Exhaust System As Well As Motor Vehicle With An Exhaust System

A1

U.S. patent application number 16/642460 was filed with the patent office on 2020-08-13 for exhaust system as well as motor vehicle with an exhaust system. The applicant listed for this patent is Faurecia Emissions Control Technologies, Germany GmbH. Invention is credited to Marianne BOUDOY, Aurelie Demont, M. Romaine Joly, Stephane Nezan, Hannes STEINKILBERG.

| Application Number | 20200256227 16/642460 |

| Document ID | 20200256227 / US20200256227 |

| Family ID | 1000004826280 |

| Filed Date | 2020-08-13 |

| Patent Application | download [pdf] |

| United States Patent Application | 20200256227 |

| Kind Code | A1 |

| STEINKILBERG; Hannes ; et al. | August 13, 2020 |

EXHAUST SYSTEM AS WELL AS MOTOR VEHICLE WITH AN EXHAUST SYSTEM

Abstract

An exhaust system for an internal combustion engine of a motor vehicle includes a single exhaust-gas inlet line, two exhaust-gas outlet lines connected in an exhaust gas-conducting manner to the exhaust-gas inlet line, and an active silencing device. The active silencing device is connected in a sound-conducting manner to the two exhaust-gas outlet lines. Furthermore, a motor vehicle with such an exhaust system is provided.

| Inventors: | STEINKILBERG; Hannes; (Augsburg, DE) ; BOUDOY; Marianne; (Montbeliard, FR) ; Joly; M. Romaine; (Arcey, FR) ; Demont; Aurelie; (Montenois, FR) ; Nezan; Stephane; (Etupes, FR) | ||||||||||

| Applicant: |

|

||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Family ID: | 1000004826280 | ||||||||||

| Appl. No.: | 16/642460 | ||||||||||

| Filed: | August 31, 2017 | ||||||||||

| PCT Filed: | August 31, 2017 | ||||||||||

| PCT NO: | PCT/EP2017/071894 | ||||||||||

| 371 Date: | February 27, 2020 |

| Current U.S. Class: | 1/1 |

| Current CPC Class: | F01N 2470/18 20130101; F01N 2470/14 20130101; F01N 2470/02 20130101; F01N 1/04 20130101 |

| International Class: | F01N 1/04 20060101 F01N001/04 |

Claims

1. An exhaust system for an internal combustion engine of a motor vehicle comprising: a single exhaust-gas inlet line; two exhaust-gas outlet lines connected in an exhaust gas-conducting manner to the single exhaust-gas inlet line; and an active silencing device, which is connected in a sound-conducting manner to the two exhaust-gas outlet lines.

2. The exhaust system according to claim 1, wherein the single exhaust-gas inlet line is connected in an exhaust gas-conducting manner to the two exhaust-gas outlet lines via a passive silencer.

3. The exhaust system according to claim 2, wherein sections of the single exhaust-gas inlet line and/or of at least one of the two exhaust-gas outlet lines, run inside a silencer housing of the passive silencer.

4. The exhaust system according to claim 1, wherein the two exhaust-gas outlet lines form a T connection or a Y connection with the single exhaust-gas inlet line or an intermediate exhaust-gas line, wherein the intermediate exhaust-gas line is connected in an exhaust gas-conducting manner to both of the two exhaust-gas outlet lines and to the single exhaust-gas inlet line.

5. The exhaust system according to claim 1, wherein the two exhaust-gas outlet lines are formed by opposite sections of a common exhaust-gas outlet pipe.

6. The exhaust system according to claim 1, wherein the active silencing device is connected in a sound-conducting manner to the two exhaust-gas outlet lines via a sound coupling-in line, wherein the sound coupling-in line surrounds exhaust-gas inlet-facing ends of the two exhaust-gas outlet lines on an outside and runs substantially concentric to the exhaust-gas inlet-facing ends of the two exhaust-gas outlet lines.

7. The exhaust system according to claim 6, wherein the single exhaust-gas inlet line is connected in an exhaust gas-conducting manner to the two exhaust-gas outlet lines via a passive silencer, and wherein the sound coupling-in line runs at least partly inside a silencer housing of the passive silencer.

8. The exhaust system according to claim 6, wherein the single exhaust gas inlet line passes through a wall of the sound coupling-in line, or wherein an intermediate exhaust-gas line is connected in an exhaust gas-conducting manner to both of the two exhaust-gas outlet lines and to the single exhaust-gas inlet line, and wherein the intermediate exhaust-gas line passes through a wall of the sound coupling-in line.

9. The exhaust system according to claim 6, wherein at least one of the two exhaust-gas outlet lines, comprises a perforated section in an area surrounded by the sound coupling-in line.

10. The exhaust system according to claim 9, wherein both of the two exhaust-gas outlet lines comprise perforated sections and the perforated sections are arranged on opposite sides of the single exhaust-gas inlet line, or wherein an intermediate exhaust-gas line is connected in an exhaust gas-conducting manner to both of the two exhaust-gas outlet lines and to the single exhaust-gas inlet line, and wherein both of the two exhaust-gas outlet lines comprise perforated sections and the perforated sections are arranged on opposite sides of the intermediate exhaust-gas line.

11. The exhaust system according to claim 6, wherein the active silencing device is connected in a sound-conducting manner to the sound coupling-in line via a sound line.

12. The exhaust system according to claim 11, wherein the single exhaust-gas inlet line is connected in an exhaust gas-conducting manner to the two exhaust-gas outlet lines via a passive silencer, and wherein the sound line runs outside a silencer housing of the passive silencer.

13. The exhaust system according to claim 1, wherein the two exhaust-gas outlet lines are exhaust tail pipes.

14. The exhaust system according to claim 1, wherein the singe exhaust-gas inlet line has a substantially oval cross section at an exhaust-gas outlet-facing end.

15. A motor vehicle including the exhaust system according to claim 1.

16. The exhaust system according to claim 2, wherein sections of the single exhaust-gas inlet line, and/or both of the two exhaust-gas outlet lines, run inside a silencer housing of the passive silencer.

Description

CROSS-REFERENCE TO RELATED APPLICATIONS

[0001] This application is the US national phase of PCT/EP2017/071894, filed 2017 Aug. 31.

BACKGROUND

[0002] The invention relates to an exhaust system for an internal combustion engine of a motor vehicle.

[0003] In addition, the invention relates to a motor vehicle with an exhaust system.

[0004] Exhaust systems with one or more tail pipes are known from the state of the art, wherein a plurality of tail pipes are used when relatively large flow cross sections are to be provided for one exhaust gas flow. The external appearance of an associated motor vehicle can also be designed by means of the number of tail pipes. In this context, particularly sporty motor vehicles often have two or more tail pipes, for example.

[0005] Exhaust systems with more than one exhaust tail pipe are also referred to as multi-flow.

[0006] Moreover, it is known from the state of the art to equip exhaust systems with active silencing devices in order to muffle noises emitted by the exhaust system to the surroundings, or ideally to eliminate them completely.

[0007] For this, the active silencing devices usually comprise a loudspeaker, with the aid of which they generate sound which is superimposed on the sound carried by the exhaust gas flow. The superposition is ideally effected destructively, i.e. it is sought to superimpose the sound generated by the loudspeaker out of phase on the sound carried by the exhaust gas flow.

[0008] Multi-flow exhaust systems which are equipped with active silencing devices are known, for example, from DE 100 85 230 B3, EP 2 915 967 A1 and DE 10 2012 200 712 A1. Each exhaust gas tract is allocated an active silencing device. As a result, such exhaust systems have a complex construction with respect to the silencing devices and are thus relatively expensive.

[0009] In addition, multi-flow exhaust systems are known, which have several exhaust-gas inlet lines. Such exhaust systems therefore have several exhaust gas inlets and several exhaust gas outlets. Such exhaust systems are used in particular in connection with internal combustion engines, the cylinders of which are arranged in a V formation. Then, one exhaust-gas inlet line is connected in an exhaust gas-routing manner to the cylinders of a first cylinder bank and another exhaust-gas inlet line is connected in an exhaust gas-routing manner to the cylinders of a second cylinder bank. Such exhaust systems can also be equipped with a silencing device, as can be learned from EP 2 818 654 A1 or EP 0 481 450 A1, for example. Here, the active silencing devices act on the exhaust gas routed in both tail pipes. Such exhaust systems have a complex construction in particular because of the two exhaust-gas inlet lines. In addition, they are not very suitable for use in connection with in-line engines.

SUMMARY

[0010] The subject disclosure provides an improved exhaust system which is multi-flow with respect to the exhaust gas outlets and comprises an active silencing device. The exhaust system should be as simple in construction and in production as possible. In addition, an effective muffling of the sound emitted via the exhaust gas flow to the surroundings should be guaranteed for all tail pipes. Furthermore, a motor vehicle with such an exhaust system is intended to be specified.

[0011] In one exemplary embodiment, an exhaust system comprises a single exhaust-gas inlet line, two exhaust-gas outlet lines connected in an exhaust gas-conducting manner to the exhaust-gas inlet line, and an active silencing device which is connected in a sound-conducting manner to the two exhaust-gas outlet lines. The exhaust-gas inlet line is connected in an exhaust gas-conducting manner to the cylinders of the internal combustion engine. Between the internal combustion engine and the exhaust-gas inlet line, further exhaust system elements can be arranged which serve, for example, for cleaning the exhaust gas. The exhaust-gas outlet lines are formed to conduct exhaust gas to the surroundings of the exhaust system. They can also be referred to as exhaust tail pipes. The exemplary exhaust system therefore combines a single exhaust-gas inlet line and a single silencing device with two exhaust-gas outlet lines. The exhaust system thus has a particularly simple construction. In particular, in comparison with the state of the art, a second exhaust-gas inlet line and/or a second active silencing device can be dispensed with. The sound-conducting connection of the silencing device to the two exhaust-gas outlet lines additionally guarantees effective silencing.

[0012] According to one embodiment, the silencing device can also be formed as a so-called sound actuator, in which the sound design is an important aspect (alternatively or in addition to the silencing).

[0013] The active silencing device can comprise a sound-generating device, in particular a loudspeaker, which is arranged in a sound-generating device housing. The sound-generating device per se therefore has a construction already known and proven from the state of the art. It is thus robust and reliable. Furthermore, it can be cost-effectively produced or obtained in the market.

[0014] According to a variant, the exhaust-gas inlet line is connected in an exhaust gas-conducting manner to the exhaust-gas outlet lines via a passive silencer. The passive silencer can be a rear silencer. The passive silencer serves to reduce the sound emitted to the surroundings. The passive silencer and the active silencing device therefore serve the same purpose. The active silencing device and the passive silencer can be matched to each other. This can be effected, for example, in that the passive silencer is designed to muffle relatively low frequencies and the active silencing device is designed to muffle relatively high frequencies. In summary, a particularly good muffling of the sound emitted to the environment by the exhaust system is guaranteed by the passive silencer.

[0015] The passive silencer preferably comprises a silencer housing.

[0016] Sections of the exhaust-gas inlet line and/or of at least one of the exhaust-gas outlet lines, preferably of both exhaust-gas outlet lines, can run inside a silencer housing of the passive silencer. The exhaust-gas inlet line thus passes through a section of the wall of the silencer housing. Observed from inside the silencer housing, the exhaust-gas inlet line therefore protrudes from a section of the wall of the silencer housing. The protruding section of the exhaust-gas inlet line, therefore the section of the exhaust-gas inlet line running inside the silencer housing, can comprise cross-section changes and/or changes of orientation, for example in the form of curvatures. The same applies to the at least one exhaust-gas outlet line or both exhaust-gas outlet lines. The cross-section changes and/or changes of orientation of the exhaust-gas inlet line and/or the exhaust-gas outlet lines can be chosen such that an improved muffling effect is achieved by the passive silencer. The sound emitted to the surroundings of the exhaust system is thus muffled particularly effectively.

[0017] In another variant in which the active sound-generating device is designed in such a way that it completely or almost completely eliminates the sound emitted by the exhaust system to the environment, a passive silencer can be dispensed with. By the complete elimination, it is meant here that the emitted sound is muffled in such a way that a predetermined threshold value is not exceeded. Such an exhaust system has a particularly simple and space-saving construction.

[0018] In an embodiment, the two exhaust-gas outlet lines form a T connection or a Y connection with the exhaust-gas inlet line or an intermediate exhaust-gas line, wherein the intermediate exhaust-gas line is connected in an exhaust gas-conducting manner to both exhaust-gas outlet lines and the exhaust-gas inlet line. In the case where the exhaust system does not comprise a passive silencer, the exhaust-gas outlet lines preferably form a T or Y connection with the exhaust-gas inlet line. If a passive silencer is used, the exhaust-gas outlet lines preferably form a T or Y connection with the intermediate exhaust-gas line. The intermediate exhaust-gas line preferably runs completely inside a silencer housing of the passive silencer and is thus connected in an exhaust gas-conducting manner to the exhaust-gas inlet line via an internal volume of the passive silencer. The T or Y connection is preferably implemented by welding or soldering of the exhaust-gas lines forming the T or Y connection, which are realized, for example, in the form of exhaust gas-conducting pipes. A simple and cost-effective construction of the exhaust system is thus ensured.

[0019] Both the T and the Y connection is a connection of three pipe sections. They differ in the angles, which the pipe sections, more precisely the center axes thereof, assume relative to each other. Whereas in the case of a T connection two of the pipe sections substantially have a common center axis and the third pipe section is oriented substantially perpendicular to this center axis, the term Y connection covers all connections of three pipe sections which cannot be referred to as a T connection.

[0020] According to a development, the two exhaust-gas outlet lines are formed by opposite sections of a common exhaust-gas outlet pipe. In other words, the exhaust-gas outlet pipe forms a T or Y connection with the exhaust-gas inlet line or the intermediate exhaust-gas line in a central section. This T or Y connection divides the exhaust-gas outlet pipe into two sections lying on opposite sides of the T or Y connection, which each represent an exhaust-gas outlet line. In the production of the exhaust system, only two pipes therefore need to be connected to each other, namely the pipe forming the exhaust-gas inlet line or the intermediate exhaust-gas line and the common exhaust-gas outlet pipe. The production of the exhaust system is thus particularly simple.

[0021] The active silencing device can be connected in a sound-conducting manner to the exhaust-gas outlet lines via a sound coupling-in line, wherein the sound coupling-in line surrounds the exhaust-gas inlet-facing ends of the exhaust-gas outlet lines on the outside and runs substantially concentric to the exhaust-gas inlet-facing ends of the exhaust-gas outlet lines. In the case where the exhaust-gas outlet lines are formed by a common exhaust-gas outlet pipe, the sound coupling-in line surrounds a central section of the common exhaust-gas outlet pipe on the outside and is substantially concentric to it. Therefore, a diameter of the sound coupling-in line is always greater in that area in which it surrounds the exhaust-gas inlet-facing ends of the exhaust-gas outlet lines or the common exhaust-gas outlet pipe on the outside than a diameter of the common exhaust-gas outlet pipe or the exhaust-gas inlet-facing ends of the exhaust-gas outlet lines. The axial ends of the sound coupling-in line thus form annular openings together with the exhaust-gas outlet lines or the common exhaust-gas outlet pipe. These are preferably closed. Such a coupling is often referred to as a Sourdine connection. This results in a simple but effective way of coupling sound emerging from the active silencing device into the exhaust-gas outlet lines.

[0022] The sound coupling-in line can run at least partly inside a silencer housing of the passive silencer. The sound coupling-in line preferably runs partly inside the silencer housing and partly outside it. The exhaust system thereby requires only a small installation space.

[0023] Moreover, the intermediate exhaust-gas line or the exhaust-gas inlet line can pass through a wall of the sound coupling-in line. The result of this is that the T or Y connection between the intermediate exhaust-gas line or the exhaust-gas inlet line and the two exhaust-gas outlet lines lies inside the sound coupling-in line. This also results in a compact construction of the exhaust system.

[0024] According to an embodiment, at least one of the exhaust-gas outlet lines, preferably both exhaust-gas outlet lines, comprises a perforated section in the area surrounded by the sound coupling-in line. Sound from the sound coupling-in line can pass into the interior of the exhaust-gas outlet line via the openings forming the perforation of the perforated section. The sound generated by the active silencing unit can thus interact with the exhaust gas routed in the exhaust-gas outlet line and muffle or completely eliminate sound carried by the exhaust gas flow. When both exhaust-gas outlet lines comprise perforated sections, these can be designed differently for example with respect to the number, size and arrangement of the openings forming the perforation. The perforation can thus be designed such that a maximum muffling effect is achieved with respect to the sound emitted by the exhaust system.

[0025] Advantageously, both exhaust-gas outlet lines comprise perforated sections and the perforated sections are arranged on opposite sides of the intermediate exhaust-gas line or on opposite sides of the exhaust-gas inlet line. The perforated sections therefore also lie on opposite sides of the T or Y connection. A compact construction of the exhaust system is thus achieved.

[0026] The active silencing device is preferably connected in a sound-conducting manner to the sound coupling-in line via a sound line. The active silencing device is thus arranged at a distance from the sound coupling-in line, which can substantially correspond to a length of the sound line. The active silencing device is thereby also spaced apart from the exhaust gas-routing components of the exhaust system. The result of this is that the components of the active silencing device can always be operated at a temperature, which lies significantly below the temperature of the exhaust gases routed in the exhaust system. A particularly reliable and durable functioning of the active silencing device is thereby ensured.

[0027] The sound line can run outside a silencer housing of the passive silencer. The sound line is therefore also coupled to the sound coupling-in line outside the silencer housing. A good compromise can thereby be achieved between a compact construction of the exhaust system and a sufficiently large distance between the active silencing device and the exhaust gas-routing components.

[0028] The exhaust-gas outlet lines are preferably exhaust tail pipes. The exhaust-gas outlet lines therefore lead directly into the surroundings of the exhaust system. Exhaust flaps can optionally be provided in the exhaust-gas outlet lines in order to close the exhaust-gas outlet lines selectively.

[0029] The exhaust-gas inlet line can have a substantially oval cross section at an exhaust-gas outlet-facing end. A compact construction of the exhaust system can be achieved via a cross section designed in such a way.

[0030] Furthermore, in another exemplary embodiment, a motor vehicle is provided with an exhaust system as described above. Such a motor vehicle likewise has a simple construction due to the simple construction of the exhaust system. In addition, such a motor vehicle emits only relatively little sound to its surroundings via its exhaust system.

BRIEF DESCRIPTION OF THE DRAWINGS

[0031] Various embodiment examples are shown in the attached drawings.

[0032] FIG. 1 schematically shows a motor vehicle with an exhaust system according to a first embodiment,

[0033] FIG. 2 shows the exhaust system of FIG. 1,

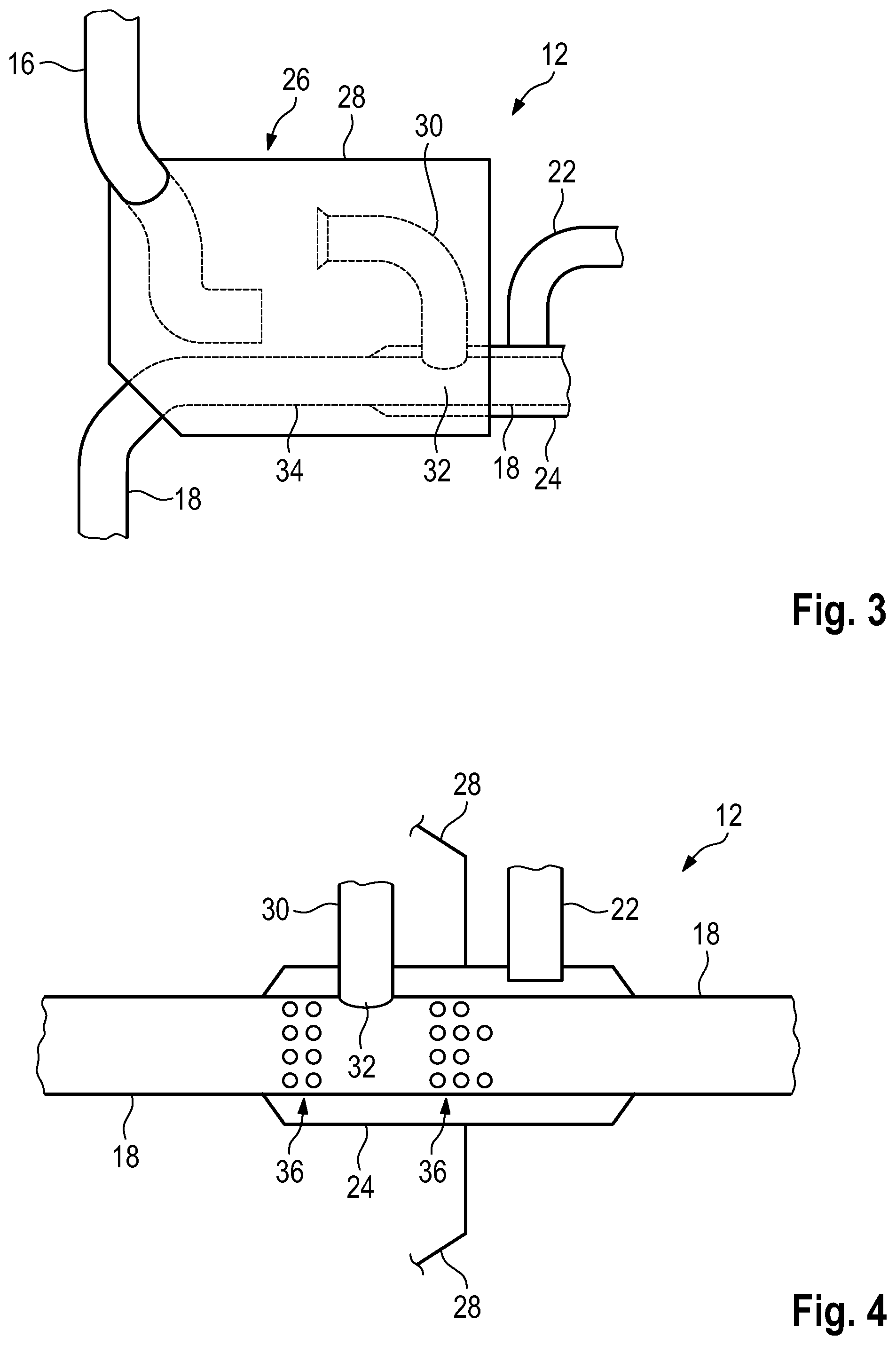

[0034] FIG. 3 shows a section of the exhaust system from FIG. 2, wherein a portion is represented transparently,

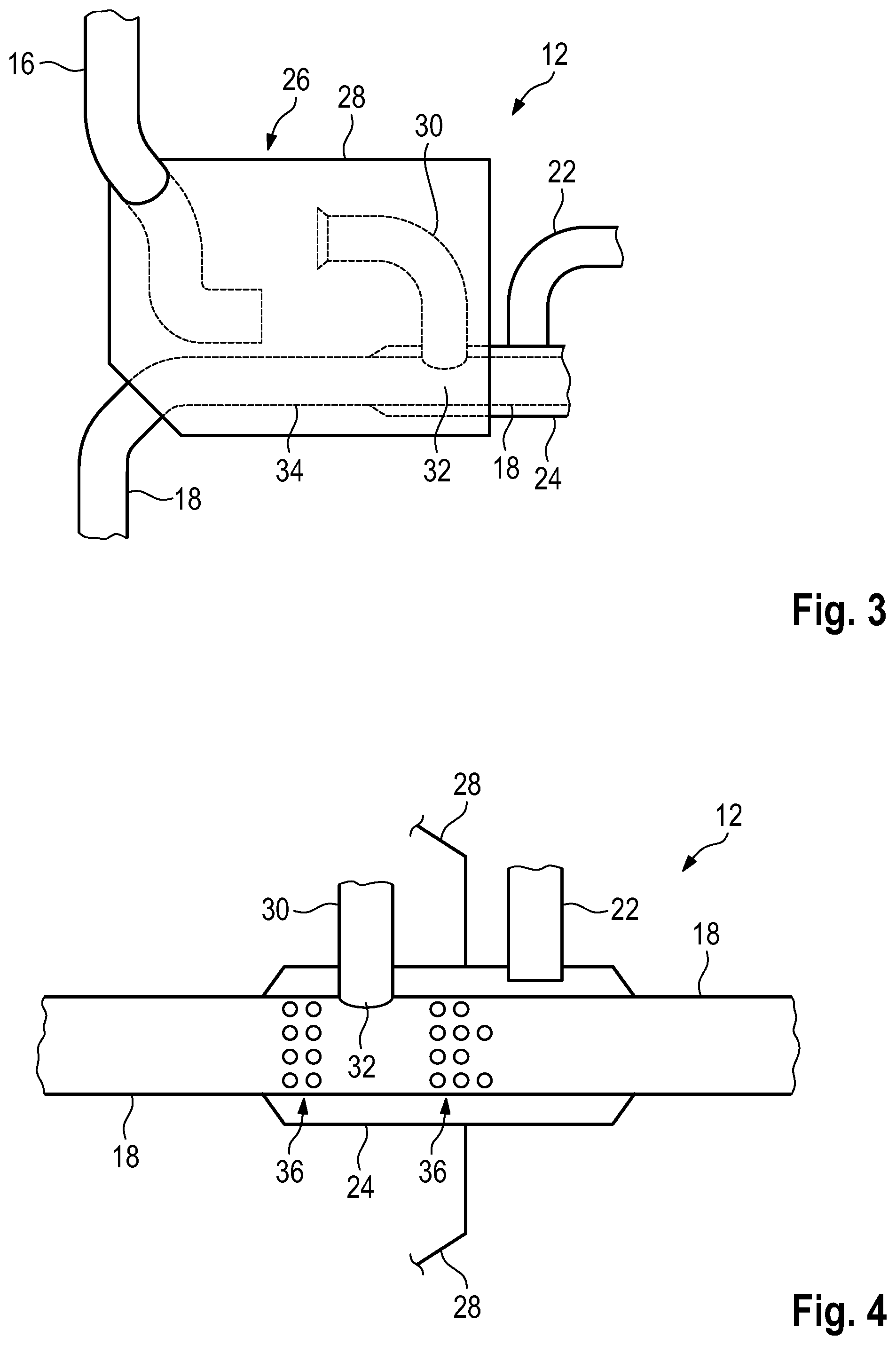

[0035] FIG. 4 schematically shows a detail of the exhaust system according to FIGS. 1 to 3, and

[0036] FIG. 5 schematically shows an exhaust system according to a second embodiment.

DETAILED DESCRIPTION

[0037] FIG. 1 shows a motor vehicle 10 with an exhaust system 12 according to a first embodiment, which is coupled to an internal combustion engine 14 which has three cylinders arranged in a row.

[0038] As can also be seen in particular in FIG. 2, the exhaust system 12 comprises a single exhaust-gas inlet line 16 and two exhaust-gas outlet lines 18 connected in an exhaust gas-conducting manner thereto, which are exhaust tail pipes in the embodiment represented.

[0039] In addition, the exhaust system 12 has an active silencing device 20 which is connected in a sound-conducting manner to the two exhaust-gas outlet lines 18.

[0040] An active silencing device known from the state of the art, which comprises a loudspeaker with which it can generate sound which is out of phase with the sound carried by the exhaust gas flow, is used as active silencing device 20.

[0041] For this purpose, the active silencing device 20 is coupled to the exhaust-gas outlet lines 18 via a sound line 22 and a sound coupling-in line 24.

[0042] In other words, the active silencing device 20 is connected in a sound-conducting manner to the sound coupling-in line 24 via the sound line 22.

[0043] The sound coupling-in line 24 in turn is connected in a sound-conducting manner to the exhaust-gas outlet lines 18.

[0044] The exhaust system 12 further has a passive silencer 26 with a silencer housing 28.

[0045] In the first embodiment, the exhaust-gas inlet line 16 is connected in an exhaust gas-conducting manner to the exhaust-gas outlet lines 18 via the passive silencer 26.

[0046] In FIG. 3, an upper side of the silencer housing 28 is represented transparent with the result that the interior thereof can be seen.

[0047] Here, sections of the exhaust-gas inlet line 16 and of both exhaust-gas outlet lines 18 run inside the silencer housing 28.

[0048] More precisely, a section of the exhaust-gas inlet line 16 facing away from the internal combustion engine 14, thus the exhaust-gas outlet-facing end thereof, runs inside the silencer housing 28.

[0049] The exhaust-gas outlet-facing end can have a substantially oval cross section.

[0050] In this context, the cross section is usually chosen such that both a good muffling performance of the passive silencer 26 and a compact construction of the exhaust system 12 as a whole are achieved.

[0051] With regard to the exhaust-gas outlet lines 18, the sections facing the internal combustion engine 14 or the exhaust-gas inlet line 16 respectively thus run inside the silencer housing 28.

[0052] In addition, the two exhaust-gas outlet lines 18 form a T connection 32 with an intermediate exhaust-gas line 30. Both exhaust-gas outlet lines 18 are thus connected in an exhaust gas-conducting manner to the intermediate exhaust-gas line 30.

[0053] The T connection 32 lies completely inside the silencer housing 28.

[0054] In addition, the intermediate exhaust-gas line 30 is connected in an exhaust gas-conducting manner to the exhaust-gas inlet line 16 via the internal volume of the passive silencer 26.

[0055] In the first embodiment, the two exhaust-gas outlet lines 18 are formed by opposite sections of a common exhaust-gas outlet pipe 34.

[0056] As already mentioned, the active silencing device 20 is connected in a sound-conducting manner to the exhaust-gas outlet lines 18 via the sound coupling-in line 24, in the present case therefore also to the exhaust-gas outlet pipe 34.

[0057] Here, the sound coupling-in line 24 has a larger diameter than the exhaust-gas outlet lines 18 and surrounds the exhaust-gas inlet-facing ends of the exhaust-gas outlet lines 18 on the outside (see FIG. 4 in particular). In the present case, the sound coupling-in line 24 therefore also surrounds the exhaust-gas outlet pipe 34.

[0058] At the same time, the sound coupling-in line 24 runs substantially concentric to the exhaust-gas outlet lines 18 which are of course formed by a common exhaust-gas outlet pipe 34.

[0059] The sound coupling-in line 24 runs partly inside the silencer housing 28 and partly outside it (cf. FIG. 4).

[0060] In order to enable an interaction between the out-of-phase sound generated by the active silencing unit 20 and the exhaust gas flow routed in the exhaust-gas outlet lines 18, both exhaust-gas outlet lines 18 have a perforated section 36.

[0061] In order to illustrate that the two perforated sections 36 can be designed the same but do not have to be, they differ in FIG. 4 with respect to the number of openings belonging to the perforated section 36 as well as the arrangement of the openings.

[0062] The perforated sections 36 are arranged in that area of the exhaust-gas outlet lines 18 which is surrounded by the sound coupling-in line 24.

[0063] Furthermore, the perforated sections 36 are placed on opposite sides of the intermediate exhaust-gas line 30.

[0064] The intermediate exhaust-gas line 30 passes through a wall of the sound coupling-in line 24. The T connection 32 thus lies inside the sound coupling-in line 24.

[0065] The sound line 22 runs completely outside the silencer housing 28.

[0066] In summary, exhaust gas emerging from the internal combustion engine 14 therefore flows via the exhaust-gas inlet line 16 into the silencer housing 28 of the passive silencer 26. From there, it passes via the intermediate exhaust-gas line 30, which is coupled to the two exhaust-gas outlet lines 18 via the T connection 32, into the two exhaust-gas outlet lines 18. These conduct the exhaust gas to the surroundings.

[0067] Within the meaning of muffling the sound carried by the exhaust gas, out-of-phase sound, which is often also referred to as anti-noise, is generated in the active silencing device 20. From there, the out-of-phase sound is routed into the sound coupling-in line 24 via the sound line 22. It thus passes into an annular space, which is formed by the sound coupling-in line 24 and the respectively exhaust-gas inlet-facing ends of the exhaust-gas outlet lines 18. From this, the sound can escape via the openings of the perforated sections 36 into the interior of the exhaust-gas outlet lines 18, where it interacts with the sound carried by the exhaust gas in order to muffle it.

[0068] In contrast to the first embodiment, the second embodiment of the exhaust system 12 shown in FIG. 5 dispenses with the passive silencer 26.

[0069] This variant can be chosen when the exhaust system 12 is to be designed in a particularly space-saving manner.

[0070] This variant can also be used when the active silencing device 20 is designed in such a way that it can ensure sufficient muffling of the sound carried by the exhaust gas without the aid of a passive silencer.

[0071] In addition, in the second embodiment no intermediate exhaust-gas line 30 is used with the result that the exhaust-gas inlet line 16 forms the T connection 32 with the exhaust-gas outlet lines 18. The exhaust gas therefore flows directly from the exhaust-gas inlet line 16 into the exhaust-gas outlet lines 18.

[0072] The path of the out-of-phase sound generated by the active silencing device 20 and its superposition with the sound carried by the exhaust gas is effected in the same way as in the first embodiment. Reference is therefore made to the above statements.

[0073] Here, the perforated sections 36 are again designed differently. This serves to illustrate that they can be made the same but do not have to be.

[0074] Although various embodiments have been disclosed, a worker of ordinary skill in this art would recognize that certain modifications would come within the scope of this disclosure. For that reason, the following claims should be studied to determine the true scope and content of this disclosure.

* * * * *

D00000

D00001

D00002

D00003

XML

uspto.report is an independent third-party trademark research tool that is not affiliated, endorsed, or sponsored by the United States Patent and Trademark Office (USPTO) or any other governmental organization. The information provided by uspto.report is based on publicly available data at the time of writing and is intended for informational purposes only.

While we strive to provide accurate and up-to-date information, we do not guarantee the accuracy, completeness, reliability, or suitability of the information displayed on this site. The use of this site is at your own risk. Any reliance you place on such information is therefore strictly at your own risk.

All official trademark data, including owner information, should be verified by visiting the official USPTO website at www.uspto.gov. This site is not intended to replace professional legal advice and should not be used as a substitute for consulting with a legal professional who is knowledgeable about trademark law.