Cosmetic Kit For Refill

SUZUKI; Takahiro

U.S. patent application number 16/626917 was filed with the patent office on 2020-07-16 for cosmetic kit for refill. The applicant listed for this patent is SHISEIDO COMPANY, LTD.. Invention is credited to Takahiro SUZUKI.

| Application Number | 20200221850 16/626917 |

| Document ID | / |

| Family ID | 64949911 |

| Filed Date | 2020-07-16 |

| United States Patent Application | 20200221850 |

| Kind Code | A1 |

| SUZUKI; Takahiro | July 16, 2020 |

COSMETIC KIT FOR REFILL

Abstract

A kit for refill is constituted by a pack member containing liquid cosmetic material for refill and a non-impregnated impregnation member that will be contained in a compact case in order to be impregnated with the liquid cosmetic material for refill. A preferred embodiment of this kit for refill further includes a pressing member that presses the non-impregnated impregnation member contained in the case to impregnate the non-impregnated impregnation member with the liquid cosmetic material for refill, and the pressing member is, for example, constituted by a puff.

| Inventors: | SUZUKI; Takahiro; (Yokohama-shi, Kanagawa, JP) | ||||||||||

| Applicant: |

|

||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Family ID: | 64949911 | ||||||||||

| Appl. No.: | 16/626917 | ||||||||||

| Filed: | April 25, 2018 | ||||||||||

| PCT Filed: | April 25, 2018 | ||||||||||

| PCT NO: | PCT/JP2018/016732 | ||||||||||

| 371 Date: | December 27, 2019 |

| Current U.S. Class: | 1/1 |

| Current CPC Class: | A45D 2034/002 20130101; A45D 34/00 20130101; A45D 2200/051 20130101; A45D 34/04 20130101; A45D 2200/1036 20130101; A45D 2200/25 20130101; A45D 40/22 20130101 |

| International Class: | A45D 34/04 20060101 A45D034/04; A45D 40/22 20060101 A45D040/22 |

Foreign Application Data

| Date | Code | Application Number |

|---|---|---|

| Jul 6, 2017 | JP | 2017-133090 |

Claims

[0038] 1. A cosmetic kit for refill for compact cosmetics that include an impregnation member impregnated with liquid cosmetic material and a case containing the impregnation member, the cosmetic kit comprising: a pack member containing liquid cosmetic material for refill, and a non-impregnated impregnation member that will be contained in the case in order to be impregnated with the liquid cosmetic material for refill.

2. A cosmetic kit for refill for compact cosmetics that include an impregnation member impregnated with liquid cosmetic material and a case containing the impregnation member, the cosmetic kit comprising: a pack member containing liquid cosmetic material for refill, a non-impregnated impregnation member that will be contained in the case in order to be impregnated with the liquid cosmetic material for refill, and a pressing member that presses the non-impregnated impregnation member contained in the case to impregnate the non-impregnated impregnation member with the liquid cosmetic material.

3. The cosmetic kit for refill, as defined in claim 2, wherein the pressing member is a puff for applying the liquid cosmetic material impregnated into the impregnation member to a user's skin.

4. The cosmetic kit for refill, as defined in claim 2, wherein the pack member, the non-impregnated impregnation member, and the pressing member are contained in another pack member that is for the kit.

5. The cosmetic kit for refill, as defined in claim 1, wherein the pack member is a pouch member made of aluminum.

6. The cosmetic kit for refill, as defined in claim 1, wherein the pack member is a tube case.

7. The cosmetic kit for refill, as defined in claim 1, wherein the density of the impregnation member is in the range of 0.006 g/cm.sup.3 to 0.1 g/cm.sup.3, and the viscosity of the liquid cosmetic material is in the range of 5000 mPas to 30000 mPas.

8. The cosmetic kit for refill, as defined in claim 7, wherein the density of the impregnation member is in the range of 0.006 g/cm.sup.3 to 0.05 g/cm.sup.3, and the viscosity of the liquid cosmetic material is in the range of 5000 mPas to 15000 mPas.

9. The cosmetic kit for refill, as defined in claim 3, wherein the pack member, the non-impregnated impregnation member, and the pressing member are contained in another pack member that is for the kit.

10. The cosmetic kit for refill, as defined in claim 2, wherein the pack member is a pouch member made of aluminum.

11. The cosmetic kit for refill, as defined in claim 3, wherein the pack member is a pouch member made of aluminum.

12. The cosmetic kit for refill, as defined in claim 4, wherein the pack member is a pouch member made of aluminum.

13. The cosmetic kit for refill, as defined in claim 2, wherein the pack member is a tube case.

14. The cosmetic kit for refill, as defined in claim 3, wherein the pack member is a tube case.

15. The cosmetic kit for refill, as defined in claim 4, wherein the pack member is a tube case.

16. The cosmetic kit for refill, as defined in claim 2, wherein the density of the impregnation member is in the range of 0.006 g/cm.sup.3 to 0.1 g/cm.sup.3, and the viscosity of the liquid cosmetic material is in the range of 5000 mPas to 30000 mPas.

17. The cosmetic kit for refill, as defined in claim 3, wherein the density of the impregnation member is in the range of 0.006 g/cm.sup.3 to 0.1 g/cm.sup.3, and the viscosity of the liquid cosmetic material is in the range of 5000 mPas to 30000 mPas.

18. The cosmetic kit for refill, as defined in claim 16, wherein the density of the impregnation member is in the range of 0.006 g/cm.sup.3 to 0.05 g/cm.sup.3, and the viscosity of the liquid cosmetic material is in the range of 5000 mPas to 15000 mPas.

19. The cosmetic kit for refill, as defined in claim 17, wherein the density of the impregnation member is in the range of 0.006 g/cm.sup.3 to 0.05 g/cm.sup.3, and the viscosity of the liquid cosmetic material is in the range of 5000 mPas to 15000 mPas.

Description

CROSS-REFERENCE TO RELATED APPLICATIONS

[0001] This application is a National Phase Entry of PCT International Application No. PCT/JP2018/016732 filed on Apr. 25, 2018, which claims priority under 35 U.S.C .sctn. 119(a) to Japanese Patent Application No. 2017-133090 filed on Jul. 6, 2017. Each of the above applications is hereby expressly incorporated by reference, in its entirety, into the present application.

TECHNICAL FIELD

[0002] The present disclosure relates to a kit for refill for compact cosmetics that include impregnated liquid cosmetic material.

BACKGROUND ART

[0003] Conventionally, compact cosmetics including an impregnation member impregnated with liquid cosmetic material and a case containing this impregnation member were known, for example, as disclosed in PCT Japanese Publication No. 2016-527972. For this kind of compact cosmetics, a demand for continuing to use a compact, which is an outer case, exists by refilling the compact with new liquid cosmetic material after using all the liquid cosmetic material, instead of throwing it away.

[0004] Therefore, conventionally, cosmetics for refill including an impregnation member impregnated with liquid cosmetic material and contained in a pack member, as disclosed also in PCT Japanese Publication No. 2016-527972, were proposed.

SUMMARY

Technical Problem

[0005] However, a cost for producing such conventional cosmetics for refill tends to be high, because a process of impregnating liquid cosmetic material into an impregnation member is needed, and an airtight case for storing the impregnation member impregnated with the cosmetic material (an inner tray with a sealing member or the like) is needed. Further, since the airtight case is thrown away after use, the discarded portion is large, and a problem about an environmental concern is recognizable.

[0006] In view of the foregoing circumstances, the present disclosure provides a kit for refill for compact cosmetics formable at low cost.

[0007] A cosmetic kit for refill of the present disclosure is a kit for refill for compact cosmetics that include an impregnation member impregnated with liquid cosmetic material and a case containing this impregnation member, and the kit for refill includes a pack member containing liquid cosmetic material for refill, and a non-impregnated impregnation member that will be contained in the case in order to be impregnated with the liquid cosmetic material for refill.

[0008] Here, it is desirable that the cosmetic kit for refill configured as described above further includes a pressing member that presses the non-impregnated impregnation member contained in the case to impregnate the liquid cosmetic material into the non-impregnated impregnation member. As such a pressing member, it is desirable to adopt a puff for applying the liquid cosmetic material impregnated into the impregnation member to a user's skin.

[0009] In the cosmetic kit for refill of the present disclosure, the pack member, the non-impregnated impregnation member, and the pressing member may be contained in one pack member for the kit (as a set), or each of them may be contained in a separate pack member for the kit.

[0010] As the pack member, for example, a pouch member made of aluminum, or a tube case may be preferably used.

[0011] In the cosmetic kit for refill of the present disclosure, the density of the impregnation member is in the range of 0.006 g/cm.sup.3 to 0.1 g/cm.sup.3, and more preferably, in the range 0.006 g/cm.sup.3 to 0.05 g/cm.sup.3, while the viscosity of the liquid cosmetic material is in the range of 5000 mPas to 30000 mPas, and more preferably, in the range of 5000 mPas to 15000 mPas.

[0012] The kit for a cosmetic refill of the present disclosure includes a pack member in which liquid cosmetic material for refill is contained and a non-impregnated impregnation member. Therefore, a process of impregnating liquid cosmetic material into the impregnation member is not needed in production, and that can lower a cost for forming the kit. Further, unlike the conventional cosmetic material for refill (refill), an airtight case (an inner tray, a sealing member) containing an impregnation member (a sponge or the like) impregnated with cosmetic material, as cosmetic material refill, is not required. Therefore, the discarded case member is reduced, and that is eco-friendly.

BRIEF DESCRIPTION OF THE DRAWINGS

[0013] FIG. 1 A partial cutaway perspective view illustrating a cosmetic kit for refill according to a first embodiment of the present disclosure

[0014] FIG. 2 A perspective view illustrating a manner of using the cosmetic kit for refill illustrated in FIG. 1

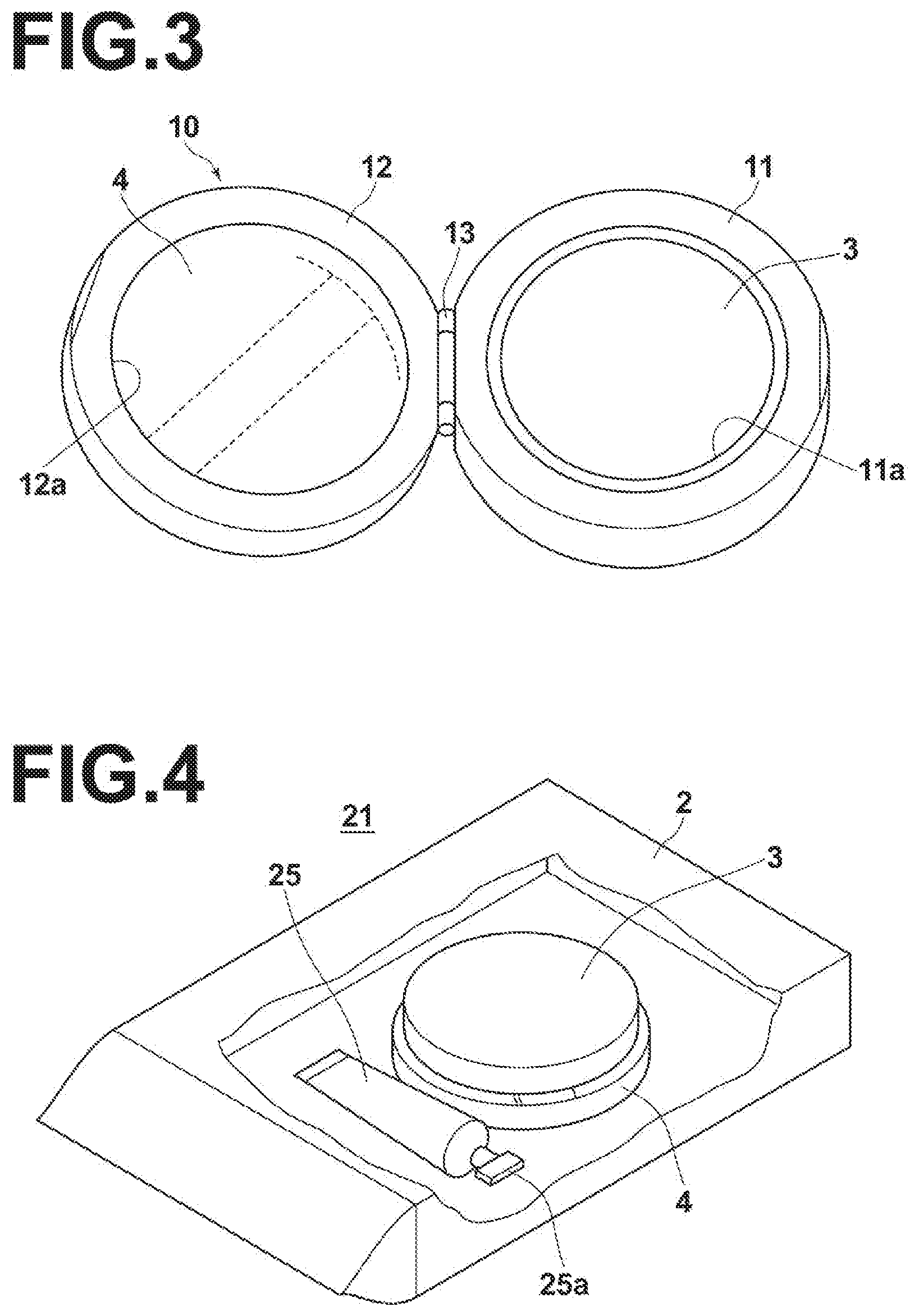

[0015] FIG. 3 A perspective view illustrating a compact case adopting the cosmetic kit for refill illustrated in FIG. 1

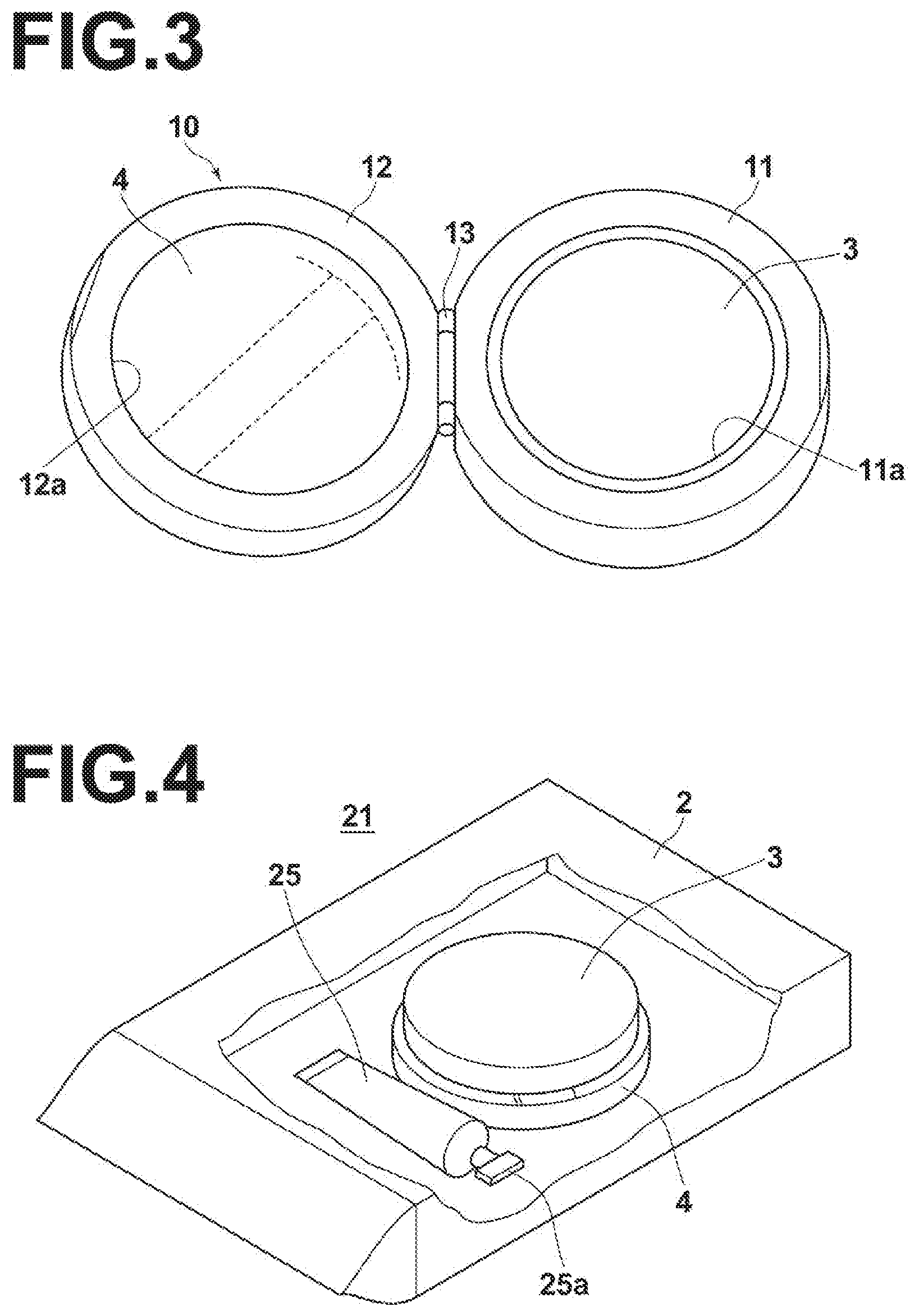

[0016] FIG. 4 A partial cutaway perspective view illustrating a cosmetic kit for refill according to a second embodiment of the present disclosure

[0017] FIG. 5 A partial cutaway perspective view illustrating a cosmetic kit for refill according to a third embodiment of the present disclosure

DESCRIPTION OF EMBODIMENTS

[0018] Next, embodiments of the present disclosure will be described with reference to drawings. FIG. 1 is a partial cutaway perspective view illustrating a cosmetic kit 1 for refill (hereinafter, simply referred to as a kit for refill in some cases). As illustrated in the drawing, this kit 1 for refill contains a non-impregnated impregnation member 3, a puff 4, as a pressing member, and a pack member 5 containing liquid cosmetic material for refill, which are contained in a pack member 2 for the kit illustrated by being partially cut away.

[0019] The pack member 2 for the kit is formed in a box or bag shape, for example, by using paper, synthetic resin film or the like. The impregnation member 3 is formed, for example, in a thin cylindrical shape or a thin rectangular parallelepiped shape by using porous material. The porous material may include at least one kind of material selected from a group consisting of butadiene rubber (BR: Butadiene Rubber), styrene butadiene rubber (SBR: Styrene Butadiene Rubber), natural rubber (NR: Natural Rubber), wet urethane, dry urethane, polyether, polyester, polyvinyl chloride, polyethylene, ethylene vinyl acetate (EVA: Ethylene Vinyl Acetate), latex, silicon, styrene isoprene styrene (SIS: Styrene Isoprene Styrene), styrene ethylene butylene styrene (SEBS: Styrene Ethylene Butylene Styrene), poly vinyl alcohol (PVA: Poly Vinyl Alcohol), silicon-based elastomer, nitrile rubber, butyl rubber, and neoprene. Especially, a sponge, for example, made of PET (polyethylene terephthalate), urethane, cellulose, acrylonitrile-butadiene rubber (NBR: Acrylo Nitrile-Butadiene Rubber), styrene butadiene rubber (SBR: Styrene Butadiene Rubber), natural rubber (NR: Natural Rubber) or the like is preferably used.

[0020] As the pressing member, any kind of member may be used as long as it can press the impregnation member (a porous member, such as a sponge) to impregnate liquid cosmetic material into the impregnation member, and for example, any member, such as a disk-shaped or plate-shaped member or a rod-shaped member with a pressing portion at its leading end, may be used. Especially, a pressing member having (substantially) the same shape as a puff, and which is usable for application, is preferable.

[0021] As the puff 4, a puff used in a general compact, in other words, a puff for applying liquid cosmetic material, impregnated into the impregnation member 3, to a user's skin is adoptable. The material of the puff 4 is not limited, but natural rubber, synthetic rubber, for example, such as diene-based material (butadiene rubber, isoprene rubber, styrene butadiene rubber, acrylonitrile-butadiene rubber, and chloroprene rubber), olefin-based material (ethylene-propylene copolymer, ethylene-propylene diene terpolymer, and chlorinated polyethylene), organic silicon compound-based material (silicone rubber), fluorine compound-based material, polyurethane-based material (a polyether type, a polyester type and the like), vinyl-based material (acryl rubber) or synthetic resin, for example, such as, polyethylene, polypropylene, acrylonitrile-butadiene styrene copolymer, and polyvinyl chloride may be named, and among them, polyurethane-based foam is suitable, because it has both an excellent sense of touch, such as a sense of volume and a sense of fit to the skin, and functions, such as flexibility and softness, required as a cosmetic tool.

[0022] The pack member 5 is, for example, constituted by a pouch member. This pouch member refers to a laminated member basically formed by adhering peripheral edges of two sheets of sheet material, such as aluminum sheets and synthetic resin films, to each other by fusion bond or the like. While the pouch member is formed, the liquid cosmetic material for refill is placed between the two sheets of sheet material, and in that state, the two sheets of sheet material are adhered to each other.

[0023] Next, a method for using the kit 1 for refill of the present embodiment will be described with reference to FIG. 2. FIG. 2 illustrates a manner of refilling a compact 10 with cosmetic material by using this kit for refill. This compact 10 is formed, for example, by using synthetic resin, and includes a case 11 and a lid member 12, which is swingably connected to the case 11 by a hinge 13. In the case 11, a cosmetic material container 11a, for example, which is a cylindrical space portion with an open end, is formed. In the lid member 12, a puff container 12a, which is a cylindrical space portion with an open end, is similarly formed. Further, a mirror 14 is arranged on the bottom of the puff container 12a.

[0024] When the compact 10 is refilled with cosmetic material, the pack member 2 for the kit illustrated in FIG. 1 is opened, and the non-impregnated impregnation member 3, the puff 4 and the pack member 5 are extracted from the pack member 2 for the kit. After then, first, the pack member 5 is opened, and liquid cosmetic material C is extracted from the pack member 5 and put in the cosmetic material container 11a of the case 11. At this time, the liquid cosmetic material C is evenly distributed so as to reach all the area of the bottom of the cosmetic material container 11a.

[0025] Next, the non-impregnated impregnation member 3 is placed in the cosmetic material container 11a in such a manner to cover the liquid cosmetic material C. Accordingly, a part of the liquid cosmetic material C is impregnated into the impregnation member 3, but further, this impregnation is accelerated by the puff 4, which is the pressing member. Specifically, the impregnation member 3 is pressed a few times from its upper side by the puff 4. When the impregnation member 3 is sufficiently impregnated with the liquid cosmetic material C in this manner, the compact 10 becomes a refilled state with the liquid cosmetic material C. Then, application of the liquid cosmetic material C to a user's skin by using the puff 4 is possible in a similar manner to using an ordinary compact 10.

[0026] FIG. 3 illustrates the compact 10 that has been refilled with the liquid cosmetic material C. As illustrated in this drawing, the impregnation member 3 is contained in the cosmetic material container 11a, and will be tightly sealed by the lid member 12.

[0027] As described above, the kit 1 for refill according to the present embodiment includes the pack member 5 containing liquid cosmetic material C for refill and the non-impregnated impregnation member 3. Therefore, a process of impregnating the liquid cosmetic material C into the impregnation member 3 is not needed in production, and in this respect, formation at low cost is possible. Further, unlike the conventional cosmetic material for refill (refill), since the inner tray that tightly seals the impregnation member impregnated with the liquid cosmetic material is not replaced together with the impregnation member, the discarded portion is small, and that is eco-friendly.

[0028] Next, with reference to FIG. 4, a cosmetic kit 21 for refill according to the second embodiment of the present disclosure will be described. The kit 21 for refill of the present embodiment differs from the kit 1 for refill of the first embodiment in the pack member containing liquid cosmetic material. Specifically, in the kit 21 for refill of the present embodiment, a pack member 25 constituted by a tube case, for example, made of soft synthetic resin or the like is used. This pack member 25 includes a tearable cap member 25a, as an example. When refill for liquid cosmetic material is performed, this cap member 25a is teared off, and the liquid cosmetic material is extracted from the pack member 25. The extracted liquid cosmetic material is impregnated into the non-impregnated impregnation member 3 contained in the cosmetic material container 11a in a similar manner to the way described with reference to FIG. 2.

[0029] Next, with reference to FIG. 5, a cosmetic kit 31 for refill according to the third embodiment of the present disclosure will be described. The kit 31 for refill of the present embodiment differs from the kit 1 for refill of the first embodiment in the pressing member for impregnating the liquid cosmetic material into the impregnation member. Specifically, in the kit 31 for refill of the present embodiment, a disk 34, for example, made of synthetic resin or the like is used instead of the aforementioned puff 4. This disk 34 is contained in the pack member 2 for the kit together with the non-impregnated impregnation member 3.

[0030] When refill for liquid cosmetic material is performed, the liquid cosmetic material C is extracted from the pack member 5 constituted by the pouch member, and put in the cosmetic material container 11a of the case 11 in a similar manner to the first embodiment (please refer to FIG. 2). After then, the non-impregnated impregnation member 3 is placed in the cosmetic material container 11a, and this impregnation member 3 is pressed from its upper side by the disk 34, and the liquid cosmetic material is impregnated into the impregnation member 3.

[0031] The pressing member for impregnating the liquid cosmetic material into the impregnation member is not limited to the puff 4 or the disk 34, as described above, and other members may be used. For example, some corners of the pack member 2 for the kit illustrated in FIGS. 1, 4 and 5 may be formed in a thick plate shape to some extent, and the plate-shaped portions may be used as the pressing member.

[0032] Next, desirable ranges of the density of the impregnation member and the viscosity of the liquid cosmetic material in cosmetic kit for refill of the present disclosure will be described. The inventors of the present disclosure produced an impregnation member (hereinafter referred to as impregnation member P) constituted by a sponge made of PET (polyethylene terephthalate) and an impregnation member (hereinafter referred to as impregnation member U) constituted by a sponge made of urethane, and a plurality of kinds of liquid cosmetic material having different viscosities from each other were impregnated into these impregnation members, and the degree of easiness of impregnation and the like were studied for each case by experiments. Here, the properties of the aforementioned two kinds of impregnation members are summarized in Table 1.

TABLE-US-00001 TABLE 1 actual volume measurement weight density material (cm.sup.3) (g) (g/cm.sup.3) impregnation PET 9 0.16 0.0178 member P impregnation urethane 9 0.9 0.1 member U

[0033] In the experiments, liquid cosmetic material, each having the viscosity of 500, 5000, 10000, 15000, 30000, and 50000 mPas, in the amount of 10 g, 15 g and 20 g was put in the cosmetic material container 11a of the case 11 illustrated in FIG. 2, and smoothed. After then, the impregnation member was placed on the liquid cosmetic material to impregnate the impregnation member with the liquid cosmetic material. This impregnation process was performed every time by pressing the impregnation member from its upper side by 20% of the height of the impregnation member by using a flat tool. In that case, the number of times of pressing until the liquid cosmetic material began to adhere to the tool was evaluated with evaluation scores A through D. Further, when no liquid cosmetic material adhered even after the impregnation member was pressed as many times as possible, evaluation score E was given. Meanwhile, the meaning of these evaluation scores A through E is summarized in Table 4. Further, when the impregnation process was performed, whether the liquid cosmetic material, which did not impregnate, spread beyond an outer frame of the cosmetic material container 11a was also checked. Specifically, when the liquid cosmetic material did not spread beyond the outer frame, evaluation score G (good) was given, and when the liquid cosmetic material spread beyond the outer frame, evaluation score P (poor) was given. Further, in the impregnation process, whether the impregnated liquid cosmetic material dropped from the impregnation member due to its own weight was also checked. Specifically, when no liquid cosmetic material dropped, evaluation score G (good) was given, and when the liquid cosmetic material dropped, evaluation score P (poor) was given.

[0034] The results of evaluation as described above are illustrated in Table 2 for the impregnation member P, and in Table 3 for the impregnation member U. In these tables, evaluation results, for example, such as "A/G/P", are written, and this shows the aforementioned three kinds of evaluation in the same order as the order of describing the evaluations. For example, the evaluation result of "A/G/P" represents that the number of times of pressing until the liquid cosmetic material began to adhere to the tool was in the range of 1 to 4, and no liquid cosmetic material spread beyond the outer frame, and the liquid cosmetic material dropped.

TABLE-US-00002 TABLE 2 impreg- density nation (g/cm.sup.3) member viscos- P ity cosmetic (mPa .cndot. 0.0178 material s) 500 5000 10000 15000 30000 50000 supplied 10 g B/G/P B/G/G C/G/G D/G/G D/G/G E/P/-- amount 15 g A/G/P B/G/G B/G/G B/G/G C/P/-- E/P/-- 20 g A/P/-- A/P/-- A/P/-- A/P/-- E/P/-- E/P/--

TABLE-US-00003 TABLE 3 impreg- density nation (g/cm.sup.3) member viscos- U ity cosmetic (mPa .cndot. 0.1 material s) 500 5000 10000 15000 30000 50000 supplied 10 g A/G/G B/G/G E/P/-- E/P/-- E/P/-- E/P/-- amount 15 g A/G/G B/P/-- E/P/-- E/P/-- E/P/-- E/P/-- 20 g A/G/G B/P/-- E/P/-- E/P/-- E/P/-- E/P/--

TABLE-US-00004 TABLE 4 degree of easiness of self-impregnation number of times of pressing 1 to 4 times A 5 to 9 times B 10 to 19 times C 20 times or more D impossible to impregnate E

[0035] In the above experiments, the impregnation member was pressed by using a tool having an area of 75% with respect to the area of the upper surface of the impregnation member. When a tool having a smaller area than this area is used, better evaluation results than the evaluation as described above are obtainable.

[0036] Further, in addition to the above experiments, the inventors also produced impregnation members P each having the diameter of 5 cm, the thickness of 1 cm, and a density in the range of 0.006 g/cm.sup.3 to 0.1 g/cm.sup.3, and confirmed by experiments that the evaluation results of "A/G/G" as described based on Tables 2, 3 were obtainable with respect to these impregnation members P.

[0037] The above experiments and evaluations show that in the cosmetic kit for refill of the present disclosure, it is desirable that the density of the non-impregnated impregnation member is in the range of 0.006 g/cm.sup.3 to 0.1 g/cm.sup.3, and more preferably, in the range of 0.006 g/cm.sup.3 to 0.05 g/cm.sup.3, while the viscosity of the liquid cosmetic material is in the range of 5000 mPas to 30000 mPas, and more preferably, in the range of 5000 mPas to 15000 mPas.

EXPLANATION OF THE REFERENCE NUMERALS

* * * * *

D00000

D00001

D00002

D00003

D00004

XML

uspto.report is an independent third-party trademark research tool that is not affiliated, endorsed, or sponsored by the United States Patent and Trademark Office (USPTO) or any other governmental organization. The information provided by uspto.report is based on publicly available data at the time of writing and is intended for informational purposes only.

While we strive to provide accurate and up-to-date information, we do not guarantee the accuracy, completeness, reliability, or suitability of the information displayed on this site. The use of this site is at your own risk. Any reliance you place on such information is therefore strictly at your own risk.

All official trademark data, including owner information, should be verified by visiting the official USPTO website at www.uspto.gov. This site is not intended to replace professional legal advice and should not be used as a substitute for consulting with a legal professional who is knowledgeable about trademark law.