Radiometry Systems And Methods For Dental Applications

Friedman; Joshua

U.S. patent application number 16/416896 was filed with the patent office on 2020-09-10 for radiometry systems and methods for dental applications. This patent application is currently assigned to AdDent, Inc.. The applicant listed for this patent is AdDent, Inc.. Invention is credited to Joshua Friedman.

| Application Number | 20200281705 16/416896 |

| Document ID | / |

| Family ID | 1000004081200 |

| Filed Date | 2020-09-10 |

| United States Patent Application | 20200281705 |

| Kind Code | A1 |

| Friedman; Joshua | September 10, 2020 |

RADIOMETRY SYSTEMS AND METHODS FOR DENTAL APPLICATIONS

Abstract

The present disclosure describes systems and methods for radiometry in dental applications. The disclosed systems include a radiometer, a dental curing light, a composite material reader module, and a restoration data storage device, where one or more of the radiometer, dental curing light, composite material reader module, and restoration data storage device include one or more communication modules that enable wireless communication between one or more of the radiometer, curing light, composite material reader module, and restoration data storage device. In some preferred embodiments, the radiometer includes at least one communication module and the curing light includes at least one communication module. In such embodiments, the communication modules may be used to transmit information between the radiometer and the curing light, and between one or more of the radiometer and curing light and one or more of the composite material reader module and restoration data storage device.

| Inventors: | Friedman; Joshua; (Ridgefield, CT) | ||||||||||

| Applicant: |

|

||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Assignee: | AdDent, Inc. Danbury CT |

||||||||||

| Family ID: | 1000004081200 | ||||||||||

| Appl. No.: | 16/416896 | ||||||||||

| Filed: | May 20, 2019 |

Related U.S. Patent Documents

| Application Number | Filing Date | Patent Number | ||

|---|---|---|---|---|

| 62815879 | Mar 8, 2019 | |||

| Current U.S. Class: | 1/1 |

| Current CPC Class: | A61C 19/003 20130101; A61C 19/04 20130101; A61B 90/06 20160201 |

| International Class: | A61C 13/15 20060101 A61C013/15; A61C 19/04 20060101 A61C019/04 |

Claims

1. A radiometry system for use in dental applications comprising: a. a radiometer comprising a detector cell, a microprocessor, a memory module, and a first set of one or more communication modules; b. a curing light that is used to generate light and that includes a second set of one or more communication modules; c. a composite material reader module that includes a third set of one or more communication modules; and d. a restoration data storage device that includes a fourth set of one or more communication modules; wherein the microprocessor is configured to record information for storage on the memory module; wherein the intensity of the light generated by the curing light is not controlled by the radiometer; and wherein the radiometer is programmed to determine the change in a rate of cure of a light-curable composite material and thereby determine whether an optimum cure time has been reached for the light-curable composite material.

2. The system of claim 1 wherein the first set of one or more communications modules, the second set of one or more communication modules, the third set of one or more communication modules, and the fourth set of one or more communication modules are configured to transmit and receive information to and from the radiometer, the curing light, the composite material reader module, and the restoration data storage device.

3. The system of claim 2 wherein the third set of one or more communication modules is configured to transmit a first set of information obtained from a package or container that contains a light-curable composite material.

4-18. (canceled)

19. A method of curing a light-curable composite material used in a dental restoration comprising using the system of claim 1.

20. A method of curing a light-curable composite material used in a dental restoration comprising using the system of claim 1.

21. The system of claim 3 wherein the radiometer is programmed to send a signal to the curing light when the optimum cure time has been reached and the curing light is programmed to automatically turn off immediately upon receipt of said signal.

22. The system of claim 21 wherein the composite material reader module includes a component that is configured to obtain the first set of information from a package or container that contains a composite material.

23. The system of claim 22 wherein the composite material reader module includes a component that is selected from the group consisting of a bar code reader, a QR code reader, and an NFC tag reader.

24. The system of claim 22 wherein the composite material reader module includes at least one optical scanner.

25. The system of claim 22 wherein the first, second, third, and fourth sets of one or more communication modules are each selected from the group consisting of Bluetooth, Wi-Fi, and ZigBee modules.

26-30. (canceled)

31. A radiometry system for use in dental applications comprising: a. a radiometer comprising a detector cell, a microprocessor, and a memory module; b. a curing light that is used to generate light; c. a composite material reader module; and d. a restoration data storage device; wherein each of the radiometer, curing light, composite material reader module, and restoration data storage device is configured to wirelessly transmit or receive information via Bluetooth, Wi-Fi, or ZigBee; wherein the microprocessor is configured to record information for storage on the memory module; wherein the intensity of the light generated by the curing light is not controlled by the radiometer; and wherein the radiometer is programmed to determine the change in a rate of cure of a light-curable composite material and thereby determine whether an optimum cure time has been reached for the light-curable composite material.

32. The system of claim 31 wherein the information includes a first set of information obtained from a package or container that contains a light-curable composite material.

33. The system of claim 32 wherein the radiometer is programmed to send a signal to the curing light when the optimum cure time has been reached and the curing light is programmed to automatically turn off immediately upon receipt of said signal.

34. The system of claim 33 wherein the composite material reader module includes a component that is configured to obtain the first set of information from a package or container that contains a composite material.

35. The system of claim 34 wherein the composite material reader module includes a component that is selected from the group consisting of a bar code reader, a QR code reader, and an NFC tag reader.

36. The system of claim 34 wherein the composite material reader module includes at least one optical scanner.

37. The system of claim 34, wherein the composite material reader module determines and wirelessly transmits the first set of information, and wherein the first set of information includes one or more of: a. a depth of the restoration; and b. a curing time.

38. The system of claim 37, wherein the composite material reader module determines and wirelessly transmits the first set of information, and wherein the first set of information further includes one or more of: c. a type of material; d. a manufacturer of the material; e. a serial number of the material; f. a lot code number of the material; g. a use-by date or expiration date of the material; and h. specification information for the material.

39. The system of claim 38 wherein the restoration data storage device is configured to obtain a second set of information, wherein the second set of information includes one or more of: i. a name of a patient; and j. a date of placement of a restoration.

Description

CROSS-REFERENCE TO RELATED APPLICATIONS

[0001] This application claims priority to U.S. Provisional Patent Application Ser. No. 62/815,879, filed on Mar. 8, 2019, the disclosure of which is incorporated herein in its entirety by reference.

BACKGROUND

Field of the Invention

[0002] The present disclosure relates to radiometers and curing lights for use in dental applications.

Description of the Related Art

[0003] Dental curing lights have been used for over three decades to polymerize composite materials for use as dental fillings. A dental clinician places an unpolymerized composite material in a patient's mouth and configures it according to clinical needs, and then subsequently rapidly polymerizes the material using the curing light so that it becomes a rigid dental filling. The basic types of dental curing light sources are tungsten halogen, light-emitting diode (LED), plasma arc, and laser.

[0004] The use of a radiometer in combination with a curing light allows a dental clinician to measure the light output of the curing light. A number of factors determine the degree of polymerization, including (1) the intensity of the curing light, (2) the depth of the restoration, (3) the shade of the composite material, (4) the type of filler and the chemistry of the composite material, (5) the age of the material, and (6) the wavelength of the light applied for curing.

[0005] U.S. Pat. No. 7,175,436 to Friedman ("the '436 patent") discloses a radiometer and a method for providing an indication of the amount of time needed to cause a light-curable dental resin composite material to optimally polymerize in response to the application of light from any light-curing source during the preparation of a dental restoration. However, the '436 patent does not include a component for communication between the radiometer and curing light used therewith or a method for electronically tracking information regarding the restorative material used to treat a specific patient.

[0006] Thus there remains a need for a dental radiometry system that includes a component for communication between a radiometer and a curing light used therewith and that allows electronic transmission of information related to the restorative material used in a given restoration.

SUMMARY

[0007] The present disclosure describes systems and methods for radiometry in dental applications. The disclosed systems comprise a radiometer, a dental curing light, a composite material reader module, and a restoration data storage device, where one or more of the radiometer, dental curing light, composite material reader module, and restoration data storage device comprise one or more communication modules that enable wireless communication between one or more of the radiometer, curing light, composite material reader module, and restoration data storage device. The one or more communication modules may comprise one or more Bluetooth, Wi-Fi, ZigBee, or other radio frequency-based modules. In alternative embodiments, the one or more communication modules may comprise one or more infrared or other optically-based modules. In some preferred embodiments, the radiometer comprises at least one communication module and the curing light also comprises at least one communication module. In such embodiments, the communication modules may be used to transmit information between the radiometer and the curing light, and between one or more of the radiometer and curing light and one or more of the composite material reader module and restoration data storage device. In some embodiments, additional communication modules may also act to relay signals between other communication modules, such as to extend the range of communication, or to convert transmissions between different formats, such as Wi-Fi to Bluetooth or ZigBee to infrared.

[0008] In some embodiments, the disclosed systems may further comprise a composite material reader module. The composite material reader module may comprise a bar code reader, QR code reader, NFC tag reader, or any other similar device. The composite material reader module may allow a user to obtain information from a package or container of a composite material that is labeled with a readable code, chip, mark, or tag such as by a bar code, QR code, or NFC tag. In some alternative embodiments, the composite material reader module may compromise an image scanner that can detect text or images to obtain information from a label associated with a package or container of a composite material.

[0009] In some embodiments, the disclosed systems may further comprise a restoration data storage device. In some embodiments, the restoration data storage device may comprise a computer configured to receive information from the radiometer. The restoration data storage device may preferably comprise one or more communication modules that are configured to wirelessly communicate with at least the communication module of the radiometer. The restoration data storage device communication modules may comprise one or more Bluetooth, Wi-Fi, ZigBee, or other radio frequency-based modules. In alternative embodiments, the one or more restoration data storage device communication modules may comprise one or more radio frequency, infrared, or other optically-based modules.

[0010] Methods of using the disclosed systems to optimally cure a light-curable composite material are also disclosed herein.

BRIEF DESCRIPTION OF THE DRAWINGS

[0011] FIG. 1 shows a block diagram of an embodiment of the disclosed systems.

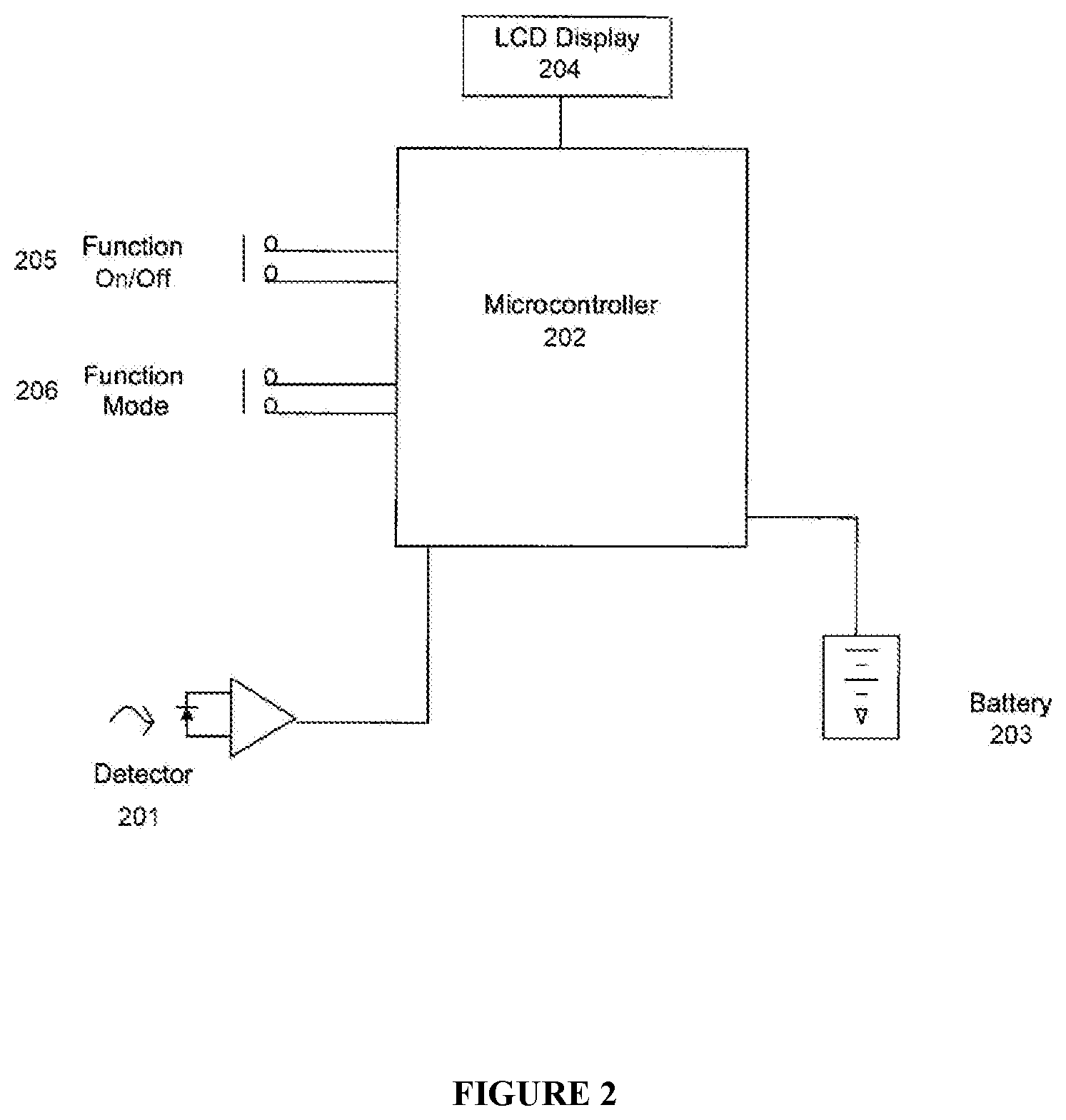

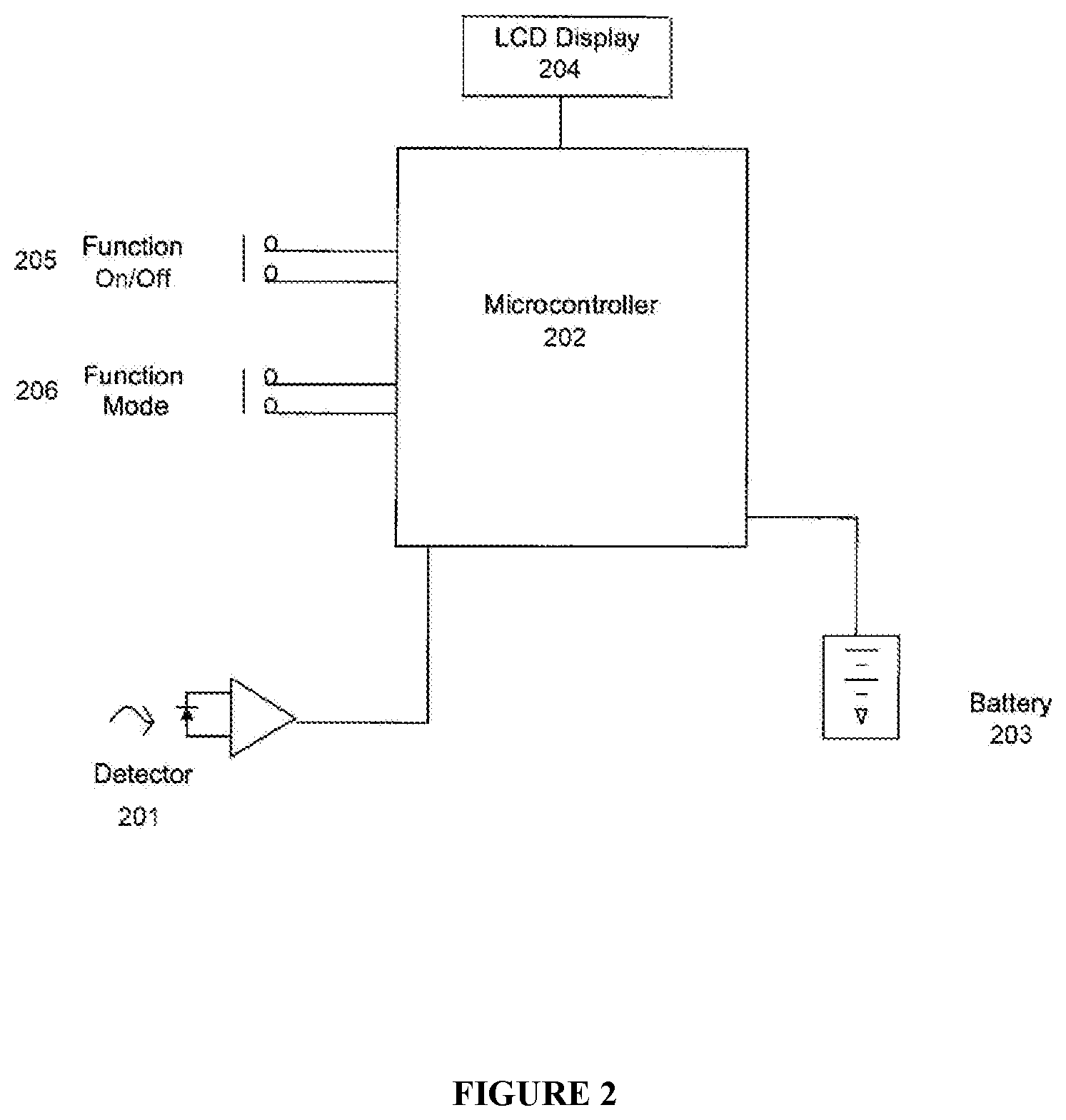

[0012] FIG. 2 shows a block diagram of an embodiment of the radiometer used in the disclosed systems.

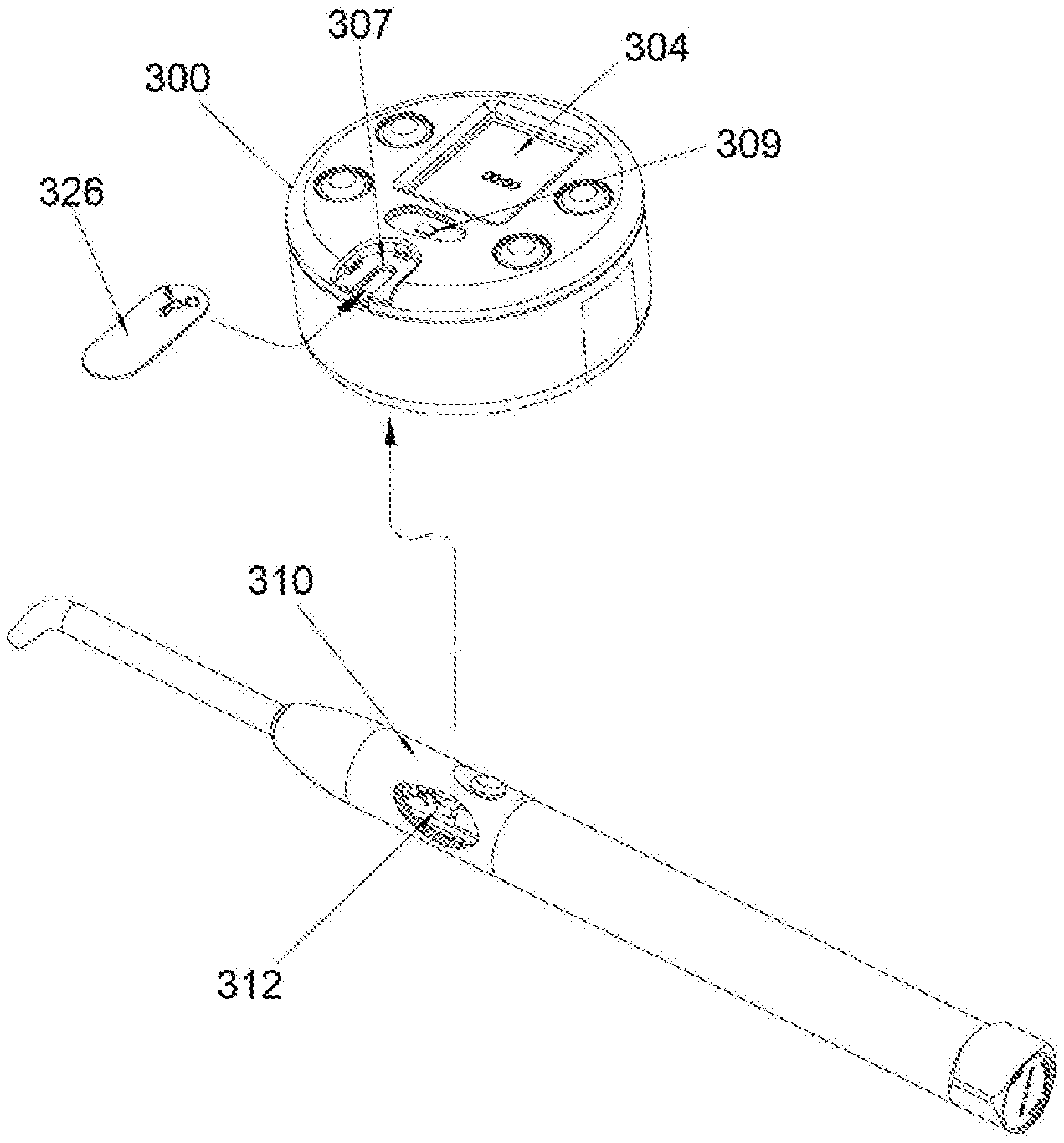

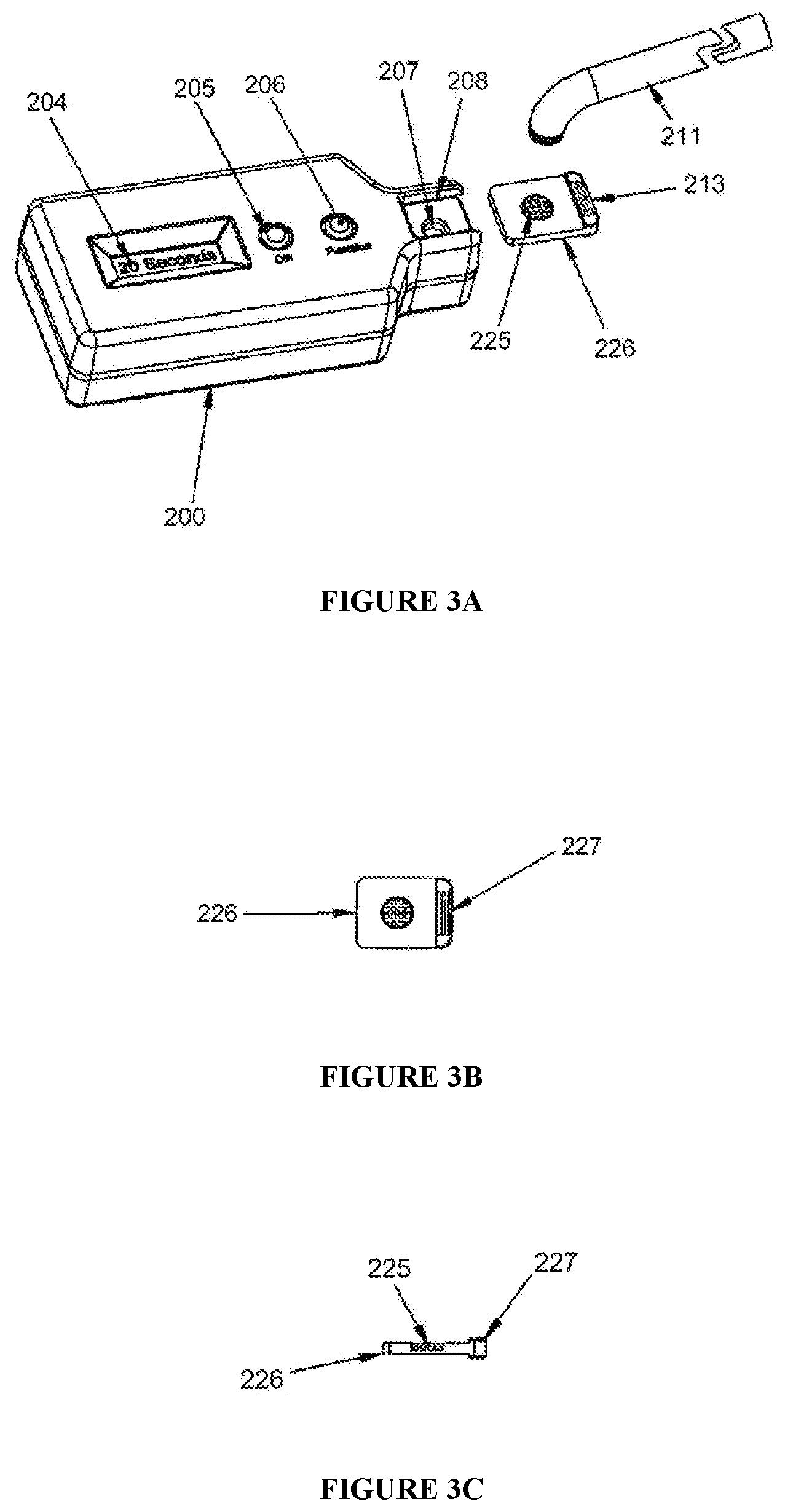

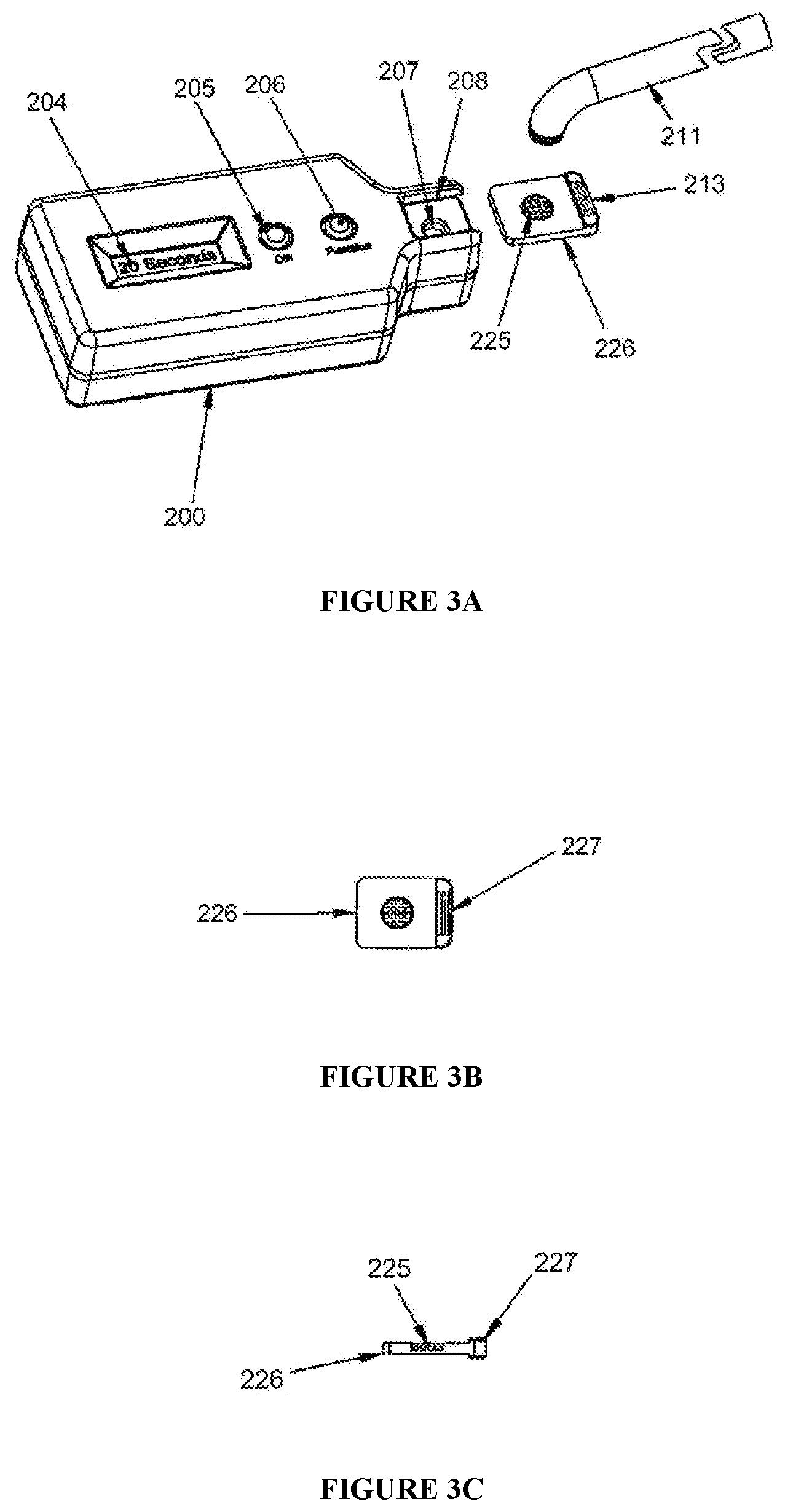

[0013] FIG. 3a shows a housing assembly of an embodiment of the radiometer used in the disclosed systems, wherein a sample holder for holding a test sample of light-curable material is shown separated from the radiometer adjacent to a light guide for a standard light source.

[0014] FIG. 3b shows a view of the sample holder shown in FIG. 3a.

[0015] FIG. 3c shows another view of the sample holder shown in FIG. 3a.

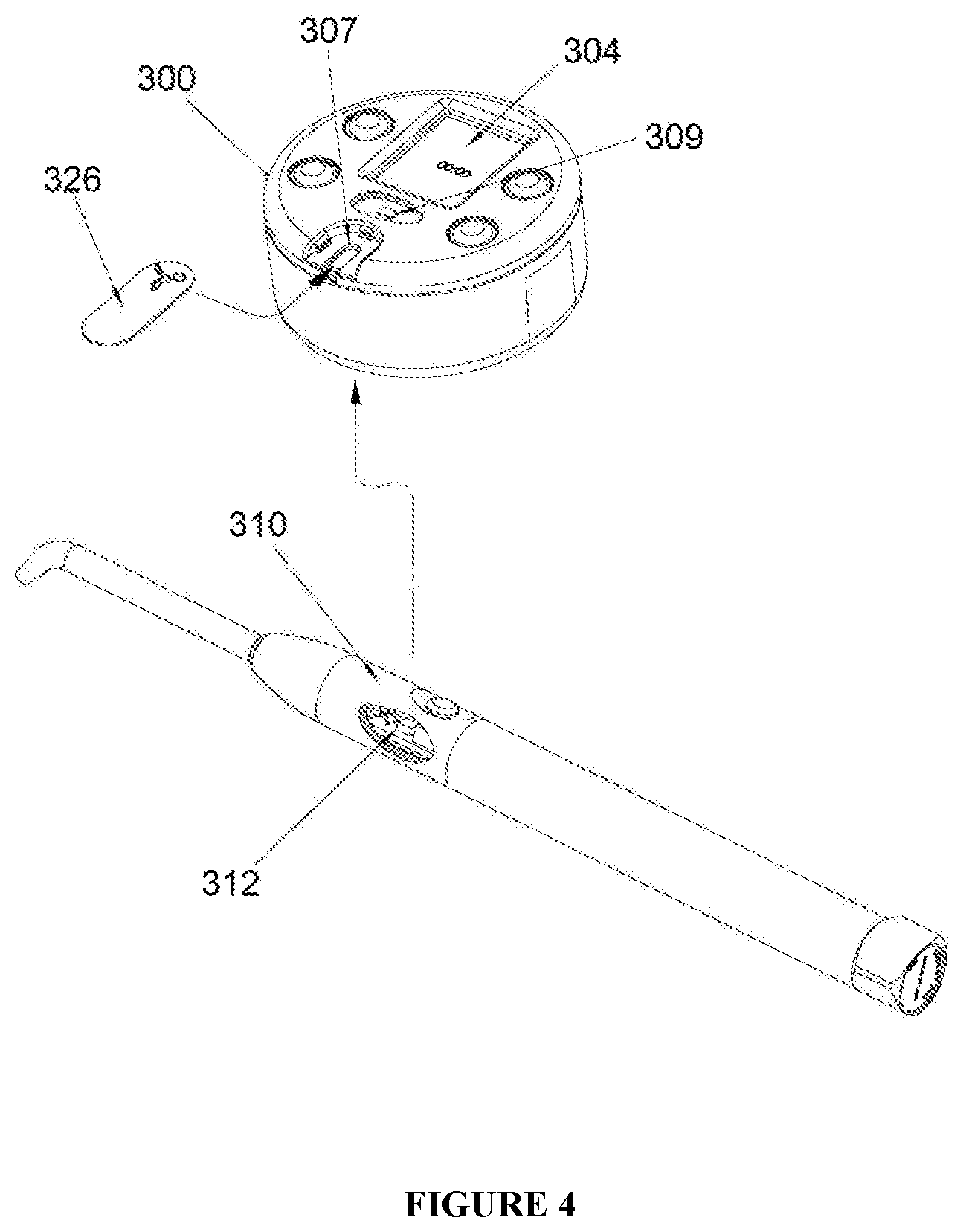

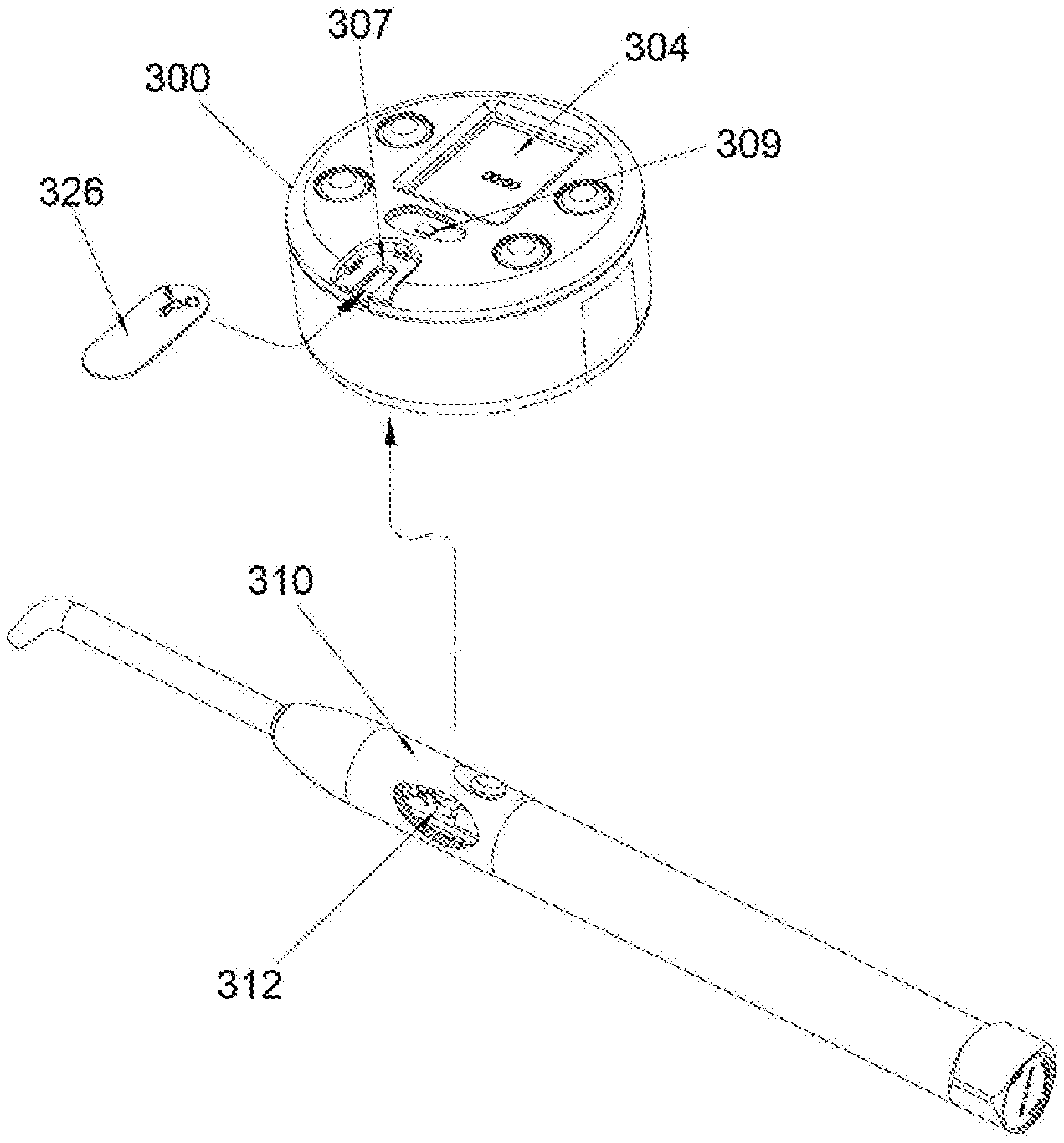

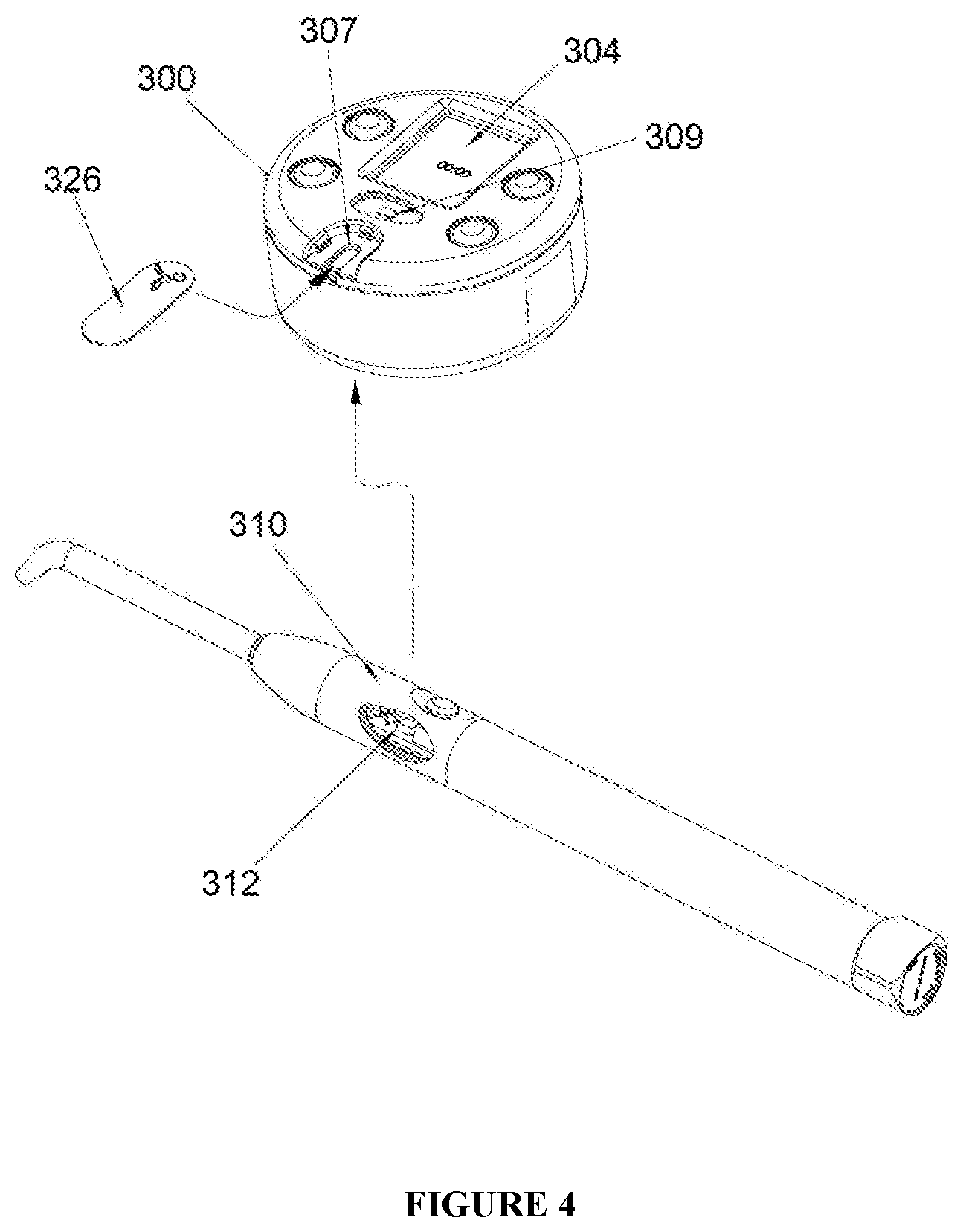

[0016] FIG. 4 shows an embodiment of the radiometer and curing light used in the disclosed systems.

DETAILED DESCRIPTION OF THE ILLUSTRATED EMBODIMENTS

[0017] The present disclosure describes systems and methods for radiometry in dental applications. The disclosed systems comprise a radiometer, a dental curing light, a composite material reader module, and a restoration data storage device, where one or more of the radiometer, dental curing light, composite material reader module, and restoration data storage device comprise one or more communication modules that enable wireless communication between one or more of the radiometer, curing light, composite material reader module, and restoration data storage device. The one or more communication modules may comprise one or more Bluetooth, Wi-Fi, ZigBee, or other radio frequency-based modules. In alternative embodiments, the one or more communication modules may comprise one or more infrared or other optically-based modules. In some preferred embodiments, the radiometer comprises at least one communication module and the curing light also comprises at least one communication module. In such embodiments, the communication modules may be used to transmit information between the radiometer and the curing light, and between one or more of the radiometer and curing light and one or more of the composite material reader module and restoration data storage device. In some embodiments, additional communication modules may also act to relay signals between other communication modules, such as to extend the range of communication, or to convert transmissions between different formats, such as Wi-Fi to Bluetooth or ZigBee to infrared.

[0018] In some embodiments, the radiometer may further comprise a microprocessor and a memory module, where the microprocessor is configured to record information for storage on the memory module. In such embodiments, the one or more communication modules of the radiometer are preferably configured to obtain information stored on the memory module and wirelessly transmit said information.

[0019] In some embodiments, the disclosed systems may further comprise a composite material reader module. The composite material reader module may comprise a bar code reader, QR code reader, NFC tag reader, or any other similar device. The composite material reader module may allow a user to obtain information from a package or container of a composite material that is labeled with a readable code, chip, mark, or tag such as by a bar code, QR code, or NFC tag. In some alternative embodiments, the composite material reader module may compromise an image scanner that can detect text or images to obtain information from a label associated with a package or container of a composite material.

[0020] In some embodiments, the disclosed systems may further comprise a restoration data storage device. In some embodiments, the restoration data storage device may comprise a computer configured to receive information from the radiometer. The restoration data storage device may preferably comprise one or more communication modules that are configured to wirelessly communicate with at least the communication module that is attached to the radiometer. The restoration data storage device communication modules may comprise one or more Bluetooth, Wi-Fi, ZigBee, or other radio frequency-based modules. In alternative embodiments, the one or more restoration data storage device communication modules may comprise one or more infrared or other optically-based modules.

[0021] Methods of using the disclosed systems to optimally cure a light-curable composite material are also disclosed herein.

[0022] FIG. 1 shows a block diagram of an embodiment of the disclosed systems. The embodiment shown in FIG. 1 comprises a radiometer 100, a curing light 110, a composite material reader module 120, and a computer 130, where each component comprises one or more communication modules (not shown) configured to transmit information between the components. A package of composite material 125 may have information stored on a readable code, chip, mark, or tag such as a bar code, QR code, or NFC tag. The composite material reader module 120 is configured to obtain information from the package of composite material 125 and is also configured to transmit information to the radiometer 100. The radiometer 100 is configured to transmit information to the curing light 110 and to the computer 130. The computer 130 may optionally store information received from the radiometer 100 in a patient records database 135.

Radiometer

[0023] In some preferred embodiments, the disclosed systems may comprise a radiometer disclosed in U.S. Pat. No. 7,175,436 to Friedman ("the '436 patent") or a similar radiometer that includes additional features or removes features as needed for optimum use in the disclosed systems. An embodiment of the radiometer 200 is shown in FIGS. 2, 3, and 4.

[0024] FIG. 2 represents a block diagram of the internal electronic components of the radiometer 200. Accordingly, the radiometer 200 comprises a detector cell 201 for providing either an output voltage or a change in electrical resistance in direct response to the degree of light exposure. The detector cell 201 may comprise a light sensor such as a silicon, CMOS, or selenium detector cell or another light sensor. In addition, the radiometer 200 further comprises a microcontroller (microprocessor) 202, a battery 203, a display 204, an on/off function switch 205, and a mode switch 206. The display 204 may preferably be an LCD display. The mode switch 206 may be used to toggle between different modes of use of the radiometer 200. In some embodiments, the radiometer may be used in an "Optical Conversion" mode, a "Power" mode, an "Energy" mode, or a "Calibration" mode. When Optical Conversion mode is selected, the display 204 may provide a time display output that indicates the shortest exposure time to provide optimal composite cure for a sample of uncured composite using any type of light source.

[0025] FIG. 3a shows a housing assembly of an embodiment of the radiometer used in the disclosed systems, wherein a sample holder for holding a test sample of light-curable material is shown separated from the radiometer adjacent to a light guide for a standard light source. FIGS. 3b and 3c show views of the sample holder shown in FIG. 3a.

[0026] In Optical Conversion mode, a light curing source (not shown) with a light guide 211 may be used to cure a sample of an uncured light-curable composite material 225 as described below. A sample of uncured light-curable composite material 225 is placed in a sample holder 226 of appropriate thickness for a given restoration. The sample holder 226 may have a thickness that corresponds to a typical required depth of a dental restoration, and thus by varying the thickness of the sample holder 226, the thickness of the sample 225 may be adjusted. The sample 225 is held by a grip detail 227, as shown in FIG. 3c, and is inserted along a groove or track 208, as shown in FIG. 3a, so that the sample sits directly over the detector window 207 of the light sensor. The light guide 211 is placed over the sample aligned with the detector window 207 so that light may be transmitted through the sample 225. Optical Conversion mode is then selected using the mode switch 206. The display 204 displays the time needed to maximally cure the composite, i.e., curing will be stopped when the display shows a time corresponding to the exposure duration needed to achieve the composite cure for the sample composite that represents a time when the sample is cured in accordance with the algorithm used in programming the microcontroller 202. The microcontroller 202 may be programmed using an algorithm such as the algorithm disclosed in the '436 patent. The extent of curing of the composite material may be 80-99.5% of the maximum possible cure value. For most composite resin materials, the extent of composite cure will plateau at 45-70% of the maximum cure value (100%) for the material. The sampling rate used by the microcontroller 202 may preferably be less than or equal to 0.1 Hz.

[0027] In Power mode, the radiometer 200 measures the curing light output intensity. The intensity may preferably be displayed in W/cm.sup.2 or mW/cm.sup.2. The display 204 may preferably be programmed to update the displayed output intensity as long as the mode switch 206 is activated. The mode switch 206 may, for example, be activated when a push button is depressed. When the mode switch 206 is deactivated, such as by releasing a push button, the radiometer will continue to measure the curing light output intensity but the display will correspond only to the peak measurements. This mode of using a radiometer is also termed "irradiance" in various references.

[0028] In Energy mode, the accumulated energy delivered to a composite material may be measured. The measurement may preferably be displayed in J or mJ. Activating the mode switch 206 may reset the measurement.

[0029] In Calibration mode, the radiometer may be calibrated using a standard light source and a calibration filter that has the same or nearly the same optical transmission characteristics as a fully cured dental composite material. The calibration filter may preferably comprise a polymer material. The exposure time displayed may then be compared using the calibration filter and the light unit being tested. The microcontroller may be programmed to adjust the offset if a given sequence of switches is activated simultaneously or serially.

[0030] The on/off function switch 205 may be used to turn on the radiometer 200. In some embodiments, the radiometer 200 may be programmed to automatically turn off or enter a low power state if it is unused for a specified period of time.

[0031] The display 204 may display real-time light intensity (power density), accumulated light energy delivered, or recommended exposure time depending on the mode of operation. The display 204 may preferably be an LCD display.

[0032] In some embodiments, the light sensor may be a solid-state photo detector.

[0033] The radiometer may preferably be battery-operated.

[0034] FIG. 3b shows a view of the sample holder 226 shown in FIG. 3a, including the grip detail 227.

[0035] FIG. 3c shows another view of the sample holder 226 shown in FIG. 3a, including the grip detail 227 and the sample 225 loaded therein.

[0036] FIG. 4 shows an embodiment of a radiometer 300 and curing light 310 used in the disclosed systems. A clinician inserts a sample of composite material into a sample holder 326. In some embodiments, the sample holder 326 may preferably have a depth of 2, 4, or 6 mm to accommodate dental restorations of various desired depths. The sample holder 326 is inserted into an optical reader port 307 of the radiometer 300. Using the same curing light and composite material to be used in the restoration procedure, the clinician polymerizes the sample composite material. As polymerization occurs, the minimum optimal cure time is determined by the radiometer as described in the '436 patent. The time is displayed on the display 304. The communication module 309 enables transmission of the optimal cure time information from the radiometer to the curing light, and transmission of this and other information between the radiometer and other components of the system. The communication module 309 preferably includes an on-board memory module with sufficient memory to store the information that will be transmitted from the radiometer to other components of the system. In some embodiments, the radiometer may be programmed to send a signal to the curing light when the optimum cure time has been reached and the curing light may be programmed to automatically turn off immediately upon receipt of said signal.

Curing Light

[0037] The disclosed systems further comprise a dental curing light. The dental curing light may be used to cure a light-curable composite material. The curing light may preferably comprise a light guide. The curing light comprises at least one communication module that allows transmission of information from the radiometer to the curing light.

[0038] FIG. 4 shows an embodiment of a curing light 310 used in the disclosed systems, including a communication module 312. The communication module may be configured to receive information from the radiometer regarding the optimum cure time for the composite material being used in a given restoration. In some embodiments, the curing light may be programmed to automatically turn off once the optimum cure time has been reached.

[0039] In some embodiments, the radiometer may be programmed to send a signal to the curing light when the optimum cure time has been reached, and the curing light may be programmed to automatically turn off immediately upon receipt of said signal.

Communication Modules

[0040] One or more components of the disclosed systems, namely the radiometer, curing light, composite material reader module, and restoration data storage device, comprise one or more communication modules that enable wireless communication between the radiometer, curing light, composite material reader module, and restoration data storage device. The one or more communication modules may comprise one or more Bluetooth, Wi-Fi, ZigBee, or other radio frequency-based modules. In alternative embodiments, the one or more communication modules may comprise one or more infrared or other optically-based modules. Each of the one or more communication modules preferably includes an on-board memory module with sufficient memory to store the information that may be transmitted between the communication module and other communication modules or other components of the system, including both information that will be transmitted by the communication module and information that will be received by the communication module. In some preferred embodiments, the radiometer comprises at least one communication module and the curing light also comprises at least one communication module. In such embodiments, the communication modules may be used to transmit information between the radiometer and the curing light, and between one or more of the radiometer and curing light and one or more of the composite material reader module and restoration data storage device described below. In some embodiments, additional communication modules may also act to relay signals between other communication modules, such as to extend the range of communication, or to convert transmissions between different formats, such as Wi-Fi to Bluetooth or ZigBee to infrared.

[0041] In some embodiments, the minimum amount of time required to optimally cure an uncured light-curable composite material may be wirelessly transmitted from the radiometer to the curing light using the communication modules of the radiometer and curing light respectively. The curing light may preferably be configured to automatically turn off at the time at which the light-curable composite material in use has been optimally cured. In other embodiments, a visual or audio signal, such as a flickering LED or a musical chime, may be used to indicate when the light-curable composite material in use has been optimally cured. The optimal curing time may be determined by the change in the rate of cure, which depends on factors such as (1) the intensity of the curing light, (2) the depth of the restoration, (3) the shade of the composite material, (4) the type of filler and the chemistry of the composite material, (5) the age of the material, and (6) the wavelength of the light applied for curing.

Composite Material Reader Module

[0042] In some embodiments, the disclosed systems may further comprise a composite material reader module. The composite material reader module may comprise a bar code reader, QR code reader, NFC tag reader, or any other similar device. The composite material reader module may allow a user to obtain information from a package or container of a light-curable composite material that is labeled with a readable code, chip, mark, or tag such as by a bar code, QR code, or NFC tag. In some alternative embodiments, the composite material reader module may compromise an image scanner that can detect text or images to obtain information from a label associated with a specific package or container of a composite material.

[0043] In some embodiments, information that may be provided on the readable code, chip, mark, or tag of a package or container of a light-curable composite material may include the type of material, manufacturer, serial number, lot code number, use-by date or expiration date, and specification information for the material such as the shade of the material and other relevant information.

[0044] The composite material reader module may preferably comprise one or more communication modules. The one or more composite material reader module communication modules may comprise one or more Bluetooth, Wi-Fi, ZigBee, or other radio frequency-based modules. In alternative embodiments, the one or more composite material reader module communication modules may comprise one or more infrared or other optically-based modules in some embodiments, the one or more composite material reader module communication modules may transmit data to the radiometer. In alternate embodiments, the one or more composite material reader module communication modules may transmit data directly to the restoration data storage device described below.

[0045] Information transmitted from the one or more composite material reader module communication modules to the one or more radiometer communication modules or restoration data storage device communication modules described below may include the type of material, manufacturer, serial number, lot code number, use-by date or expiration date, and specification information for the material such as the shade of the material and other relevant information.

[0046] In some embodiments, the composite material reader module may preferably be a digital scanner.

Restoration Data Storage Device

[0047] The disclosed systems may further comprise a restoration data storage device. In some embodiments, the restoration data storage device may comprise a computer configured to receive data from the radiometer. The restoration data storage device may preferably comprise one or more communication modules that are configured to wirelessly communicate with at least the communication module of the radiometer. The one or more restoration data storage device communication modules may comprise one or more Bluetooth, Wi-Fi, ZigBee, or other radio frequency-based modules. In alternative embodiments, the one or more restoration data storage device communication modules may comprise one or more infrared or other optically-based modules.

[0048] Information transmitted from the one or more radiometer communication modules to the one or more restoration data storage device communication modules may include the depth of the restoration and the curing time.

[0049] Information transmitted from the one or more composite material reader module communication modules to the one or more restoration data storage device communication modules may include the type of material, manufacturer, serial number, lot code number, use-by date or expiration date, and specification information for the material such as the shade of the material and other relevant information. In some embodiments, this information may be transmitted from the one or more composite material reader module communication modules to the one or more radiometer communication modules and then from the one or more radiometer communication modules to the one or more restoration data storage device communication modules. In alternate embodiments, this information may be transmitted directly from the one or more composite material reader module communication modules to the one or more restoration data storage device communication modules.

[0050] Additional information recorded by the restoration data storage device may include the name of the patient and the date of placement of the restoration.

Advantages of Using Disclosed Systems

[0051] Wireless transmission of data using the disclosed systems provides numerous advantages for clinicians performing dental restorations. Wireless transmission of data reduces or eliminates the possibility of human error in recording the appropriate curing time or other relevant information. It allows dental clinicians to focus on patient treatment rather than data recordation. In addition, in the event of a future issue with a dental restoration such as breakage, discoloration, unusual wear, or an allergic reaction, a dental clinician would be able to access specific details regarding the restoration, including the type of material used, that would inform decisions regarding resolution of the issue. Moreover, by providing manufacturers of composite materials with information regarding the specific successes and failures of specific restorations, manufacturers will be better informed and able to reach more accurate and specific conclusions regarding issues such as whether a particular lot of material was defective or whether a particular use-by date is appropriate for a given composite material. In addition, a manufacturer would be able to communicate information regarding a defective batch or lot of material and clinicians would be able to identify necessary remedial measures on a patient-by-patient basis.

[0052] Wireless transmission of data using the disclosed systems may also be used to allow a computer to update and adapt a radiometer, a curing light, or a composite material reader module to operate within the disclosed systems. For example, a firmware upgrade may be pushed out by a computer. As another example, a computer may send instructions to a curing light restricting operation of the curing light to prevent a user from damaging a selected composite material. As yet another example, the curing light output may be monitored or controlled using a handheld computer, such as a smartphone or tablet.

[0053] The previous description of the disclosed embodiments is provided to enable any person skilled in the art to make or use the invention disclosed herein. Various modifications to these embodiments will be readily apparent to those skilled in the art, and the generic principles defined herein may be applied to other embodiments without departing from the spirit or scope of the disclosure. The examples are intended to be merely illustrative and are not intended to limit or otherwise restrict the invention. Thus, the present disclosure is not intended to be limited to the embodiments shown herein but is to be accorded the widest scope consistent with the principles and novel features disclosed herein.

[0054] All references cited herein are expressly incorporated by reference.

* * * * *

D00000

D00001

D00002

D00003

D00004

XML

uspto.report is an independent third-party trademark research tool that is not affiliated, endorsed, or sponsored by the United States Patent and Trademark Office (USPTO) or any other governmental organization. The information provided by uspto.report is based on publicly available data at the time of writing and is intended for informational purposes only.

While we strive to provide accurate and up-to-date information, we do not guarantee the accuracy, completeness, reliability, or suitability of the information displayed on this site. The use of this site is at your own risk. Any reliance you place on such information is therefore strictly at your own risk.

All official trademark data, including owner information, should be verified by visiting the official USPTO website at www.uspto.gov. This site is not intended to replace professional legal advice and should not be used as a substitute for consulting with a legal professional who is knowledgeable about trademark law.