assembly comprising an adapted case and such a refill.

[0020] Thus, the invention relates to a refill configured to be inserted into a makeup case. The refill comprises a vessel containing a liquid makeup. The vessel comprises a container comprising an open upper face forming an opening for the delivery of the makeup, said container being delimited by a lateral wall aligned with the opening and a container bottom. The refill comprises an absorbent complex within the container. The vessel further comprises at least one additional volume outside the container, in fluidic communication with the inside of said container.

[0021] The presence of an absorbent complex such as a sponge in the container and thus at the location of the opening for delivery of the product enables, just as in the prior art, good retention of a product even if very fluid, and easy delivery of the product by pressure on the absorbent complex.

[0022] Furthermore, the presence of volumes of the vessel that are additional to the container gives additional capacity to contain liquid makeup, which is all the greater that the additional volumes do not contain any absorbent complex which would limit the storage capacity thereof.

[0023] The retaining capacity of the product by the refill is not compromised, since the absorbent complex enables that retention at the location of the delivery opening for the liquid makeup. When makeup is taken from the refill by pressure on the absorbent complex, the latter is refilled with liquid makeup coming from the additional volumes, by gravity and/or by capillarity.

[0024] The refill may have a substantially parallelepiped shape with a substantially square base and a height less than half of one side of its base.

[0025] The container may have a substantially cylindrical shape.

[0026] The refill may comprise a hollow first part forming the outside walls of the vessel and of the refill, and the bottom of said vessel and of the refill, and a second part forming the lateral wall of the container and an upper wall of the vessel comprising the opening for delivery of the makeup.

[0027] According to a first embodiment, the second part furthermore forms a bottom of the container.

[0028] According to a second embodiment, the first part forms a bottom of the container.

[0029] The second part may form a hinge, the refill further comprising a flap connected to said hinge, the flap being able to tilt between a closed position in which it obturates the opening for delivery of the makeup and an open position freeing said opening for delivery of the makeup.

[0030] The refill may comprise passages formed in the lateral wall of the container which provide said fluidic connection of the additional volume or volumes with the inside of said container.

[0031] The refill may comprise a space between the lateral wall of the container and the bottom of the container which provides said fluidic communication of the additional volume or volumes with the inside of said container.

[0032] The refill may comprise a film which, prior to the first use of said refill, obturates in fluid-tight manner the delivery opening formed by the open face of the container. In this case, the film may be fastened to a rigid ring connected to an upper edge of the lateral wall of the container. Alternatively, the film may be fastened to a rim formed on an upper edge of the lateral wall of the container.

[0033] The invention also relates to an assembly comprising a case for makeup having a main body forming an inside volume for receiving a refill and a refill according to one of the preceding claims of matching shape and which is inserted and fastened inside said receiving volume of the case. Such an assembly may further comprise a pad enabling the recovery of liquid makeup by pressing on the absorbent complex of the refill, and wherein the case further comprises a lid forming a reception space for said pad when the case is closed by said lid.

[0034] Still other particularities and advantages of the invention will appear in the following description.

[0035] In the accompanying drawings, given by way of non-limiting example:

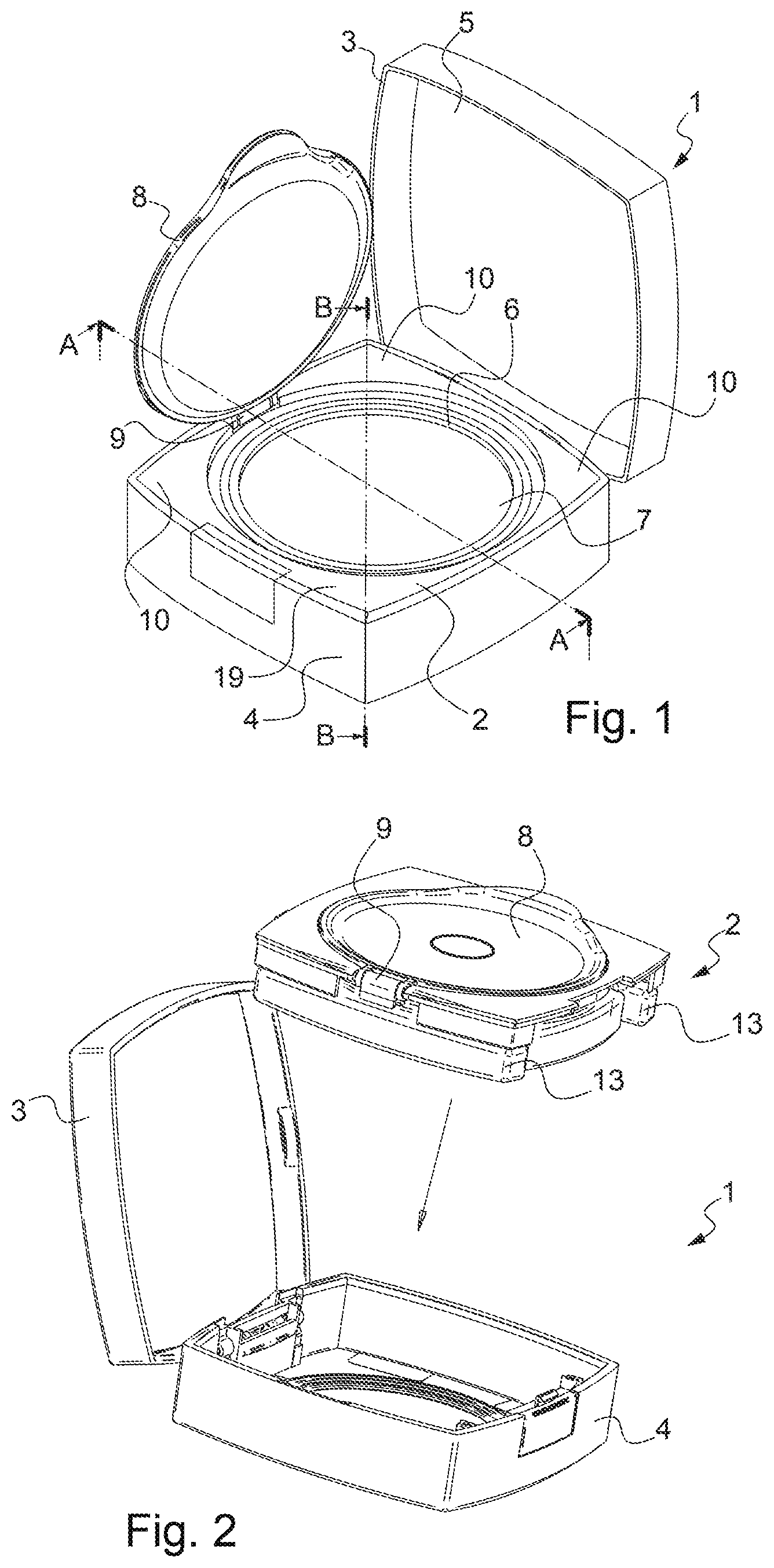

[0036] FIG. 1 shows, in a three-dimensional view, an assembly comprising a case and a liquid makeup refill according to one embodiment of the invention;

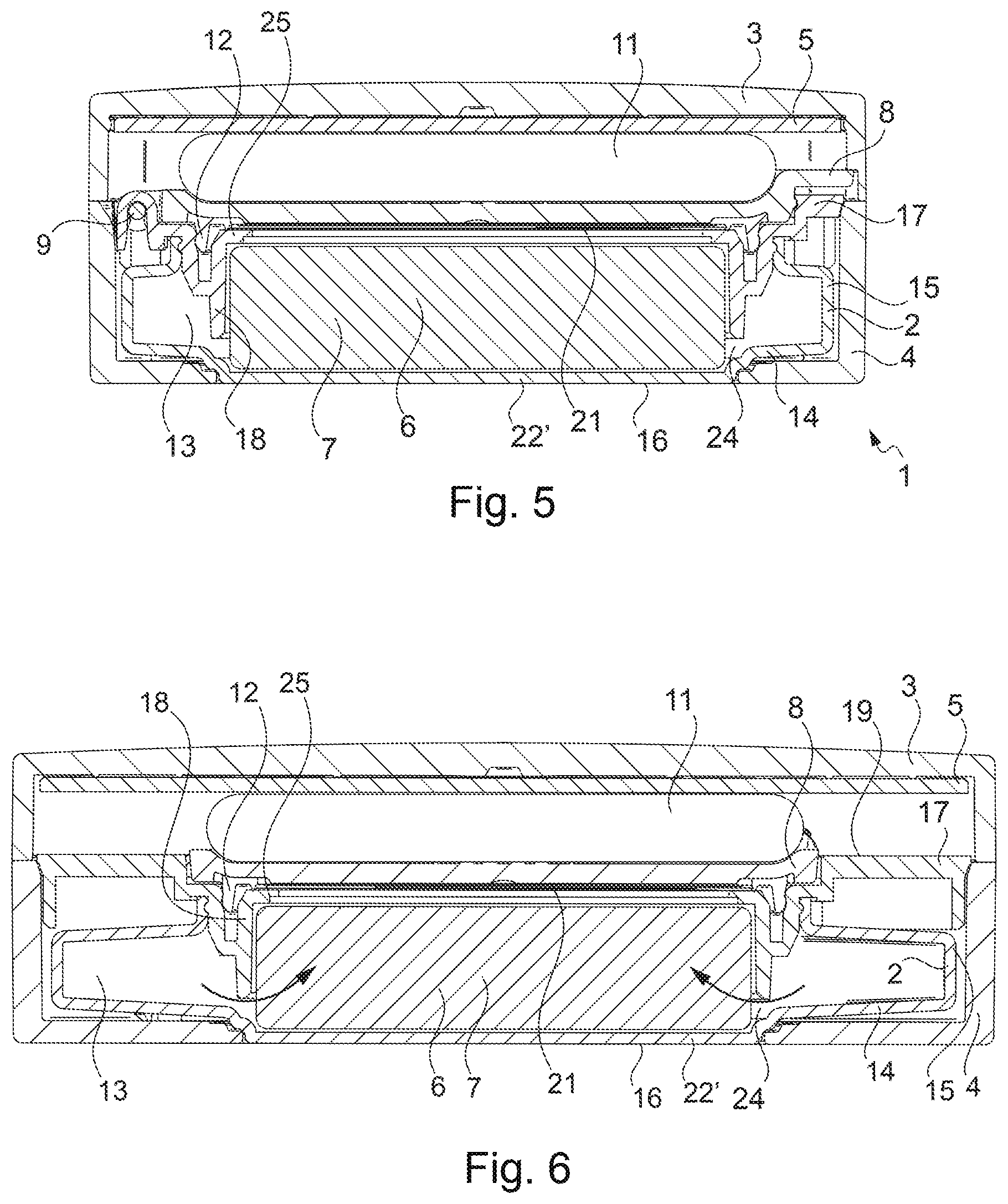

[0037] FIG. 2 shows, in a three-dimensional view, the assembly of FIG. 1 in which the refill has been detached from the case;

[0038] FIG. 3 presents, in a first cross-section view, an assembly comprising a case and a liquid makeup refill according to a first embodiment of the invention;

[0039] FIG. 4 shows the assembly of FIG. 3 in a second cross-section view;

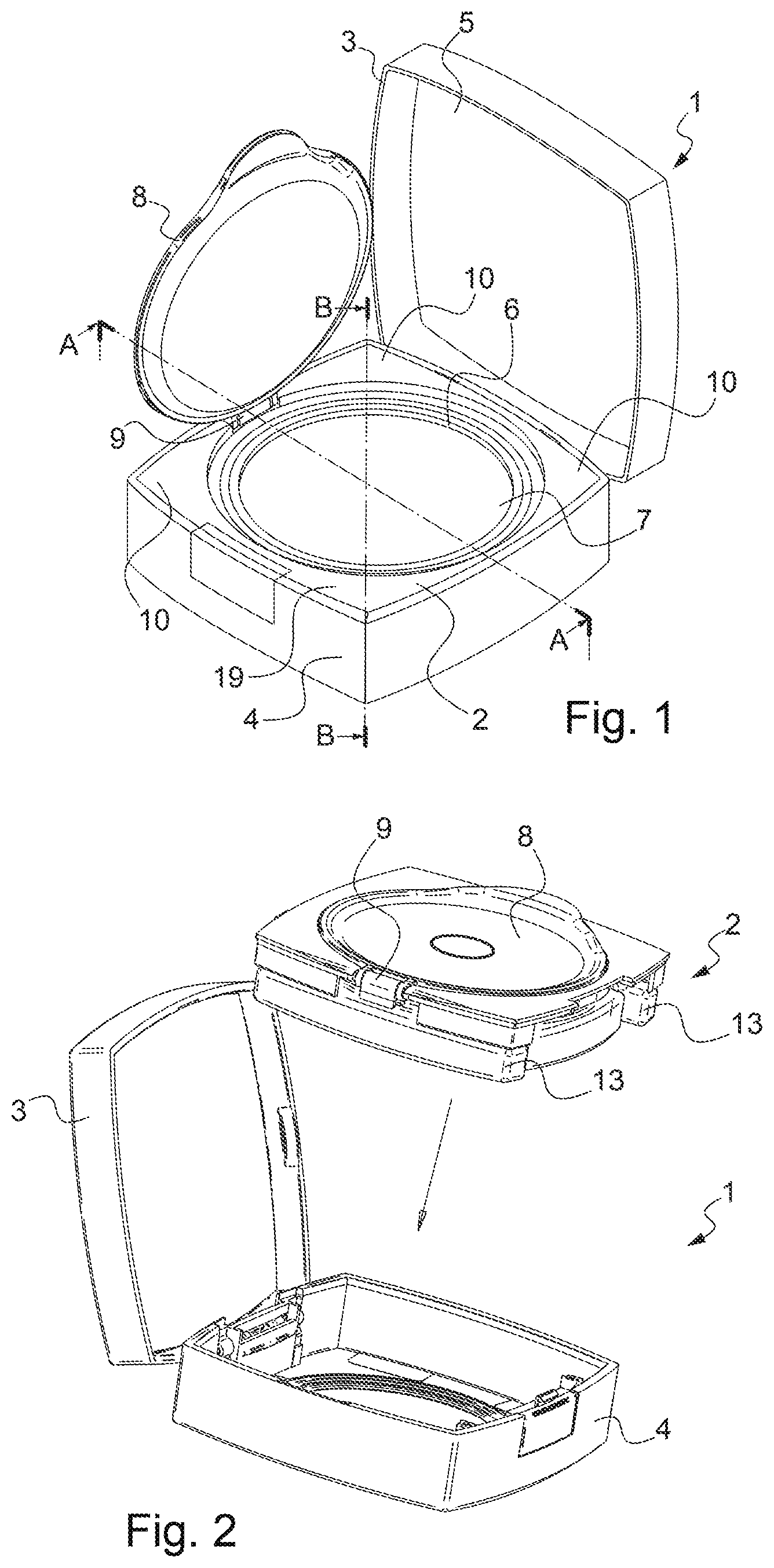

[0040] FIG. 5 shows, in a first cross-section view, an assembly comprising a case and a liquid makeup refill according to a second embodiment of the invention;

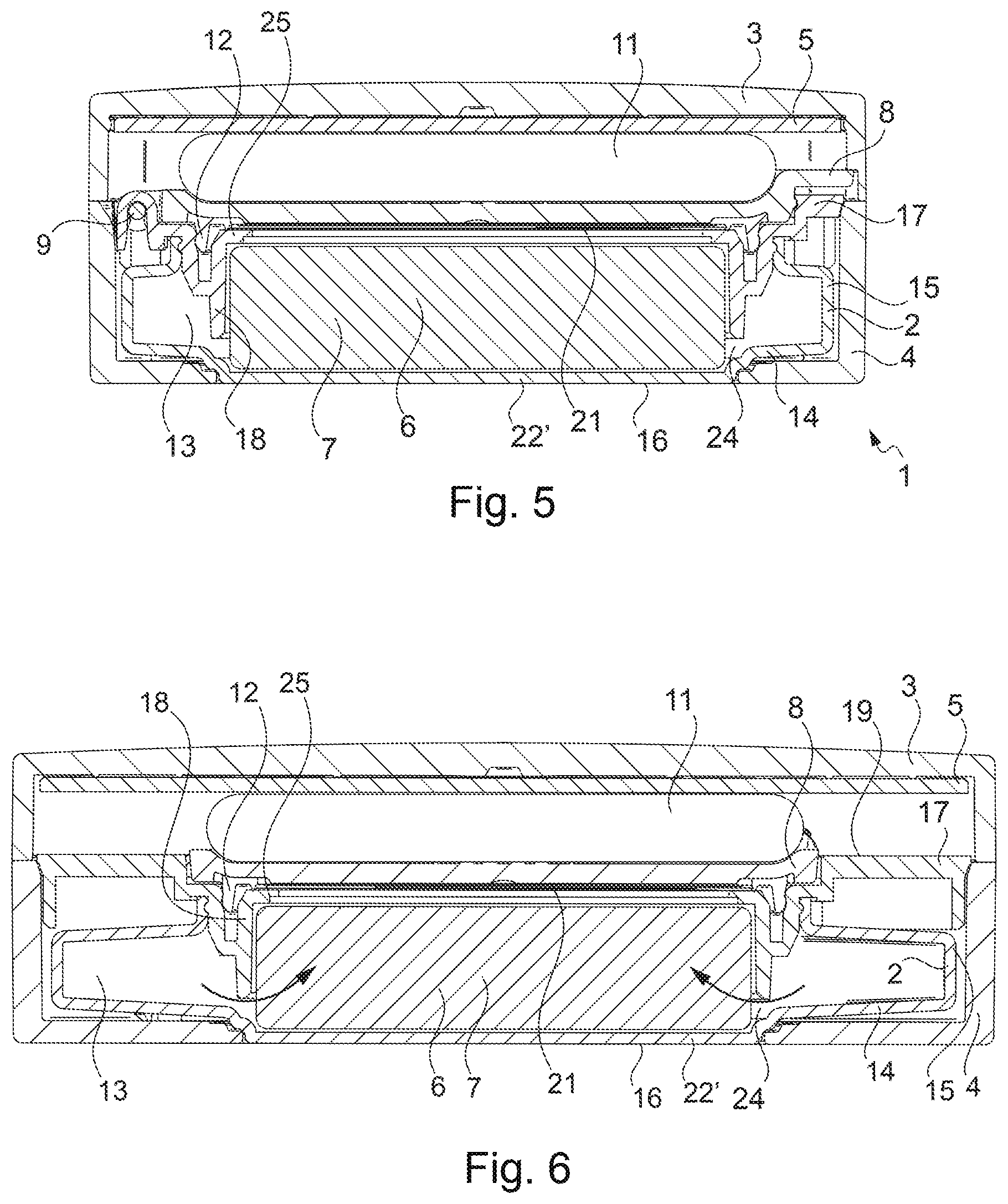

[0041] FIG. 6 shows the assembly of FIG. 5 in a second cross-section view.

[0042] FIG. 1 shows a "nomadic" or transportable makeup assembly. The assembly comprises a case 1 which contains a refill 2, holding liquid makeup. In the example represented here, the case has a shape referred to as substantially square, that is to say a substantially parallelepiped shape having a square base, which is "flattened" that is to say of small height compared with its sides, for example of height less than half of one side of the base. In the example shown in FIG. 1, the base is not strictly square in that it has sides that are slightly rounded outwardly giving the case an attractive appearance.

[0043] The case may be closed using a lid 3. The lid 3 may tilt relative to a main body 4 of the case 1. A primary function of the lid 3 is to serve for the closing and the opening of the case for the delivery of makeup, but may have other functions. It may form an internal volume, above the refill 2, able to serve as reception space to accommodate therein an an accessory for makeup application, for example a pad. The lid 3 may also, in its bottom, be equipped with a mirror 5 enabling the user to apply make-up to herself easily. The refill is provided with a container 6 having an open upper face for the delivery of the makeup. The container is central in relation to the case 1 and the refill 2. In the example shown, the container 6 has the shape of a cylinder of revolution and the opening it forms is thus round. The container is defined in the refill by a lateral wall, which here is a peripheral wall, the container being cylindrical. An absorbent complex 7 is disposed in the container. The absorbent complex fills the entire volume of the container 6, and for this has a shape substantially matching the internal volume of the container 6. The dimensions of the absorbent complex may be slightly greater than those of the container such that the absorbent complex is slightly compressed therein. The absorbent complex 7 is conventionally a natural or synthetic sponge, or any other type of open solid foam. The absorbent complex 7, may also be formed, in non-limiting manner, from non-woven materials or laminated fibers. The absorbent complex 7 has a high capacity for absorbing fluid, but must nevertheless enable the retention of the liquid makeup in the absence of externally applied forces other than gravity for example.

[0044] In order to apply makeup to herself, the user presses or dabs the pad (or other accessory for applying makeup, or a finger) on the absorbent complex 7. Under the effect of the applied pressure, the absorbent complex releases some of the liquid makeup it contains, at the location of its compressed zone. The surface of the pad is then covered with makeup, so enabling the user to apply it to herself easily.

[0045] The refill also comprises a flap 8, which may also be called a plate. The flap 8 is connected to the edge of the container 6 by a hinge 9. The flap typically has a general shape which matches that of the opening formed by the open face of the container 6.

[0046] When in a closed position, the flap enables sealing to be ensured for the liquid makeup at the location of the open face of the container 6 that forms an opening for delivery of the makeup. This avoids any leakage of makeup during transport, for example in a bag.

[0047] In an open position, shown in FIG. 1, the delivery opening of the refill is freed, enabling makeup to be collected from the container.

[0048] A particular feature of the refill 2 is that, in addition to the container 6, it has an additional volume (or volumes) for storing liquid makeup, fluidically connected to the container. The additional volume is thus defined outside the container, typically between a lateral wall of said container 6 and an outside wall of the refill. Typically, in the example shown in FIG. 1, the four corners 10 of the square formed by the base of the case, and correspondingly by the refill inserted into the case, are employed as additional volumes as detailed with reference to FIGS. 3 to 6.

[0049] This is can be seen in particular in FIG. 2 which shows the assembly of FIG. 1, the refill 2 being detached from the main body 4 of the case 1, for example for it to be replaced by a full refill. The refill 2 has an external shape which matches the geometry of the internal volume of the main body 4. In the example shown here, the case 1 has a square general shape, and the refill 2 correspondingly has a substantially square shape. The refill thus has as large a volume as possible in relation to the volume available in the main body 4 of the case 1.

[0050] When the refill 2 is inserted into the case 1, the refill 2 is held there by matching of shape and/or snap engagement.

[0051] FIG. 3 is a cross-section view, on a median plane A-A shown in FIG. 1, of an assembly comprising a case 1 and a refill 2 such as that of FIG. 1. FIG. 4 shows the same assembly in a cross-section view, on a diagonal plane B-B shown in FIG. 1.

[0052] The case is shown in closed position, that is to say that its lid 3 is closed.

[0053] A pad 11 is disposed between the mirror 5 and the flap 8 of the refill 2.

[0054] In FIGS. 3 to 6, the flap 8 is in closed position, and sealingly obturates the open face of the container 6 that forms an opening for delivery of the makeup. The sealing is obtained by the pinching of a seal 12 carried by one face of the lid, as in the example shown here. Alternatively, the seal 12 may be disposed on the upper edge of the container 6.

[0055] The refill is constituted as described below. The refill comprises a vessel to contain the liquid makeup. The vessel comprises the container 6, which contains a sponge, and the additional volume 13.

[0056] In order to form the vessel, the refill 2 comprises: [0057] a hollow first part 14 forming the outside walls 15 of the vessel and of the refill, and the bottom 16 of said vessel and of the refill, and [0058] a second part 17 forming the lateral wall 18 of the container and an upper wall 19 of the vessel comprising the opening for delivery of the makeup, that is to say the open face of the container 6.

[0059] The second part 17 is fastened to the first part 16, for example by fitting inside the latter.

[0060] The parts constituting the vessel may be made from plastic material, and for example be obtained by molding.

[0061] In the embodiment of FIGS. 3 to 4, a ring 20 is mounted, for example by snap engagement, on the upper edge of the lateral wall 18 of the container 6. The ring 20 bears a film 21 (or label), which sealingly obturates the refill 2 against liquids and air before its first use for which the sealing film 21 is removed.

[0062] The ring 20 can also form a slight restriction of the opening of the container 6, so making it possible to improve the holding of the absorbent complex 7 in the container 6.

[0063] In order to enable the extraction of the refill 2 from the case 1, the latter may, as in the example represented here, be provided with an open bottom. The open bottom of the case enables the user to press on the bottom of the refill 2 inner make it come out from the case 1. The bottom of the refill 2, formed by the first part 14 may advantageously comprise a step formation which comes to be inserted into the opening of the bottom of the case 1, in order for the assembly constituted by the case 1 and the refill 2 to present a flat bottom.

[0064] In general terms, the extraction of the refill 2 from the case 1, preferably when the refill is empty of makeup, enables its replacement in the case by a full refill.

[0065] In the embodiment of FIGS. 3 and 4, the second part 17 also forms a bottom 22 of the container 6. On mounting the refill 2, the bottom 22 of the container 6 comes to rest on the bottom of the refill constituted by the first part 14.

[0066] In the embodiment of FIGS. 3 and 4, in which the second part 17 forms both the lateral wall 18 of the container 6 and its bottom 22, the lateral walls 18 comprise passages 23 enabling the liquid makeup contained in the additional volume 13 to pass into the container 6 in order to imbibe or re-imbibe the absorbent complex 7. In other words, the passages 23 put the container 6 in fluidic communication with the additional volume 13.

[0067] As shown in FIGS. 3 and 4, the additional volume is mainly located in the corners 10, but nevertheless extends all around the container 6. The additional volume is thus, in the example shown, a single volume formed around the container. If several additional volumes are provided, for example an independent additional volume in each corner of a refill, a passage must be provided between each additional volume and the container 6.

[0068] The embodiment shown in FIGS. 5 and 6 substantially corresponds to that of FIGS. 3 and 4, optimized in two respects. The above description made with reference to FIGS. 3 and 4 thus applies, except for the differences detailed below, to the embodiment of FIGS. 5 and 6.

[0069] FIG. 5 is a cross-section view, on a median plane A-A shown in FIG. 1; FIG. 6 is a cross-section view, on a diagonal plane B-B shown in FIG. 1.

[0070] In the embodiment shown in FIGS. 5 and 6, a first difference arises from the fact that the second part 17 does not form a bottom for the container 6. In this embodiment, the bottom of the container 22' corresponds to the bottom of the refill. The bottom of the container 22' is thus formed by the first part. This configuration has two advantages. One is that the volume of the container is increased. The other is that the fluidic communication between the additional volume 13 of the container 6 can be formed simply by providing a space 24 between the lateral wall of the container (formed by the second part 17) and the bottom 22' of the container (formed by the first part). The liquid makeup is thus able to flow freely between the additional volume 1 and the container 6, over the entire periphery of the container.

[0071] A second difference comes from the fact that there is no ring 20 in the embodiment shown in FIGS. 5 and 6. The functions of the ring 20 are provided by a rim 25 formed at the location of the upper edge of the container 6, directed inwards of its open face. The rim 25 enables the fastening of the film 21. The rim 25 also enables proper holding of the absorbent complex 7 in the container 6.

[0072] Naturally, each of the two differences raised above between the embodiment of FIGS. 3 and 4 and that of FIGS. 5 and 6 may be adopted independently of each other.

[0073] In all the embodiments represented, the additional volume is free of any member (typically, it contains no absorbent complex), which enables the total capacity for liquid makeup of the refill to be maximized.

[0074] In an embodiment not represented, the lateral wall of the container may be apertured with multiple orifices in order to facilitate the fluidic communication between the additional volume 13 and the container 6.

[0075] The invention thus provides a refill for a makeup case, containing a liquid makeup offering a presentation unknown in the state of the art. Thanks to the configuration developed in the invention, the refill provides an optimized storage volume for makeup, within a limited total volume enabling the case and its refill to be transported easily, while preserving the ease of use compared with the refills having a sponge of the state of the art, and the advantage of being adapted to very fluid products.

[0076] For example, the refill provided in the invention may contain and release of the order of 15 grams of a product, even if very liquid, in a case that is for example substantially square with very small bulk.

* * * * *

D00000

D00001

D00002

D00003

XML

uspto.report is an independent third-party trademark research tool that is not affiliated, endorsed, or sponsored by the United States Patent and Trademark Office (USPTO) or any other governmental organization. The information provided by uspto.report is based on publicly available data at the time of writing and is intended for informational purposes only.

While we strive to provide accurate and up-to-date information, we do not guarantee the accuracy, completeness, reliability, or suitability of the information displayed on this site. The use of this site is at your own risk. Any reliance you place on such information is therefore strictly at your own risk.

All official trademark data, including owner information, should be verified by visiting the official USPTO website at www.uspto.gov. This site is not intended to replace professional legal advice and should not be used as a substitute for consulting with a legal professional who is knowledgeable about trademark law.