Novel Metalloproteases

BABE; LILIA M. ; et al.

U.S. patent application number 16/881226 was filed with the patent office on 2020-09-17 for novel metalloproteases. The applicant listed for this patent is DANISCO US INC.. Invention is credited to LILIA M. BABE, ROOPA GHIRNIKAR, FRITS GOEDEGEBUUR, XIAOGANG GU, MARC KOLKMAN, JIAN YAO.

| Application Number | 20200291374 16/881226 |

| Document ID | / |

| Family ID | 1000004860225 |

| Filed Date | 2020-09-17 |

View All Diagrams

| United States Patent Application | 20200291374 |

| Kind Code | A1 |

| BABE; LILIA M. ; et al. | September 17, 2020 |

NOVEL METALLOPROTEASES

Abstract

Aspects of the present compositions and methods relate to novel metalloproteases, polynucleotides encoding the novel metalloproteases, and compositions and methods for use thereof.

| Inventors: | BABE; LILIA M.; (Emerald Hills, CA) ; GOEDEGEBUUR; FRITS; (VLAARDINGEN, NL) ; GHIRNIKAR; ROOPA; (SUNNYVALE, CA) ; GU; XIAOGANG; (SHANGHAI, CN) ; KOLKMAN; MARC; (OEGSTGEEST, NL) ; YAO; JIAN; (SUNNYVALE, CA) | ||||||||||

| Applicant: |

|

||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Family ID: | 1000004860225 | ||||||||||

| Appl. No.: | 16/881226 | ||||||||||

| Filed: | May 22, 2020 |

Related U.S. Patent Documents

| Application Number | Filing Date | Patent Number | ||

|---|---|---|---|---|

| 15835551 | Dec 8, 2017 | 10696958 | ||

| 16881226 | ||||

| 14893473 | Nov 23, 2015 | |||

| PCT/US2014/039928 | May 29, 2014 | |||

| 15835551 | ||||

| Current U.S. Class: | 1/1 |

| Current CPC Class: | C12Y 304/24 20130101; C11D 3/38681 20130101; C12N 9/52 20130101; C11D 3/386 20130101; C12N 9/54 20130101; C12N 9/485 20130101 |

| International Class: | C12N 9/52 20060101 C12N009/52; C12N 9/48 20060101 C12N009/48; C12N 9/54 20060101 C12N009/54; C11D 3/386 20060101 C11D003/386 |

Foreign Application Data

| Date | Code | Application Number |

|---|---|---|

| May 29, 2013 | CN | 13/076384 |

| May 29, 2013 | CN | 13/076387 |

| May 29, 2013 | CN | 13/076398 |

| May 29, 2013 | CN | 13/076401 |

| May 29, 2013 | CN | 13/076406 |

| May 29, 2013 | CN | 13/076414 |

| May 29, 2013 | CN | 13/076415 |

| May 29, 2013 | CN | 13/076419 |

Claims

1. A polypeptide comprising an amino acid sequence having at least 60% sequence identity to the amino acid sequence selected from the group consisting of SEQ ID NOs: 3, 8, 13, 18, 23, 28, 33 and 38.

2. The polypeptide of claim 1, wherein said polypeptide has at least 80% sequence identity to the amino acid sequence selected from the group consisting of SEQ ID NOs: 3, 8, 13, 18, 23, 28, 33 and 38.

3. The polypeptide of any of claim 1 or 2, wherein said polypeptide has at least 95% sequence identity to the amino acid sequence selected from the group consisting of SEQ ID NOs: 3, 8, 13, 18, 23, 28, 33 and 38.

4. The polypeptide of any of the above claims, wherein said amino acid sequence is the amino acid sequence selected from the group consisting of SEQ ID NOs: 3, 8, 13, 18, 23, 28, 33 and 38.

5. The polypeptide of any of the above claims, wherein said polypeptide is derived from a member of the order Bacillales.

6. The polypeptide of any of the above claims, wherein said Bacillales member is a Paenibacillaceae family member.

7. The polypeptide of claim 6, wherein said Bacillales member is a Paenibacillus spp.

8. The polypeptide of any of claims 1-4, wherein said polypeptide is derived from a Planococcus species.

9. The polypeptide of any of the above claims, wherein said polypeptide has protease activity.

10. The polypeptide of claim 9, wherein said protease activity comprises casein hydrolysis, collagen hydrolysis, elastin hydrolysis, keratin hydrolysis, soy protein hydrolysis or corn meal protein hydrolysis.

11. The polypeptide of any of the above claims, wherein said polypeptide retains at least 50% of its maximal activity between pH 4.5 and 10.

12. The polypeptide of any of the above claims, wherein said polypeptide retains at least 50% of its maximal activity between 30.degree. C. and 70.degree. C.

13. The polypeptide of any of the above claims, wherein said polypeptide has cleaning activity in a detergent composition.

14. The polypeptide of claim 13, wherein said detergent composition is an ADW detergent composition.

15. The polypeptide of claim 13, wherein said detergent composition is a laundry detergent composition.

16. The polypeptide of claim 15, wherein said detergent composition is a liquid laundry detergent composition.

17. The polypeptide of claim 15, wherein said detergent composition is a powder laundry detergent composition.

18. The polypeptide of claim 13, wherein said detergent composition comprises a bleach component.

19. The polypeptide of any of the above claims, wherein said polypeptide is a recombinant polypeptide.

20. A composition comprising the polypeptide of any of the above claims.

21. The composition of claim 20, wherein said composition is a cleaning composition.

22. The composition of claim 21, wherein said composition is a detergent composition.

23. The composition of claim 22, wherein said detergent composition is selected from the group consisting of a laundry detergent, a fabric softening detergent, a dishwashing detergent, and a hard-surface cleaning detergent.

24. The composition of any of claims 20 to 22, wherein said composition further comprising a surfactant.

25. The composition of claim 24, wherein said surfactant is selected from the group consisting of an anionic surfactant, a cationic surfactant, a zwitterionic surfactant, a ampholytic surfactant, a semi-polar non-ionic surfactant, and a combination thereof.

26. The composition of claim 24, wherein said surfactant is an ionic surfactant.

27. The composition of claim 24, wherein said surfactant is a non-ionic surfactant.

28. The composition of any of claims 20-27, wherein said composition further comprises at least one calcium ion and/or zinc ion.

29. The composition of any of claims 20-28, wherein said composition further comprises at least one stabilizer.

30. The composition of any of claims 20-29, wherein said composition comprises from about 0.001 to about 0.1 weight % of said polypeptide.

31. The composition of any of claims 20-30, further comprising at least one bleaching agent.

32. The composition of any of claims 20-31, wherein said cleaning composition is phosphate-free.

33. The composition of any of claims 20-31, wherein said cleaning composition contains phosphate.

34. The composition of any of claims 20-33, further comprising at least one adjunct ingredient.

35. The composition of any of claims 20-34, wherein said composition is a granular, powder, solid, bar, liquid, tablet, gel, or paste composition.

36. The composition of any of claims 20-35, further comprising one or more additional enzymes or enzyme derivatives selected from the group consisting of acyl transferases, alpha-amylases, beta-amylases, alpha-galactosidases, arabinosidases, aryl esterases, beta-galactosidases, carrageenases, catalases, cellobiohydrolases, cellulases, chondroitinases, cutinases, endo-beta-1, 4-glucanases, endo-beta-mannanases, esterases, exo-mannanases, galactanases, glucoamylases, hemicellulases, hyaluronidases, keratinases, laccases, lactases, ligninases, lipases, lipoxygenases, mannanases, oxidases, pectate lyases, pectin acetyl esterases, pectinases, pentosanases, peroxidases, phenoloxidases, phosphatases, phospholipases, phytases, polygalacturonases, proteases, pullulanases, reductases, rhamnogalacturonases, beta-glucanases, tannases, transglutaminases, xylan acetyl-esterases, xylanases, xyloglucanases, and xylosidases, additional metallopotease enzymes and combinations thereof.

37. The composition of any of claims 20-36, wherein said composition is formulated at a pH of from about 5.5 to about 8.5.

38. A method for the pretreatment of animal feed comprising treating an animal feed pre-product with the polypeptide of any one of claims 1-19.

39. A method of cleaning, comprising contacting a surface or an item with a cleaning composition comprising the polypeptide of any one of claims 1-19.

40. A method of cleaning comprising contacting a surface or an item with the composition of any one of claims 20-37.

41. The method of claim 39 or 40, further comprising rinsing said surface or item after contacting said surface or item, respectively, with said composition.

42. The method of claims 39-41, wherein said item is dishware.

43. The method of any one of claims 39-41, wherein said item is fabric.

44. The method of any one of claims 39-43, further comprising the step of rinsing said surface or item after contacting said surface or item with said composition.

45. The method of claim 44, further comprising the step of drying said surface or item after said rinsing of said surface or item.

46. A method of cleaning a surface or item, comprising: providing the composition of any of claims 20-37 and a surface or item in need of cleaning; and contacting said composition with said surface or item in need of cleaning under conditions suitable for the cleansing of said surface of said surface or item, to produce a cleansed surface or item.

47. The method of claim 46, further comprising the step of rinsing said cleansed surface or item to produce a rinsed surface or item.

48. The method of any of claim 46 or 47, further comprising the step of drying said rinsed surface or item.

49. A method for producing the polypeptide of any of claims 1-19 comprising: a. stably transforming a host cell with an expression vector comprising a polynucleotide encoding the polypeptide of any of claims 1-19; b. cultivating said transformed host cell under conditions suitable for said host cell to produce said protease; and c. recovering said protease.

50. The method of claim 49, wherein said host cell is a filamentous fungus or bacterial cell.

51. The method of claim 49 or 50, wherein said host cell is selected from Bacillus spp., Streptomyces spp., Escherichia spp., Aspergillus spp., Trichoderma spp., Pseudomonas spp., Corynebacterium spp., Saccharomyces spp., or Pichia spp.

52. The method of any one of claims 49-51, wherein said expression vector comprises a polynucleotide sequence comprising: a. at least 70% sequence identity to the polynucleotide sequence selected from the group consisting of SEQ ID NOs: 4, 9, 14, 19, 24, 29, 34 and 39; or b. being capable of hybridizing to a probe derived from the polynucleotide sequence selected from the group consisting of SEQ ID NOs: 4, 9, 14, 19, 24, 29, 34 and 39 under conditions of intermediate to high stringency, or c. a polynucleotide sequence complementary to a polynucleotide sequence having at least 70% sequence identity to the polynucleotide sequence selected from the group consisting of SEQ ID NOs: 4, 9, 14, 19, 24, 29, 34 and 39.

53. The method of any one of claims 49-52, wherein said vector comprises a DNA sequence coding for a native or non-naturally occurring signal peptide.

54. The method of any one of claims 49-53, wherein said vector comprises a heterologous promoter and/or DNA sequence coding for a signal peptide.

55. The method of any one of claims 49-53, wherein said vector comprises a homologous promoter and/or DNA sequence coding for a signal peptide.

56. The method of any one of claims 49-65, wherein said host cell is cultivated in a culture media or a fermentation broth.

57. A nucleic acid sequence comprising a nucleic acid sequence: (i) having at least 70% identity to a sequence selected from the group consisting of SEQ ID NOs: 4, 9, 14, 19, 24, 29, 34 and 39, or (ii) being capable of hybridizing to a probe derived from the polynucleotide sequence selected from the group consisting of SEQ ID NOs: 4, 9, 14, 19, 24, 29, 34 and 39, under conditions of intermediate to high stringency, or (iii) being complementary to the polynucleotide sequence selected from the group consisting of SEQ ID NOs: 4, 9, 14, 19, 24, 29, 34 and 39.

58. A vector comprising the nucleic acid sequence of claim 57.

59. A host cell transformed with the vector of claim 58.

60. The host cell of claim 59 selected from Bacillus spp., Streptomyces spp., Escherichia spp., Aspergillus spp., Trichoderma spp., Pseudomonas spp., Corynebacterium spp., Saccharomyces spp., or Pichia spp.

61. The host cell of claim 59 or 60, wherein said Bacillus spp. is Bacillus subtilis.

62. A textile processing composition comprising the polypeptide of any one of claims 1-19.

63. An animal feed composition comprising the polypeptide of any one of claims 1-19.

64. A leather processing composition comprising the polypeptide of any one of claims 1-19.

65. A feather processing composition comprising the polypeptide or recombinant polypeptide of any one of claims 1-19.

66. A feather processing composition comprising the polypeptide or recombinant polypeptide of any one of claims 1-19.

67. A corn soy protein processing composition comprising the polypeptide or recombinant polypeptide of any one of claims 1-19.

Description

CROSS REFERENCE TO RELATED APPLICATIONS

[0001] This application is a Divisional of U.S. Ser. No. 15/835,551 filed Dec. 8, 2017, which is Continuation of U.S. Ser. No. 14/893,473, filed Nov. 23, 2015, which is a 371 of International Patent Application No. PCT/US2014/039928, filed May 29, 2014, which claims benefit of priority from International patent applications Serial No. PCT/CN2013/076419; Serial No. PCT/CN2013/076387; Serial No. PCT/CN2013/076401; Serial No. PCT/CN2013/076406; Serial No. PCT/CN2013/076414; Serial No. PCT/CN2013/076384; Serial No. PCT/CN2013/076398; and Serial No. PCT/CN2013/076415; all filed on 29 May 2013, the contents of which are incorporated herein by reference in their entirety.

SEQUENCE LISTING

[0002] The sequence listing submitted via EFS, in compliance with 37 C.F.R. .sctn. 1.52(e), is incorporated herein by reference. The sequence listing text file submitted via EFS contains the file "20200522_NB40167USPCD2_SeqLst" created on May 22, 2020, which is 207 kilo bytes in size.

FIELD OF THE INVENTION

[0003] The present disclosure relates to proteases and variants thereof. Compositions containing the proteases are suitable for use in cleaning, food and feed as well as in a variety of other industrial applications.

BACKGROUND

[0004] Metalloproteases (MPs) are among the hydrolases that mediate nucleophilic attack on peptide bonds using a water molecule coordinated in the active site. In their case, a divalent ion, such as zinc, activates the water molecule. This metal ion is held in place by amino acid ligands, usually 3 in number. The clan MA consists of zinc-dependent MPs in which two of the zinc ligands are the histidines in the motif: HisGluXXHis (SEQ ID NO: 41). This Glu is the catalytic residue. These are two domain proteases with the active site between the domains. In subclan MA(E), also known as Glu-zincins, the 3.sup.rd ligand is a Glu located C-terminal to the HDXXH (SEQ ID NO: 42) motif. Members of the families: M1, 3, 4, 13, 27 and 34 are all secreted proteases, almost exclusively from bacteria (Rawlings and Salvessen (2013) Handbook of Proteolytic Enzymes, Elsevier Press). They are generally active at elevated temperatures and this stability is attributed to calcium binding. Thermolysin-like proteases are found in the M4 family as defined by MEROPS (Rawlings et al., (2012) Nucleic Acids Res 40:D343-D350). Although proteases have long been known in the art of industrial enzymes, there remains a need for novel proteases that are suitable for particular conditions and uses.

SUMMARY

[0005] The present disclosure provides novel metalloprotease enzymes, nucleic acids encoding the same, and compositions and methods related to the production and use thereof.

[0006] In some embodiments, the invention is a polypeptide comprising an amino acid sequence having at least 60%, at least 80%, or at least 95% sequence identity to the amino acid sequence of SEQ ID NO: 3. In some embodiments, the invention is any of the above, wherein said polypeptide is derived from a member of the order Bacillales; family Bacillaceae, Paenibacillaceae, Alicyclobacillaceae, Lactobacillaceae, or a Bacillus, Alicyclobacillus, Geobacillus, Exiguobacterium, Lactobacillus, or Paenibacillus spp., such as Paenibacillus polymyxa. In some embodiments, the invention is any of the above, wherein said polypeptide is derived from a member of the Pseudococcidae, or a Planococcus spp., such as Planococcus donghaensis. In various embodiments of the invention, any of the above polypeptides has protease activity, such as azo-casein hydrolysis. In various embodiments of the invention, any of the above polypeptides retains at least 50% of its maximal activity between pH 5 and 9.5. In various embodiments of the invention, any of the above polypeptides retains at least 50% of its maximal activity between 30.degree. C. and 70.degree. C. In various embodiments of the invention, any of the above polypeptides has cleaning activity in a detergent composition, such as an ADW, laundry, liquid laundry, or powder laundry detergent composition.

[0007] In some embodiments, the invention is a polypeptide comprising an amino acid sequence having at least 60%, at least 80%, or at least 95% sequence identity to the amino acid sequence of SEQ ID NO: 8. In some embodiments, the invention is any of the above, wherein said polypeptide is derived from a member of the order Bacillales; family Bacillaceae, Paenibacillaceae, or Brevibacillaceae, or a Bacillus, Brevibacillus, or Paenibacillus spp., such as Paenibacillus sp. In some embodiments, the invention is any of the above, wherein said polypeptide is derived from Brevibacillus sp. In various embodiments of the invention, any of the above polypeptides has protease activity, such as azo-casein hydrolysis. In various embodiments of the invention, any of the above polypeptides retains at least 50% of its maximal activity between pH 5 and 10. In various embodiments of the invention, any of the above polypeptides retains at least 50% of its maximal activity between 35.degree. C. and 70.degree. C. In various embodiments of the invention, any of the above polypeptides has cleaning activity in a detergent composition, such as an ADW, laundry, liquid laundry, or powder laundry detergent composition.

[0008] In some embodiments, the invention is a polypeptide comprising an amino acid sequence having at least 60%, at least 80%, or at least 95% sequence identity to the amino acid sequence of SEQ ID NO: 13. In some embodiments, the invention is any of the above, wherein said polypeptide is derived from a member of the order Bacillales; family Bacillaceae, Paenibacillaceae, or Brevibacillaceae, or a Bacillus, Geobacillus, Brevibacillus, or Paenibacillus spp., such as Paenibacillus humicus. In some embodiments, the invention is any of the above, wherein said polypeptide is derived from Bacillus polymyxa. In various embodiments of the invention, any of the above polypeptides has protease activity, such as azo-casein hydrolysis. In various embodiments of the invention, any of the above polypeptides retains at least 50% of its maximal activity between pH 5 and 9.5. In various embodiments of the invention, any of the above polypeptides retains at least 50% of its maximal activity between 35.degree. C. and 70.degree. C. In various embodiments of the invention, any of the above polypeptides has cleaning activity in a detergent composition, such as an ADW, laundry, liquid laundry, or powder laundry detergent composition.

[0009] In some embodiments, the invention is a polypeptide comprising an amino acid sequence having at least 60%, at least 80%, or at least 95% sequence identity to the amino acid sequence of SEQ ID NO: 18. In some embodiments, the invention is any of the above, wherein said polypeptide is derived from a member of the order Bacillales; family Bacillaceae, Paenibacillaceae, or Brevibacillaceae, or a Bacillus, Geobacillus, Brevibacillus, or Paenibacillus spp., such as Paenibacillus ehimensis. In some embodiments, the invention is any of the above, wherein said polypeptide is derived from Brevibacillus sp. In various embodiments of the invention, any of the above polypeptides has protease activity, such as azo-casein hydrolysis. In various embodiments of the invention, any of the above polypeptides retains at least 50% of its maximal activity between pH 5 and 10.5. In various embodiments of the invention, any of the above polypeptides retains at least 50% of its maximal activity between 45.degree. C. and 75.degree. C. In various embodiments of the invention, any of the above polypeptides has cleaning activity in a detergent composition, such as an ADW, laundry, liquid laundry, or powder laundry detergent composition.

[0010] In some embodiments, the invention is a polypeptide comprising an amino acid sequence having at least 60%, at least 80%, or at least 95% sequence identity to the amino acid sequence of SEQ ID NO: 23. In some embodiments, the invention is any of the above, wherein said polypeptide is derived from a member of the order Bacillales; family Bacillaceae, Paenibacillaceae, Alicyclobacillaceae, Lactobacillaceae, or a Bacillus, Geobacillus, Alicyclobacillus, Brevibacillus, Paenibacillus, or Lactobacillus spp., such as Paenibacillus barcinonensis. In some embodiments, the invention is any of the above, wherein said polypeptide is derived from a member of the family Pseudococcidae, or a Planococcus spp., such as Planococcus donghaensis. In various embodiments of the invention, any of the above polypeptides has protease activity, such as azo-casein hydrolysis. In various embodiments of the invention, any of the above polypeptides retains at least 50% of its maximal activity between pH 5 and 10. In various embodiments of the invention, any of the above polypeptides retains at least 50% of its maximal activity between 35.degree. C. and 65.degree. C. In various embodiments of the invention, any of the above polypeptides has cleaning activity in a detergent composition, such as an ADW, laundry, liquid laundry, or powder laundry detergent composition.

[0011] In some embodiments, the invention is a polypeptide comprising an amino acid sequence having at least 60%, at least 80%, or at least 95% sequence identity to the amino acid sequence of SEQ ID NO: 28. In some embodiments, the invention is any of the above, wherein said polypeptide is derived from a member of the order Bacillales; family Bacillaceae, Paenibacillaceae, or a Bacillus, Brevibacillus, Paenibacillus, or Lactobacillus spp., such as Paenibacillus polymyxa. In some embodiments, the invention is any of the above, wherein said polypeptide is derived from a member of the family Pseudococcidae, or a Planococcus spp., such as Planococcus donghaensis. In various embodiments of the invention, any of the above polypeptides has protease activity, such as azo-casein hydrolysis. In various embodiments of the invention, any of the above polypeptides retains at least 50% of its maximal activity between pH 5 and 9.5. In various embodiments of the invention, any of the above polypeptides retains at least 50% of its maximal activity between 30.degree. C. and 65.degree. C. In various embodiments of the invention, any of the above polypeptides has cleaning activity in a detergent composition, such as an ADW, laundry, liquid laundry, or powder laundry detergent composition.

[0012] In some embodiments, the invention is a polypeptide comprising an amino acid sequence having at least 60%, at least 80%, or at least 95% sequence identity to the amino acid sequence of SEQ ID NO: 33. In some embodiments, the invention is any of the above, wherein said polypeptide is derived from a member of the order Bacillales; family Bacillaceae, Paenibacillaceae, or a Bacillus, Geobacillus, Brevibacillus, or Paenibacillus spp., such as Paenibacillus hunanensis. In some embodiments, the invention is any of the above, wherein said polypeptide is derived from Bacillus polymyxa. In various embodiments of the invention, any of the above polypeptides has protease activity, such as azo-casein hydrolysis. In various embodiments of the invention, any of the above polypeptides retains at least 50% of its maximal activity between pH 4.5 and 9.0. In various embodiments of the invention, any of the above polypeptides retains at least 50% of its maximal activity between 35.degree. C. and 70.degree. C. In various embodiments of the invention, any of the above polypeptides has cleaning activity in a detergent composition, such as an ADW, laundry, liquid laundry, or powder laundry detergent composition.

[0013] In some embodiments, the invention is a polypeptide comprising an amino acid sequence having at least 60%, at least 80%, or at least 95% sequence identity to the amino acid sequence of SEQ ID NO: 38. In some embodiments, the invention is any of the above, wherein said polypeptide is derived from a member of the order Bacillales; family Bacillaceae, Paenibacillaceae, Lactobacillaceae, or a Bacillus, Brevibacillus, Lactobacillus, Paenibacillus, or Geobacillus spp., such as Paenibacillus amylolyticus. In various embodiments of the invention, any of the above polypeptides has protease activity, such as azo-casein hydrolysis. In various embodiments of the invention, any of the above polypeptides retains at least 50% of its maximal activity between pH 5.5 and 10. In various embodiments of the invention, any of the above polypeptides retains at least 50% of its maximal activity between 35.degree. C. and 65.degree. C. In various embodiments of the invention, any of the above polypeptides has cleaning activity in a detergent composition, such as an ADW, laundry, liquid laundry, or powder laundry detergent composition.

[0014] In some embodiments, the invention is a composition comprising any of the above, such as a cleaning or detergent composition. In some embodiments, the composition further comprises a surfactant, at least one calcium ion and/or zinc ion, at least one stabilizer, at least one bleaching agent, and can contain phosphate, or be phosphate-free. In some embodiments, the composition further comprises one or more additional enzymes or enzyme derivatives selected from the group consisting of acyl transferases, alpha-amylases, beta-amylases, alpha-galactosidases, arabinosidases, aryl esterases, beta-galactosidases, carrageenases, catalases, cellobiohydrolases, cellulases, chondroitinases, cutinases, endo-beta-1, 4-glucanases, endo-beta-mannanases, esterases, exo-mannanases, galactanases, glucoamylases, hemicellulases, hyaluronidases, keratinases, laccases, lactases, ligninases, lipases, lipoxygenases, mannanases, oxidases, pectate lyases, pectin acetyl esterases, pectinases, pentosanases, peroxidases, phenoloxidases, phosphatases, phospholipases, phytases, polygalacturonases, proteases, pullulanases, reductases, rhamnogalacturonases, beta-glucanases, tannases, transglutaminases, xylan acetyl-esterases, xylanases, xyloglucanases, and xylosidases, and combinations thereof. In some embodiments, the composition is formulated at a pH of from about 5.5 to about 8.5. In some embodiments, the invention is a method of cleaning using any of the above polypeptides or compositions. In some embodiments, the invention is a textile processing composition, animal feed composition, leather processing composition, or feather processing composition.

BRIEF DESCRIPTION OF THE DRAWINGS

[0015] FIG. 1.1 provides a plasmid map of pGX085 (aprE-PspPro3), described in Example 1.2.

[0016] FIG. 1.2 provides a dose response curve of PspPro3 in the azo-casein assay.

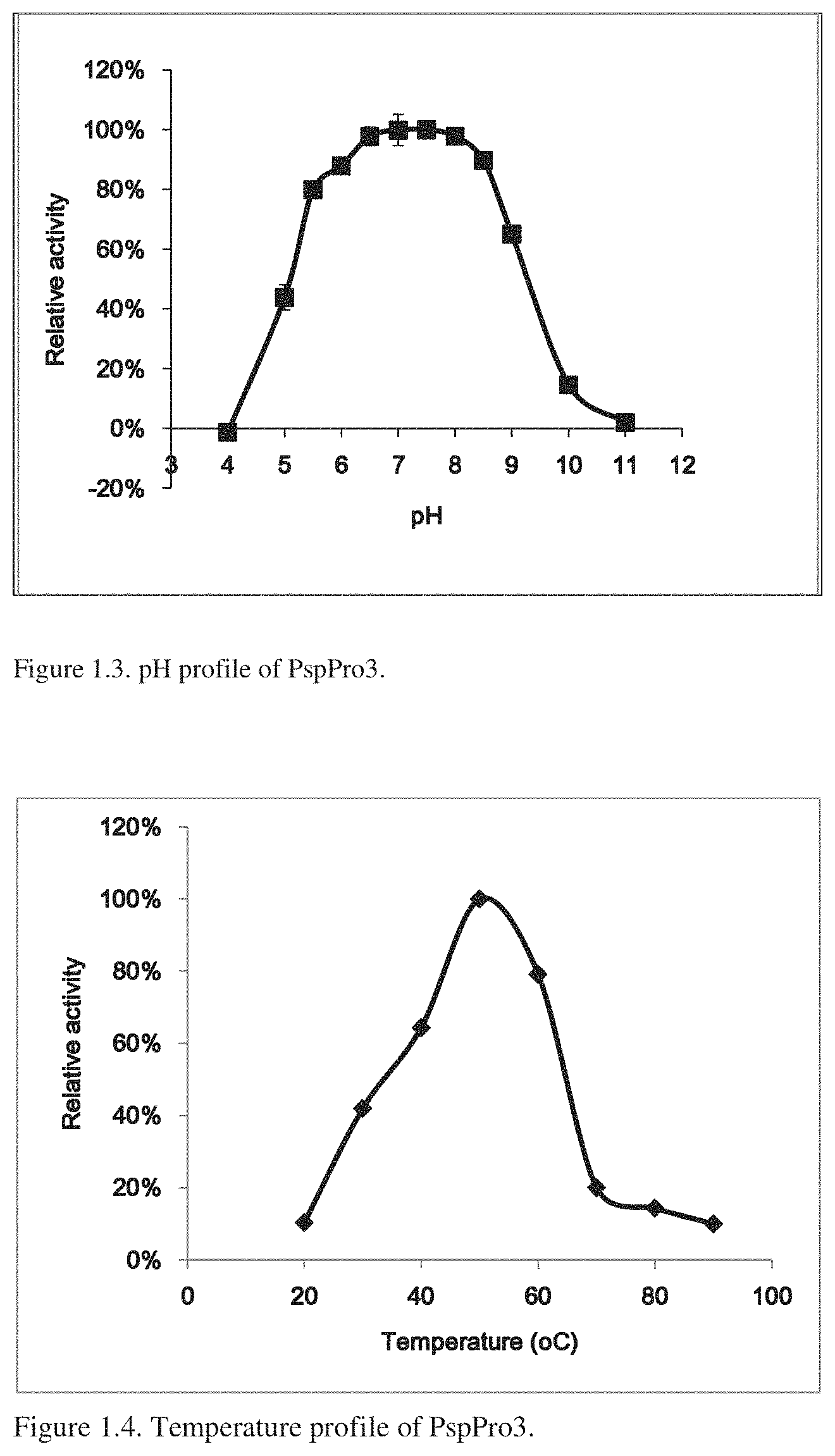

[0017] FIG. 1.3 provides the pH profile of PspPro3.

[0018] FIG. 1.4 provides the temperature profile of PspPro3.

[0019] FIG. 1.5A shows dose response for cleaning of PA-S-38 microswatches by PspPro3 protein in ADW detergent at pH 6 and 8.

[0020] FIG. 1.5B shows dose response for cleaning of PA-S-38 microswatches shows by PspPro3 protein in ADW detergent at pH 6 and 8 in the presence of bleach.

[0021] FIG. 1.6 shows cleaning performance of PspPro3 protein in liquid laundry detergent.

[0022] FIG. 1.7 (SEQ ID NOS: 3, 44, and 45, respectively) shows alignment of PspPro3 with other protein homologs.

[0023] FIG. 1.8 provides the phylogenetic tree for PspPro3 and its homologs.

[0024] FIG. 2.1 provides a plasmid map of pGX084 (aprE-PspPro2), described in Example 2.2.

[0025] FIG. 2.2 provides a dose response curve of PspPro2 in the azo-casein assay.

[0026] FIG. 2.3 provides the pH profile of purified PspPro2.

[0027] FIG. 2.4 provides the temperature profile of purified PspPro2.

[0028] FIG. 2.5A shows dose response for cleaning performance of PspPro2 at pH 6 in AT dish detergent with bleach.

[0029] FIG. 2.5B shows dose response for cleaning performance of purified PspPro2 at pH 8 in AT detergent with bleach.

[0030] FIG. 2.6A shows cleaning performance of PspPro2 protein in liquid laundry detergent.

[0031] FIG. 2.6B shows cleaning performance of PspPro2 protein in powder laundry detergent.

[0032] FIG. 2.7 (SEQ ID NOS: 8, 46, and 45, respectively) shows alignment of PspPro2 with other protein homologs.

[0033] FIG. 2.8 provides the phylogenetic tree for PspPro2 and its homologs.

[0034] FIG. 3.1 provides a plasmid map of pGX150 (aprE-PhuPro2), described in Example 3.2.

[0035] FIG. 3.2 provides a dose response curve of PhuPro2 in the azo-casein assay.

[0036] FIG. 3.3 provides the pH profile of purified PhuPro2.

[0037] FIG. 3.4 provides the temperature profile of purified PhuPro2.

[0038] FIG. 3.5A shows dose response for c leaning performance of PhuPro2 in AT dish detergent at pH 6.

[0039] FIG. 3.5B shows dose response for cleaning performance of PhuPro2 in AT dish detergent at pH 8.

[0040] FIG. 3.6 (SEQ ID NOS: 13, 47 and 45, respectively) shows alignment of PhuPro2 with other protein homologs.

[0041] FIG. 3.7 provides the phylogenetic tree for PhuPro2 and its homologs.

[0042] FIG. 4.1 provides a plasmid map of pGX148 (aprE-PehPro1), described in Example 4.2.

[0043] FIG. 4.2 provides a dose response curve of PehPro1 in the azo-casein assay.

[0044] FIG. 4.3 provides the pH profile of purified PehPro1.

[0045] FIG. 4.4 provides the temperature profile of purified PehPro1.

[0046] FIG. 4.5A shows dose response for cleaning performance of PehPro1 at pH 6 in AT dish detergent with bleach.

[0047] FIG. 4.5B shows dose response for cleaning performance of purified PehPro1 at pH 8 in AT detergent with bleach.

[0048] FIG. 4.6 (SEQ ID NOS: 18, 48, and 45, respectively) shows alignment of PehPro1 with other protein homologs.

[0049] FIG. 4.7 provides the phylogenetic tree for PehPro1 and its homologs.

[0050] FIG. 5.1 provides a plasmid map of pGX147 (aprE-PbaPro1), described in Example 5.2.

[0051] FIG. 5.2 provides a dose response curve of PbaPro1 in the azo-casein assay.

[0052] FIG. 5.3 provides the pH profile of purified PbaPro1.

[0053] FIG. 5.4 provides the temperature profile of purified PbaPro1.

[0054] FIG. 5.5A shows dose response for cleaning of PA-S-38 microswatches by PbaPro1protein in ADW detergent at pH 6.

[0055] FIG. 5.5B shows dose response for cleaning of PA-S-38 microswatches shows by PbaPro1protein in ADW detergent at pH 8.

[0056] FIG. 5.6 (SEQ ID NOS: 23, 49, and 45, respectively) shows the alignment of PbaPro1 with protease homologs.

[0057] FIG. 5.7 provides the phylogenetic tree for PbaPro1 and its homologs.

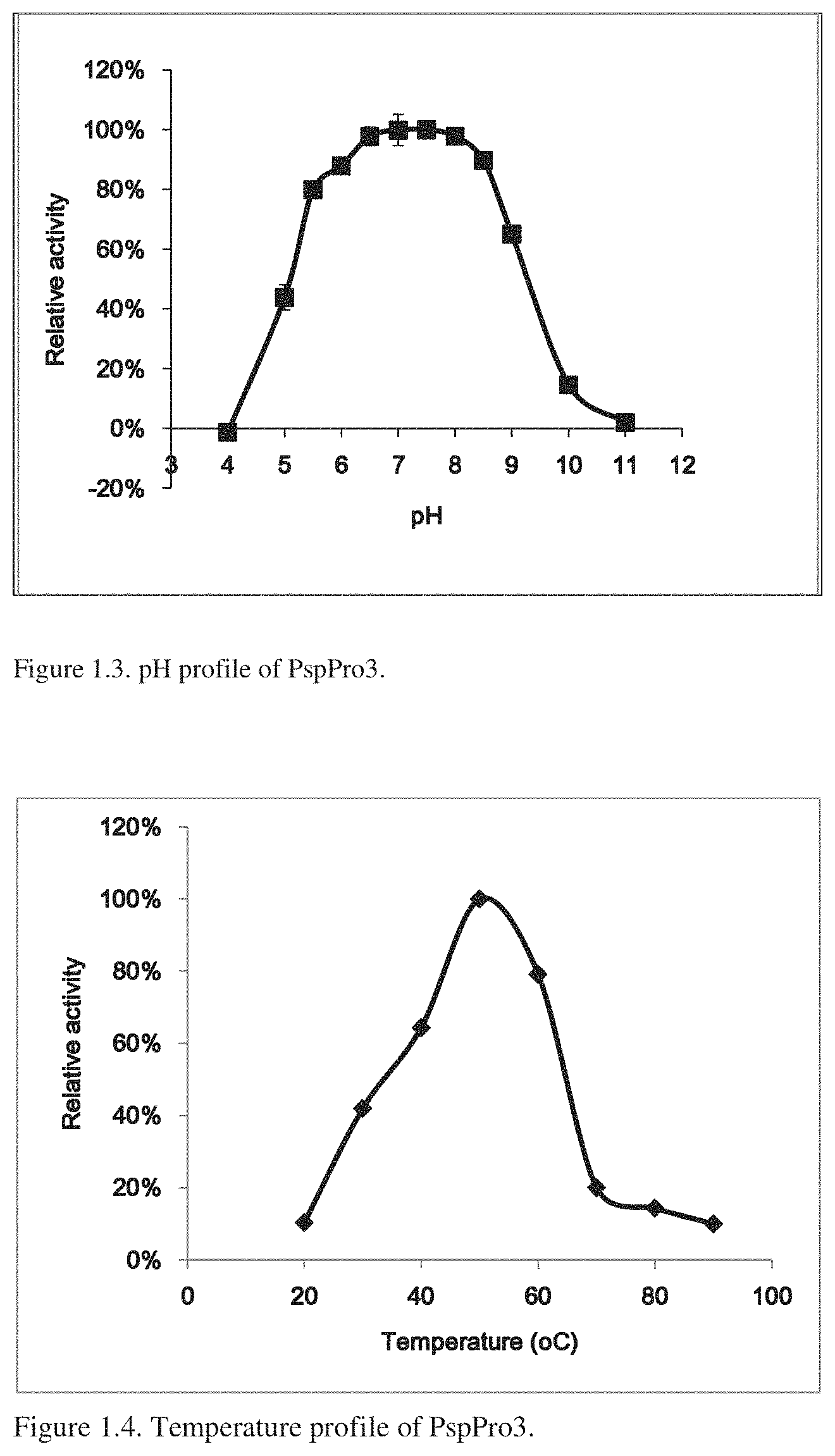

[0058] FIG. 6.1 provides a plasmid map of pGX138 (aprE-PpoPro1), described in Example 6.2.

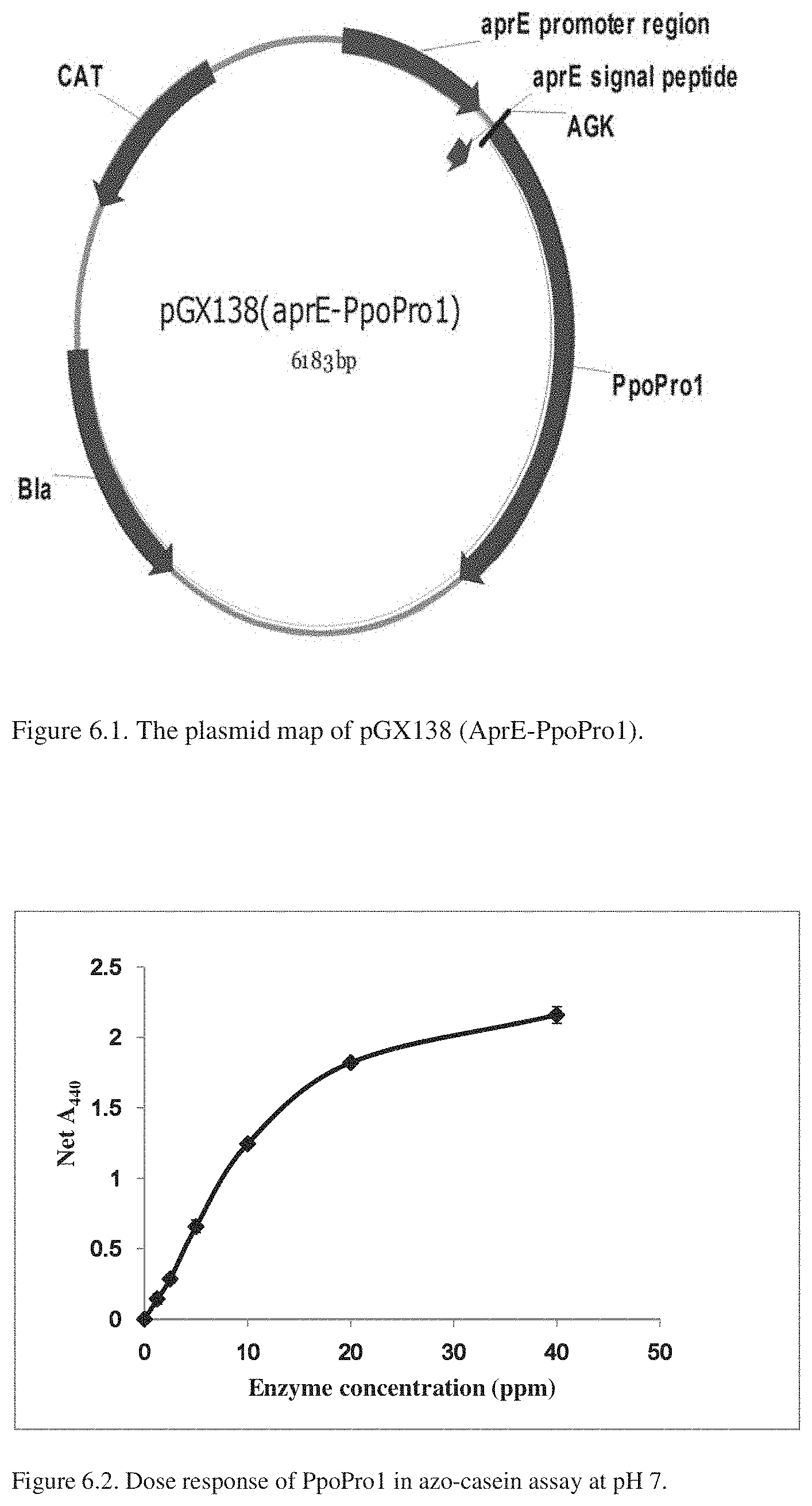

[0059] FIG. 6.2 provides a dose response curve of PpoPro1 in the azo-casein assay.

[0060] FIG. 6.3 provides the pH profile of purified PpoPro1.

[0061] FIG. 6.4 provides the temperature profile of purified PpoPro1.

[0062] FIG. 6.5A shows dose response for cleaning of PA-S-38 microswatches by PpoPro1protein in ADW detergent at pH 6 in the presence of bleach.

[0063] FIG. 6.5B shows dose response for cleaning of PA-S-38 microswatches shows by PpoPro1protein in ADW detergent at pH 8 in the presence of bleach.

[0064] FIG. 6.6 (SEQ ID NOS: 28, 50, and 45, respectively) shows the alignment of PpoPro1 with protease homologs.

[0065] FIG. 6.7 provides the phylogenetic tree for PpoPro1 and its homologs.

[0066] FIG. 7.1 provides a plasmid map of pGX149 (aprE-PhuPro1), described in Example 7.2.

[0067] FIG. 7.2 provides a dose response curve of PhuPro1 in the azo-casein assay.

[0068] FIG. 7.3 provides the pH profile of purified PhuPro1.

[0069] FIG. 7.4 provides the temperature profile of purified PhuPro1.

[0070] FIG. 7.5A shows dose response for cleaning of PA-S-38 microswatches by PhuPro1 protein in ADW detergent at pH 6.

[0071] FIG. 7.5B shows dose response for cleaning of PA-S-38 microswatches shows by Phu Pro1protein in ADW detergent at pH 8.

[0072] FIG. 7.6 (SEQ ID NOS: 33, 51, and 45, respectively) shows alignment of PhuPro1 with other protein homologs.

[0073] FIG. 7.7 provides the phylogenetic tree for PhuPro1 and its homologs.

[0074] FIGS. 7.8A and 7.8B show cleaning performances of PhuPro1 and Purafect.RTM. Prime HA proteases.

[0075] FIG. 8.1 provides a plasmid map of pGX146 (aprE-PamPro1), described in Example 8.2.

[0076] FIG. 8.2 provides a dose response curve of PamPro1 in the azo-casein assay.

[0077] FIG. 8.3 provides the pH profile of purified PamPro1.

[0078] FIG. 8.4 provides the temperature profile of purified PamPro1.

[0079] FIG. 8.5A shows dose response for cleaning of PA-S-38 microswatches by PamPro1 protein in ADW detergent at pH 6.

[0080] FIG. 8.5B shows dose response for cleaning of PA-S-38 microswatches shows by PamPro1 protein in ADW detergent at pH 8.

[0081] FIG. 8.6 (SEQ ID NOS: 38, 52, and 45, respectively) shows the alignment of PamPro1 with protease homologs.

[0082] FIG. 8.7 provides the phylogenetic tree for PamPro1 and its homologs.

[0083] FIGS. 9.1A thru 9.1D (SEQ ID NOS: 53-62, 38, 23, 13, 63, 8, 28, 64, 3, 18, 33, 65-68, respectively) show the alignment of the various Paenibacillus metalloproteases with other bacterial metalloprotease homologs.

[0084] FIG. 9.2 provides the phylogenetic tree of the various Paenibacillus metalloproteases with other bacterial metalloprotease homologs.

DETAILED DESCRIPTION

[0085] The present invention provides novel metalloprotease enzymes, especially enzymes useful for detergent compositions cloned from various Paenibacillus sp. The compositions and methods are based, in part, on the observation that the novel metalloproteases of the present invention have proteolytic activity in the presence of detergent compositions. This feature makes metalloproteases of the present invention particularly well suited to and useful in a variety of cleaning applications where the enzyme can hydrolyze polypeptides in the presence of surfactants and other components found in detergent compositions. The invention includes compositions comprising at least one of the novel metalloprotease enzymes set forth herein. Some such compositions comprise detergent compositions. The metalloprotease enzymes of the present invention can be combined with other enzymes useful in detergent compositions. The invention also provides methods of cleaning using metalloprotease enzymes of the present invention.

Definitions and Abbreviations

[0086] Unless otherwise indicated, the practice of the present invention involves conventional techniques commonly used in molecular biology, protein engineering, microbiology, and recombinant DNA technology, which are within the skill of the art. Such techniques are known to those of skill in the art and are described in numerous texts and reference works well known to those of skill in the art. All patents, patent applications, articles and publications mentioned herein, both supra and infra, are hereby expressly incorporated herein by reference.

[0087] Unless defined otherwise herein, all technical and scientific terms used herein have the same meaning as commonly understood by one of ordinary skill in the art to which this invention pertains. Many technical dictionaries are known to those of skill in the art. Although any methods and materials similar or equivalent to those described herein find use in the practice of the present invention, some suitable methods and materials are described herein. Accordingly, the terms defined immediately below are more fully described by reference to the Specification as a whole. Also, as used herein, the singular "a", "an" and "the" includes the plural reference unless the context clearly indicates otherwise. Unless otherwise indicated, nucleic acids are written left to right in 5' to 3' orientation; amino acid sequences are written left to right in amino to carboxy orientation, respectively. It is to be understood that this invention is not limited to the particular methodology, protocols, and reagents described, as these may vary, depending upon the context they are used by those of skill in the art.

[0088] Furthermore, the headings provided herein are not limitations of the various aspects or embodiments of the invention.

[0089] It is intended that every maximum numerical limitation given throughout this specification includes every lower numerical limitation, as if such lower numerical limitations were expressly written herein. Every minimum numerical limitation given throughout this specification will include every higher numerical limitation, as if such higher numerical limitations were expressly written herein. Every numerical range given throughout this specification will include every narrower numerical range that falls within such broader numerical range, as if such narrower numerical ranges were all expressly written herein.

[0090] As used herein, the terms "protease" and "proteinase" refer to an enzyme that has the ability to break down proteins and peptides. A protease has the ability to conduct "proteolysis," by hydrolysis of peptide bonds that link amino acids together in a peptide or polypeptide chain forming the protein. This activity of a protease as a protein-digesting enzyme is referred to as "proteolytic activity." Many well known procedures exist for measuring proteolytic activity (See e.g., Kalisz, "Microbial Proteinases," In: Fiechter (ed.), Advances in Biochemical Engineering/Biotechnology, (1988)). For example, proteolytic activity may be ascertained by comparative assays which analyze the respective protease's ability to hydrolyze a suitable substrate. Exemplary substrates useful in the analysis of protease or proteolytic activity, include, but are not limited to, di-methyl casein (Sigma C-9801), bovine collagen (Sigma C-9879), bovine elastin (Sigma E-1625), and bovine keratin (ICN Biomedical 902111). Colorimetric assays utilizing these substrates are well known in the art (See e.g., WO 99/34011 and U.S. Pat. No. 6,376,450, both of which are incorporated herein by reference). The pNA peptidyl assay (See e.g., Del Mar et al., Anal. Biochem. 99:316-320 [1979]) also finds use in determining the active enzyme concentration. This assay measures the rate at which p-nitroaniline is released as the enzyme hydrolyzes a soluble synthetic substrate, such as succinyl-alanine-alanine-proline-phenylalanine-p-nitroanilide (suc-AAPF-pNA)(SEQ ID NO: 43). The rate of production of yellow color from the hydrolysis reaction is measured at 410 nm on a spectrophotometer and is proportional to the active enzyme concentration. In addition, absorbance measurements at 280 nanometers (nm) can be used to determine the total protein concentration in a sample of purified protein. The activity on substrate/protein concentration gives the enzyme specific activity.

[0091] As used herein, the term "variant polypeptide" refers to a polypeptide comprising an amino acid sequence that differs in at least one amino acid residue from the amino acid sequence of a parent or reference polypeptide (including but not limited to wild-type polypeptides).

[0092] As used herein, "the genus Bacillus" includes all species within the genus "Bacillus," as known to those of skill in the art, including but not limited to B. subtilis, B. licheniformis, B. lentus, B. brevis, B. stearothermophilus, B. alkalophilus, B. amyloliquefaciens, B. clausii, B. halodurans, B. megaterium, B. coagulans, B. circulans, and B. thuringiensis. It is recognized that the genus Bacillus continues to undergo taxonomical reorganization. Thus, it is intended that the genus include species that have been reclassified, including but not limited to such organisms as B. stearothermophilus, which is now named "Geobacillus stearothermophilus." The production of resistant endospores under stressful environmental conditions is considered the defining feature of the genus Bacillus, although this characteristic also applies to the recently named Alicyclobacillus, Amphibacillus, Aneurinibacillus, Paenibacillus, Brevibacillus, Filobacillus, Gracilibacillus, Halobacillus, Paenibacillus, Salibacillus, Thermobacillus, Ureibacillus, and Virgibacillus.

[0093] The terms "polynucleotide" and "nucleic acid," which are used interchangeably herein, refer to a polymer of any length of nucleotide monomers covalently bonded in a chain. DNA (deoxyribonucleic acid), a polynucleotide comprising deoxyribonucleotides, and RNA (ribonucleic acid), a polymer of ribonucleotides, are examples of polynucleotides or nucleic acids having distinct biological function. Polynucleotides or nucleic acids include, but are not limited to, a single-, double- or triple-stranded DNA, genomic DNA, cDNA, RNA, DNA-RNA hybrid, or a polymer comprising purine and pyrimidine bases, or other natural, chemically, biochemically modified, non-natural or derivatized nucleotide bases. The following are non-limiting examples of polynucleotides: genes, gene fragments, chromosomal fragments, expressed sequence tag(s) (EST(s)), exons, introns, messenger RNA (mRNA), transfer RNA (tRNA), ribosomal RNA (rRNA), ribozymes, complementary DNA (cDNA), recombinant polynucleotides, branched polynucleotides, plasmids, vectors, isolated DNA of any sequence, isolated RNA of any sequence, nucleic acid probes, and primers.

[0094] As used herein, the term "mutation" refers to changes made to a reference amino acid or nucleic acid sequence. It is intended that the term encompass substitutions, insertions and deletions.

[0095] As used herein, the term "vector" refers to a nucleic acid construct used to introduce or transfer nucleic acid(s) into a target cell or tissue. A vector is typically used to introduce foreign DNA into a cell or tissue. Vectors include plasmids, cloning vectors, bacteriophages, viruses (e.g., viral vector), cosmids, expression vectors, shuttle vectors, and the like. A vector typically includes an origin of replication, a multicloning site, and a selectable marker. The process of inserting a vector into a target cell is typically referred to as transformation. The present invention includes, in some embodiments, a vector that comprises a DNA sequence encoding a metalloprotease polypeptide (e.g., precursor or mature metalloprotease polypeptide) that is operably linked to a suitable prosequence (e.g., secretory, signal peptide sequence, etc.) capable of effecting the expression of the DNA sequence in a suitable host, and the folding and translocation of the recombinant polypeptide chain.

[0096] As used herein, the term "expression cassette," "expression plasmid" or "expression vector" refers to a nucleic acid construct or vector generated recombinantly or synthetically for the expression of a nucleic acid of interest in a target cell. An expression vector or expression cassette typically comprises a promoter nucleotide sequence that drives expression of the foreign nucleic acid. The expression vector or cassette also typically includes any other specified nucleic acid elements that permit transcription of a particular nucleic acid in a target cell. A recombinant expression cassette can be incorporated into a plasmid, chromosome, mitochondrial DNA, plastid DNA, virus, or nucleic acid fragment. Many prokaryotic and eukaryotic expression vectors are commercially available.

[0097] In some embodiments, the ends of the sequence are closed such that the DNA construct forms a closed circle. The nucleic acid sequence of interest, which is incorporated into the DNA construct, using techniques well known in the art, may be a wild-type, mutant, or modified nucleic acid. In some embodiments, the DNA construct comprises one or more nucleic acid sequences homologous to the host cell chromosome. In other embodiments, the DNA construct comprises one or more non-homologous nucleotide sequences. Once the DNA construct is assembled in vitro, it may be used, for example, to: 1) insert heterologous sequences into a desired target sequence of a host cell; and/or 2) mutagenize a region of the host cell chromosome (i.e., replace an endogenous sequence with a heterologous sequence); 3) delete target genes; and/or 4) introduce a replicating plasmid into the host. "DNA construct" is used interchangeably herein with "expression cassette."

[0098] As used herein, a "plasmid" refers to an extrachromosomal DNA molecule which is capable of replicating independently from the chromosomal DNA. A plasmid is double stranded (ds) and may be circular and is typically used as a cloning vector.

[0099] As used herein in the context of introducing a nucleic acid sequence into a cell, the term "introduced" refers to any method suitable for transferring the nucleic acid sequence into the cell. Such methods for introduction include but are not limited to protoplast fusion, transfection, transformation, electroporation, conjugation, and transduction (See e.g., Ferrari et al., "Genetics," in Hardwood et al. (eds.), Bacillus, Plenum Publishing Corp., pp. 57-72 [1989]).

[0100] Transformation refers to the genetic alteration of a cell which results from the uptake, optional genomic incorporation, and expression of genetic material (e.g., DNA).

[0101] As used herein, a nucleic acid is "operably linked" with another nucleic acid sequence when it is placed into a functional relationship with another nucleic acid sequence. For example, a promoter or enhancer is operably linked to a nucleotide coding sequence if the promoter affects the transcription of the coding sequence. A ribosome binding site may be operably linked to a coding sequence if it is positioned so as to facilitate translation of the coding sequence. Typically, "operably linked" DNA sequences are contiguous. However, enhancers do not have to be contiguous. Linking is accomplished by ligation at convenient restriction sites. If such sites do not exist, synthetic oligonucleotide adaptors or linkers may be used in accordance with conventional practice.

[0102] As used herein the term "gene" refers to a polynucleotide (e.g., a DNA segment), that encodes a polypeptide and includes regions preceding and following the coding regions as well as intervening sequences (introns) between individual coding segments (exons).

[0103] As used herein, "recombinant" when used with reference to a cell typically indicates that the cell has been modified by the introduction of a foreign nucleic acid sequence or that the cell is derived from a cell so modified. For example, a recombinant cell may comprise a gene not found in identical form within the native (non-recombinant) form of the cell, or a recombinant cell may comprise a native gene (found in the native form of the cell) but which has been modified and re-introduced into the cell. A recombinant cell may comprise a nucleic acid endogenous to the cell that has been modified without removing the nucleic acid from the cell; such modifications include those obtained by gene replacement, site-specific mutation, and related techniques known to those of ordinary skill in the art. Recombinant DNA technology includes techniques for the production of recombinant DNA in vitro and transfer of the recombinant DNA into cells where it may be expressed or propagated, thereby producing a recombinant polypeptide. "Recombination," "recombining," and "recombined" of polynucleotides or nucleic acids refer generally to the assembly or combining of two or more nucleic acid or polynucleotide strands or fragments to generate a new polynucleotide or nucleic acid. The recombinant polynucleotide or nucleic acid is sometimes referred to as a chimera. A nucleic acid or polypeptide is "recombinant" when it is artificial or engineered.

[0104] A nucleic acid or polynucleotide is said to "encode" a polypeptide if, in its native state or when manipulated by methods known to those of skill in the art, it can be transcribed and/or translated to produce the polypeptide or a fragment thereof. The anti-sense strand of such a nucleic acid is also said to encode the sequence.

[0105] "Host strain" or "host cell" refers to a suitable host for an expression vector comprising a DNA sequence of interest.

[0106] A "protein" or "polypeptide" comprises a polymeric sequence of amino acid residues. The terms "protein" and "polypeptide" are used interchangeably herein. The single and 3-letter code for amino acids as defined in conformity with the IUPAC-IUB Joint Commission on Biochemical Nomenclature (JCBN) is used through out this disclosure. The single letter X refers to any of the twenty amino acids. It is also understood that a polypeptide may be coded for by more than one nucleotide sequence due to the degeneracy of the genetic code. Mutations can be named by the one letter code for the parent amino acid, followed by a position number and then the one letter code for the variant amino acid. For example, mutating glycine (G) at position 87 to serine (S) is represented as "G087S" or "G87S". Mutations can also be named by using the three letter code for an amino acid followed by its position in the polypeptide chain as counted from the N-terminus; for example, Ala10 for alanine at position 10. Multiple mutations are indicated by inserting a "-" between the mutations. Mutations at positions 87 and 90 are represented as either "G087S-A090Y" or "G87S-A90Y" or "G87S+A90Y" or "G087S+A090Y". For deletions, the one letter code "Z" is used. For an insertion relative to the parent sequence, the one letter code "Z" is on the left side of the position number. For a deletion, the one letter code "Z" is on the right side of the position number. For insertions, the position number is the position number before the inserted amino acid(s), plus 0.01 for each amino acid. For example, an insertion of three amino acids alanine (A), serine (S) and tyrosine (Y) between position 87 and 88 is shown as "Z087.01A-Z087.02S-Z087.03Y." Thus, combining all the mutations above plus a deletion at position 100 is: "G087S-Z087.01A-Z087.02S-Z087.03Y-A090Y-A100Z." When describing modifications, a position followed by amino acids listed in parentheses indicates a list of substitutions at that position by any of the listed amino acids. For example, 6(L,I) means position 6 can be substituted with a leucine or isoleucine.

[0107] A "prosequence" or "propetide sequence" refers to an amino acid sequence between the signal peptide sequence and mature protease sequence that is necessary for the proper folding and secretion of the protease; they are sometimes referred to as intramolecular chaperones. Cleavage of the prosequence or propeptide sequence results in a mature active protease. Bacterial metalloproteases are often expressed as pro-enzymes.

[0108] The term "signal sequence" or "signal peptide" refers to a sequence of amino acid residues that may participate in the secretion or direct transport of the mature or precursor form of a protein. The signal sequence is typically located N-terminal to the precursor or mature protein sequence. The signal sequence may be endogenous or exogenous. A signal sequence is normally absent from the mature protein. A signal sequence is typically cleaved from the protein by a signal peptidase after the protein is transported.

[0109] The term "mature" form of a protein, polypeptide, or peptide refers to the functional form of the protein, polypeptide, or peptide without the signal peptide sequence and propeptide sequence.

[0110] The term "precursor" form of a protein or peptide refers to a mature form of the protein having a prosequence operably linked to the amino or carbonyl terminus of the protein. The precursor may also have a "signal" sequence operably linked to the amino terminus of the prosequence. The precursor may also have additional polypeptides that are involved in post-translational activity (e.g., polypeptides cleaved therefrom to leave the mature form of a protein or peptide).

[0111] The term "wild-type" in reference to an amino acid sequence or nucleic acid sequence indicates that the amino acid sequence or nucleic acid sequence is native or naturally occurring sequence. As used herein, the term "naturally-occurring" refers to anything (e.g., proteins, amino acids, or nucleic acid sequences) that are found in nature.

[0112] As used herein, the term "non-naturally occurring" refers to anything that is not found in nature (e.g., recombinant nucleic acids and protein sequences produced in the laboratory), as modification of the wild-type sequence.

[0113] As used herein with regard to amino acid residue positions, "corresponding to" or "corresponds to" or "corresponds" refers to an amino acid residue at the enumerated position in a protein or peptide, or an amino acid residue that is analogous, homologous, or equivalent to an enumerated residue in a protein or peptide. As used herein, "corresponding region" generally refers to an analogous position in a related proteins or a reference protein.

[0114] The terms "derived from" and "obtained from" refer to not only a protein produced or producible by a strain of the organism in question, but also a protein encoded by a DNA sequence isolated from such strain and produced in a host organism containing such DNA sequence. Additionally, the term refers to a protein which is encoded by a DNA sequence of synthetic and/or cDNA origin and which has the identifying characteristics of the protein in question. To exemplify, "proteases derived from Bacillus" refers to those enzymes having proteolytic activity which are naturally produced by Bacillus, as well as to serine proteases like those produced by Bacillus sources but which through the use of genetic engineering techniques are produced by non-Bacillus organisms transformed with a nucleic acid encoding the serine proteases.

[0115] The term "identical" in the context of two nucleic acids or polypeptidesequences refers to the residues in the two sequences that are the same when aligned for maximum correspondence, as measured using one of the following sequence comparison or analysis algorithms.

[0116] As used herein, "homologous genes" refers to a pair of genes from different, but usually related species, which correspond to each other and which are identical or very similar to each other. The term encompasses genes that are separated by speciation (i.e., the development of new species) (e.g., orthologous genes), as well as genes that have been separated by genetic duplication (e.g., paralogous genes).

[0117] As used herein, "% identity or percent identity" refers to sequence similarity. Percent identity may be determined using standard techniques known in the art (See e.g., Smith and Waterman, Adv. Appl. Math. 2:482 [1981]; Needleman and Wunsch, J. Mol. Biol. 48:443 [1970]; Pearson and Lipman, Proc. Natl. Acad. Sci. USA 85:2444 [1988]; software programs such as GAP, BESTFIT, FASTA, and TFASTA in the Wisconsin Genetics Software Package (Genetics Computer Group, Madison, Wis.); and Devereux et al., Nucl. Acid Res. 12:387-395 [1984]). One example of a useful algorithm is PILEUP. PILEUP creates a multiple sequence alignment from a group of related sequences using progressive, pair-wise alignments. It can also plot a tree showing the clustering relationships used to create the alignment. PILEUP uses a simplification of the progressive alignment method of Feng and Doolittle (See, Feng and Doolittle, J. Mol. Evol. 35:351-360 [1987]). The method is similar to that described by Higgins and Sharp (See, Higgins and Sharp, CABIOS 5:151-153 [1989]). Useful PILEUP parameters include a default gap weight of 3.00, a default gap length weight of 0.10, and weighted end gaps. Other useful algorithm is the BLAST algorithms described by Altschul et al., (See, Altschul et al., J. Mol. Biol. 215:403-410 [1990]; and Karlin and Altschul, Proc. Natl. Acad. Sci. USA 90:5873-5787 [1993]). The BLAST program uses several search parameters, most of which are set to the default values.

[0118] The NCBI BLAST algorithm finds the most relevant sequences in terms of biological similarity but is not recommended for query sequences of less than 20 residues (Altschul, S F et al. (1997) Nucleic Acids Res. 25:3389-3402 and Schaffer, A A et al. (2001) Nucleic Acids Res. 29:2994-3005). Example default BLAST parameters for a nucleic acid sequence searches are: [0119] Neighboring words threshold: 11 [0120] E-value cutoff: 10 [0121] Scoring Matrix: NUC.3.1 (match=1, mismatch=-3) [0122] Gap Opening: 5 [0123] Gap Extension: 2 and the following parameters for amino acid sequence searches: [0124] Word size: 3 [0125] E-value cutoff: 10 [0126] Scoring Matrix: BLOSUM62 [0127] Gap Opening: 11 [0128] Gap extension: 1

[0129] A percent (%) amino acid sequence identity value is determined by the number of matching identical residues divided by the total number of residues of the "reference" sequence including any gaps created by the program for optimal/maximum alignment. If a sequence is 90% identical to SEQ ID NO: A, SEQ ID NO: A is is the "reference" sequence. BLAST algorithms refer the "reference" sequence as "query" sequence.

[0130] The CLUSTAL W algorithm is another example of a sequence alignment algorithm. See Thompson et al. (1994) Nucleic Acids Res. 22:4673-4680. Default parameters for the CLUSTAL W algorithm are: [0131] Gap opening penalty: 10.0 [0132] Gap extension penalty: 0.05 [0133] Protein weight matrix: BLOSUM series [0134] DNA weight matrix: IUB [0135] Delay divergent sequences %: 40 [0136] Gap separation distance: 8 [0137] DNA transitions weight: 0.50 [0138] List hydrophilic residues: GPSNDQEKR [0139] Use negative matrix: OFF [0140] Toggle Residue specific penalties: ON [0141] Toggle hydrophilic penalties: ON [0142] Toggle end gap separation penalty OFF.

[0143] In CLUSTAL algorithms, deletions occurring at either terminus are included. For example, a variant with five amino acid deletion at either terminus (or within the polypeptide) of a polypeptide of 500 amino acids would have a percent sequence identity of 99% (495/500 identical residues.times.100) relative to the "reference" polypeptide. Such a variant would be encompassed by a variant having "at least 99% sequence identity" to the polypeptide.

[0144] A polypeptide of interest may be said to be "substantially identical" to a reference polypeptide if the polypeptide of interest comprises an amino acid sequence having at least about 60%, least about 65%, least about 70%, at least about 75%, at least about 80%, at least about 85%, at least about 90%, at least about 91%, at least about 92%, at least about 93%, at least about 94%, at least about 95%, at least about 96%, at least about 97%, at least about 98%, at least about 99%, or at least about 99.5% sequence identity to the amino acid sequence of the reference polypeptide. The percent identity between two such polypeptides can be determined manually by inspection of the two optimally aligned polypeptide sequences or by using software programs or algorithms (e.g., BLAST, ALIGN, CLUSTAL) using standard parameters. One indication that two polypeptides are substantially identical is that the first polypeptide is immunologically cross-reactive with the second polypeptide. Typically, polypeptides that differ by conservative amino acid substitutions are immunologically cross-reactive. Thus, a polypeptide is substantially identical to a second polypeptide, for example, where the two peptides differ only by a conservative amino acid substitution or one or more conservative amino acid substitutions.

[0145] A nucleic acid of interest may be said to be "substantially identical" to a reference nucleic acid if the nucleic acid of interest comprises a nucleotide sequence having least about 60%, least about 65%, at least about 70%, at least about 75%, at least about 80%, at least about 85%, at least about 90%, at least about 91%, at least about 92%, at least about 93%, at least about 94%, at least about 95%, at least about 96%, at least about 97%, at least about 98%, at least about 99%, or at least about 99.5% sequence identity to the nucleotide sequence of the reference nucleic acid. The percent identity between two such nucleic acids can be determined manually by inspection of the two optimally aligned nucleic acid sequences or by using software programs or algorithms (e.g., BLAST, ALIGN, CLUSTAL) using standard parameters. One indication that two nucleic acid sequences are substantially identical is that the two nucleic acid molecules hybridize to each other under stringent conditions (e.g., within a range of medium to high stringency).

[0146] A nucleic acid or polynucleotide is "isolated" when it is at least partially or completely separated from other components, including but not limited to for example, other proteins, nucleic acids, cells, etc. Similarly, a polypeptide, protein or peptide is "isolated" when it is at least partially or completely separated from other components, including but not limited to for example, other proteins, nucleic acids, cells, etc. On a molar basis, an isolated species is more abundant than are other species in a composition. For example, an isolated species may comprise at least about 60%, about 65%, about 70%, about 75%, about 80%, about 85%, about 90%, about 91%, about 92%, about 93%, about 94%, about 95%, about 96%, about 97%, about 98%, about 99%, or about 100% (on a molar basis) of all macromolecular species present. Preferably, the species of interest is purified to essential homogeneity (i.e., contaminant species cannot be detected in the composition by conventional detection methods). Purity and homogeneity can be determined using a number of techniques well known in the art, such as agarose or polyacrylamide gel electrophoresis of a nucleic acid or a protein sample, respectively, followed by visualization upon staining. If desired, a high-resolution technique, such as high performance liquid chromatography (HPLC) or a similar means can be utilized for purification of the material.

[0147] "Hybridization" refers to the process by which one strand of nucleic acid forms a duplex with, i.e., base pairs with, a complementary strand. A nucleic acid sequence is considered to be "selectively hybridizable" to a reference nucleic acid sequence if the two sequences specifically hybridize to one another under moderate to high stringency hybridization and wash conditions. Hybridization conditions are based on the melting temperature (Tm) of the nucleic acid binding complex or probe. For example, "maximum stringency" typically occurs at about Tm-5.degree. C. (5.degree. below the Tm of the probe); "high stringency" at about 5-10.degree. C. below the Tm; "intermediate stringency" at about 10-20.degree. C. below the Tm of the probe; and "low stringency" at about 20-25.degree. C. below the Tm. Functionally, maximum stringency conditions can be used to identify sequences having strict identity or near-strict identity with the hybridization probe; while intermediate or low stringency hybridization can be used to identify or detect polynucleotide sequence homologs.

[0148] Moderate and high stringency hybridization conditions are well known in the art. Stringent hybridization conditions are exemplified by hybridization under the following conditions: 65.degree. C. and 0.1.times.SSC (where 1.times.SSC=0.15 M NaCl, 0.015 M Na3 citrate, pH 7.0). Hybridized, duplex nucleic acids are characterized by a melting temperature (T.sub.m), where one half of the hybridized nucleic acids are unpaired with the complementary strand. Mismatched nucleic acids within the duplex lower the T.sub.m. Very stringent hybridization conditions involve 68.degree. C. and 0.1.times.SSC. A nucleic acid encoding a variant metalloprotease can have a T.sub.m reduced by 1.degree. C.-3.degree. C. or more compared to a duplex formed between the nucleic acid and its identical complement.

[0149] Another example of high stringency conditions includes hybridization at about 42.degree. C. in 50% formamide, 5.times.SSC, 5.times.Denhardt's solution, 0.5% SDS and 100 .mu.g/ml denatured carrier DNA followed by washing two times in 2.times.SSC and 0.5% SDS at room temperature and two additional times in 0.1.times.SSC and 0.5% SDS at 42.degree. C. An example of moderate stringent conditions include an overnight incubation at 37.degree. C. in a solution comprising 20% formamide, 5.times.SSC (150 mM NaCl, 15 mM trisodium citrate), 50 mM sodium phosphate (pH 7.6), 5.times.Denhardt's solution, 10% dextran sulfate and 20 mg/ml denatured sheared salmon sperm DNA, followed by washing the filters in 1.times.SSC at about 37-50.degree. C. Those of skill in the art know how to adjust the temperature, ionic strength, etc. to accommodate factors such as probe length and the like.

[0150] The term "purified" as applied to nucleic acids or polypeptides generally denotes a nucleic acid or polypeptide that is essentially free from other components as determined by analytical techniques well known in the art (e.g., a purified polypeptide or polynucleotide forms a discrete band in an electrophoretic gel, chromatographic eluate, and/or a media subjected to density gradient centrifugation). For example, a nucleic acid or polypeptide that gives rise to essentially one band in an electrophoretic gel is "purified." A purified nucleic acid or polypeptide is at least about 50% pure, usually at least about 60%, about 65%, about 70%, about 75%, about 80%, about 85%, about 90%, about 91%, about 92%, about 93%, about 94%, about 95%, about 96%, about 9'7%, about 98%, about 99%, about 99.5%, about 99.6%, about 99.'7%, about 99.8% or more pure (e.g., percent by weight on a molar basis). In a related sense, the invention provides methods of enriching compositions for one or more molecules of the invention, such as one or more polypeptides or polynucleotides of the invention. A composition is enriched for a molecule when there is a substantial increase in the concentration of the molecule after application of a purification or enrichment technique. A substantially pure polypeptide or polynucleotide of the invention (e.g., substantially pure metalloprotease polypeptide or polynucleotide encoding a metalloprotease polypeptide of the invention, respectively) will typically comprise at least about 55%, about 60%, about 65%, about 70%, about 75%, about 80%, about 85%, about 90%, about 91%, about 92%, about 93%, about 94%, about 95%, about 96%, about 97%, about 98, about 99%, about 99.5% or more by weight (on a molar basis) of all macromolecular species in a particular composition.

[0151] The term "enriched" refers to a compound, polypeptide, cell, nucleic acid, amino acid, or other specified material or component that is present in a composition at a relative or absolute concentration that is higher than a starting composition.

[0152] In a related sense, the invention provides methods of enriching compositions for one or more molecules of the invention, such as one or more polypeptides of the invention (e.g., one or more metalloprotease polypeptides of the invention) or one or more nucleic acids of the invention (e.g., one or more nucleic acids encoding one or more metalloprotease polypeptides of the invention). A composition is enriched for a molecule when there is a substantial increase in the concentration of the molecule after application of a purification or enrichment technique. A substantially pure polypeptide or polynucleotide will typically comprise at least about 55%, about 60%, about 65%, about 70%, about 75%, about 80%, about 85%, about 90%, about 91%, about 92%, about 93%, about 94%, about 95%, about 96%, about 97%, about 98, about 99%, about 99.5% or more by weight (on a molar basis) of all macromolecular species in a particular composition.

[0153] As used herein, the term "functional assay" refers to an assay that provides an indication of a protein's activity. In some embodiments, the term refers to assay systems in which a protein is analyzed for its ability to function in its usual capacity. For example, in the case of a protease, a functional assay involves determining the effectiveness of the protease to hydrolyze a proteinaceous substrate.

[0154] The terms "modified nucleic acid sequence" and "modified gene" are used interchangeably herein to refer to a nucleic acid sequence that includes a deletion, insertion or interruption of naturally occurring (i.e., wild-type) nucleic acid sequence. In some embodiments, the expression product of the modified nucleic acid sequence is a truncated protein (e.g., if the modification is a deletion or interruption of the sequence). In some embodiments, the truncated protein retains biological activity. In alternative embodiments, the expression product of the modified nucleic acid sequence is an elongated protein (e.g., modifications comprising an insertion into the nucleic acid sequence). In some embodiments, a nucleotide insertion in the nucleic acid sequence leads to a truncated protein (e.g., when the insertion results in the formation of a stop codon). Thus, an insertion may result in either a truncated protein or an elongated protein as an expression product.

[0155] A "mutant" nucleic acid sequence typically refers to a nucleic acid sequence that has an alteration in at least one codon occurring in a host cell's wild-type sequence such that the expression product of the mutant nucleic acid sequence is a protein with an altered amino acid sequence relative to the wild-type protein. The expression product may have an altered functional capacity (e.g., enhanced enzymatic activity).

[0156] As used herein, the phrase "alteration in substrate specificity" refers to changes in the substrate specificity of an enzyme. In some embodiments, a change in substrate specificity is defined as a change in k.sub.cat and/or K.sub.m for a particular substrate, resulting from mutations of the enzyme or alteration of reaction conditions. The substrate specificity of an enzyme is determined by comparing the catalytic efficiencies it exhibits with different substrates. These determinations find particular use in assessing the efficiency of mutant enzymes, as it is generally desired to produce variant enzymes that exhibit greater ratios of k.sub.cat/K.sub.m for substrates of interest. However, it is not intended that the present invention be limited to any particular substrate composition or substrate specificity.

[0157] As used herein, "surface property" is used in reference to electrostatic charge, as well as properties such as the hydrophobicity and hydrophilicity exhibited by the surface of a protein. As used herein, the term "net charge" is defined as the sum of all charges present in a molecule. "Net charge changes" are made to a parent protein molecule to provide a variant that has a net charge that differs from that of the parent molecule (i.e., the variant has a net charge that is not the same as that of the parent molecule). For example, substitution of a neutral amino acid with a negatively charged amino acid or a positively charged amino acid with a neutral amino acid results in net charge of -1 with respect to the parent molecule. Substitution of a positively charged amino acid with a negatively charged amino acid results in a net charge of -2 with respect to the parent. Substitution of a neutral amino acid with a positively charged amino acid or a negatively charged amino acid with a neutral amino acid results in net charge of +1 with respect to the parent. Substitution of a negatively charged amino acid with a positively charged amino acid results in a net charge of +2 with respect to the parent. The net charge of a parent protein can also be altered by deletion and/or insertion of charged amino acids. A net change change applies to changes in charge of a variant versus a parent when measured at the same pH conditions.

[0158] The terms "thermally stable" and "thermostable" and "thermostability" refer to proteases that retain a specified amount of enzymatic activity after exposure to identified temperatures over a given period of time under conditions prevailing during the proteolytic, hydrolyzing, cleaning or other process of the invention, while being exposed to altered temperatures. "Altered temperatures" encompass increased or decreased temperatures. In some embodiments, the proteases retain at least about 50%, about 60%, about 70%, about 75%, about 80%, about 85%, about 90%, about 92%, about 95%, about 96%, about 97%, about 98%, or about 99% proteolytic activity after exposure to altered temperatures over a given time period, for example, at least about 60 minutes, about 120 minutes, about 180 minutes, about 240 minutes, about 300 minutes, etc.

[0159] The term "enhanced stability" in the context of an oxidation, chelator, thermal, chemical, autolytic and/or pH stable protease refers to a higher retained proteolytic activity over time as compared to other proteases (e.g., thermolysin proteases) and/or wild-type enzymes.

[0160] The term "diminished stability" in the context of an oxidation, chelator, thermal and/or pH stable protease refers to a lower retained proteolytic activity over time as compared to other proteases (e.g., thermolysin proteases) and/or wild-type enzymes.

[0161] The term "cleaning activity" refers to a cleaning performance achieved by a metalloprotease polypeptide or reference protease under conditions prevailing during the proteolytic, hydrolyzing, cleaning, or other process of the invention. In some embodiments, cleaning performance of a metalloprotease polypeptide or reference protease may be determined by using various assays for cleaning one or more various enzyme sensitive stains on an item or surface (e.g., a stain resulting from food, grass, blood, ink, milk, oil, and/or egg protein). Cleaning performance of a variant or reference protease can be determined by subjecting the stain on the item or surface to standard wash condition(s) and assessing the degree to which the stain is removed by using various chromatographic, spectrophotometric, or other quantitative methodologies. Exemplary cleaning assays and methods are known in the art and include, but are not limited to those described in WO 99/34011 and U.S. Pat. No. 6,605,458, both of which are herein incorporated by reference, as well as those cleaning assays and methods included in the Examples provided below.

[0162] The term "cleaning effective amount" of a metalloprotease polypeptide or reference protease refers to the amount of protease that achieves a desired level of enzymatic activity in a specific cleaning composition. Such effective amounts are readily ascertained by one of ordinary skill in the art and are based on many factors, such as the particular protease used, the cleaning application, the specific composition of the cleaning composition, and whether a liquid or dry (e.g., granular, tablet, bar) composition is required, etc.

[0163] The term "cleaning adjunct material" refers to any liquid, solid, or gaseous material included in cleaning composition other than a metalloprotease polypeptide of the invention. In some embodiments, the cleaning compositions of the present invention include one or more cleaning adjunct materials. Each cleaning adjunct material is typically selected depending on the particular type and form of cleaning composition (e.g., liquid, granule, powder, bar, paste, spray, tablet, gel, foam, or other composition). Preferably, each cleaning adjunct material is compatible with the protease enzyme used in the composition.

[0164] The term "enhanced performance" in the context of cleaning activity refers to an increased or greater cleaning activity by an enzyme with respect to a parent or reference protein as measured on certain enzyme sensitive stains such as egg, milk, grass, ink, oil, and/or blood, as determined by usual evaluation after a standard wash cycle and/or multiple wash cycles.

[0165] The term "diminished performance" in the context of cleaning activity refers to a decreased or lesser cleaning activity by an enzyme on certain enzyme sensitive stains such as egg, milk, grass or blood, as determined by usual evaluation after a standard wash cycle and/or multiple wash cycles.

[0166] Cleaning compositions and cleaning formulations include any composition that is suited for cleaning, bleaching, disinfecting, and/or sterilizing any object, item, and/or surface. Such compositions and formulations include, but are not limited to for example, liquid and/or solid compositions, including cleaning or detergent compositions (e.g., liquid, tablet, gel, bar, granule, and/or solid laundry cleaning or detergent compositions and fine fabric detergent compositions; hard surface cleaning compositions and formulations, such as for glass, wood, ceramic and metal counter tops and windows; carpet cleaners; oven cleaners; fabric fresheners; fabric softeners; and textile, laundry booster cleaning or detergent compositions, laundry additive cleaning compositions, and laundry pre-spotter cleaning compositions; dishwashing compositions, including hand or manual dishwash compositions (e.g., "hand" or "manual" dishwashing detergents) and automatic dishwashing compositions (e.g., "automatic dishwashing detergents").