Washing Machine And Method For Controlling Same

WOO; Ji-hyun ; et al.

U.S. patent application number 16/755006 was filed with the patent office on 2020-10-01 for washing machine and method for controlling same. The applicant listed for this patent is Samsung Electronics Co., Ltd.. Invention is credited to Eun-suk BANG, Sang-yeon PYO, Ji-hyun WOO.

| Application Number | 20200308750 16/755006 |

| Document ID | / |

| Family ID | 1000004931821 |

| Filed Date | 2020-10-01 |

View All Diagrams

| United States Patent Application | 20200308750 |

| Kind Code | A1 |

| WOO; Ji-hyun ; et al. | October 1, 2020 |

WASHING MACHINE AND METHOD FOR CONTROLLING SAME

Abstract

Disclosed are a washing machine and a method for controlling same. A washing machine according to the present invention comprises: a drum for accommodating laundry; an additive input unit which inputs an additive into the drum so as to coat the laundry with fragrant particles; a temperature adjustment unit which generates a hot wind and a cold wind to adjust the temperature inside the drum; and a control unit that controls the temperature adjustment unit so that the temperature inside the drum is set to a first threshold temperature, controls the additive input unit so that the additive is input into the drum when the temperature is set to the first threshold temperature, and controls the temperature adjustment unit so that the temperature inside the drum is set to a second threshold temperature lower than the first threshold temperature when the additive is input into the drum. Accordingly, the washing machine can provide the same effect as a piece of laundry being washed in a normal washing cycle when laundry is washed through a refresh cycle.

| Inventors: | WOO; Ji-hyun; (Seoul, KR) ; PYO; Sang-yeon; (Yongin-Si, KR) ; BANG; Eun-suk; (Hwaseong-Si, KR) | ||||||||||

| Applicant: |

|

||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Family ID: | 1000004931821 | ||||||||||

| Appl. No.: | 16/755006 | ||||||||||

| Filed: | October 10, 2018 | ||||||||||

| PCT Filed: | October 10, 2018 | ||||||||||

| PCT NO: | PCT/KR2018/011858 | ||||||||||

| 371 Date: | April 9, 2020 |

| Current U.S. Class: | 1/1 |

| Current CPC Class: | D06F 2105/42 20200201; D06F 2105/38 20200201; D06F 2103/24 20200201; D06F 33/37 20200201; D06F 2103/26 20200201; D06F 23/02 20130101; D06F 39/04 20130101; D06F 2105/48 20200201; D06F 2105/14 20200201 |

| International Class: | D06F 33/37 20060101 D06F033/37; D06F 39/04 20060101 D06F039/04; D06F 23/02 20060101 D06F023/02 |

Foreign Application Data

| Date | Code | Application Number |

|---|---|---|

| Oct 13, 2017 | KR | 10-2017-0133527 |

Claims

1. A washing machine comprising: a drum configured to accommodate laundry; an additive input unit configured to put an additive into the drum to coat the laundry with fragrant particles; a temperature adjustment unit configured to adjust a temperature inside the drum by generating hot air and cold air; and a control unit configured to: control the temperature adjustment unit to set the temperature inside the drum to a first threshold temperature, control the additive input unit to put the additive into the drum in case that the temperature inside the drum is set to the first threshold temperature, and control the temperature adjustment unit to set the temperature inside the drum to a second threshold temperature lower than the first threshold temperature in case that the additive is put into the drum.

2. The washing machine as claimed in claim 1, wherein the control unit is configured to rotate the drum at a first threshold speed while the temperature inside the drum is set and maintained at the first threshold temperature or the second threshold temperature.

3. The washing machine as claimed in claim 2, wherein the control unit is configured to rotate the drum at a second threshold speed faster than the first threshold speed before the additive is put into the drum, and control the additive input unit to put the additive into the drum in case that a rotational speed of the drum reaches the second threshold speed.

4. The washing machine as claimed in claim 3, further comprising a detection unit configured to detect vibration of the washing machine, wherein the control unit is configured to end the rotation of the drum and then rotate the drum again at the second threshold speed in case that vibration intensity detected by the detection unit is equal to or greater than predetermined threshold intensity before the rotational speed of the drum reaches the second threshold speed.

5. The washing machine as claimed in claim 4, wherein the control unit is configured to control the additive input unit not to put the additive into the drum in case that the vibration intensity detected by the detection unit is equal to or greater than the predetermined threshold intensity after the drum is rotated again for a predetermined threshold number of times.

6. The washing machine as claimed in claim 3, wherein the control unit is configured to control the additive input unit to put the additive into the drum in case that the rotational speed of the drum reaches the second threshold speed within a predetermined threshold time.

7. The washing machine as claimed in claim 3, wherein the control unit is configured to control the temperature adjustment unit to maintain the first threshold temperature for a first threshold time and rotate the drum at the second threshold speed faster than the first threshold speed after the first threshold time.

8. The washing machine as claimed in claim 7, wherein the control unit is configured to control the temperature adjustment unit to maintain the second threshold temperature for the second threshold time less than the first threshold time after all the additive is put into the drum.

9. The washing machine as claimed in claim 8, wherein the control unit is configured to control the temperature adjustment unit to set the temperature inside the drum to a third threshold temperature lower than the second threshold temperature after the second threshold time, and rotate the drum at the first threshold speed while the temperature inside the drum is set and maintained at the third threshold temperature.

10. The washing machine as claimed in claim 9, further comprising a drainage unit, wherein the control unit is configured to control the drainage unit to discharge the additive contained in the drum to an outside before the temperature inside the drum is set to the third threshold temperature.

11. A method for controlling a washing machine comprising: setting a temperature inside a drum to a first threshold temperature through a temperature adjustment unit configured to adjust the temperature inside the drum accommodating laundry by generating hot air and cold air; putting an additive into the drum to coat the laundry with fragrant particles in case that the temperature inside the drum is set to the first threshold temperature; and setting the temperature inside the drum to a second threshold temperature lower than the first threshold temperature through the temperature adjustment unit in case that the additive is put into the drum.

12. The method for controlling a washing machine as claimed in claim 11, wherein the drum is rotated at a first threshold speed while the temperature inside the drum is set and maintained at the first threshold temperature or the second threshold temperature.

13. The method for controlling a washing machine as claimed in claim 12, further comprising rotating the drum at a second threshold speed faster than the first threshold speed before the additive is put into the drum, wherein in the putting of the additive into the drum, the additive is put into the drum in case that a rotational speed of the drum reaches the second threshold speed.

14. The method for controlling a washing machine as claimed in claim 13, wherein in the rotating of the drum at the second threshold speed, the rotation of the drum is ended and the drum is rotated again at the second threshold speed in case that vibration intensity due to the rotation of the drum is equal to or greater than predetermined threshold intensity before the rotational speed of the drum reaches the second threshold speed.

15. The method for controlling a washing machine as claimed in claim 14, wherein in the putting of the additive into the drum, the additive is not put into the drum in case that the detected vibration intensity is equal to or greater than the predetermined threshold intensity after the drum is rotated again for a predetermined threshold number of times.

Description

CROSS-REFERENCE TO RELATED APPLICATIONS

[0001] This application is a 371 of International Application No. PCT/KR2018/011858 filed on Oct. 10, 2018, which claims priority to Korean Patent Application No. 10-2017-0133527 filed on Oct. 13, 2017, the disclosures of which are herein incorporated by reference in their entirety.

BACKGROUND

1. Field

[0002] The disclosure relates to a washing machine and a method for controlling the same, and more particularly to, a washing machine for sterilizing laundry through a refresh cycle and a method for controlling the same.

2. Description of Related Art

[0003] In general, a drum type washing machine may provide a washing cycle for washing laundry and a drying cycle for drying the washed laundry.

[0004] In addition, a recent drum type washing machine may provide a refresh cycle function in addition to the cycles described above. The refresh cycle function may wash the laundry without water washing the laundry by using a detergent as in the washing cycle.

[0005] That is, the refresh cycle function may sterilize and dry the laundry at a high temperature to deodorize a smell permeating the laundry. The laundry may be prevented from being damaged by having a reduced number of water washings due to this refresh cycle.

[0006] However, the recently developed refresh cycle function may simply sterilize and dry the laundry. Therefore, even though washed through the refresh cycle function, the laundry may have a limit in having the same effect as the laundry washed using additives such as a fabric softener in a normal washing cycle.

[0007] The disclosure provides laundry washed in a refresh cycle with the same effect as laundry washed in a normal washing cycle.

SUMMARY

[0008] According to an embodiment of the disclosure, a washing machine includes: a drum configured to contain laundry; an additive input unit configured to put an additive into the drum to coat the laundry with fragrant particles; a temperature adjustment unit configured to adjust a temperature inside the drum by generating hot air and cold air; and a control unit configured to: control the temperature adjustment unit to set the temperature inside the drum to a first threshold temperature, control the additive input unit to put the additive into the drum in case that the temperature inside the drum is set to the first threshold temperature, and control the temperature adjustment unit to set the temperature inside the drum to a second threshold temperature lower than the first threshold temperature in case that the additive is put into the drum.

[0009] In addition, the control unit may be configured to rotate the drum at a first threshold speed while the temperature inside the drum is set and maintained at the first threshold temperature or the second threshold temperature.

[0010] In addition, the control unit may be configured to rotate the drum at a second threshold speed faster than the first threshold speed before the additive is put into the drum, and control the additive input unit to put the additive into the drum in case that a rotational speed of the drum reaches the second threshold speed.

[0011] In addition, the washing machine may further include a detection unit configured to detect vibration of the washing machine, wherein the control unit may be configured to end the rotation of the drum and then rotate the drum again at the second threshold speed in case that vibration intensity detected by the detection unit is equal to or greater than predetermined threshold intensity before the rotational speed of the drum reaches the second threshold speed.

[0012] In addition, the control unit may be configured to control the additive input unit not to put the additive into the drum in case that the vibration intensity detected by the detection unit is equal to or greater than the predetermined threshold intensity after the drum is rotated again for a predetermined threshold number of times.

[0013] In addition, the control unit may be configured to control the additive input unit to put the additive into the drum in case that the rotational speed of the drum reaches the second threshold speed within a predetermined threshold time.

[0014] In addition, the control unit may be configured to control the temperature adjustment unit to maintain the first threshold temperature for a first threshold time and rotate the drum at the second threshold speed faster than the first threshold speed after the first threshold time.

[0015] In addition, the control unit may be configured to control the temperature adjustment unit to maintain the second threshold temperature for the second threshold time less than the first threshold time after all the additive is put into the drum.

[0016] In addition, the control unit may be configured to control the temperature adjustment unit to set the temperature inside the drum to a third threshold temperature lower than the second threshold temperature after the second threshold time, and rotate the drum at the first threshold speed while the temperature inside the drum is set and maintained at the third threshold temperature.

[0017] In addition, the washing machine may further include a drainage unit, wherein the control unit may be configured to control the drainage unit to discharge the additive contained in the drum to an outside before the temperature inside the drum is set to the third threshold temperature.

[0018] Meanwhile, according to another embodiment of the disclosure, a method for controlling a washing machine includes: setting a temperature inside a drum to a first threshold temperature through a temperature adjustment unit configured to adjust the temperature inside the drum accommodating laundry by generating hot air and cold air; putting an additive into the drum to coat the laundry with fragrant particles in case that the temperature inside the drum is set to the first threshold temperature; and setting the temperature inside the drum to a second threshold temperature lower than the first threshold temperature through the temperature adjustment unit in case that the additive is put into the drum.

[0019] In addition, the drum may be rotated at a first threshold speed while the temperature inside the drum is set and maintained at the first threshold temperature or the second threshold temperature.

[0020] In addition, the method for controlling a washing machine may further include rotating the drum at a second threshold speed faster than the first threshold speed before the additive is put into the drum, wherein in the putting of the additive into the drum, the additive is put into the drum in case that a rotational speed of the drum reaches the second threshold speed.

[0021] In addition, in the rotating of the drum at the second threshold speed, the rotation of the drum may be ended and the drum may be rotated again at the second threshold speed in case that vibration intensity due to the rotation of the drum is equal to or greater than predetermined threshold intensity before the rotational speed of the drum reaches the second threshold speed.

[0022] In addition, in the putting of the additive into the drum, the additive may not be put into the drum in case that the detected vibration intensity is equal to or greater than the predetermined threshold intensity after the drum is rotated again for a predetermined threshold number of times.

[0023] In addition, in the putting of the additive into the drum, the additive may be put into the drum in case that the rotational speed of the drum reaches the second threshold speed within a predetermined threshold time.

[0024] In addition, in the setting of the temperature inside the drum to the first threshold temperature, the temperature inside the drum may be set to be maintained at the first threshold temperature for a first threshold time, and in the rotating of the drum at the second threshold speed, the drum may be rotated at the second threshold speed faster than the first threshold speed after the first threshold time.

[0025] In addition, in the setting of the temperature inside the drum to the second threshold temperature, the temperature inside the drum may be set to be maintained at the second threshold temperature for a second threshold time less than the first threshold time.

[0026] In addition, the method for controlling a washing machine may further include setting the temperature inside the drum to a third threshold temperature lower than the second threshold temperature through the temperature adjustment unit after the second threshold time, wherein the drum may be rotated at the first threshold speed while the temperature inside the drum is set and maintained at the third threshold temperature.

[0027] In addition, the method for controlling a washing machine may further include discharging the additive contained in the drum to an outside through a drainage unit before the temperature inside the drum is set to the third threshold temperature.

[0028] As set forth above, according to the disclosure, the washing machine may provide the laundry washed in the refresh cycle with the same effect as the laundry washed in the normal washing cycle.

BRIEF DESCRIPTION OF THE DRAWINGS

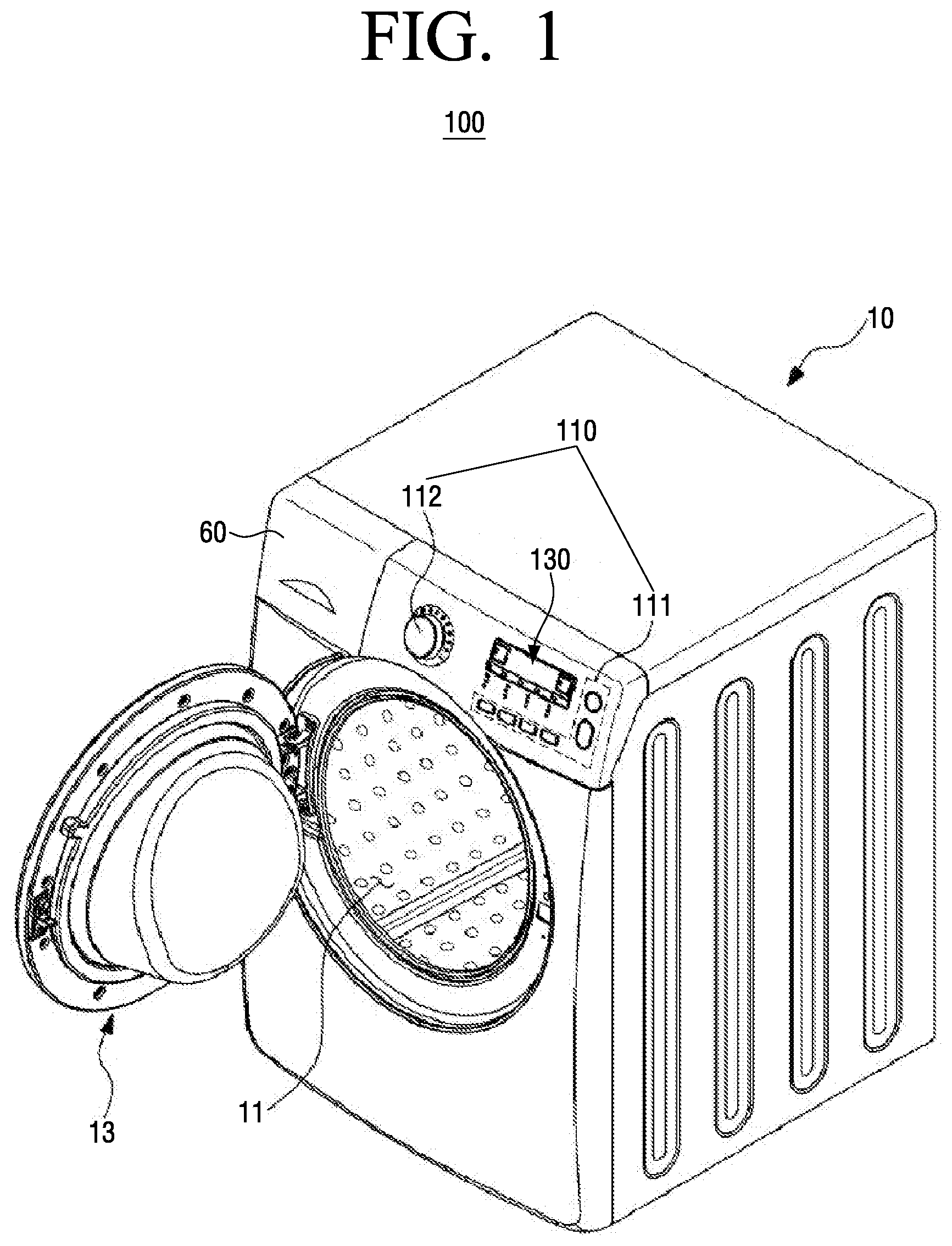

[0029] FIG. 1 is a perspective view showing an appearance of a washing machine according to an embodiment of the disclosure;

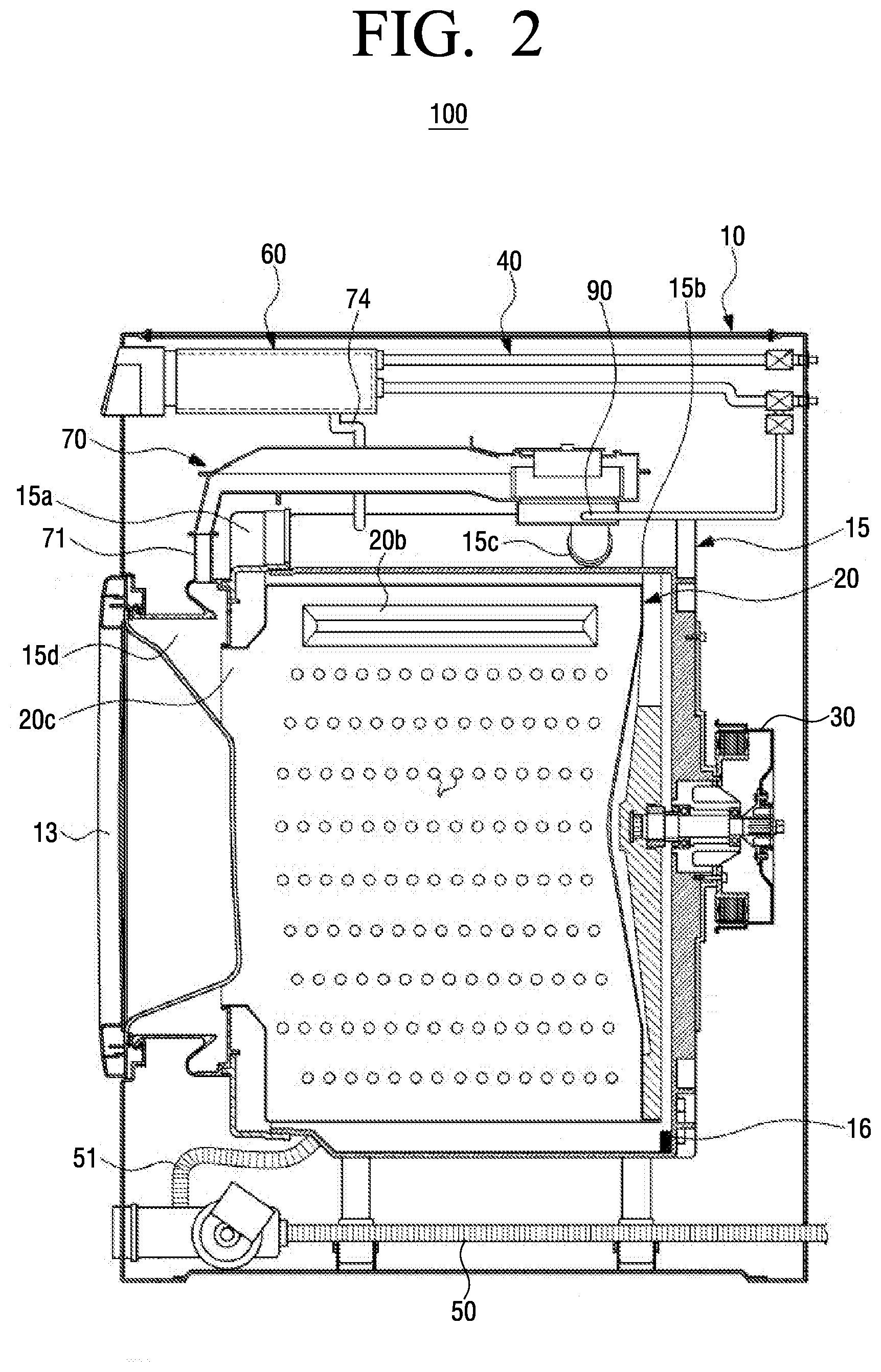

[0030] FIG. 2 is a side cross-sectional view showing an inside of the washing machine according to an embodiment of the disclosure;

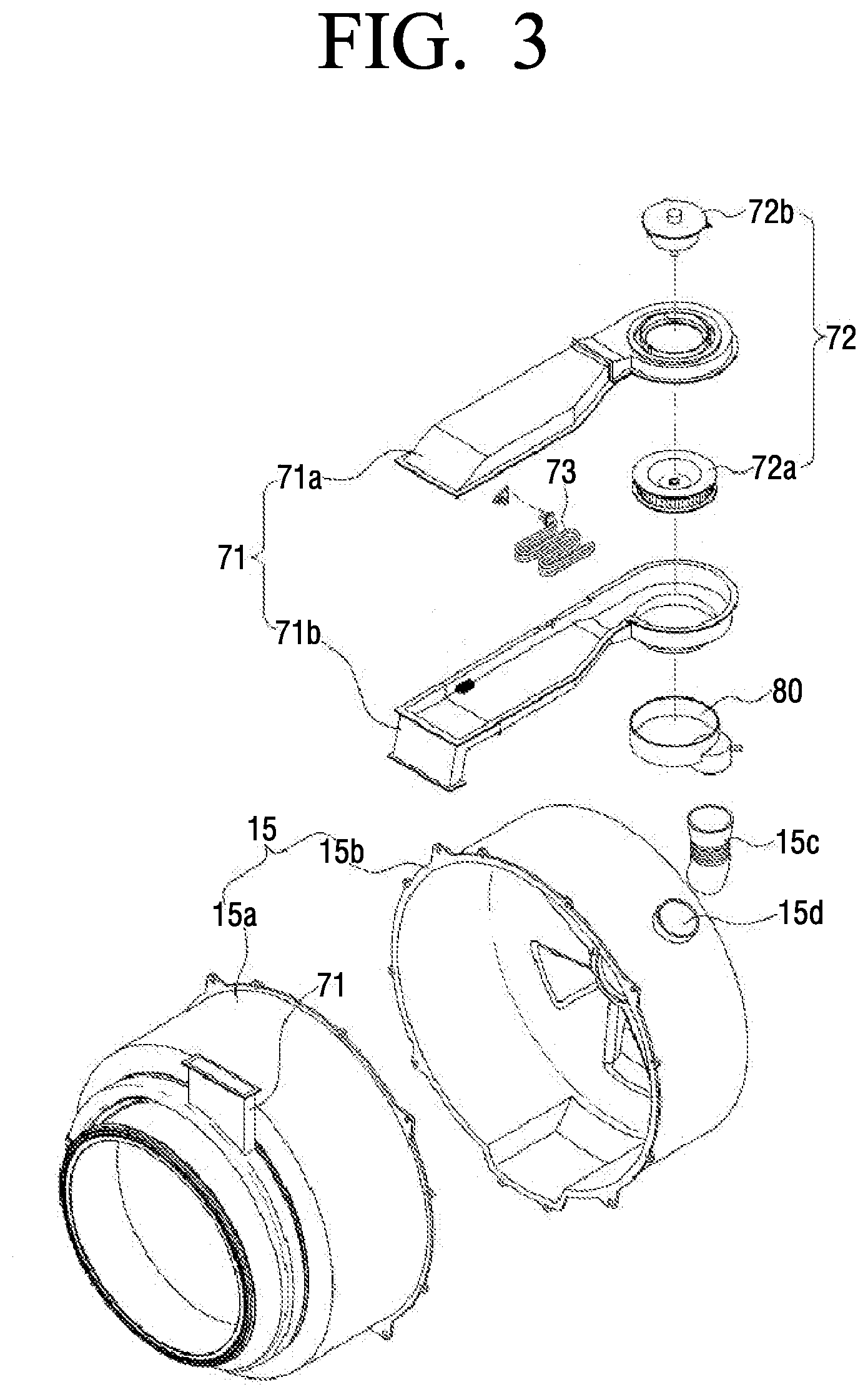

[0031] FIG. 3 is an exploded perspective view of a temperature adjustment unit according to an embodiment of the disclosure;

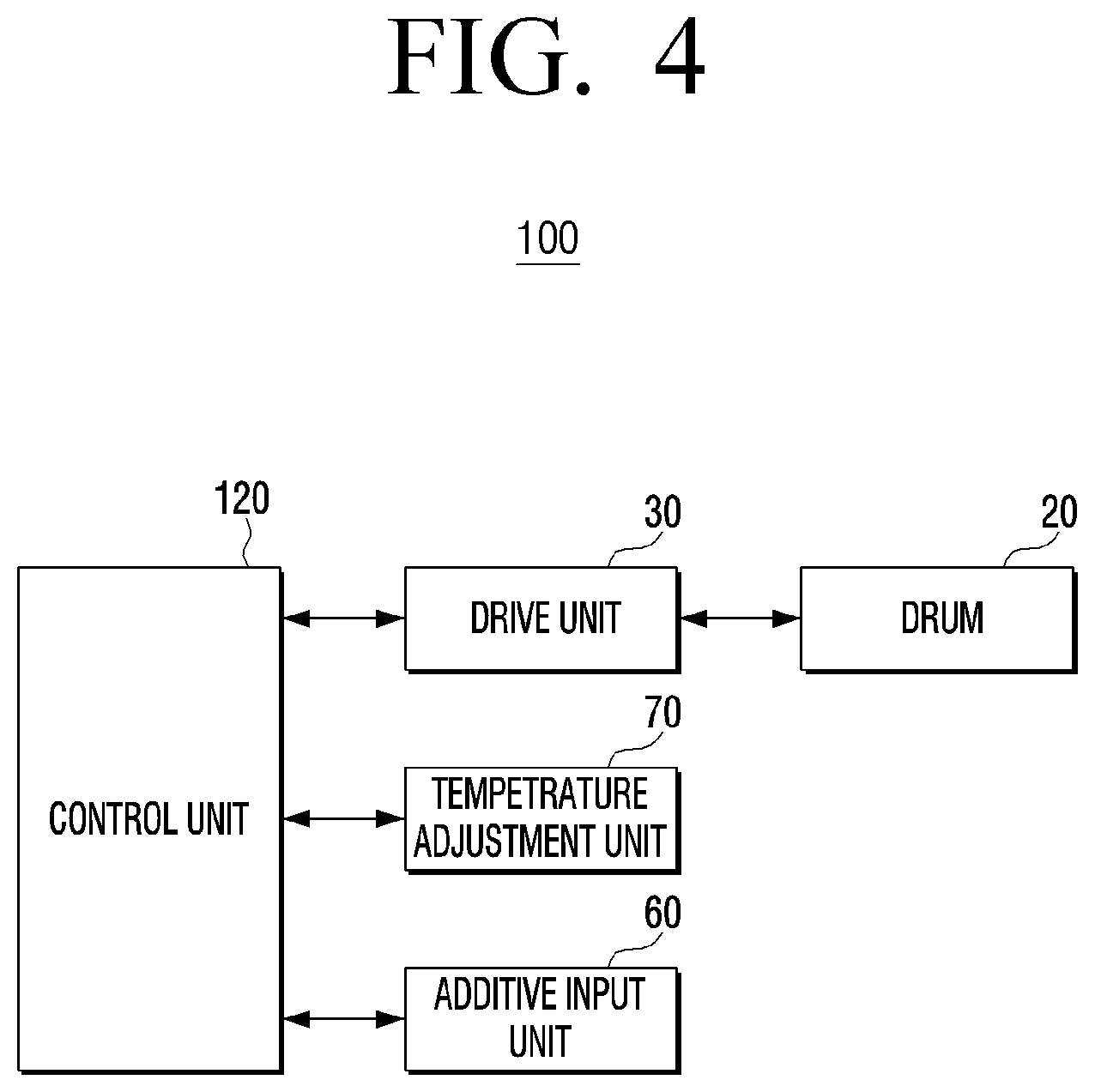

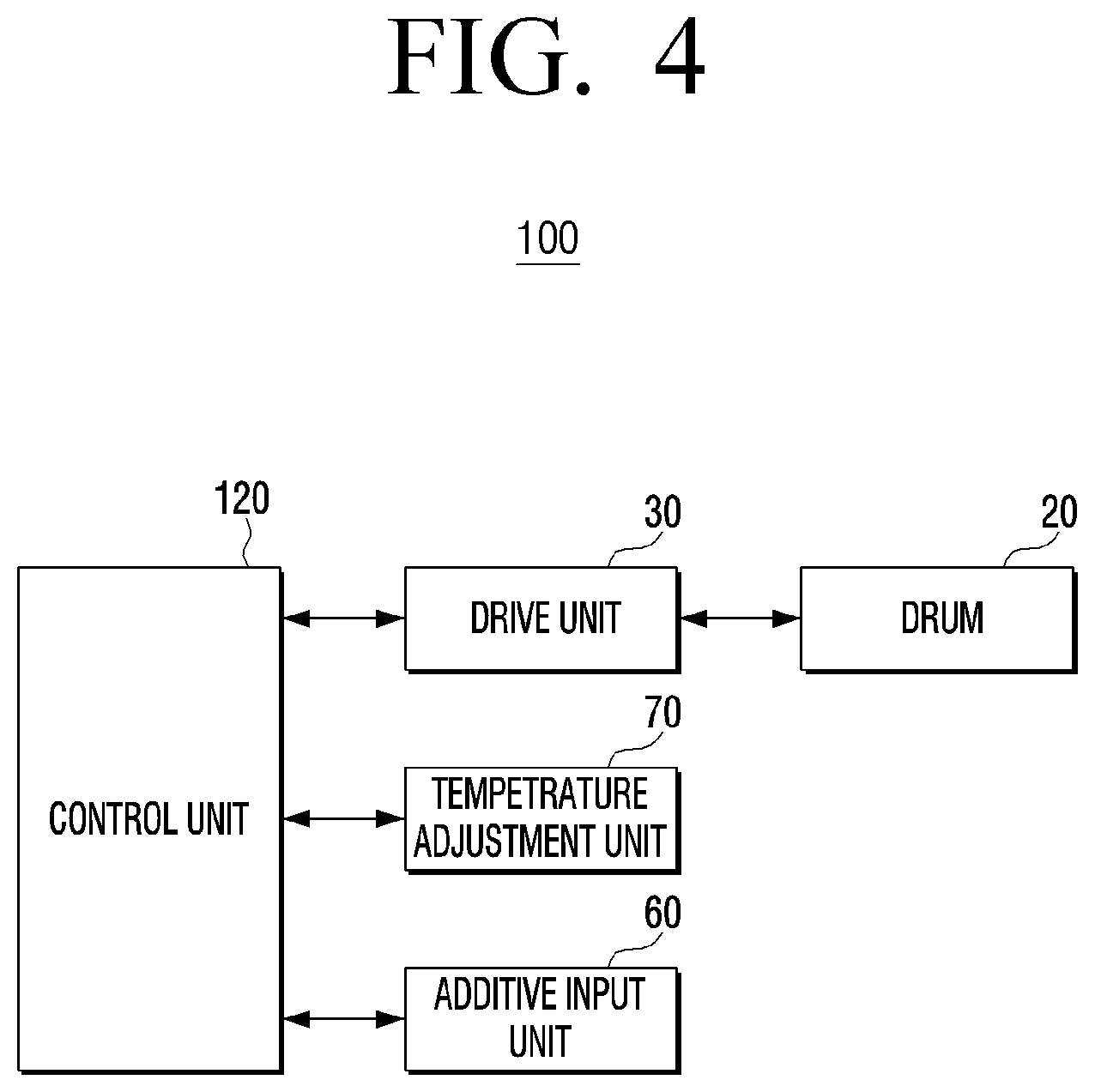

[0032] FIG. 4 is a block diagram showing the washing machine performing a refresh cycle according to an embodiment of the disclosure;

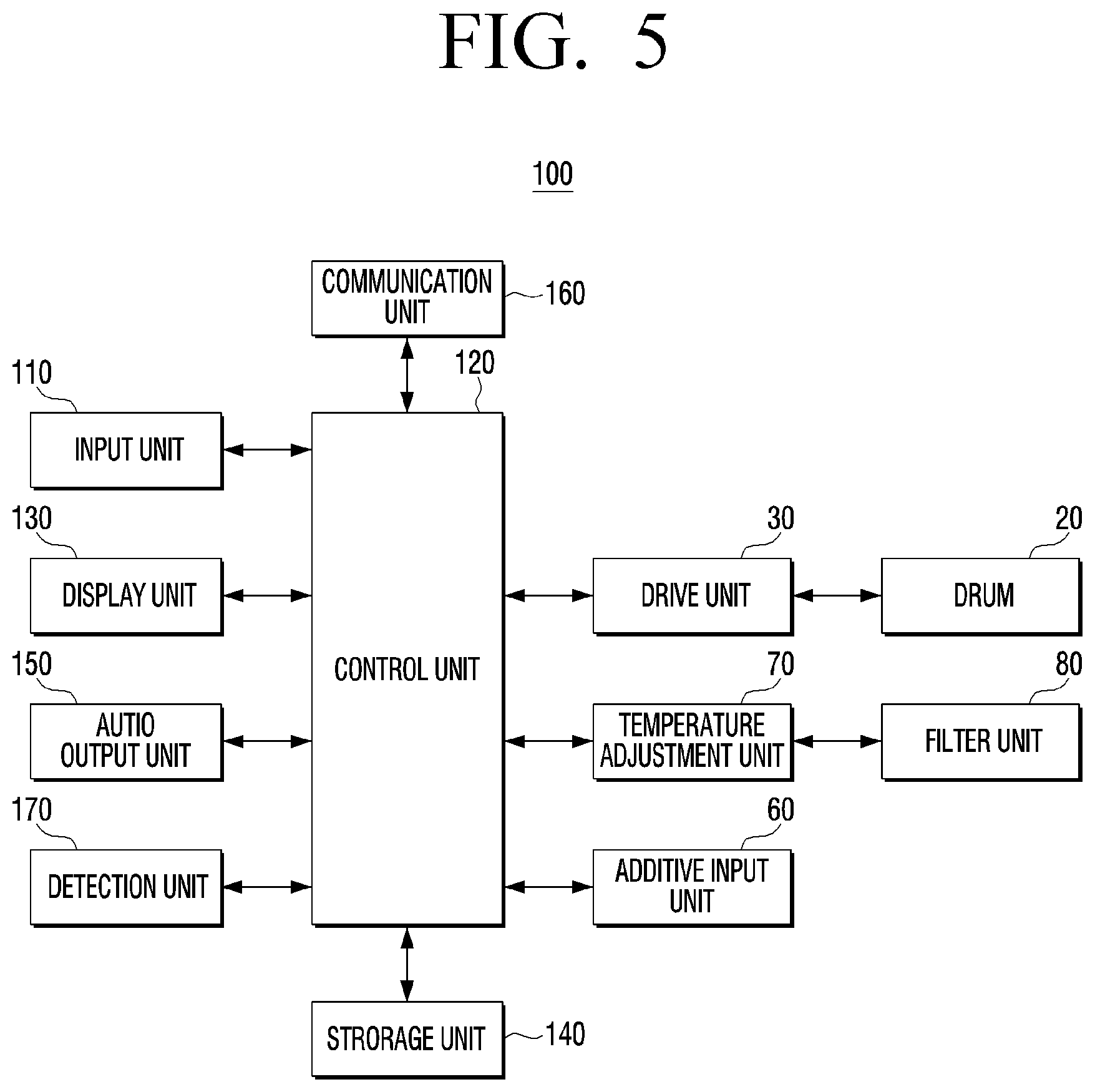

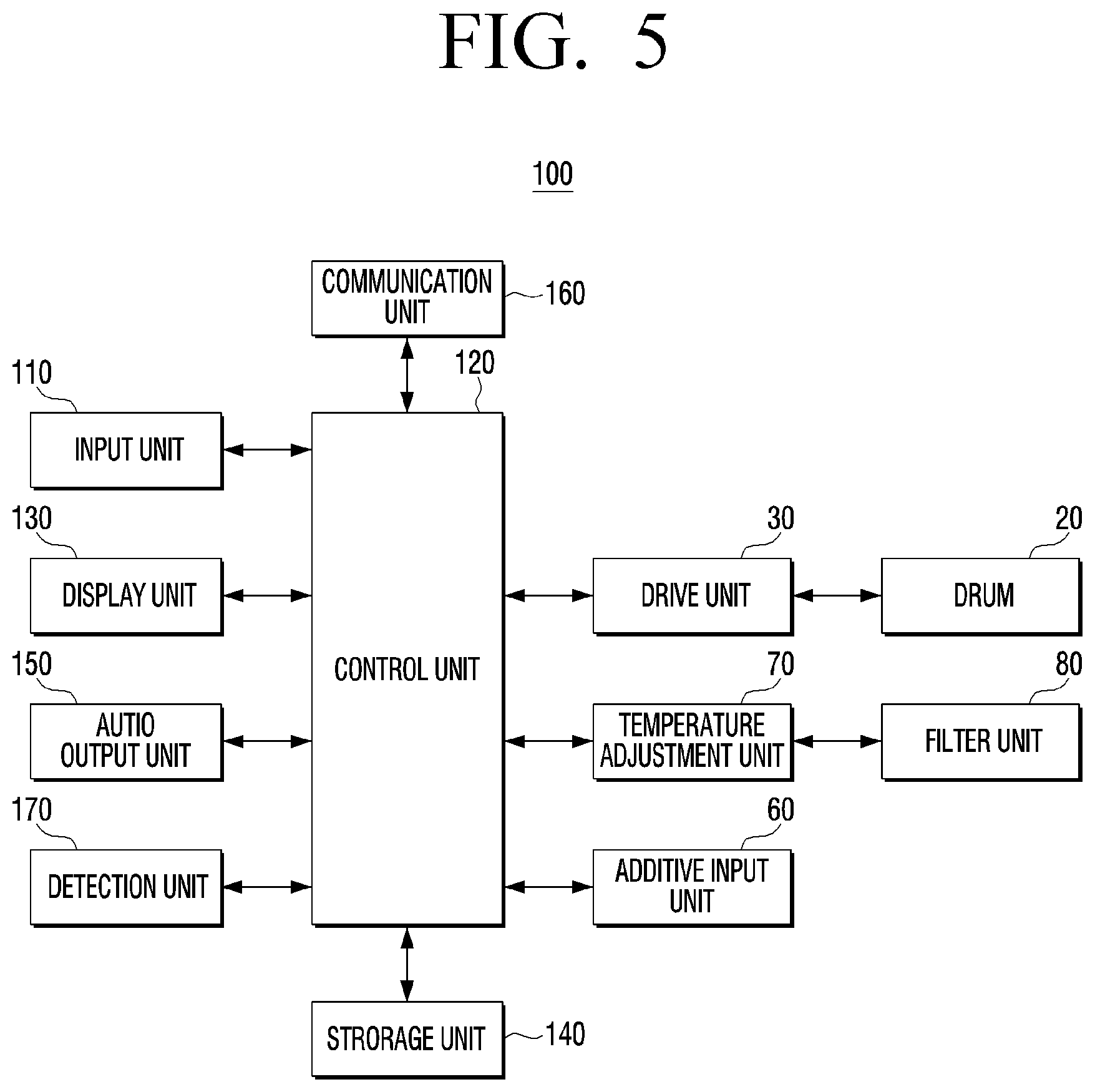

[0033] FIG. 5 is a detailed block diagram of the washing machine according to an embodiment of the disclosure;

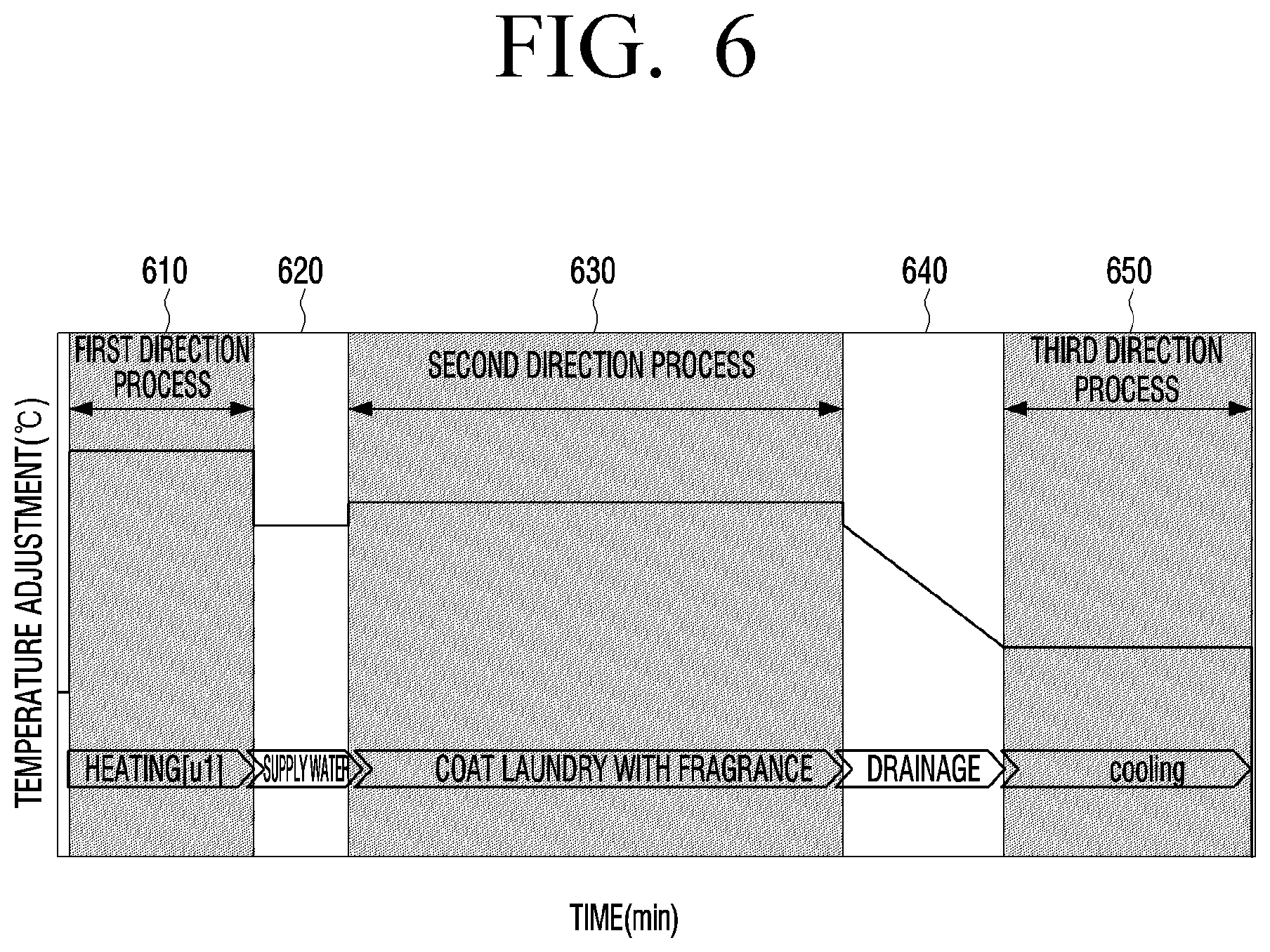

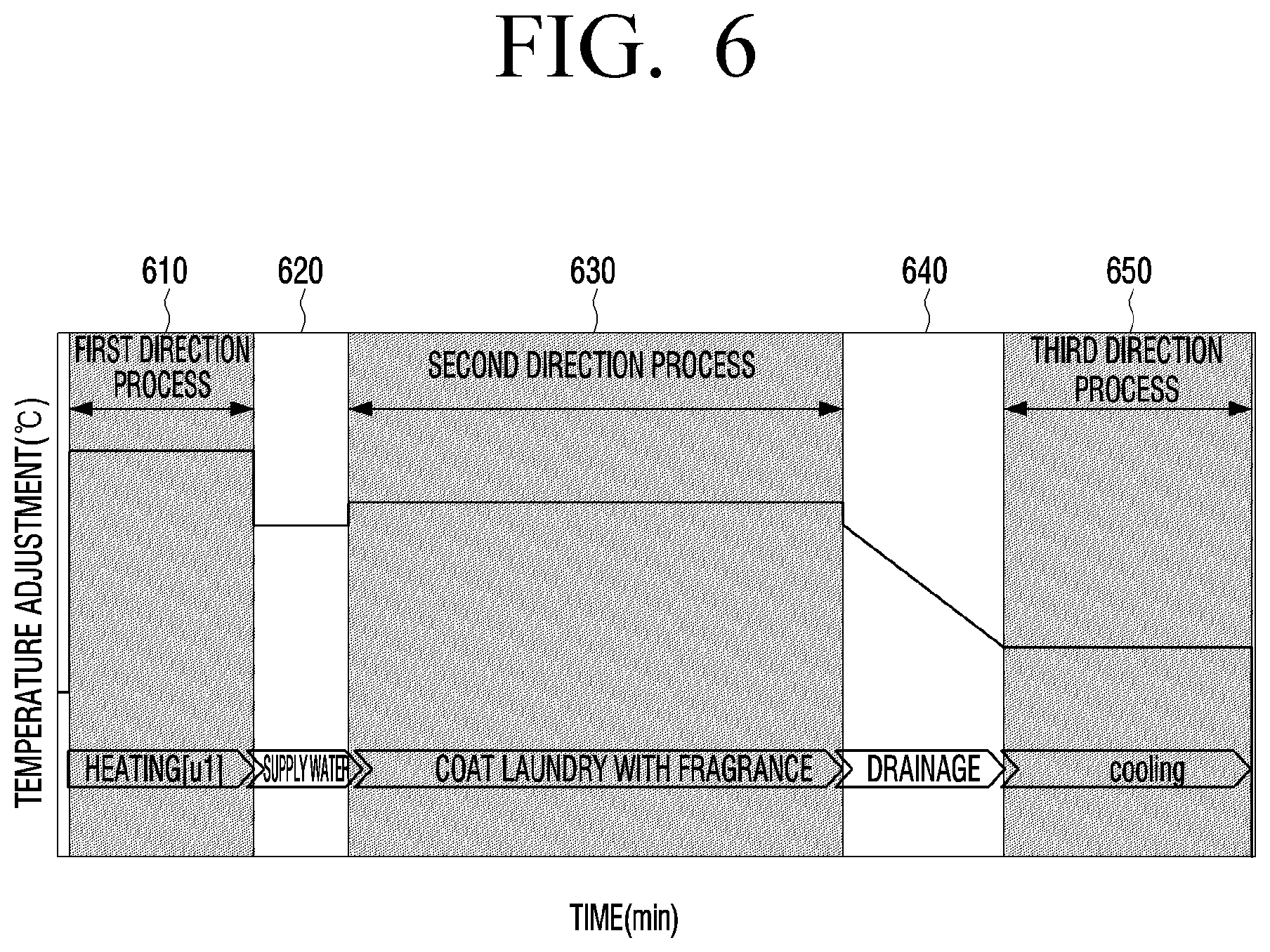

[0034] FIG. 6 is an exemplary view showing processes of the washing machine performing the refresh cycle according to an embodiment of the disclosure;

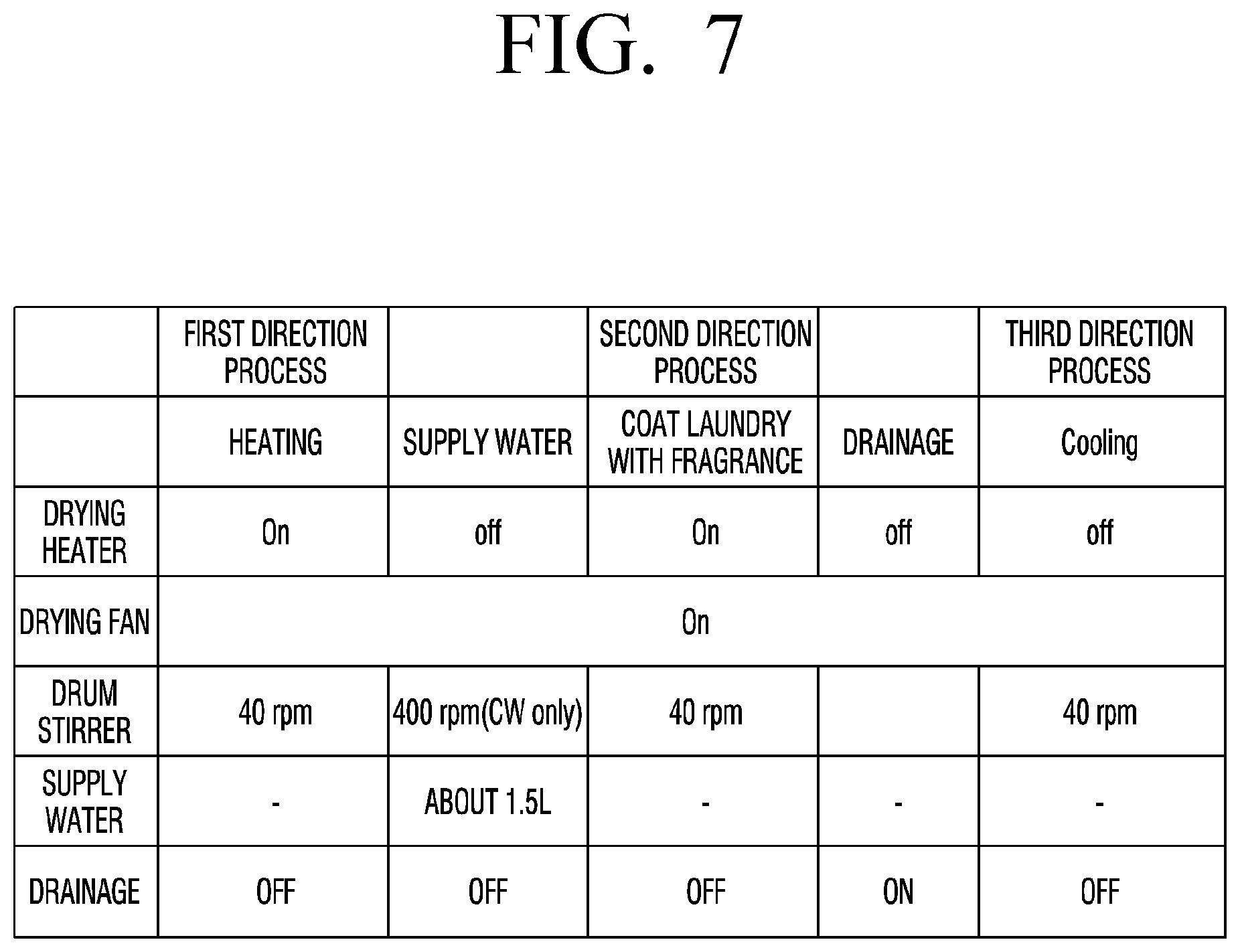

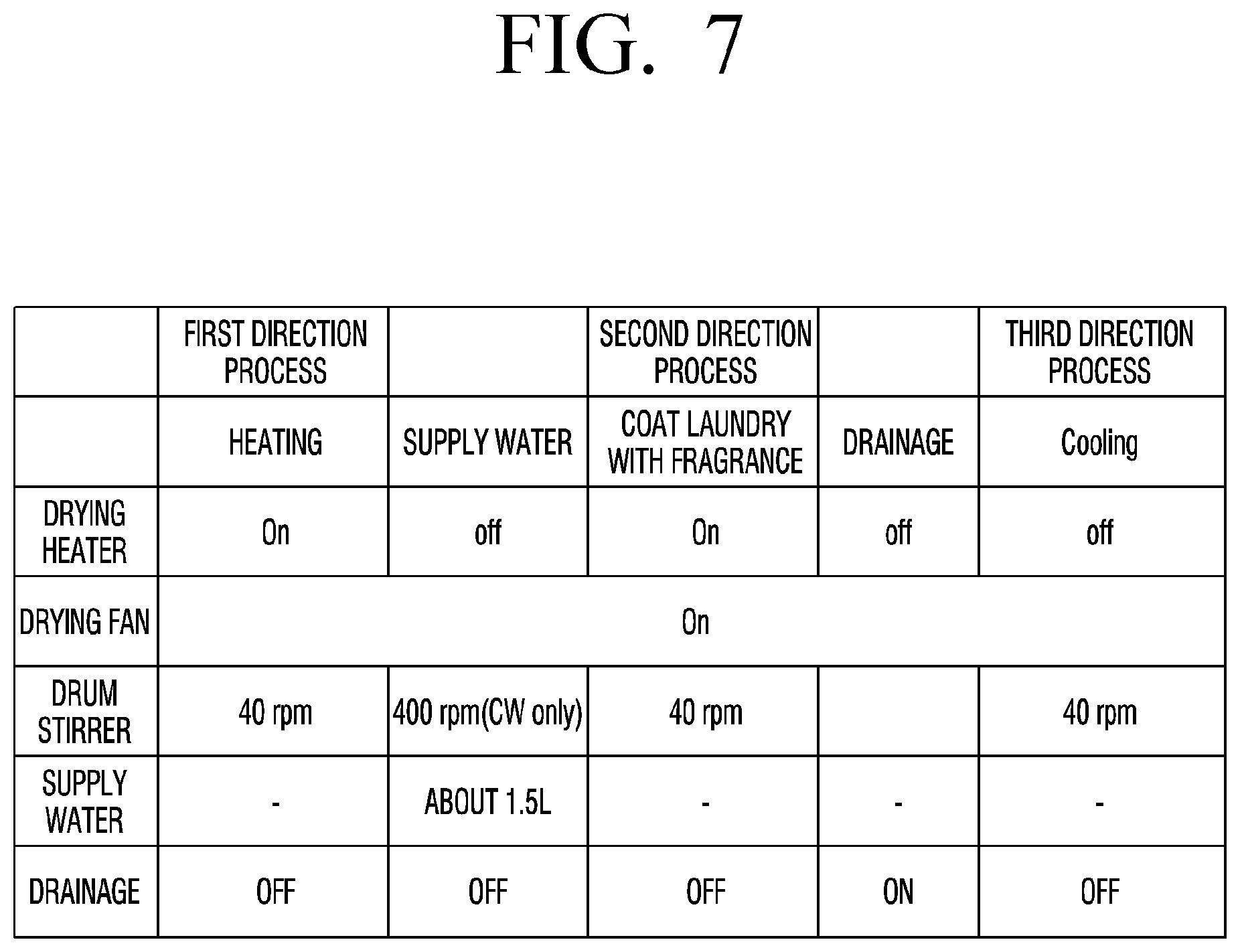

[0035] FIG. 7 is an exemplary view showing an operation of each component for each process of the refresh cycle performed in the washing machine according to an embodiment of the disclosure;

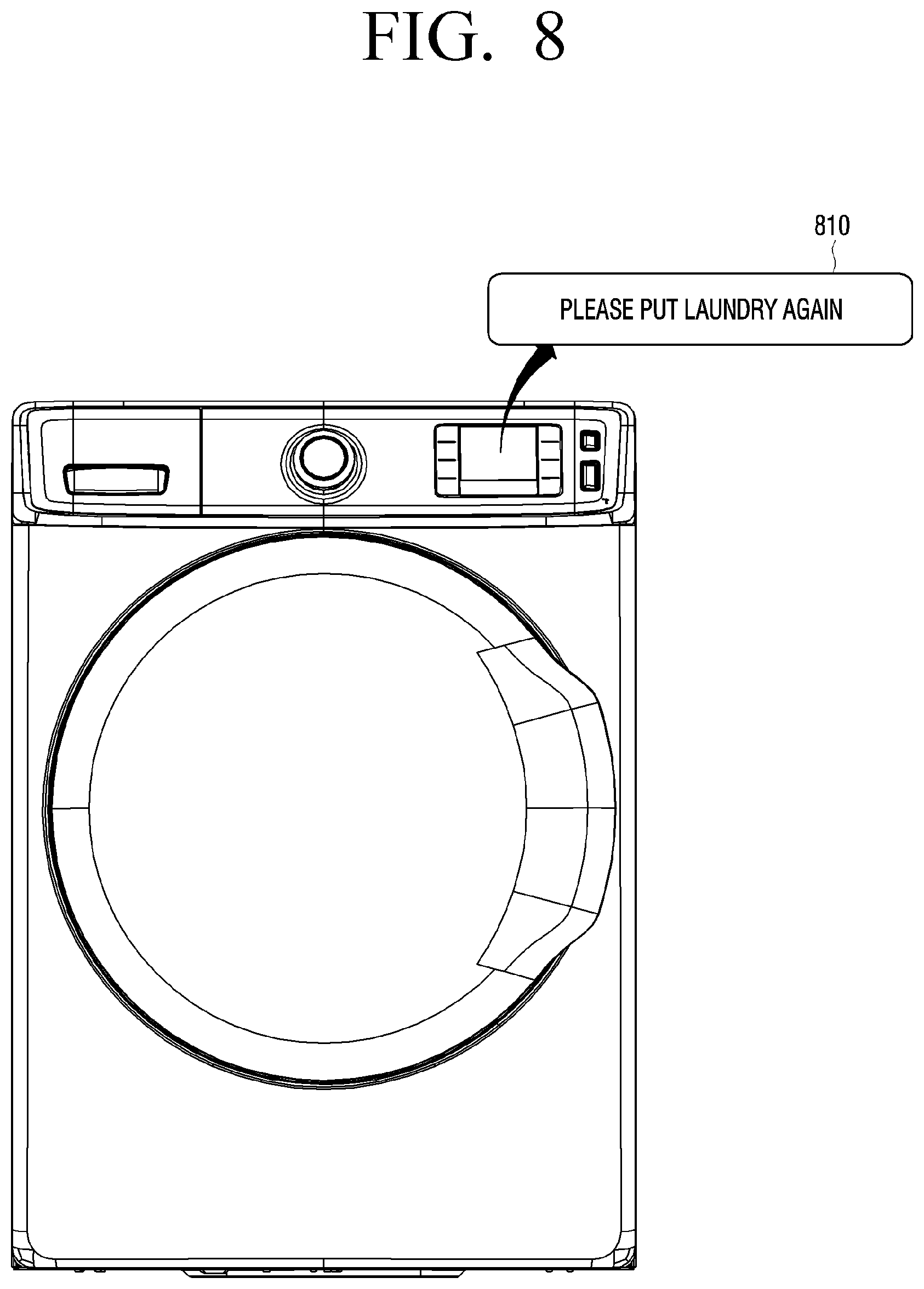

[0036] FIG. 8 is an exemplary view showing that the washing machine provides a user interface (UI) based on occurrence of an event according to an embodiment of the disclosure;

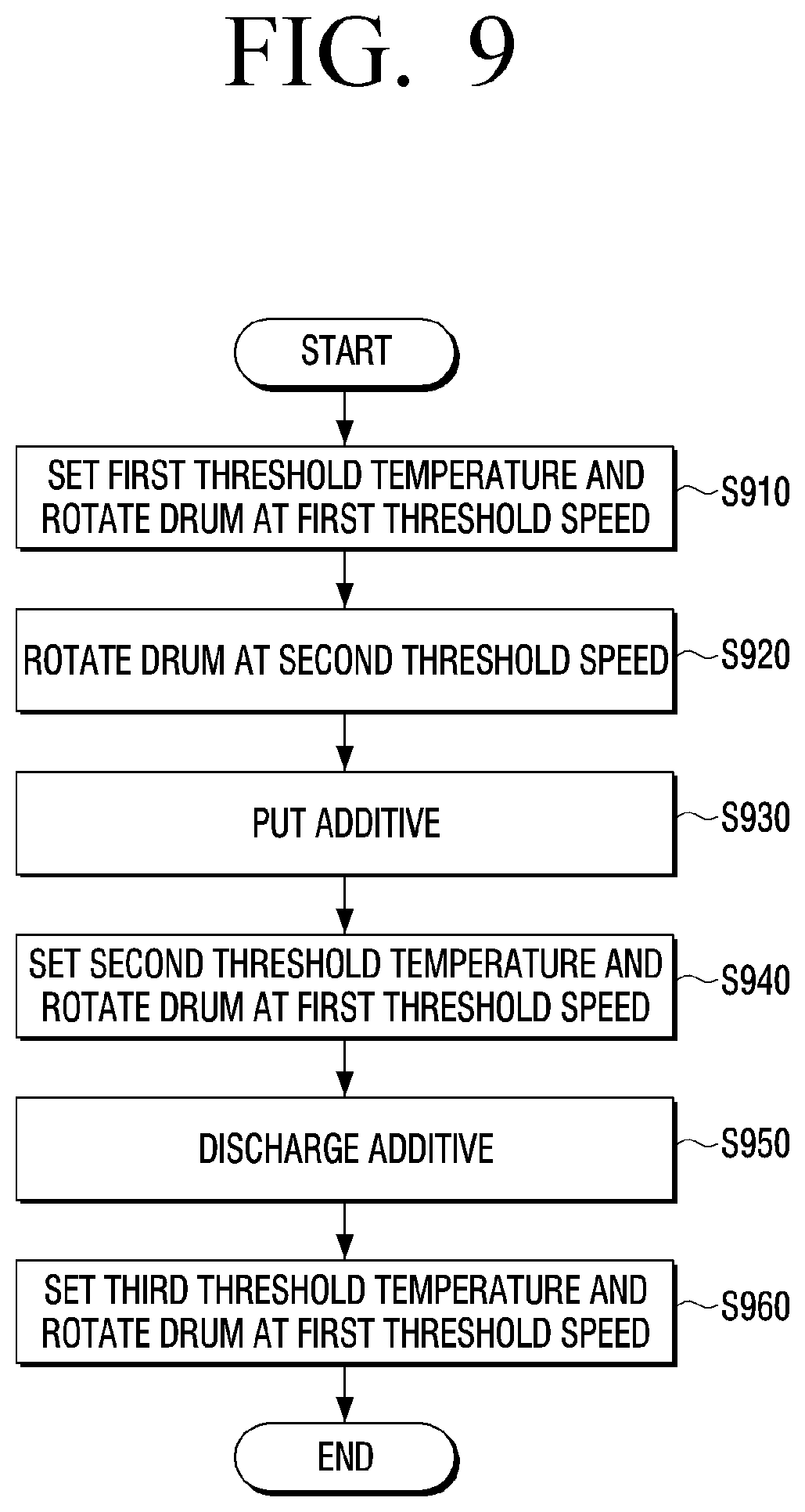

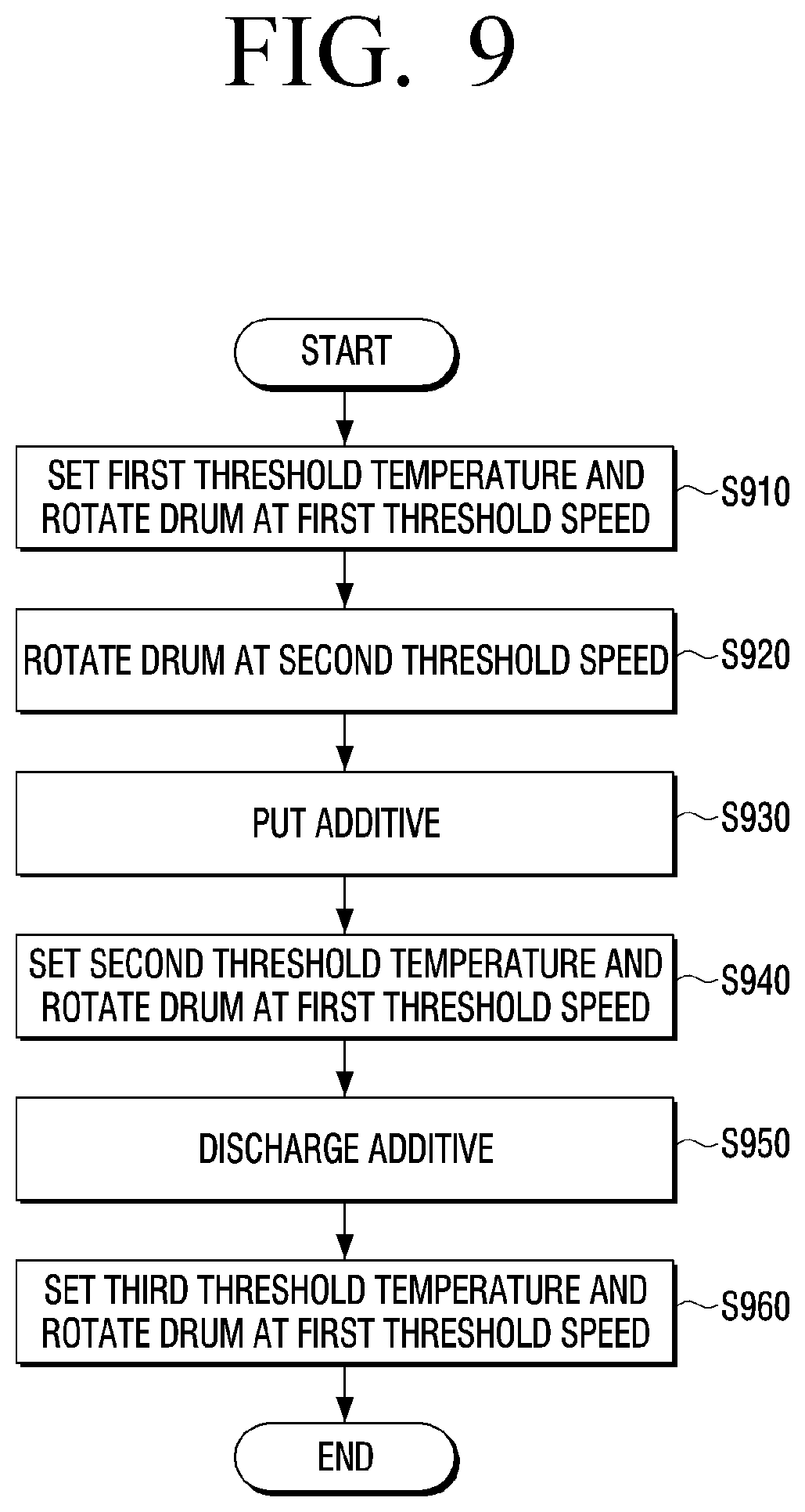

[0037] FIG. 9 is a flowchart showing a method of a washing machine to perform a refresh cycle according to an embodiment of the disclosure;

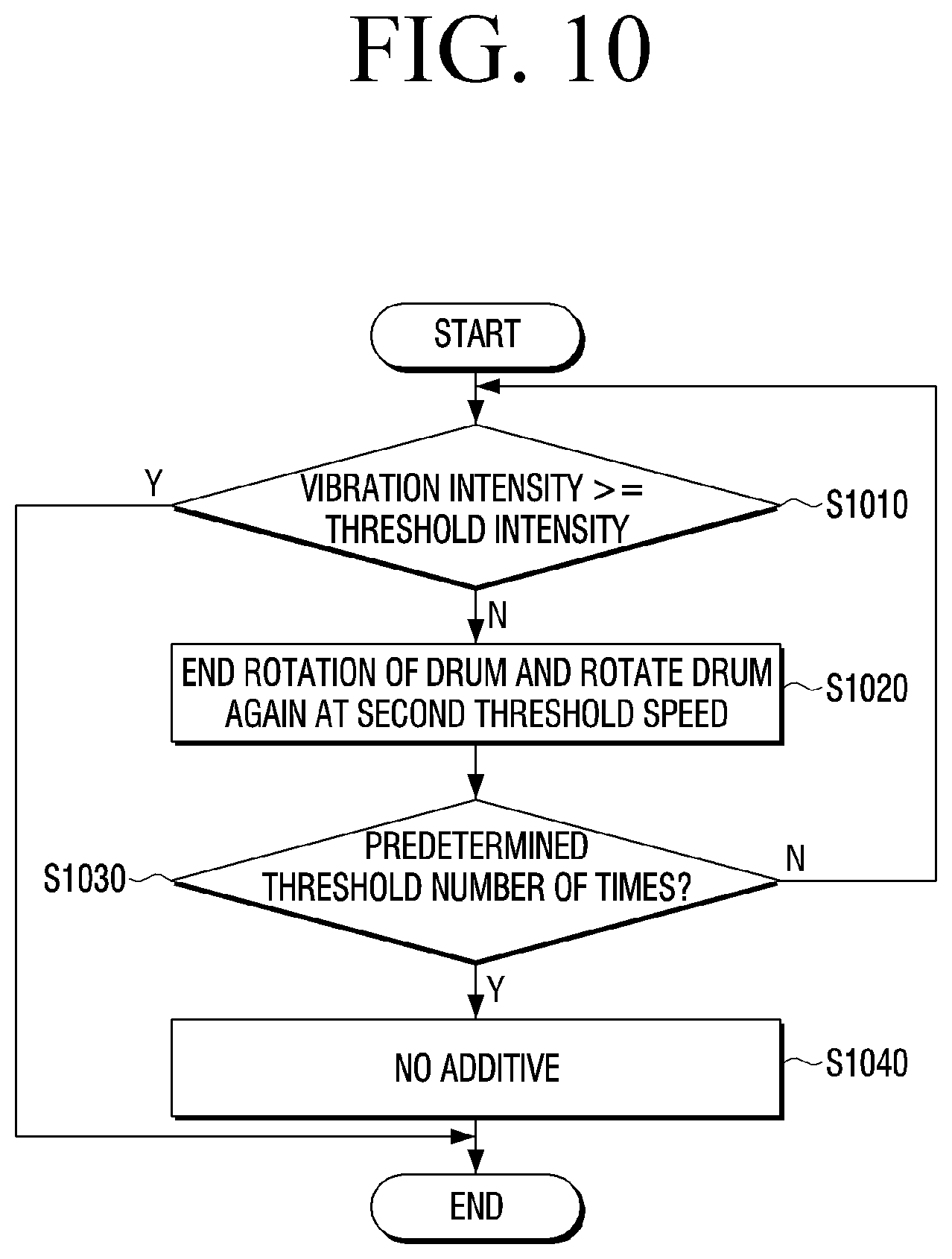

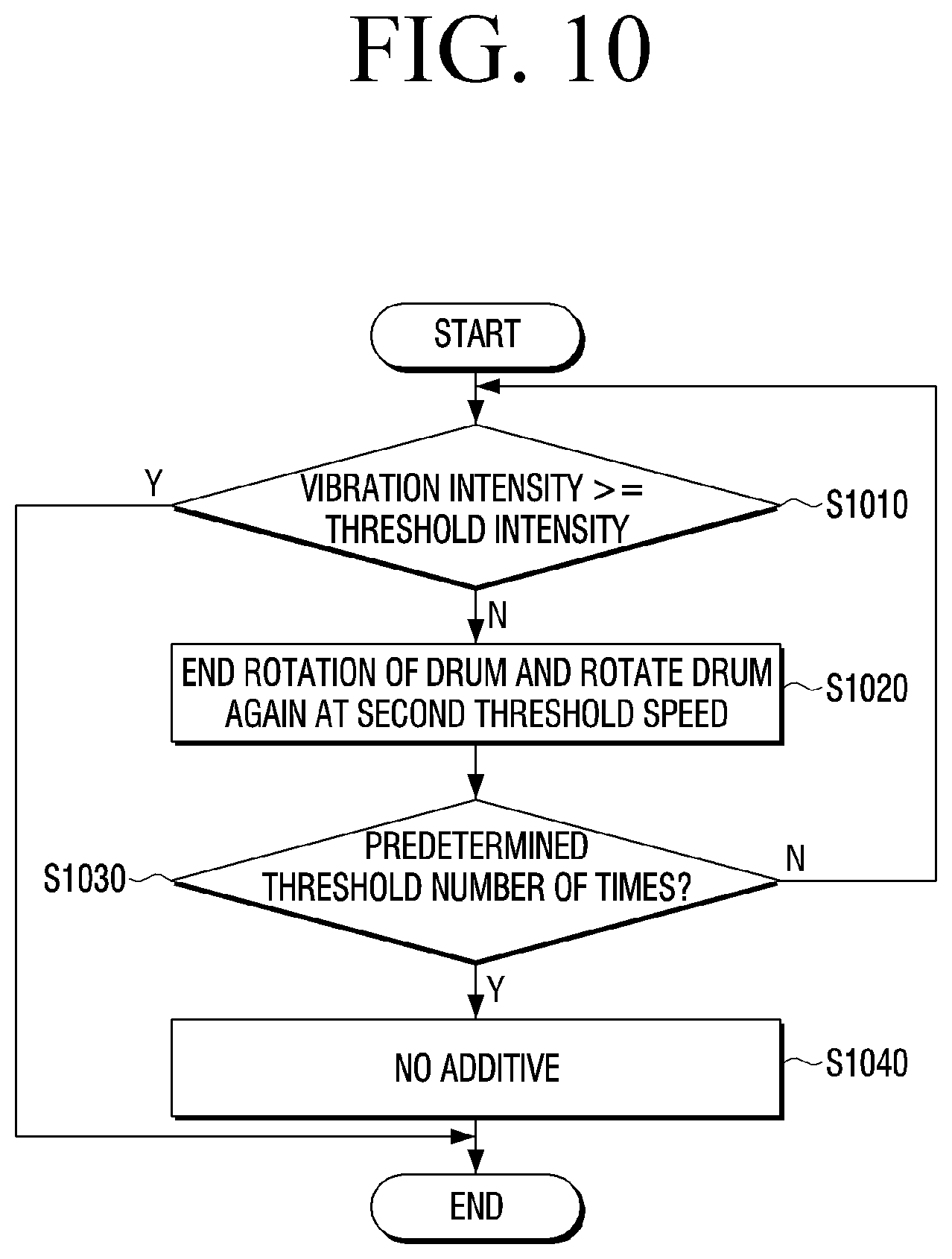

[0038] FIG. 10 is a first flowchart showing a method of the washing machine to determine whether to put an additive into a drum according to an embodiment of the disclosure; and

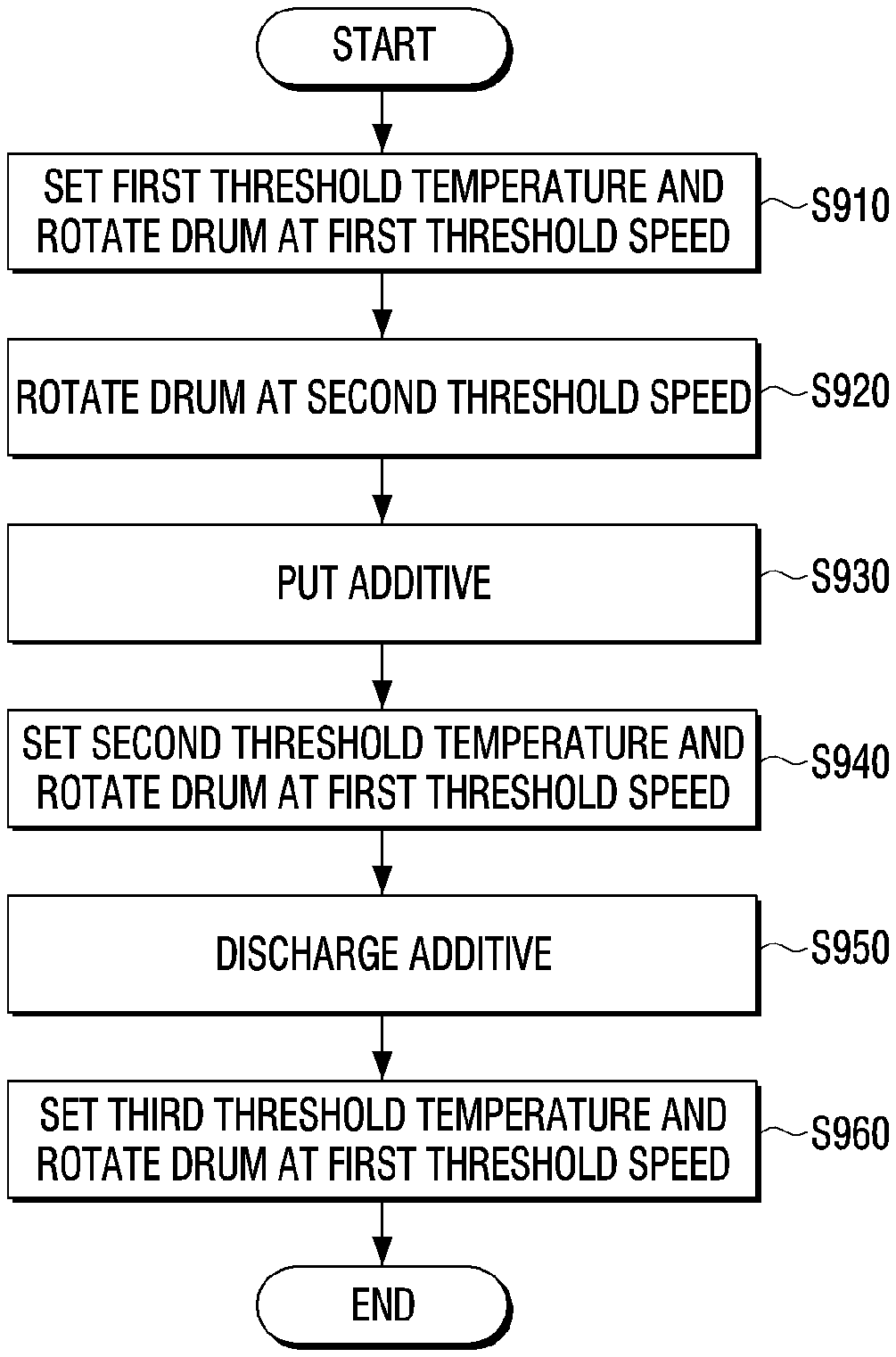

[0039] FIG. 11 is a second flowchart showing a method of the washing machine to determine whether to put an additive into a drum according to according to another embodiment of the disclosure.

DETAILED DESCRIPTION

[0040] Hereinafter, various embodiments of the disclosure are described with reference to the accompanying drawings. However, it is to be understood that technologies mentioned in the disclosure are not limited to specific embodiments, but include various modifications, equivalents, and/or alternatives according to embodiments of the disclosure. Throughout the accompanying drawings, similar components are denoted by similar reference numerals.

[0041] In addition, expressions, "first", "second" or the like, used in the disclosure may indicate various components regardless of a sequence and/or importance of the components, are used only to distinguish one component from the other components, and do not limit the corresponding components. For example, a `first portion` and a `second portion` may indicate different portions regardless of a sequence or importance. For example, a first component may be named a second component and the second component may also be similarly named the first component, without departing from the scope of the disclosure.

[0042] In addition, terms used in the disclosure may be used only to describe specific embodiments rather than restricting the scope of other embodiments. Singular forms may include plural forms unless the context clearly indicates otherwise. Terms used in the specification including technical and scientific terms have the same meanings as those that are generally understood by those skilled in the art to which the disclosure pertains. Terms defined by a general dictionary among terms used in the disclosure may be interpreted as meanings that are the same as or similar to meanings within a context of the related art, and are not interpreted as ideal or excessively formal means unless clearly defined in the disclosure. In some cases, terms may not be interpreted to exclude embodiments of the disclosure even though they are defined in the disclosure.

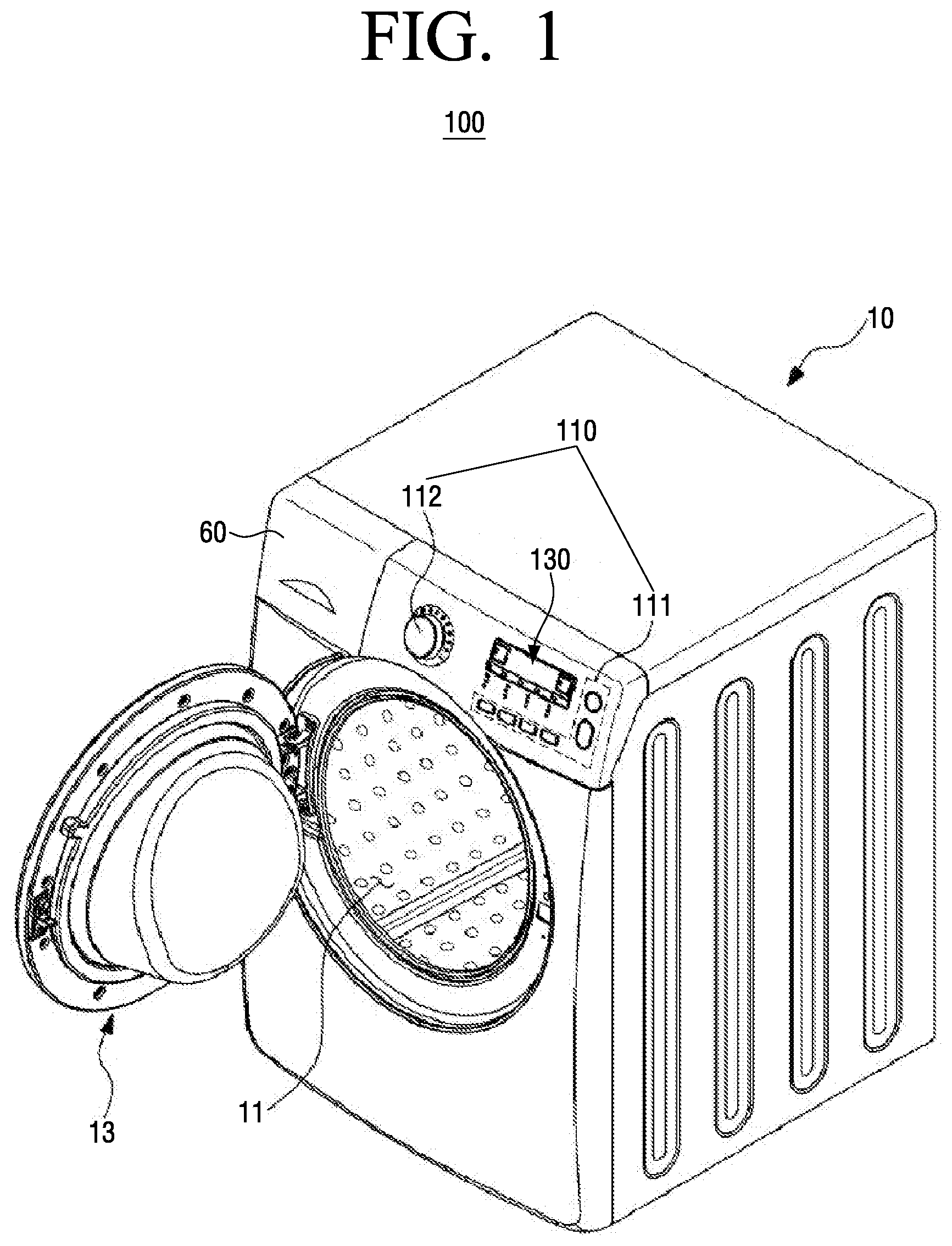

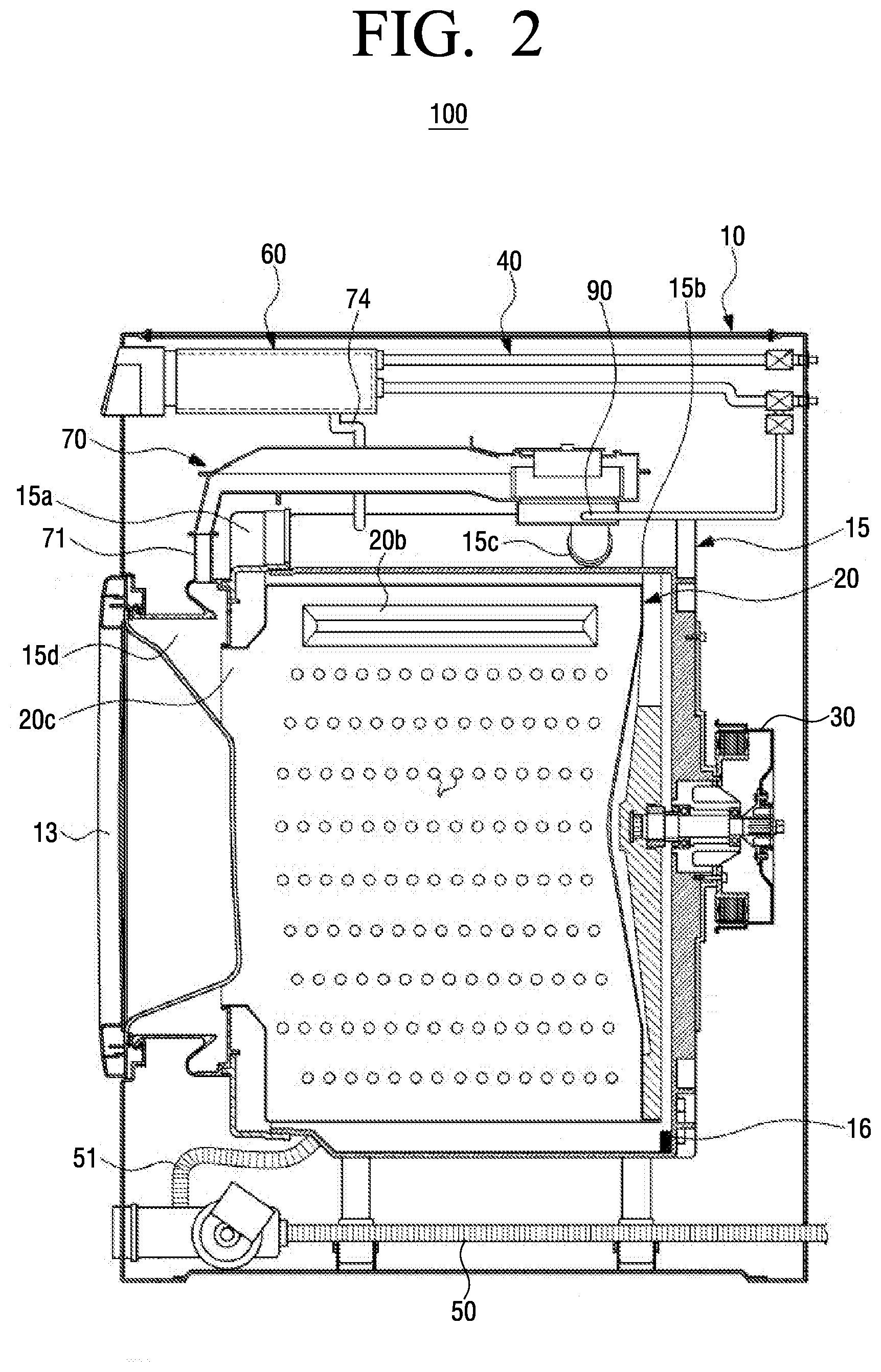

[0043] FIG. 1 is a perspective view showing an appearance of a washing machine according to an embodiment of the disclosure; and FIG. 2 is a side cross-sectional view showing an inside of the washing machine according to an embodiment of the disclosure.

[0044] As shown in FIGS. 1 and 2, a washing machine 100 may include: a main body 10 forming its appearance; a tub 15 configured to contain water used for washing; a drum 20 configured to accommodate laundry and wash the laundry through rotation; a drive unit 30 configured to rotate the drum 20; a water supply unit 40 configured to supply the water to the tub 15; a drainage unit 50 configured to discharge the water contained in the tub 15 to an outside of the washing machine 100; an additive input unit 60 configured to put an additive into the drum; a temperature adjustment unit 70 configured to adjust a temperature of air inside the drum 20 to dry the laundry accommodated in the drum 20; and a filter unit 80 configured to filter lint occurring from the laundry accommodated in the drum 20.

[0045] In addition, the washing machine 100 may include a control unit 120. The control unit 120, as described above, may control an overall operation of each component for washing, drying and refresh cycles of the laundry accommodated in the drum 20. Here, the refresh cycle is a cycle for sterilizing and deodorizing the laundry accommodated in the drum 20 without performing the washing cycle.

[0046] Meanwhile, an inlet 11 may be formed in a center of a front surface of the main body 10 to put into or take the laundry out of the drum 20, and a door 13 may be provided to the inlet 11 for opening and closing the inlet 11. The door 13 may be pivotally mounted to the main body 10 by a hinge, and may be formed not to be easily opened by a hook in case that the inlet 11 is closed.

[0047] In addition, a control panel 5 may be disposed on an upper portion of the front surface on which the inlet 11 is formed, and the control panel 5 may include an input unit 110 receiving a user instruction for the washing, drying and refresh cycles and a display unit 130 displaying information on operation of each cycle. However, the disclosure is not limited thereto, and the control panel 5 including the input unit 110 and the display unit 130 may be disposed on a side portion or a lower portion of the front surface or on one region of upper, left or right surface of the main body 10.

[0048] In detail, the input unit 110 may be an input device receiving the user instruction on an operation of the washing machine 100, such as washing time, rinsing number of times, dehydration time, drying time, time and operation related to the refresh cycle, pause and the like. The input unit 110 may include a touch input unit 111 receiving a touch instruction from a user and an operation unit 112 receiving an operation instruction from the user.

[0049] The display unit 130 may display amount of the laundry, the washing and drying cycles, water temperature information, rinsing information, dehydration intensity, washing time information, refresh cycle progress information and the like. The display unit 130 may be implemented as a liquid crystal display (LCD) panel, a light emitting diode (LED) panel or the like.

[0050] Meanwhile, the above-described touch input unit 111 may be implemented as a touch pad forming a mutual layer structure along with the display unit 130, and in this case, the touch input unit 111 and the display unit 130 may be implemented in a form of a touch screen.

[0051] The tub 15 may be provided inside the main body 10, and may include a tub rear member 15b formed in a shape of a cylinder having a closed rear end and a tub front member 15a disposed in front of the tub rear member 15b. In addition, a drive unit 30 rotating the drum 20 may be provided at a rear surface of the tub rear member 15b.

[0052] According to an embodiment, the drive unit 30 may connect a drive motor rotating the drum 20 and the drum 20, and may include a drive shaft rotated by the drive motor and a bearing housing supporting the drive shaft to be rotated. Therefore, the drum 20 may be rotated around the drive shaft rotated by the drive motor.

[0053] According to an embodiment, the drive motor may be implemented as a brushless direct current (BLDC) motor with easy control of its rotational speed, an alternation current (AC) motor or the like.

[0054] Meanwhile, a guide tube 15c may be provided on an upper portion of the tub rear member 15b to guide the air inside a drying unit 70, the filter unit 80, the tub 15 and the drum 20 toward the drying unit 70. In addition, the drying unit 70 may be provided above the opening 15d to deliver the air introduced through the guide tube 15c into the tub 15 and the drum 20.

[0055] In addition, a temperature sensor 16 may be provided in the tub 15 to detect a temperature inside the tub 15. In addition, the tub 15 may be connected to the water supply unit 40 and the additive input unit 60 through a connection tube 74 provided on an upper portion of the tub 15, and may receive the additive diluted in washing water. Here, the additive may be a material in which a detergent for washing the laundry or a fabric softener for coating the laundry with fragrant particles is diluted in the washing water.

[0056] In addition, the tub 15 may be connected to the drainage unit 50 through a drainage tube 51 provided at a lower portion of the tub 15 to discharge the washing water contained in the tub 15 to the outside of the washing machine 100.

[0057] The drum 20 may be rotatably provided in the tub 15, and may include a plurality of through holes 20a introducing the washing water contained in the tub 15 into the drum 20, a lifter 20b lifting the washing water introduced into the drum 20 upwards and an opening 20c discharging the washing water introduced into the drum 20.

[0058] The water supply unit 40 may be provided above the tub 15 and deliver the washing water supplied from a water supply source (not shown) to the additive input unit 60 through a water supply tube. That is, the water supply unit 40 may receive the washing water supplied from the water supply source (not shown) through the water supply tube by opening a water supply valve provided on one side of the water supply tube based on a control instruction of the control unit 120 to be described below. Here, the water supply valve may be implemented as a solenoid valve according to an embodiment. The washing water supplied through the water supply unit 40 may be introduced into the additive input unit 60, and the detergent or the fabric softener supplied to the additive supply unit 60 may be supplied into the tub 15 through the connection tube 74 together with the washing water introduced into the additive input unit 60.

[0059] The drainage unit 50 may be provided below the tub 15, and pump the washing water in the tub 15 through a drainage pump and discharge the pumped washing water to an outside of the main body 10 through a drainage hose.

[0060] The temperature adjustment unit 70 may be provided above the tub 15 to adjust a temperature inside the drum 20 by generating hot air and cold air to dry the laundry accommodated in the drum 20 during the drying cycle. In addition, the temperature adjustment unit 70 may adjust the temperature inside the drum 20 by generating the hot air and the cold air to sterilize and deodorize the laundry accommodated in the drum 20 during the refresh cycle.

[0061] Here, the refresh cycle may be a washing process to provide the same effect as a water washing, in which the laundry accommodated in the drum 20 may be sterilized by the hot air and the cold air generated inside the drum 20 through the temperature adjustment unit 70 instead of being washed by the washing water.

[0062] Meanwhile, the temperature adjustment unit 70 may draw the air inside the tub 15 and the drum 20, heat the drawn air, and discharge the heated air to the tub 15 and the drum 20.

[0063] The filter unit 80 may be provided between the temperature adjustment unit 70 and the tub 15. The filter unit 80 may filter out a foreign material including lint to prevent the foreign material including the lint occurring in the laundry accommodated in drum 20 from being drawn into the temperature adjustment unit 70 in a process in which the air inside the tub 15 and the drum 20 is drawn into the temperature adjustment unit 70 during the drying cycle or the refresh cycle.

[0064] The filter unit 80 may include a cleaning unit (not shown) for removing the foreign material including the lint filtered from the filter unit 80. Therefore, the foreign material filtered from the filter unit 80 may be periodically removed by the cleaning unit (not shown). It is thus possible to improve deterioration in drying and sterilization efficiency of the laundry, which occurs in case that the air inside the tub 15 and the drum 20 fails to be delivered into the temperature adjustment unit 70 due to the foreign material filtered by the filter unit 80.

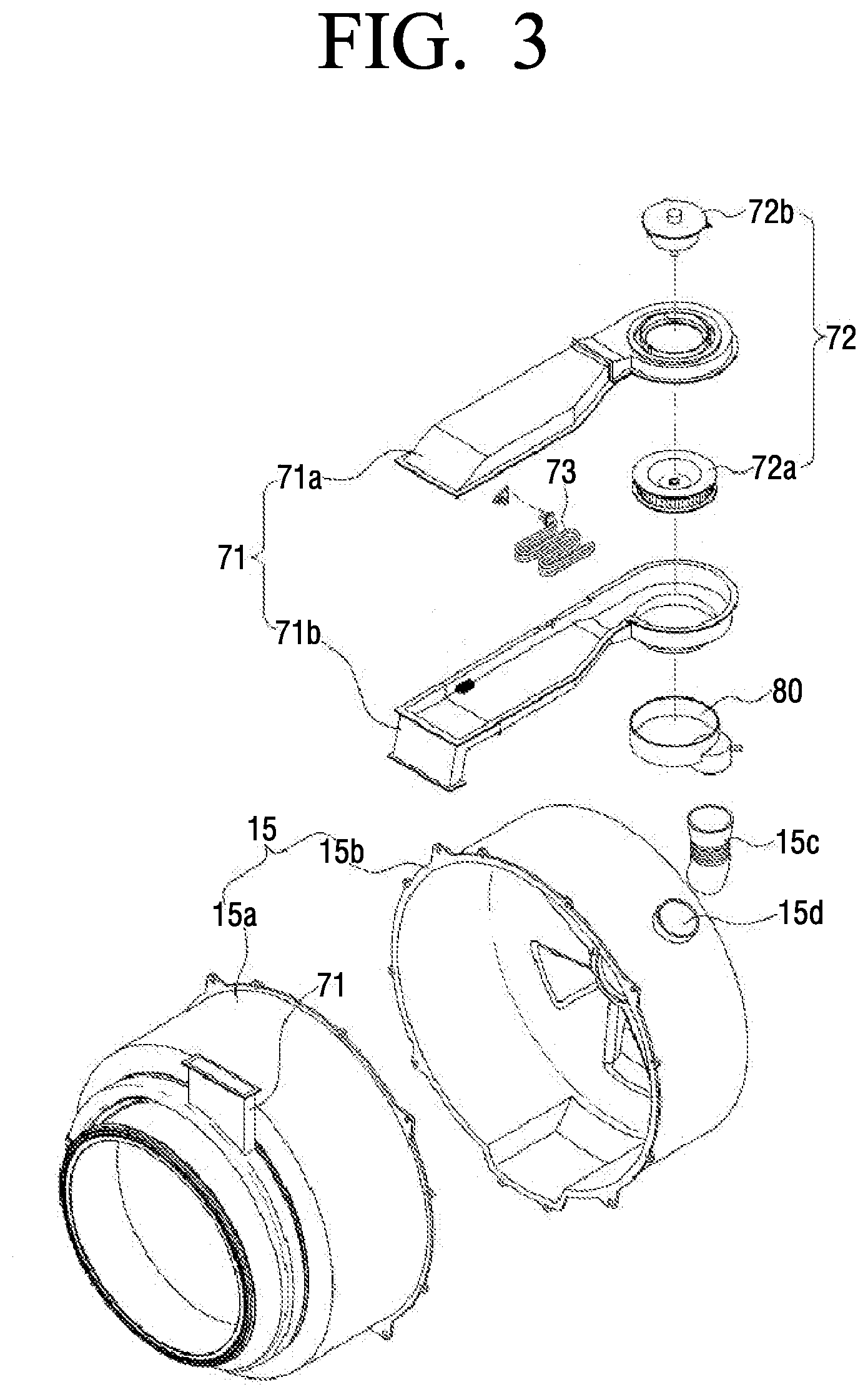

[0065] FIG. 3 is an exploded perspective view of a temperature adjustment unit according to an embodiment of the disclosure.

[0066] As shown in FIG. 3, the temperature adjustment unit 70 may include a drying duct 71, an intake unit 72 and a heater unit 73.

[0067] The drying duct 71 may heat the air introduced from the tub 15 and the drum 20 and deliver the heated air to the tub 15. In detail, the drying duct 71 may include an upper duct plate 71a and a lower duct plate 71b. One end of the drying duct 71 in which the upper duct plate 71a and the lower duct plate 71b are coupled to each other may be connected to the tub front member 15a, and the other end of the drying duct 71 may be connected to the tub rear member 15b. Therefore, the drying duct 71 may deliver the air introduced from the tub rear member 15b to the tub front member 15a through a passage formed by the coupling of the upper duct plate 71a and the lower duct plate 71b.

[0068] The intake unit 72 may draw the air inside the tub 15 and the drum 20 and deliver the drawn air to the drying duct 71. The intake unit 72 may include an intake fan 72a and an intake motor 72b rotating the intake fan 72a. The intake pan 72a may be disposed in a lower plate opening (not shown) formed in the lower duct plate 71b of the drying duct 71, and the intake motor 72b may be disposed in an upper plate opening (not shown) formed in the upper duct plate 71a of the drying duct 71.

[0069] In addition, the heater unit 73 may heat the air drawn from the inside of the tub 15 and the drum 20 through the intake unit 72. The heater unit 73 may be formed in the passage formed by the coupling of the upper duct plate 71a and the lower duct plate 71b. Therefore, the heater unit 73 may heat the air introduced from the inside of the tub 15 and the drum 20 into the drying duct 71 through the intake unit 72, and the drying duct 71 may deliver the air heated through the heater unit 73 to the tub front member 15a.

[0070] In addition, a temperature sensor (not shown) may be provided in the passage formed by the coupling of the upper duct plate 71a and the lower duct plate 71b. In detail, the temperature sensor (not shown) may be disposed in a direction connected to the tub front member 15a. Accordingly, the temperature sensor (not shown) may measure a temperature of the air heated through the heater unit 73.

[0071] As such, in case that the air, which is drawn from the inside of the tub 15 and the drum 20 through the intake unit 72, is introduced into the drying duct 71, the drying duct 71 may heat the air through the heater unit 73 and deliver the heated air into the tub 15 and the drum 20. Therefore, during the drying cycle or the refresh cycle, the air inside the tub 15 and the drum 20 may be maintained at an appropriate temperature.

[0072] As above, the description schematically describes each component of the washing machine 100 according to the disclosure. Hereinafter, the description specifically focuses on each component of the washing machine 100 performing the refresh cycle of the laundry according to the disclosure.

[0073] FIG. 4 is a block diagram showing the washing machine performing a refresh cycle according to an embodiment of the disclosure.

[0074] As described above, the washing machine 100 is a washing device capable of performing the washing cycle, the drying cycle and the refresh cycle, and may be, for example, a drum washing machine. In case of performing the refresh cycle, the washing machine 100 may not only sterilize the laundry accommodated in the drum 20, but also coat the laundry with the fragrant particles by the additive such as the fabric softener.

[0075] To this end, the washing machine 100 may include the drum 20, the drive unit 30, the temperature adjustment unit 70 and the additive input unit 60, as shown in FIG. 4.

[0076] As described above, the drum 20 may accommodate the laundry, and the drive unit 30 may rotate the drum 20 accommodating the laundry. In detail, the drive unit 30 may drive the drive motor to rotate the drum 20 accommodating the laundry. In addition, the drive unit 30 may drive the water supply unit 40 to supply the washing water into the tub 15 or may drive the drainage unit 50 to discharge the washing water contained in the tub 15 to the outside of the washing machine 100.

[0077] The temperature adjustment unit 70 may adjust the temperature inside the drum 20 by generating the hot air and the cold air. Accordingly, the laundry accommodated in the drum 20 may be sterilized by the hot air and the cold air generated by the temperature adjustment unit 70.

[0078] The additive input unit 60 may put the additive into the drum 20 to coat the laundry with the fragrant particles. In detail, in case of receiving a material such as the fabric softener by the user, the additive input unit 60 may dilute the material in the washing water and put the additive obtained by diluting the material in the washing water into the drum 20.

[0079] The control unit 120 may control the overall operation of the each component of the washing machine 100. In particular, in case of receiving an instruction on the refresh cycle from the user, the control unit 120 may perform a first refresh cycle in which the temperature adjustment unit 70 is controlled to set the temperature inside the drum 20 to a first threshold temperature. Here, the control unit 120 may control the temperature adjustment unit 70 to maintain the temperature inside the drum 20 at the first threshold temperature for a first threshold time. Accordingly, the temperature adjustment unit 70 may generate the hot air until the temperature inside the drum 20 is set to the first threshold temperature. In case that the temperature inside the drum 20 is set to the first threshold temperature, the temperature adjustment unit 70 may adjust the temperature inside the drum 20 to be maintained at the first threshold temperature for the first threshold time from a time point at which the temperature inside the drum 20 is set to the first threshold temperature.

[0080] According to an embodiment, the first threshold temperature may be an appropriate temperature advantageous for sterilizing and deodorizing the laundry accommodated in the drum 20 and for coating the laundry with the fragrant particles by the additive put into the drum 20, and may be, for example, 65.degree. C. to 70.degree. C.

[0081] In addition, the first threshold time may be half of a total time to perform the refresh cycle. For example, in case that the total time to perform the refresh cycle is 29 minutes, the first threshold time may be about 14 to 15 minutes.

[0082] As such, in case that the predetermined first threshold time passes after the temperature inside the drum 20 is set to the first threshold temperature, the control unit 120 may control the additive input unit 60 to put the additive into the drum 20. Accordingly, the additive input unit 60 may dilute the material such as the fabric softener contained at the additive input unit 60 in the washing water and put the diluted material into the drum 20.

[0083] Then, after all the additive is put into the drum 20, the control unit 120 may perform a second refresh cycle in which the temperature adjustment unit 70 is controlled to set the temperature inside the drum 20 to a second threshold temperature which is lower than the first threshold temperature. Here, the control unit 120 may control the temperature adjustment unit 70 to maintain the temperature inside the drum 20 at the second threshold temperature for a second threshold time.

[0084] Accordingly, the temperature adjustment unit 70 may generate the hot air to set the temperature inside the drum 20 to the second threshold temperature. In case that the temperature inside the drum 20 is set to the second threshold temperature, the temperature adjustment unit 70 may adjust the temperature inside the drum 20 to be maintained at the second threshold temperature for the second threshold time.

[0085] According to an embodiment, the second threshold temperature may be an appropriate temperature advantageous for preventing the fragrant particles of the additive coated on the laundry from disappearing from the laundry during the sterilization of the laundry put into the drum 20, and may be, for example, 55.degree. C. to 60.degree. C.

[0086] The second threshold time may be less than the first threshold time described above, and may be, for example, about 2 to 3 minutes.

[0087] Meanwhile, the control unit 120 may rotate the drum 20 at a first threshold speed while the temperature inside the drum 20 is set to the first threshold temperature or the second threshold temperature. In detail, the control unit 120 may control the drive unit 30 to rotate the drum 20 at the first threshold speed during a period of the first refresh cycle in which the temperature inside the drum 20 is set and maintained at the first threshold temperature or during a period of the second refresh cycle in which the temperature inside the drum 20 is set and maintained at the second threshold temperature. According to an embodiment, the first threshold speed may be 40 rpm. Accordingly, the drive unit 30 may rotate the drum 20 at the speed of 40 rpm.

[0088] Therefore, the drum 20 accommodating the laundry may be rotated at the speed of 40 rpm by the drive unit 30 during the periods of the first and second refresh cycles.

[0089] According to an additional aspect of the disclosure, the control unit 120 may rotate the drum 20 in predetermined time unit during the period of the second refresh cycle. That is, the control unit 120 may control the drive unit 30 to rotate the drum 20 in time unit during the period of the second refresh cycle. For example, the control unit 120 may control the drive unit 30 to rotate and stop the drum 20 in a unit of 5 seconds during the period of the second refresh cycle. Accordingly, the drive unit 30 may rotate the drum 20 at the speed of 40 rpm at an interval of 5 seconds during the period of the second refresh cycle.

[0090] Meanwhile, the control unit 120 may rotate the drum 20 at a second threshold speed which is faster than the first threshold speed before the additive is put into the drum 20, and control the additive input unit 60 to put the additive into the drum 20 in case that a rotational speed of the drum 20 reaches the second threshold speed.

[0091] That is, as described above, the control unit 120 may control the drive unit 30 to rotate the drum 20 at the second threshold speed after the first refresh cycle is ended. Here, the second threshold speed may be 400 rpm. Accordingly, the drive unit 30 may rotate the drum 20 at the speed of 400 rpm.

[0092] As such, in case that the rotational speed of the drum 20 reaches the second threshold speed by the drive unit 30, the control unit 120 may control the additive input unit 60 to put the additive into the drum 20. Accordingly, the additive input unit 60 may put the additive into the drum 20. Meanwhile, the drive unit 30 may rotate the drum 20 at the second threshold speed while all the additive is put into the drum 20 through the additive input unit 60. As such, as the drum 20 is rotated at the second threshold speed while the additive is put thereinto, the laundry accommodated in the drum 20 may be coated with the fragrant particles by the additive without being wetted by the additive.

[0093] Meanwhile, according to an additional aspect of the disclosure, the control unit 120 may determine whether to put the additive into the drum 20 through the following embodiments.

[0094] According to an embodiment, the control unit 120 may determine whether to put the additive into the drum 20 based on a vibration state of the drum 20 accommodating the laundry.

[0095] In detail, the control unit 120 may periodically obtain vibration intensity of the drum 20 while the drum 20 is rotated based on detection information detected by the detection unit 170 to be described below. Therefore, the control unit 120 may compare predetermined threshold intensity with the vibration intensity obtained based on the detection information detected by the detection unit 170 from a time point at which the drive unit 30 is controlled to rotate the drum 20 at the second threshold speed after the first refresh cycle is ended.

[0096] That is, the control unit 120 may compare the predetermined threshold intensity with the vibration intensity obtained based on the detection information detected by the detection unit 170 until the rotational speed of the drum 20 reaches the second threshold speed. As a result of the comparison, if the vibration intensity is equal to or greater than the predetermined threshold intensity, the control unit 120 may end the rotation of the drum 20 and then rotate the drum 20 again at the second threshold speed. That is, in case that the drum 20 has the vibration intensity equal to or greater than the threshold intensity before the rotational speed of the drum 20 reaches the second threshold speed, the control unit 120 may control the drive unit 30 to end the rotation of the drum 20 and then rotate the drum 20 again at the second threshold speed. Accordingly, the drive unit 30 may stop the rotation of the drum 20 and then rotate the drum 20 again.

[0097] Then, in case that the predetermined threshold intensity is compared with the vibration intensity of the drum 20 rotated again, if the vibration intensity is less than the predetermined threshold intensity until the rotational speed of the drum 20 reaches the second threshold speed, the control unit 120 may control the additive input unit 60 to put the additive into the drum 20. Accordingly, the additive input unit 60 may put the additive into the drum 20 while the drum 20 is rotated at the second threshold speed.

[0098] Meanwhile, in case that the predetermined threshold intensity is compared with the vibration intensity of the drum 20 rotated again, if the vibration intensity is equal to or greater than the predetermined threshold intensity until the rotational speed of the drum 20 reaches the second threshold speed, the control unit 120 may control the drive unit 30 to end the rotation of the drum 20 and then rotate the drum 20 again at the second threshold speed.

[0099] Meanwhile, in case that the vibration intensity detected by the detection unit 170 is equal to or greater than the predetermined threshold intensity after the drum 20 is rotated again for a predetermined threshold number of times, the control unit 120 may control the additive input unit 60 not to put the additive into the drum 20.

[0100] That is, after the drum 20 is rotated again for the predetermined threshold number of times, if the vibration intensity detected by the detection unit 170 is equal to or greater than the predetermined threshold intensity, the control unit 120 may control the temperature adjustment unit 70 to proceed with the second refresh cycle after the first refresh cycle. Accordingly, the laundry accommodated in the drum 20 may only be sterilized and deodorized without being coated with the fragrant particles by the additive.

[0101] According to another embodiment, the control unit 120 may determine whether to put the additive into the drum 20 based on whether the rotational speed of the drum 20 reaches the second threshold speed within a predetermined threshold time after the first refresh cycle is ended.

[0102] In detail, the control unit 120 may determine whether the rotational speed of the drum 20 is the second threshold speed for the predetermined threshold time from the time point at which the drive unit 30 is controlled to rotate the drum 20 at the second threshold speed after the first refresh cycle is ended. As a result of the determination, in case that the rotational speed of the drum 20 reaches the second rotational speed within the second threshold time, the control unit 120 may control the additive input unit 60 to put the additive into the drum 20. Accordingly, the additive input unit 60 may put the additive into the drum 20 while the drum 20 is rotated at the second threshold speed.

[0103] Meanwhile, in case that the rotational speed of the drum 20 does not reach the second threshold speed within the predetermined threshold time, the control unit 120 may control the additive input unit 60 not to put the additive into the drum 20.

[0104] That is, in case that the rotational speed of the drum 20 does not reach the second threshold speed within the predetermined threshold time, the control unit 120 may control the temperature adjustment unit 70 to proceed with the second refresh cycle after the first refresh cycle. Accordingly, the laundry accommodated in the drum 20 may only be sterilized and deodorized without being coated with the fragrant particles by the additive.

[0105] According to an additional aspect of the disclosure, the control unit 120 may perform a third refresh cycle in which the temperature adjustment unit 70 is controlled to set the temperature inside the drum 20 to a third threshold temperature which is lower than the above-described second threshold temperature after the second refresh cycle is ended.

[0106] In detail, the control unit 120 may control the temperature adjustment unit 70 to set the temperature inside the drum 20 to the third threshold temperature which is lower than the second threshold temperature after the second threshold time at which the second refresh cycle is performed. Accordingly, the temperature adjustment unit 70 may generate the hot air until the temperature inside the drum 20 is set to the third threshold temperature.

[0107] Meanwhile, in case that the temperature inside the drum 20 is set to the third threshold temperature by the temperature adjustment unit 70, the control unit 120 may control the temperature adjustment unit 70 to maintain the temperature inside the drum 20 at the third threshold temperature for a predetermined third threshold time. Accordingly, as the temperature inside the drum 20 is set to be maintained at the third threshold temperature, the temperature adjustment unit 70 may adjust the temperature inside the drum 20 to maintain the temperature inside the drum 20 at the third threshold temperature for the predetermined third threshold time.

[0108] According to an embodiment, the predetermined third threshold temperature may be lower than the above-described first and second threshold temperatures, and may be, for example, 55.degree. C., and the predetermined third threshold time may be the same time as the above-described second threshold time.

[0109] Meanwhile, the control unit 120 may control the drive unit 30 to rotate the drum 20 at the first threshold speed while the temperature inside the drum 20 is set and maintained at the third threshold temperature. According to an embodiment, the first threshold speed may be 40 rpm. Accordingly, the drive unit 30 may rotate the drum 20 at the speed of 40 rpm, as described above.

[0110] Meanwhile, according to an additional aspect of the disclosure, the control unit 120 may control the drainage unit 50 to discharge the additive contained in the drum 20 to the outside before the temperature inside the drum 20 is set to the third threshold temperature. That is, the control unit 120 may control the drainage unit 50 to discharge the additive contained in the drum 20 to the outside in case that the second refresh cycle is ended. Based on this control instruction, the drainage unit 50 may discharge the additive contained in the drum 20 to the outside.

[0111] FIG. 5 is a detailed block diagram of the washing machine according to an embodiment of the disclosure.

[0112] As shown in FIG. 5, the washing machine 100 may further include the input unit 110, the display unit 130, a storage unit 140, an audio output unit 150, a communication unit 160 and the detection unit 170 in addition to the above-described components.

[0113] The input unit 110 and the display unit 130 are described in detail above, and detailed descriptions thereof are thus omitted hereinafter.

[0114] The storage unit 140 may store control information and an operation program for executing operations of the washing, drying and refresh cycles of the washing machine 100. Here, as described above, the control information may include driving information for rotating the drum 20 for each cycle, information for setting the temperature inside the drum 20 and the like. In addition, the operation program may be a program which is read from the storage unit 140, compiled and operated to operate each component of the washing machine 100 in case that the washing machine 100 is turned on. The storage unit 140 may be implemented as at least one of: a memory card (e.g. secure digital (SD) card or memory stick) attachable to/detachable from a read-only memory (ROM), a random access memory (RAM) or the washing machine 100; a nonvolatile memory; a volatile memory; a hard disk drive (HDD); or a solid state drive (SSD).

[0115] The audio output unit 150 may output each operation state of the washing, drying and the refresh cycles of the washing machine 100 in a form of an audible sound of a speaker (not shown).

[0116] The communication unit 160 may perform wireless communication with at least one user terminal device (not shown). According to an embodiment, the communication unit 160 may perform data communication with the user terminal device (not shown) through a local area communication module, such as a bluetooth module, a near field communication (NFC) module, a wi-fi module or a zigbee module, to transfer information on the states of the washing cycle, the drying cycle and the refresh cycle to the user terminal device (not shown) or receive an instruction to control each of the cycles from the user terminal device (not shown).

[0117] In addition, the communication unit 160 may be connected to an external network according to a wireless communication protocol such as Institute of electrical and electronics engineers (IEEE) to perform the communication, such as a wireless LAN module.

[0118] The detection unit 170 may detect the operation states of the washing, drying and refresh cycles of the washing machine 100. According to an embodiment, the detection unit 170 may include a sensor detecting the vibration intensity based on the rotation of the drum 20 accommodating the laundry during the refresh cycle. In addition, the detection unit 170 may further include the temperature sensor detecting temperatures of the air inside the tub 15 and the drum 20 or a temperature of the air heated by the drying unit 70, a sensor measuring a weight of the drum 20 accommodating the laundry and the like.

[0119] FIG. 6 is an exemplary view showing processes of the washing machine performing the refresh cycle according to an embodiment of the disclosure.

[0120] As shown in FIG. 6, in case that a refresh cycle instruction is input while the laundry is accommodated in the drum 20, the washing machine 100 may perform a first refresh process (first direction process, 610) generating the hot air to maintain the temperature inside the drum 20 at the first threshold temperature for the first threshold time. Here, the first threshold time may be about half of the total time to perform the refresh cycle, and the first threshold temperature may be 65.degree. C. to 70.degree. C.

[0121] Through the first refresh process 610, the washing machine 100 may sterilize the laundry accommodated in the drum 20 to deodorize a smell permeating the laundry. In addition, through the first refresh process 610, the washing machine 100 may allow the fragrant particles of the additive put into the drum 20 to be diffused in the drum 20 in a process to be described below.

[0122] After the first refresh process 610, the washing machine 100 may perform a water supply process 620 for putting the additive to coat the fragrant particles on the laundry accommodated in the drum 20. That is, in the water supply process 620, the washing machine 100 may put into the drum 20, the additive obtained by diluting the material such as the fabric softener in the washing water.

[0123] After the water supply process 620, the washing machine 100 may perform a second refresh process (second direction process, 630) generating the hot air to maintain the temperature inside the drum 20 at the second threshold temperature for the second threshold time. Here, the second threshold time may be less than the above-described first refresh process time, and the second threshold temperature may be 55.degree. C. to 60.degree. C.

[0124] Through the second refresh process 630, the washing machine 100 may allow the fragrant particles of the additive put into the drum 20 to be attached to the laundry accommodated in the drum 20.

[0125] After the second refresh process 630, the washing machine 100 may perform a drainage process 640 discharging the additive contained in the drum 20 to the outside.

[0126] After the drainage process 640, the washing machine 100 may perform a third refresh process (third direction process, 650) generating the cold air to lower the temperature inside the drum 20 to the third threshold temperature for the third threshold time. Here, the third threshold time may be the same time as the time for which the temperature inside the drum 20 is maintained at the second threshold temperature in the above-described second refresh process 630, and the third threshold temperature may be 55.degree. C.

[0127] Through the third refresh process 650, the washing machine 100 may allow the fragrant particles of the additive attached to the laundry accommodated in the drum 20 to be fixed to the laundry.

[0128] FIG. 7 is an exemplary view showing an operation of each component for each process of the refresh cycle performed in the washing machine according to an embodiment of the disclosure.

[0129] As shown in FIG. 7, the washing machine 100 may circulate the air inside the drum 20 through the temperature adjustment unit 70 to dry the laundry accommodated in the drum 20 during the refresh cycle. That is, the washing machine 100 may dry the laundry accommodated in the drum 20 by circulating the air inside the drum 20 through the intake unit 72 included in the temperature adjustment unit 70 during the refresh cycle.

[0130] Meanwhile, the washing machine 100 may turn on the temperature adjustment unit 70 during the first refresh process 610 of all the processes included in the refresh cycle. Accordingly, as the respective components configuring the temperature adjustment unit 70 are activated, the washing machine 100 may set and maintain the temperature inside the drum 20 at the predetermined first threshold temperature by the hot air generated through the temperature adjustment unit 70. In addition, the washing machine 100 may drive the drive unit 30 to rotate the drum 20 at the speed of 40 rpm during the first refresh process 610.

[0131] During the water supply process 620 after the first refresh process 610, the washing machine 100 may turn off the heater unit 73 of all the components configuring the temperature adjustment unit 70, and drive the drive unit 30 to rotate the drum 20 at the speed of 400 rpm. As such, as the drum 20 is rotated at the speed of 400 rpm, the laundry accommodated in the drum 20 may be prevented from being wet by the additive put into the drum 20. In case that the drum 20 is rotated at the speed of 400 rpm, the washing machine 100 may put the additive into the drum 20 through the additive input unit 60. According to an embodiment, the washing machine 100 may put about 1.5 liters (L) of the additive into the drum 20 through the additive input unit 60.

[0132] During the second refresh process 630 after the water supply process 620, the washing machine 100 may turn on the temperature adjustment unit 70. Accordingly, as the respective components configuring the temperature adjustment unit 70 are activated, the washing machine 100 may set and maintain the temperature inside the drum 20 at the predetermined second threshold temperature by the hot air generated through the temperature adjustment unit 70. In addition, the washing machine 100 may drive the drive unit 30 to rotate the drum 20 at the speed of 40 rpm during the second refresh process 630.

[0133] During the drainage process 640 after the second refresh process 630, the washing machine 100 may turn off the heater unit 73 configuring the temperature adjustment unit 70 and the drive unit 30 rotating the drum 20, and turn on the drainage unit 50 to discharge the additive contained in the drum 20 to the outside. Accordingly, as the drainage unit 50 is opened, the additive contained in the drum 20 may be discharged to the outside.

[0134] During the third refresh process 650 after the drainage process 640, the washing machine 100 may drive the drive unit 30 to rotate the drum 20 at the speed of 40 rpm. Here, the washing machine 100 may turn off the drainage unit 50 as the drainage process 640 is ended and the third refresh process 650 is started. Here, the heater unit 73 configuring the temperature adjustment unit 70 may also be maintained off.

[0135] FIG. 8 is an exemplary view showing that the washing machine provides a user interface (UI) based on occurrence of an event according to an embodiment of the disclosure.

[0136] The washing machine 100 may determine whether to put the additive into the drum 20 through the above-described embodiments.

[0137] As described above, in case that the water supply process 620 is started, the washing machine 100 may compare the predetermined threshold intensity with the detected vibration intensity of the drum 20 until the rotational speed of the drum 20 reaches the second threshold speed. As a result of the comparison, if the vibration intensity is equal to or greater than the predetermined threshold intensity, the washing machine 100 may end the rotation of the drum 20 and then rotate the drum 20 again at the second threshold speed.

[0138] Then, in case that the detected vibration intensity of the drum 20 is equal to or greater than the predetermined threshold intensity after the washing machine 100 rotates the drum 20 again for the predetermined threshold number of times, the washing machine 100 may display a user interface (UI) 810, which is read, "Please put the laundry again" through the display unit 113.

[0139] In addition, in case that the water supply process 620 is started, the washing machine 100 may determine whether the rotational speed of the drum 20 reaches the second threshold speed within the predetermined threshold time. As a result of the determination, if the rotational speed of the drum 20 does not reach the second threshold speed within the predetermined threshold time, the washing machine 100 may display the UI 810, which is read, "Please put the laundry again" through the display unit 113.

[0140] Accordingly, the user may put the laundry again into the drum 20 according to the UI 810 displayed through the display unit 113.

[0141] In case that the water supply process 620 is performed again after the laundry is accommodated in the drum 20 again, the washing machine 100 may determine whether the drum 20 normally reaches the second threshold speed through the above-described embodiment. As a result of the determination, if the drum 20 does not reach the second threshold speed, the washing machine 100 may end the water supply process 620 for putting the additive into the drum 20. In addition, the washing machine 100 may omit the second refresh process 630 and the drainage process 640, and perform the third refresh process 650.

[0142] As above, the description specifically focuses on each component of the washing machine 100 performing the refresh cycle according to the disclosure. Hereinafter, the description specifically focuses on a method of performing the refresh cycle in the washing machine 100 according to an embodiment of the disclosure.

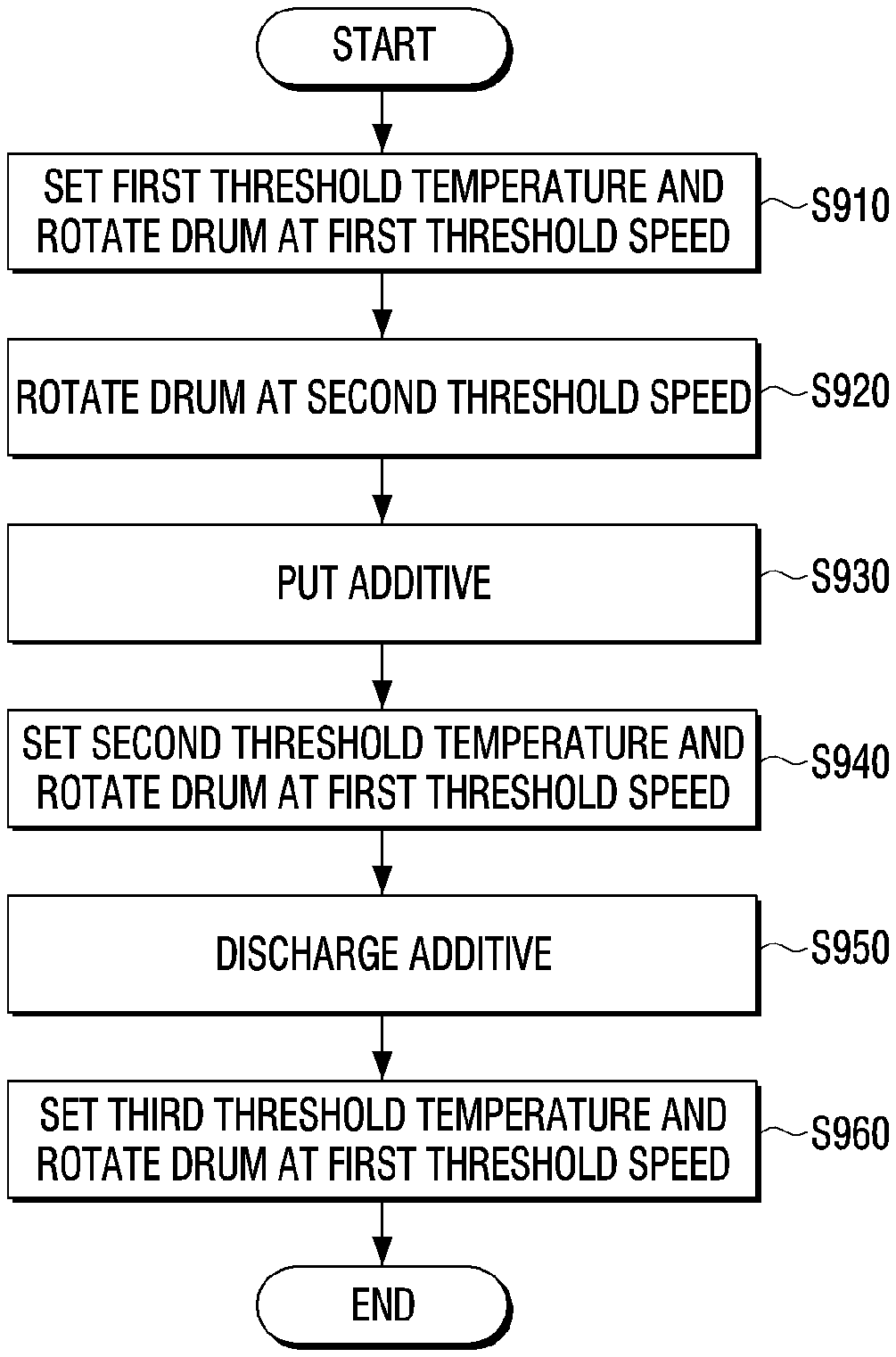

[0143] FIG. 9 is a flowchart showing a method of a washing machine to perform a refresh cycle according to an embodiment of the disclosure.

[0144] As shown in FIG. 9, in case that a user instruction for the refresh cycle is input while laundry is accommodated in a drum, a washing machine 100 may set a temperature inside the drum to a first threshold temperature and rotate the drum at a first threshold speed (S910).

[0145] In detail, the washing machine 100 may set the temperature inside the drum to the first threshold temperature through a temperature adjustment unit adjusting the temperature inside the drum accommodating the laundry by generating hot air and cold air. In addition, in case that the temperature inside the drum is set to the first threshold temperature, the washing machine 100 may maintain the temperature inside the drum at the first threshold temperature for a predetermined first threshold time. In addition, the washing machine 100 may rotate the drum at a first threshold speed while the temperature inside the drum is set and maintained at the first threshold temperature.

[0146] Here, the first threshold temperature may be an appropriate temperature advantageous for sterilizing and deodorizing the laundry accommodated in the drum and for coating the laundry with fragrant particles using an additive put into the drum, and may be, for example, 65.degree. C. to 70.degree. C.

[0147] In addition, the first threshold time may be half of a total time to perform the refresh cycle. For example, in case that the total time to perform the refresh cycle is 29 minutes, the first threshold time may be about 14 to 15 minutes.

[0148] In addition, the first threshold speed may be 40 rpm.

[0149] Then, the washing machine 100 may rotate the drum at a second threshold speed (S920), and put the additive into the drum in case that a rotational speed of the drum reaches the second threshold speed (S930). Here, the second threshold speed may be faster than the first threshold speed. For example, the second threshold speed may be 400 rpm. In addition, the additive may be a material in which a detergent for washing the laundry or a fabric softener for coating the laundry with the fragrant particles is diluted in washing water.

[0150] That is, in case that the drum is rotated at the second threshold speed, the washing machine 100 may put the additive into the drum while the drum is rotated at the second threshold speed. Accordingly, the laundry accommodated in the drum may be coated with the fragrant particles by the additive without being wetted by the additive.

[0151] In case that all the additive is put into the drum, the washing machine 100 may set the temperature inside the drum to a predetermined second threshold temperature, and rotate the drum at the first threshold speed (S940). Here, the washing machine 100 may maintain the temperature inside the drum at the predetermined second threshold temperature for a predetermined second threshold time.

[0152] Here, the second threshold temperature may be an appropriate temperature advantageous for preventing the fragrant particles of the additive coated on the laundry from disappearing from the laundry during the sterilization of the laundry put into the drum, and may be, for example, 55.degree. C. to 60.degree. C. In addition, the second threshold time may be less than the first threshold time described above, and may be, for example, about 2 to 3 minutes. In addition, the first threshold speed may be 40 rpm, as described above.

[0153] Then, the washing machine 100 may discharge the additive contained in the drum to the outside through the drainage unit (S950).

[0154] Then, the washing machine 100 may set the temperature inside the drum to a predetermined third threshold temperature, and rotate the drum at the first threshold speed (S960). Here, in case that the temperature inside the drum reaches the predetermined third threshold temperature, the washing machine 100 may maintain the temperature inside the drum at the third threshold temperature for a predetermined third threshold time.

[0155] Here, the predetermined third threshold temperature may be lower than the above-described first and second threshold temperatures, and may be, for example, 55.degree. C., and the predetermined third threshold time may be the same time as the above-described second threshold time. In addition, the first threshold speed may be 40 rpm, as described above.

[0156] Meanwhile, the washing machine 100 may determine whether to put the additive into the drum through the following embodiments.

[0157] FIG. 10 is a first flowchart showing a method of the washing machine to determine whether to put an additive into a drum according to an embodiment of the disclosure.

[0158] As shown in FIG. 10, in case that a water supply cycle process is started to put the additive into the drum, the washing machine 100 may rotate the drum at the second threshold speed.

[0159] Therefore, the washing machine 100 may periodically detect vibration intensity of the drum until the rotational speed of the drum reaches the second threshold speed, and compare the detected vibration intensity with predetermined threshold intensity (S1010).

[0160] As a result of the comparison, if the detected vibration intensity is less than the predetermined threshold intensity while the rotational speed of the drum reaches the second threshold speed, the washing machine 100 may put the additive into the drum through the above-described process S930 after the rotational speed of the drum reaches the second threshold speed.

[0161] Meanwhile, in case that the detected vibration intensity is equal to or greater than the predetermined threshold intensity until the rotational speed of the drum reaches the second threshold speed, the washing machine 100 may end the rotation of the drum and then rotate the drum again at the second threshold speed (S1020).

[0162] Then, the washing machine 100 may determine whether a number of times in which the drum is rotated again at the second threshold speed is greater than a predetermined threshold number of times (S1030); and in case of determining that the drum has the number of times of the rotation greater than the predetermined threshold number of times, the washing machine 100 may not put the additive into the drum (S1040). That is, in case of determining that the number of times in which the drum is rotated again at the second threshold speed is greater than the predetermined threshold number of times, the washing machine 100 may perform none of the above-described processes S930 and S950, and perform the above-described process S960.

[0163] FIG. 11 is a second flowchart showing a method of the washing machine to determine whether to put an additive into a drum according to according to another embodiment of the disclosure.

[0164] As shown in FIG. 11, in case that the water supply cycle process is started to put the additive into the drum, the washing machine 100 may rotate the drum at the second threshold speed.

[0165] Therefore, the washing machine 100 may determine whether the rotational speed of the drum reaches the second threshold speed within a predetermined threshold time (S1110). As a result of the determination, if the drum is rotated at the second threshold speed within the predetermined threshold time, the washing machine 100 may perform the process S930 described above to put the additive into the drum.

[0166] Meanwhile, as a result of the determination, if the drum is not rotated at the second threshold speed within the predetermined threshold time, the washing machine 100 may not put the additive into the drum (S1120). That is, in case of determining that the number of times in which the drum is rotated again is greater than the predetermined threshold number of times, the washing machine 100 may perform none of the above-described processes S930 and S950, and perform the above-described process S960.

[0167] Hereinabove, the disclosure is described with reference to embodiments.

[0168] Although the embodiments of the disclosure are illustrated and described hereinabove, the disclosure is not limited to the above-mentioned specific embodiments, and may be variously modified by those skilled in the art to which the disclosure pertains without departing from the scope and spirit of the disclosure as disclosed in the accompanying claims. These modifications also need to be understood to fall within the scope of the disclosure.

* * * * *

D00000

D00001

D00002

D00003

D00004

D00005

D00006

D00007

D00008

D00009

D00010

D00011

XML

uspto.report is an independent third-party trademark research tool that is not affiliated, endorsed, or sponsored by the United States Patent and Trademark Office (USPTO) or any other governmental organization. The information provided by uspto.report is based on publicly available data at the time of writing and is intended for informational purposes only.

While we strive to provide accurate and up-to-date information, we do not guarantee the accuracy, completeness, reliability, or suitability of the information displayed on this site. The use of this site is at your own risk. Any reliance you place on such information is therefore strictly at your own risk.

All official trademark data, including owner information, should be verified by visiting the official USPTO website at www.uspto.gov. This site is not intended to replace professional legal advice and should not be used as a substitute for consulting with a legal professional who is knowledgeable about trademark law.