Methods For Generating A Glucose Permease Library And Uses Thereof

Manchester; Shawn ; et al.

U.S. patent application number 16/722658 was filed with the patent office on 2020-04-23 for methods for generating a glucose permease library and uses thereof. The applicant listed for this patent is Zymergen Inc.. Invention is credited to Shawn Manchester, Jeffrey Mellin.

| Application Number | 20200123529 16/722658 |

| Document ID | / |

| Family ID | 60785478 |

| Filed Date | 2020-04-23 |

| United States Patent Application | 20200123529 |

| Kind Code | A1 |

| Manchester; Shawn ; et al. | April 23, 2020 |

METHODS FOR GENERATING A GLUCOSE PERMEASE LIBRARY AND USES THEREOF

Abstract

The present disclosure describes methods for generating microbial strains expressing a heterologous bacterial glucose permease gene that produce biomolecules of interest. In aspects, the disclosure provides novel bacterial strains, which express a heterologous bacterial glucose permease gene whose expression is controlled by a native Corynebacterium glutamicum promoter or a mutant promoter derived therefrom. Also provided herein are methods for producing a library of bacterial glucose permease genes using a promoter ladder comprising a plurality of promoters derived from Corynebacterium glutamicum.

| Inventors: | Manchester; Shawn; (Oakland, CA) ; Mellin; Jeffrey; (Oakland, CA) | ||||||||||

| Applicant: |

|

||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Family ID: | 60785478 | ||||||||||

| Appl. No.: | 16/722658 | ||||||||||

| Filed: | December 20, 2019 |

Related U.S. Patent Documents

| Application Number | Filing Date | Patent Number | ||

|---|---|---|---|---|

| 16313613 | Dec 27, 2018 | 10544411 | ||

| PCT/US2017/039997 | Jun 29, 2017 | |||

| 16722658 | ||||

| 62356924 | Jun 30, 2016 | |||

| Current U.S. Class: | 1/1 |

| Current CPC Class: | C12P 1/04 20130101; C12P 21/02 20130101; C12Y 207/01001 20130101; C12Y 207/01069 20130101; C12P 19/02 20130101; C12N 15/1037 20130101; C07K 1/047 20130101; C12N 9/1205 20130101 |

| International Class: | C12N 15/10 20060101 C12N015/10; C12P 1/04 20060101 C12P001/04; C12N 9/12 20060101 C12N009/12; C12P 21/02 20060101 C12P021/02; C07K 1/04 20060101 C07K001/04; C12P 19/02 20060101 C12P019/02 |

Claims

1.-66. (canceled)

67. A host cell comprising a heterologous glucose permease gene functionally linked to a first promoter polynucleotide sequence, wherein the first promoter polynucleotide sequence is derived from Corynebacterium glutamicum, is less than 100 base pairs in length, is able to constitutively express genes across different growth conditions, and is able to form a ladder of promoters comprising a plurality of promoters with incrementally increasing levels of promoter activity.

68. The host cell of claim 67, wherein the glucose permease gene is a gene that encodes a polypeptide with an amino acid sequence selected from SEQ ID NO: 13, SEQ ID NO: 10, SEQ ID NO: 11, SEQ ID NO: 12, SEQ ID NO: 9 and SEQ ID NO: 14.

69. The host cell of claim 67, wherein the glucose permease gene is a gene with a nucleotide sequence selected from SEQ ID NO: 23, SEQ ID NO: 20, SEQ ID NO: 21, SEQ ID NO: 22, SEQ ID NO: 19 and SEQ ID NO: 24.

70. The host cell of claim 67, further comprising a hexokinase gene functionally linked to a second promoter polynucleotide sequence, wherein the second promoter polynucleotide sequence is derived from Corynebacterium glutamicum, is less than 100 base pairs in length, is able to constitutively express genes across different growth conditions, and is able to form a ladder of promoters comprising a plurality of promoters with incrementally increasing levels of promoter activity.

71. The host cell of claim 70, wherein the hexokinase gene is a gene that encodes a polypeptide sequence selected from SEQ ID NO: 15 and SEQ ID NO: 16.

72. The host cell of claim 70, wherein the hexokinase gene is a gene with a nucleotide sequence selected from SEQ ID NO: 25 and SEQ ID NO: 26.

73. A method for generating a microorganism capable of increased production of a biomolecule from glucose, the method comprising: (a) genetically modifying a host microorganism, wherein the modifying comprises introducing a glucose permease gene from a library of glucose permease genes into the genome of the host microorganism, wherein each glucose permease gene from the library of glucose permease genes is functionally linked to a promoter polynucleotide sequence, wherein the promoter polynucleotide sequence is derived from Corynebacterium glutamicum, is less than 100 base pairs in length, is able to constitutively express genes across different growth conditions, and is able to form a ladder of promoters comprising a plurality of promoters with incrementally increasing levels of promoter activity, wherein the modification generates a strain of the host microorganism expressing the glucose permease gene; (b) repeating step (a) for a plurality of rounds until a plurality of strains of the host microorganism are generated, wherein each strain of the plurality of strains of the host microorganism expresses a separate glucose permease gene from the library of glucose permease genes; (c) contacting each strain of the plurality of strains of the host microorganism with a carbon source comprising glucose under fermentative conditions; and (d) selecting each strain of the host microorganism that produces an increased amount of a biomolecule from glucose as compared to the amount of the biomolecule produce from glucose from a control microorganism, wherein the control microorganism does not express a glucose permease gene from the library of glucose permease genes.

74. The method of claim 73, wherein the library of glucose permease genes comprises genes that encode polypeptide sequences of SEQ ID NO: 13, SEQ ID NO: 10, SEQ ID NO: 11, SEQ ID NO: 12, SEQ ID NO: 9, SEQ ID NO: 14 or a combination thereof.

75. The method of claim 73, wherein the library of glucose permease genes comprises genes with a nucleotide sequence of SEQ ID NO: 23, SEQ ID NO: 20, SEQ ID NO: 21, SEQ ID NO: 22, SEQ ID NO: 19, SEQ ID NO: 24 or a combination thereof.

76. The method of claim 73, further comprising introducing a hexokinase gene from a library of hexokinase genes, wherein each hexokinase gene from the library of hexokinase genes is functionally linked to a promoter polynucleotide sequence, wherein the promoter polynucleotide sequence is derived from Corynebacterium glutamicum, is less than 100 base pairs in length, is able to constitutively express genes across different growth conditions, and is able to form a ladder of promoters comprising a plurality of promoters with incrementally increasing levels of promoter activity.

77. The method of claim 76, wherein the library of hexokinase genes comprises genes that encode polypeptide sequences of SEQ ID NO: 15 and/or SEQ ID NO: 16.

78. The method of claim 76, wherein the library of hexokinase genes comprises genes with nucleotide sequences of SEQ ID NO: 25 and/or SEQ ID NO: 26.

79. A library of glucose permease genes, wherein each glucose permease gene in the library of glucose permease genes is functionally linked to a promoter polynucleotide sequence, wherein the promoter polynucleotide sequence is derived from Corynebacterium glutamicum, is less than 100 base pairs in length, is able to constitutively express genes across different growth conditions, and is able to form a ladder of promoters comprising a plurality of promoters with incrementally increasing levels of promoter activity.

80. The library of claim 79, wherein the library of glucose permease genes comprises genes that encode polypeptide sequences of SEQ ID NO: 13, SEQ ID NO: 10, SEQ ID NO: 11, SEQ ID NO: 12, SEQ ID NO: 9, SEQ ID NO: 14 or a combination thereof.

81. The library of claim 79, wherein the library of glucose permease genes comprises genes with nucleotide sequences of SEQ ID NO: 23, SEQ ID NO: 20, SEQ ID NO: 21, SEQ ID NO: 22, SEQ ID NO: 19, SEQ ID NO: 24 or a combination thereof.

82. The library of claim 79, wherein each glucose permease gene in the library of glucose permease genes is a first portion of a chimeric construct, wherein the chimeric construct comprises a second portion, wherein the second portion is a hexokinase gene.

83. The library of claim 82, wherein the hexokinase gene is functionally linked to a promoter polynucleotide sequence, wherein the promoter polynucleotide sequence is derived from Corynebacterium glutamicum, is less than 100 base pairs in length, is able to constitutively express genes across different growth conditions, and is able to form a ladder of promoters comprising a plurality of promoters with incrementally increasing levels of promoter activity.

84. The library of claim 83, wherein the library of hexokinase-genes comprises genes that encode polypeptide sequences of SEQ ID NO: 15 and/or SEQ ID NO: 16.

85. The library of claim 83, wherein the library of hexokinase genes comprises genes with nucleotide sequences of SEQ ID NO: 25 and/or SEQ ID NO: 26.

86. A method of producing a biomolecule comprising introducing a glucose permease gene from the library of claim 79 into a host cell and culturing the host cell under conditions suitable for producing the biomolecule.

Description

CROSS REFERENCE TO RELATED APPLICATIONS

[0001] This application claims the benefit of priority from U.S. Provisional Application Ser. No. 62/356,924, filed Jun. 30, 2016, which is hereby incorporated by reference in its entirety for all purposes.

STATEMENT REGARDING SEQUENCE LISTING

[0002] The Sequence Listing associated with this application is provided in text format in lieu of a paper copy, and is hereby incorporated by reference into the specification. The name of the text file containing the Sequence Listing is ZYMR_005_01WO_SeqList_ST25.txt. The text file is 49 KB, was created on Jun. 28, 2017, and is being submitted electronically via EFS-Web.

FIELD

[0003] The present disclosure is directed to microbial genomic engineering. The disclosed genomic engineering method entails the generation of a library of glucose permease genes and/or glucokinase genes and introducing said library into microbial hosts in order to produce strains with a desired phenotype (e.g. microbial production of commercial products).

BACKGROUND

[0004] Glucose transport in some microorganisms such as, for example, Corynebacterium. glutamicum is natively accomplished using the phosphotransferase transport system (PTS). In this system, phosphorylation of glucose is carried out simultaneously to transport. The phospho donor is phosphoenolpyruvate (PEP), therefore linking transport directly to glycolytic flux. In addition, the PTS system is natively regulated by a number of transcriptional processes in ways that are not always ideal for the production of commercial products.

[0005] Microbial processes for the production of various commercial products from glucose strive to maximize the efficiency with which the carbon skeleton of glucose is converted into the desired product. Control of glucose flux is critical for the production of products in ways that are dependent on the fermentation process, strain of microbial host being used (e.g., C. glutamicum), and small molecule being produced. If there is too much flux through glycolysis under high concentrations of glucose, glycolytic by-products (usually organic acids) are produced which decrease yield of product. If there is too little transport of glucose into the cell, then it is difficult to produce product at high rates. The genotypes of strains which are engineered in various ways to produce specific products interact with process conditions to lead to situations in which more or less glucose transport occurs than would be ideal to maximize yield or productivity.

[0006] Microbial strain improvement has been attempted by the expression of different glucose permeases and glucokinases which may alter glucose transport in such a way as to increase yield or productivity of commercial products. This has been demonstrated in a number of cases. For example, deletion of the native PTS system for glucose transport and overexpression of a native C. glutamicum permease along with a native C. glutamicum kinase led to the increased yield of lysine production from glucose (see Linder et al. Appl. Environ. Microbiol. June 2011 vol. 77, no. 11 pp 3571-3581, the contents of which are hereby incorporated by reference in their entirety). In another example, overexpression of the glucose permease and glucokinase from Z. mobilis in C. glutamicum was used for the production of small molecules (see U.S. Pat. No. 5,602,030, the contents of which are hereby incorporated by reference in its entirety).

[0007] However, the selection of a particular glucose permease to create the ideal level of glucose transport for a given metabolic process to produce a specific commercial product relies on a good understanding of a number of interacting factors, including the interaction of the genotype of a strain with the process environment in which fermentation takes place. Further, the correct expression, affinity, and transport rate, in combination with glucose and other carbon source concentrations may be required to deliver a balanced flux of glucose into the cell to match the flux through the pathway of interest. Understanding these parameters a priori and then choosing a single permease which embodies them can be difficult or impossible.

[0008] Thus, there is a great need in the art for new methods of engineering industrial microbes for producing specific commercial products, which do not suffer from the aforementioned drawbacks inherent with traditional strain improvement programs.

SUMMARY OF THE DISCLOSURE

[0009] In one aspect, provided herein is a host cell comprising a heterologous glucose permease gene functionally linked to a first promoter polynucleotide, wherein the first promoter polynucleotide comprises a nucleotide sequence selected from SEQ ID NO: 1, SEQ ID NO: 2, SEQ ID NO: 3, SEQ ID NO: 4, SEQ ID NO: 5, SEQ ID NO: 6, SEQ ID NO: 7, and SEQ ID NO: 8. In some cases, the glucose permease gene is a bacterial glucose permease gene. In some cases, the bacterial glucose permease gene is a gene that encodes a polypeptide sequence selected from SEQ ID NO: 13, SEQ ID NO: 10, SEQ ID NO: 11, SEQ ID NO: 12, SEQ ID NO: 9 and SEQ ID NO: 14. In some cases, the bacterial glucose permease gene is a gene with a nucleotide sequence selected from SEQ ID NO: 23, SEQ ID NO: 20, SEQ ID NO: 21, SEQ ID NO: 22, SEQ ID NO: 19 and SEQ ID NO: 24. In some cases, the host cell further comprises a hexokinase gene functionally linked to a second promoter polynucleotide, wherein the second promoter polynucleotide comprises a nucleotide sequence selected from SEQ ID NO: 2, SEQ ID NO: 1, SEQ ID NO: 3, SEQ ID NO: 4, SEQ ID NO: 5, SEQ ID NO: 6, SEQ ID NO: 7, and SEQ ID NO: 8. In some cases, the hexokinase gene is a glucokinase gene. In some cases, the glucokinase gene is a bacterial glucokinase gene. In some cases, the bacterial glucokinase gene is a gene that encodes a polypeptide with an amino acid sequence selected from SEQ ID NO: 15 and SEQ ID NO: 16. In some cases, the bacterial glucokinase gene is a gene with a nucleotide sequence selected from SEQ ID NO: 25 and SEQ ID NO: 26. In some cases, the first promoter polynucleotide and the second promoter polynucleotide are different. In some cases, the first promoter polynucleotide and the second promoter polynucleotide are identical. In some cases, the host cell belongs to the genus Corynebacterium. In some cases, the host cell is Corynebacterium glutamicum. In some cases, the host cell is used in a method of producing a biomolecule from glucose comprising culturing the host cell under conditions suitable for producing the biomolecule. In some cases, the biomolecule is a small molecule, a nucleotide, an amino acid, an organic acid, or an alcohol. In some cases, the amino acid is tyrosine, phenylalanine, tryptophan, aspartic acid, asparagine, threonine, isoleucine, methionine, or lysine. In some cases, the organic acid is succinate, lactate or pyruvate. In some cases, the alcohol is ethanol or isobutanol.

[0010] In another aspect, provided herein is a method for generating a microorganism capable of increased production of a biomolecule from glucose, the method comprising: a) genetically modifying a host microorganism, wherein the modifying comprises introducing a glucose permease gene from a library of glucose permease genes into the genome of the host microorganism, wherein each glucose permease gene from the library of glucose permease genes is functionally linked to a promoter comprising a nucleotide sequence selected from SEQ ID NO: 1, SEQ ID NO: 2, SEQ ID NO: 3, SEQ ID NO: 4, SEQ ID NO: 5, SEQ ID NO: 6, SEQ ID NO: 7, and SEQ ID NO: 8 and wherein the modification generates a strain of the host microorganism expressing the glucose permease gene; b) repeating step a) for a plurality of rounds until a plurality of strains of the host microorganism are generated, wherein each strain of the plurality of strains of the host microorganism expresses a separate glucose permease gene from the library of glucose permease genes; c) contacting each strain of the plurality of strains of the host microorganism with a carbon source comprising glucose under fermentative conditions; and d) selecting each strain of the host microorganism that produces an increased amount of a biomolecule from glucose as compared to the amount of the biomolecule produce from glucose from a control microorganism, wherein the control microorganism does not express a glucose permease gene from the library of glucose permease genes. In some cases, each of the glucose permease genes in the library of glucose permease genes is a bacterial glucose permease gene. In some cases, the library of bacterial glucose permease genes comprises genes that encode polypeptide sequences of SEQ ID NO: 13, SEQ ID NO: 10, SEQ ID NO: 11, SEQ ID NO: 12, SEQ ID NO: 9, SEQ ID NO: 14 or a combination thereof. In some cases, the library of bacterial glucose permease genes comprises genes with a nucleotide sequence of SEQ ID NO: 23, SEQ ID NO: 20, SEQ ID NO: 21, SEQ ID NO: 22, SEQ ID NO: 19, SEQ ID NO: 24 or a combination thereof. In some cases, the method further comprises introducing a hexokinase gene from a library of hexokinase genes, wherein each hexokinase gene from the library of hexokinase genes is functionally linked to a promoter polynucleotide, wherein the promoter polynucleotide comprises a sequence selected from SEQ ID NO: 2, SEQ ID NO: 1, SEQ ID NO: 3, SEQ ID NO: 4, SEQ ID NO: 5, SEQ ID NO: 6, SEQ ID NO: 7, and SEQ ID NO: 8. In some cases, the introduction of each hexokinase gene from the library of hexokinase genes is concurrent with the introduction of each glucose permease gene from the library of glucose permease genes. In some cases, each hexokinase gene from the library of hexokinase genes is present in a chimeric construct comprising a glucose permease gene from the library of glucose permease genes. In some cases, the hexokinase gene is a glucokinase gene. In some cases, the glucokinase gene is a bacterial glucokinase gene. In some cases, the library of bacterial glucokinase genes comprises genes that encode polypeptide sequences of SEQ ID NO: 15 and/or SEQ ID NO: 16. In some cases, the library of bacterial glucokinase genes comprises genes with nucleotide sequences of SEQ ID NO: 25 and/or SEQ ID NO: 26. In some cases, the promoter polynucleotide functionally linked to the glucose permease gene and the promoter polynucleotide functionally linked to the hexokinase gene are different. In some cases, the promoter polynucleotide functionally linked to the glucose permease gene and the promoter polynucleotide functionally linked to the hexokinase gene are identical. In some cases, the host microorganism belongs to the genus Corynebacterium. In some cases, the host microorganism is Corynebacterium glutamicum. In some cases, the introducing is performed by transformation, transduction or electroporation. In some cases, the biomolecule is a small molecule, an amino acid, a nucleotide, an organic acid, or an alcohol. In some cases, the amino acid is tyrosine, phenylalanine, tryptophan, aspartic acid, asparagine, threonine, isoleucine, methionine, or lysine. In some cases, the organic acid is succinate, lactate or pyruvate. In some cases, the alcohol is ethanol or isobutanol.

[0011] In yet another aspect, provided herein is a library of glucose permease genes, wherein each glucose permease gene in the library of glucose permease genes is functionally linked to a promoter comprising a nucleotide sequence selected from SEQ ID NO: 1, SEQ ID NO: 2, SEQ ID NO: 3, SEQ ID NO: 4, SEQ ID NO: 5, SEQ ID NO: 6, SEQ ID NO: 7, and SEQ ID NO: 8. In some cases, each glucose permease gene is a bacterial glucose permease gene. In some cases, the library of bacterial glucose permease genes comprises genes that encode polypeptide sequences of SEQ ID NO: 13, SEQ ID NO: 10, SEQ ID NO: 11, SEQ ID NO: 12, SEQ ID NO: 9, SEQ ID NO: 14 or a combination thereof. In some cases, the library of bacterial glucose permease genes comprises genes with nucleotide sequences of SEQ ID NO: 23, SEQ ID NO: 20, SEQ ID NO: 21, SEQ ID NO: 22, SEQ ID NO: 19, SEQ ID NO: 24 or a combination thereof. In some cases, each glucose permease gene in the library of glucose permease genes is a first portion of a chimeric construct, wherein the chimeric construct comprises a second portion, wherein the second portion is a hexokinase gene. In some cases, the hexokinase gene is functionally linked to a promoter polynucleotide, wherein the promoter polynucleotide comprises a sequence selected from SEQ ID NO: 2, SEQ ID NO: 1, SEQ ID NO: 3, SEQ ID NO: 4, SEQ ID NO: 5, SEQ ID NO: 6, SEQ ID NO: 7, and SEQ ID NO: 8. In some cases, the hexokinase gene is a glucokinase gene. In some cases, the glucokinase gene is a bacterial glucokinase gene. In some cases, the library of bacterial glucokinase genes comprises genes that encode polypeptide sequences of SEQ ID NO: 15 and/or SEQ ID NO: 16. In some cases, the library of bacterial glucokinase genes comprises genes with nucleotides sequences of SEQ ID NO: 25 and/or SEQ ID NO: 26. In some cases, the promoter polynucleotide functionally linked to the glucose permease gene and the promoter polynucleotide functionally linked to the hexokinase gene are different. In some cases, the promoter polynucleotide functionally linked to the glucose permease gene and the promoter polynucleotide functionally linked to the hexokinase gene are identical. In some cases, the library is used in a method of producing a biomolecule comprising introducing a glucose permease gene from the library into a host cell and culturing the host cell under conditions suitable for producing the biomolecule. In some cases, the biomolecule is an amino acid, a nucleotide, an organic acid, or an alcohol. In some cases, the amino acid is tyrosine, phenylalanine, tryptophan, aspartic acid, asparagine, threonine, isoleucine, methionine, or lysine. In some cases, the organic acid is succinate, lactate or pyruvate. In some cases, the alcohol is ethanol or isobutanol. In some cases, the host cell belongs to the genus Corynebacterium. In some cases, the host cell is Corynebacterium glutamicum. In some cases, the introducing is performed by transformation, transduction or electroporation.

[0012] In another aspect, provided herein is an isolated, synthetic or recombinant polynucleotide comprising a codon optimized polynucleotide selected from SEQ ID NO: 23, SEQ ID NO: 20, SEQ ID NO: 21, SEQ ID NO: 22, SEQ ID NO: 19 and SEQ ID NO: 24, wherein the polynucleotide is codon optimized for expression in a host cell. In some cases, the host cell is E. coli and/or C. glutamicum.

[0013] In a further aspect, provided herein is an isolated, synthetic or recombinant polynucleotide comprising a codon optimized polynucleotide selected from SEQ ID NO: 25 and SEQ ID NO: 26, wherein the polynucleotide is codon optimized for expression in a host cell. In some cases, the host cell is E. coli and/or C. glutamicum.

[0014] In yet another aspect, provided herein is an isolated, synthetic or recombinant polynucleotide comprising a first codon optimized polynucleotide and a second codon optimized polynucleotide, wherein the first polynucleotide and the second polynucleotide are each codon optimized for expression in a host cell, and wherein the first codon optimized polynucleotide encodes a polypeptide with glucose permease activity and the second codon optimized polynucleotide encodes a polypeptide with glucokinase activity. In some cases, the first codon optimized polynucleotide is selected from SEQ ID NO: 23, SEQ ID NO: 20, SEQ ID NO: 21, SEQ ID NO: 22, SEQ ID NO: 19 and SEQ ID NO: 24. In some cases, the second codon optimized polynucleotide is selected from SEQ ID NO: 25 and SEQ ID NO: 26. In some cases, the polypeptide with glucose permease activity comprises a sequence selected from SEQ ID NO: 13, SEQ ID NO: 10, SEQ ID NO: 11, SEQ ID NO: 12, SEQ ID NO: 9 and SEQ ID NO: 14. In some cases, the polypeptide with glucokinase activity comprises a sequence selected from SEQ ID NO: 15 and SEQ ID NO: 16. In some cases, the host cell is E. coli and/or C. glutamicum.

BRIEF DESCRIPTION OF THE FIGURES

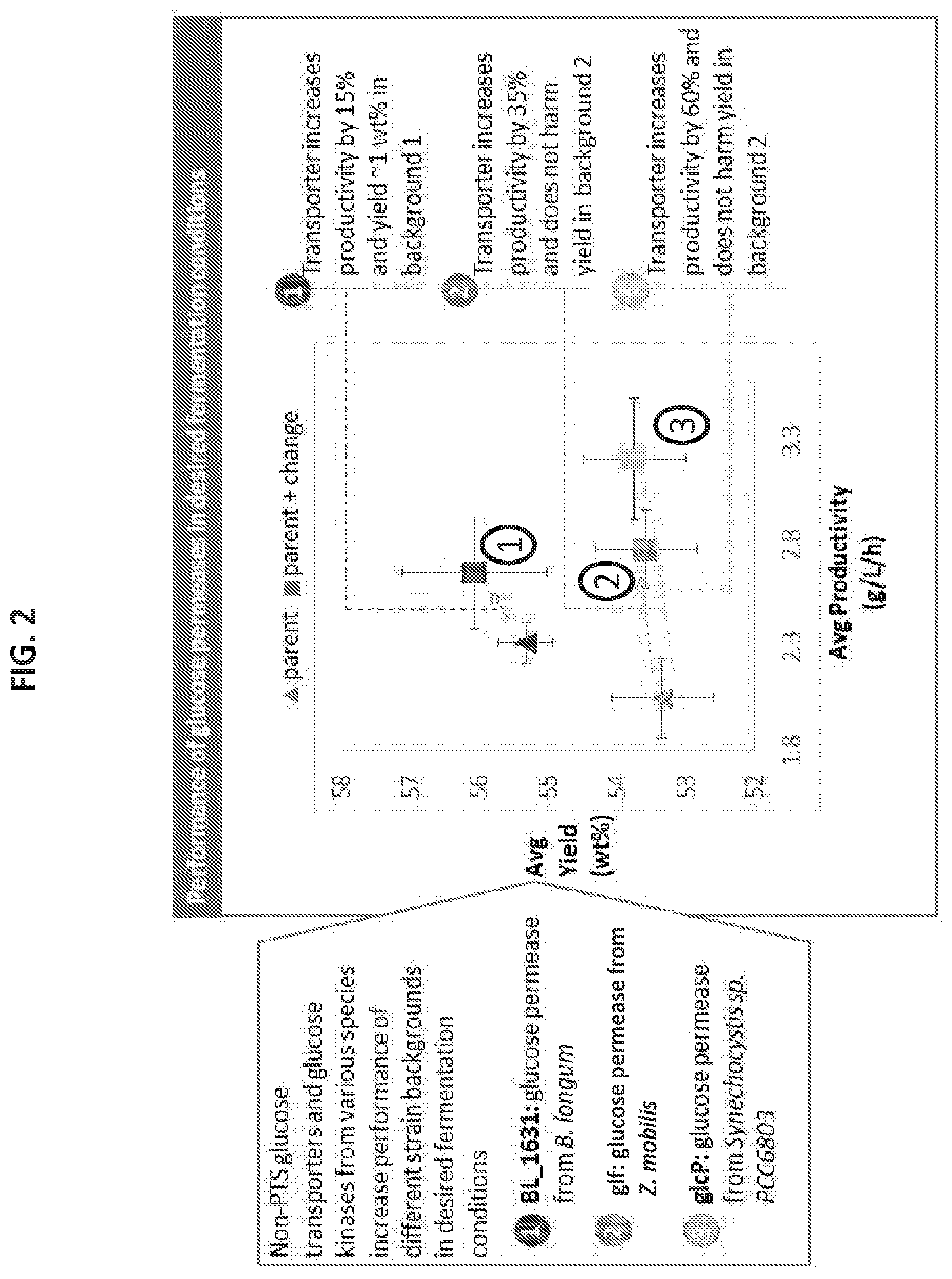

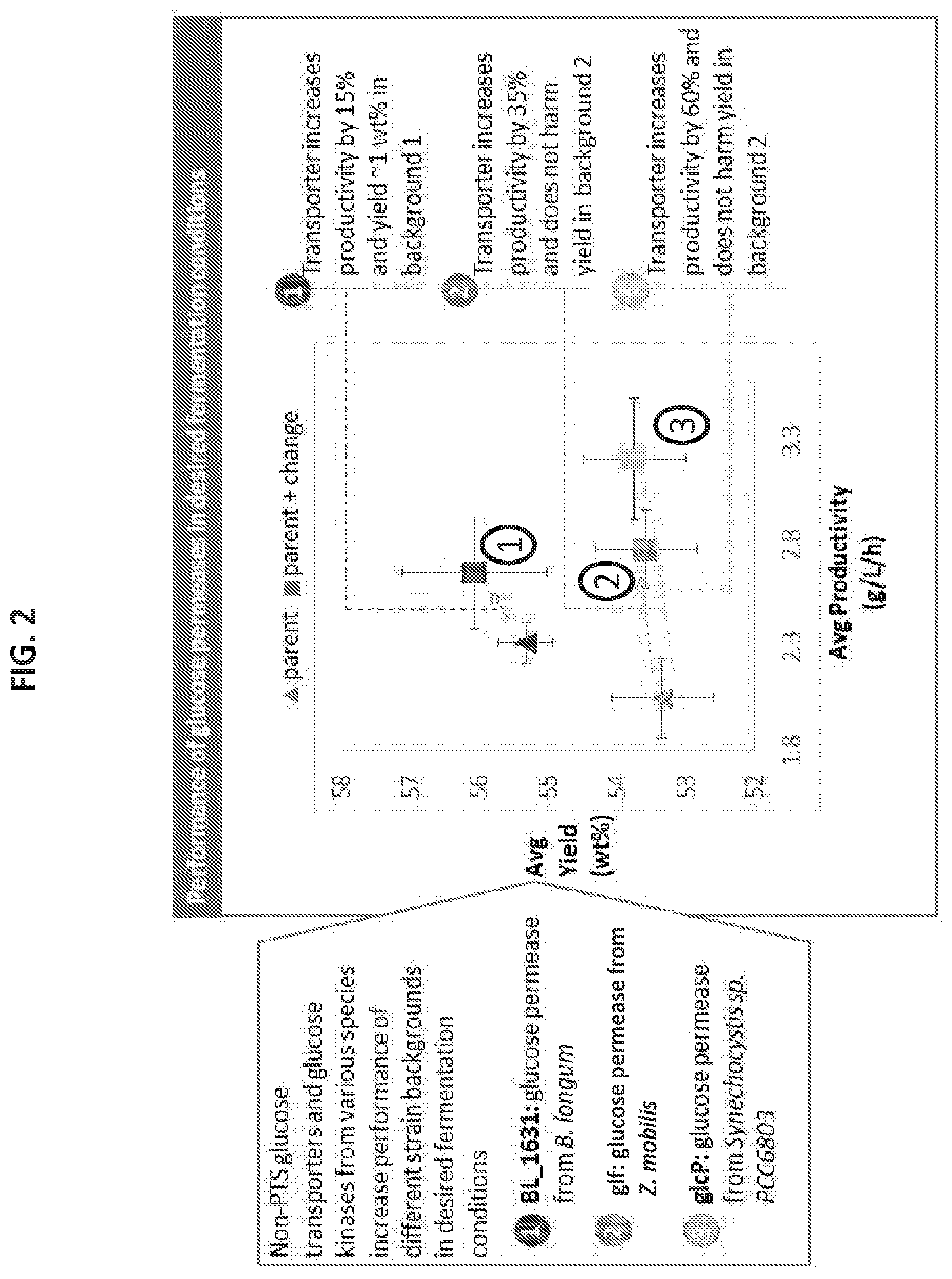

[0015] FIG. 1 illustrates performance of glucose permeases in evaluation method as described in Example 1.

[0016] FIG. 2 illustrates performance of glucose permeases in desired fermentation conditions as described in Example 1.

[0017] FIG. 3 illustrates assembly of transformation plasmids of the present disclosure, and their integration into host organisms. The insert sequence insert DNA is generated by combining one or more synthesized oligonucleotides in an assembly reaction. DNA inserts contain desired promoter sequence flanked by direct repeat region (i.e., homology arms) designed for looping out DNA in subsequent steps. Assembled plasmids contain the insert DNA (permease gene and/or glucokinase gene functionally linked to promoters provided herein), and optionally, one or more selection markers.

[0018] FIG. 4 illustrates a procedure for looping-out selected regions of DNA from host strains. Direct repeat (DR) regions of the inserted DNA form a loop with corresponding sequences in the host strain's genome. Cells counter selected for selection marker exhibit DNA deletion of loop DNA.

DETAILED DESCRIPTION

Definitions

[0019] While the following terms are believed to be well understood by one of ordinary skill in the art, the following definitions are set forth to facilitate explanation of the presently disclosed subject matter.

[0020] The term "a" or "an" refers to one or more of that entity, i.e. can refer to a plural referents. As such, the terms "a" or "an", "one or more" and "at least one" are used interchangeably herein. In addition, reference to "an element" by the indefinite article "a" or "an" does not exclude the possibility that more than one of the elements is present, unless the context clearly requires that there is one and only one of the elements.

[0021] Unless the context requires otherwise, throughout the present specification and claims, the word "comprise" and variations thereof, such as, "comprises" and "comprising" are to be construed in an open, inclusive sense that is as "including, but not limited to".

[0022] Reference throughout this specification to "one embodiment" or "an embodiment" means that a particular feature, structure or characteristic described in connection with the embodiment may be included in at least one embodiment of the present disclosure. Thus, the appearances of the phrases "in one embodiment" or "in an embodiment" in various places throughout this specification may not necessarily all refer to the same embodiment. It is appreciated that certain features of the invention, which are, for clarity, described in the context of separate embodiments, may also be provided in combination in a single embodiment. Conversely, various features of the invention, which are, for brevity, described in the context of a single embodiment, may also be provided separately or in any suitable sub-combination.

[0023] As used herein the terms "cellular organism" "microorganism" or "microbe" should be taken broadly. These terms can be used interchangeably and include, but may not be limited to, the two prokaryotic domains, Bacteria and Archaea, as well as certain eukaryotic fungi and protists. In some embodiments, the disclosure refers to the "microorganisms" or "cellular organisms" or "microbes" of lists/tables and figures present in the disclosure. This characterization can refer to not only the identified taxonomic genera of the tables and figures, but also the identified taxonomic species, as well as the various novel and newly identified or designed strains of any organism in said tables or figures. The same characterization holds true for the recitation of these terms in other parts of the Specification, such as in the Examples.

[0024] The term "prokaryotes" is art recognized and refers to cells which contain no nucleus or other cell organelles. The prokaryotes are generally classified in one of two domains, the Bacteria and the Archaea. The definitive difference between organisms of the Archaea and Bacteria domains is based on fundamental differences in the nucleotide base sequence in the 16S ribosomal RNA.

[0025] The term "Archaea" refers to a categorization of organisms of the division Mendosicutes, typically found in unusual environments and distinguished from the rest of the prokaryotes by several criteria, including the number of ribosomal proteins and the lack of muramic acid in cell walls. On the basis of ssrRNA analysis, the Archaea consist of two phylogenetically-distinct groups: Crenarchaeota and Euryarchaeota. On the basis of their physiology, the Archaea can be organized into three types: methanogens (prokaryotes that produce methane); extreme halophiles (prokaryotes that live at very high concentrations of salt (NaCl); and extreme (hyper) thermophilus (prokaryotes that live at very high temperatures). Besides the unifying archaeal features that distinguish them from Bacteria (i.e., no murein in cell wall, ester-linked membrane lipids, etc.), these prokaryotes exhibit unique structural or biochemical attributes which adapt them to their particular habitats. The Crenarchaeota consists mainly of hyperthermophilic sulfur-dependent prokaryotes and the Euryarchaeota contains the methanogens and extreme halophiles.

[0026] "Bacteria" or "eubacteria" refers to a domain of prokaryotic organisms. Bacteria include at least 11 distinct groups as follows: (1) Gram-positive (gram+) bacteria, of which there are two major subdivisions: (1) high G+C group (Actinomycetes, Mycobacteria, Micrococcus, others) (2) low G+C group (Bacillus, Clostridia, Lactobacillus, Staphylococci, Streptococci, Mycoplasmas); (2) Proteobacteria, e.g., Purple photosynthetic+non-photosynthetic Gram-negative bacteria (includes most "common" Gram-negative bacteria); (3) Cyanobacteria, e.g., oxygenic phototrophs; (4) Spirochetes and related species; (5) Planctomyces; (6) Bacteroides, Flavobacteria; (7) Chlamydia; (8) Green sulfur bacteria; (9) Green non-sulfur bacteria (also anaerobic phototrophs); (10) Radioresistant micrococci and relatives; (11) Thermotoga and Thermosipho thermophiles.

[0027] A "eukaryote" is any organism whose cells contain a nucleus and other organelles enclosed within membranes. Eukaryotes belong to the taxon Eukarya or Eukaryota. The defining feature that sets eukaryotic cells apart from prokaryotic cells (the aforementioned Bacteria and Archaea) is that they have membrane-bound organelles, especially the nucleus, which contains the genetic material, and is enclosed by the nuclear envelope.

[0028] The terms "genetically modified microorganism," "recombinant microorganism," "recombinant host cell," and "recombinant strain" can be used interchangeably herein and can refer to microorganisms that have been genetically modified. Thus, the terms include a microorganism (e.g., bacteria, yeast cell, fungal cell, etc.) that has been genetically altered, modified, or engineered, such that it exhibits an altered, modified, or different genotype and/or phenotype (e.g., when the genetic modification affects coding nucleic acid sequences of the microorganism), as compared to the naturally-occurring microorganism from which it was derived. It is understood that the terms refer not only to the particular recombinant microorganism in question, but also to the progeny or potential progeny of such a microorganism.

[0029] The term "wild-type microorganism" can describe a cell that occurs in nature, i.e. a cell that has not been genetically modified.

[0030] The term "genetically engineered" may refer to any manipulation of a microorganism's genome (e.g. by insertion or deletion of nucleic acids).

[0031] As used herein, the term "allele(s)" can mean any of one or more alternative forms of a gene, all of which alleles relate to at least one trait or characteristic. In a diploid cell, the two alleles of a given gene can occupy corresponding loci on a pair of homologous chromosomes. Since the present disclosure, in embodiments, relates to QTLs, i.e. genomic regions that may comprise one or more genes or regulatory sequences, it is in some instances more accurate to refer to "haplotype" (i.e. an allele of a chromosomal segment) instead of "allele", however, in those instances, the term "allele" should be understood to comprise the term "haplotype".

[0032] As used herein, the term "locus" (loci plural) can mean a specific place or places or a site on a chromosome where for example a gene or genetic marker is found.

[0033] As used herein, the term "genetically linked" can refer to two or more traits that are co-inherited at a high rate during breeding such that they are difficult to separate through crossing.

[0034] A "recombination" or "recombination event" as used herein can refer to a chromosomal crossing over or independent assortment. The term "recombinant" can refer to an organism having a new genetic makeup arising as a result of a recombination event.

[0035] As used herein, the term "phenotype" can refer to the observable characteristics of an individual cell, cell culture, organism, or group of organisms which results from the interaction between that individual's genetic makeup (i.e., genotype) and the environment.

[0036] As used herein, the term "chimeric" or "recombinant" when describing a nucleic acid sequence or a protein sequence can refer to a nucleic acid, or a protein sequence, that links at least two heterologous polynucleotides, or two heterologous polypeptides, into a single macromolecule, or that can re-arrange one or more elements of at least one natural nucleic acid or protein sequence. For example, the term "recombinant" can refer to an artificial combination of two otherwise separated segments of sequence, e.g., by chemical synthesis or by the manipulation of isolated segments of nucleic acids by genetic engineering techniques.

[0037] As used herein, a "synthetic nucleotide sequence" or "synthetic polynucleotide sequence" can be a nucleotide sequence that is not known to occur in nature or that is not naturally occurring. Generally, such a synthetic nucleotide sequence will comprise at least one nucleotide difference when compared to any other naturally occurring nucleotide sequence.

[0038] As used herein, the term "nucleic acid" can refer to a polymeric form of nucleotides of any length, either ribonucleotides or deoxyribonucleotides, or analogs thereof. This term can refer to the primary structure of the molecule, and thus includes double- and single-stranded DNA, as well as double- and single-stranded RNA. It can also include modified nucleic acids such as methylated and/or capped nucleic acids, nucleic acids containing modified bases, backbone modifications, and the like. The terms "nucleic acid" and "nucleotide sequence" can be used interchangeably.

[0039] As used herein, the term "gene" can refer to any segment of DNA associated with a biological function. Thus, genes can include, but are not limited to, coding sequences and/or the regulatory sequences required for their expression. Genes can also include non-expressed DNA segments that, for example, form recognition sequences for other proteins. Genes can be obtained from a variety of sources, including cloning from a source of interest or synthesizing from known or predicted sequence information, and may include sequences designed to have desired parameters.

[0040] As used herein, the term "homologous" or "homologue" or "ortholog" is known in the art and can refer to related sequences that share a common ancestor or family member and are determined based on the degree of sequence identity. The terms "homology," "homologous," "substantially similar" and "corresponding substantially" can be used interchangeably herein. They can refer to nucleic acid fragments wherein changes in one or more nucleotide bases do not affect the ability of the nucleic acid fragment to mediate gene expression or produce a certain phenotype. These terms can also refer to modifications of the nucleic acid fragments of the instant disclosure such as deletion or insertion of one or more nucleotides that do not substantially alter the functional properties of the resulting nucleic acid fragment relative to the initial, unmodified fragment. It is therefore understood, as those skilled in the art will appreciate, that the disclosure can encompass more than the specific exemplary sequences. These terms can describe the relationship between a gene found in one species, subspecies, variety, cultivar or strain and the corresponding or equivalent gene in another species, subspecies, variety, cultivar or strain. For purposes of this disclosure homologous sequences can be compared. "Homologous sequences" or "homologues" or "orthologs" can be thought, believed, or known to be functionally related. A functional relationship may be indicated in any one of a number of ways, including, but not limited to: (a) degree of sequence identity and/or (b) the same or similar biological function. Preferably, both (a) and (b) are indicated. Homology can be determined using software programs readily available in the art, such as those discussed in Current Protocols in Molecular Biology (F. M. Ausubel et al., eds., 1987) Supplement 30, section 7.718, Table 7.71. Some alignment programs are MacVector (Oxford Molecular Ltd, Oxford, U.K.), ALIGN Plus (Scientific and Educational Software, Pennsylvania) and AlignX (Vector NTI, Invitrogen, Carlsbad, Calif.). Another alignment program is Sequencher (Gene Codes, Ann Arbor, Mich.), using default parameters.

[0041] As used herein, the term "nucleotide change" can refer to, e.g., nucleotide substitution, deletion, and/or insertion, as is well understood in the art. For example, mutations contain alterations that produce silent substitutions, additions, or deletions, but do not alter the properties or activities of the encoded protein or how the proteins are made.

[0042] As used herein, the term "protein modification" can refer to, e.g., amino acid substitution, amino acid modification, deletion, and/or insertion, as is well understood in the art.

[0043] As used herein, the term "at least a portion" or "fragment" of a nucleic acid or polypeptide can mean a portion having the minimal size characteristics of such sequences, or any larger fragment of the full length molecule, up to and including the full length molecule. A fragment of a polynucleotide of the disclosure may encode a biologically active portion of a genetic regulatory element. A biologically active portion of a genetic regulatory element can be prepared by isolating a portion of one of the polynucleotides of the disclosure that comprises the genetic regulatory element and assessing activity as described herein. Similarly, a portion of a polypeptide may be 4 amino acids, 5 amino acids, 6 amino acids, 7 amino acids, and so on, going up to the full length polypeptide. The length of the portion to be used can depend on the particular application. A portion of a nucleic acid useful as a hybridization probe may be as short as 12 nucleotides; in some embodiments, it is 20 nucleotides. A portion of a polypeptide useful as an epitope may be as short as 4 amino acids. A portion of a polypeptide that performs the function of the full-length polypeptide can generally be longer than 4 amino acids.

[0044] Variant polynucleotides also encompass sequences that can be derived from a mutagenic and recombinogenic procedure such as DNA shuffling. Strategies for such DNA shuffling are known in the art. See, for example, Stemmer (1994) PNAS 91:10747-10751; Stemmer (1994) Nature 370:389-391; Crameri et al. (1997) Nature Biotech. 15:436-438; Moore et al. (1997) J. Mol. Biol. 272:336-347; Zhang et al. (1997) PNAS 94:4504-4509; Crameri et al. (1998) Nature 391:288-291; and U.S. Pat. Nos. 5,605,793 and 5,837,458.

[0045] For PCR amplifications of the polynucleotides disclosed herein, oligonucleotide primers can be designed for use in PCR reactions to amplify corresponding DNA sequences from cDNA or genomic DNA extracted from any organism of interest. Methods for designing PCR primers and PCR cloning are generally known in the art and are disclosed in Sambrook et al. (2001) Molecular Cloning: A Laboratory Manual (3.sup.rd ed., Cold Spring Harbor Laboratory Press, Plainview, N.Y.). See also Innis et al., eds. (1990) PCR Protocols: A Guide to Methods and Applications (Academic Press, New York); Innis and Gelfand, eds. (1995) PCR Strategies (Academic Press, New York); and Innis and Gelfand, eds. (1999) PCR Methods Manual (Academic Press, New York). Known methods of PCR can include, but are not limited to, methods using paired primers, nested primers, single specific primers, degenerate primers, gene-specific primers, vector-specific primers, partially-mismatched primers, and the like.

[0046] The term "primer" as used herein can refer to an oligonucleotide which is capable of annealing to the amplification target allowing a DNA polymerase to attach, thereby serving as a point of initiation of DNA synthesis when placed under conditions in which synthesis of primer extension product is induced, i.e., in the presence of nucleotides and an agent for polymerization such as DNA polymerase and at a suitable temperature and pH. The (amplification) primer is preferably single stranded for maximum efficiency in amplification. Preferably, the primer is an oligodeoxyribonucleotide. The primer must be sufficiently long to prime the synthesis of extension products in the presence of the agent for polymerization. The exact lengths of the primers will depend on many factors, including temperature and composition (A/T vs. G/C content) of primer. A pair of bi-directional primers consists of one forward and one reverse primer as commonly used in the art of DNA amplification such as in PCR amplification.

[0047] The terms "stringency" or "stringent hybridization conditions" can refer to hybridization conditions that affect the stability of hybrids, e.g., temperature, salt concentration, pH, formamide concentration and the like. These conditions can be empirically optimized to maximize specific binding and minimize non-specific binding of primer or probe to its target nucleic acid sequence. The terms as used can include reference to conditions under which a probe or primer will hybridize to its target sequence, to a detectably greater degree than other sequences (e.g. at least 2-fold over background). Stringent conditions can be sequence dependent and will be different in different circumstances. Longer sequences can hybridize specifically at higher temperatures. Generally, stringent conditions can be selected to be about 5.degree. C. lower than the thermal melting point (Tm) for the specific sequence at a defined ionic strength and pH. The Tm can be the temperature (under defined ionic strength and pH) at which 50% of a complementary target sequence hybridizes to a perfectly matched probe or primer. Typically, stringent conditions may be those in which the salt concentration is less than about 1.0 M Na+ ion, typically about 0.01 to 1.0 M Na+ion concentration (or other salts) at pH 7.0 to 8.3 and the temperature is at least about 30.degree. C. for short probes or primers (e.g. 10 to 50 nucleotides) and at least about 60.degree. C. for long probes or primers (e.g. greater than 50 nucleotides). Stringent conditions may also be achieved with the addition of destabilizing agents such as formamide. Exemplary low stringent conditions or "conditions of reduced stringency" can include hybridization with a buffer solution of 30% formamide, 1 M NaCl, 1% SDS at 37.degree. C. and a wash in 2.times.SSC at 40.degree. C. Exemplary high stringency conditions include hybridization in 50% formamide, 1M NaCl, 1% SDS at 37.degree. C., and a wash in 0.1.times.SSC at 60.degree. C. Hybridization procedures are well known in the art and are described by e.g. Ausubel et al., 1998 and Sambrook et al., 2001. In some embodiments, stringent conditions are hybridization in 0.25 M Na2HPO4 buffer (pH 7.2) containing 1 mM Na2EDTA, 0.5-20% sodium dodecyl sulfate at 45.degree. C., such as 0.5%, 1%, 2%, 3%, 4%, 5%, 6%, 7%, 8%, 9%, 10%, 11%, 12%, 13%, 14%, 15%, 16%, 17%, 18%, 19% or 20%, followed by a wash in 5.times.SSC, containing 0.1% (w/v) sodium dodecyl sulfate, at 55.degree. C. to 65.degree. C.

[0048] As used herein, "promoter" or "promoter polynucleotide" can refer to a DNA sequence capable of controlling the expression of a coding sequence or functional RNA. The promoter sequence consists of proximal and more distal upstream elements, the latter elements can often be referred to as enhancers. Accordingly, an "enhancer" can be a DNA sequence that can stimulate promoter activity, and may be an innate element of the promoter or a heterologous element inserted to enhance the level or tissue specificity of a promoter. Promoters may be derived in their entirety from a native gene, or be composed of different elements derived from different promoters found in nature, or even comprise synthetic DNA segments. It is understood by those skilled in the art that different promoters may direct the expression of a gene in different tissues or cell types, or at different stages of development, or in response to different environmental conditions. It is further recognized that since in most cases the exact boundaries of regulatory sequences have not been completely defined, DNA fragments of some variation may have identical promoter activity.

[0049] As used herein, the phrases "recombinant construct", "expression construct", "chimeric construct", "construct", and "recombinant DNA construct" can be used interchangeably herein. A recombinant construct comprises an artificial combination of nucleic acid fragments, e.g., regulatory and coding sequences that are not found together in nature. For example, a chimeric construct may comprise regulatory sequences and coding sequences that are derived from different sources, or regulatory sequences and coding sequences derived from the same source, but arranged in a manner different than that found in nature. In some cases, a chimeric construct can be a recombinant construct comprising a plurality of regulatory (e.g., promoter) and coding sequences (e.g., glucose permease gene and hexokinase gene (glucokinase gene)). Each coding sequence in a chimeric construct comprising a plurality of coding sequences can be controlled by or functionally linked to a separate regulatory sequence). Such constructs described herein may be used by itself or may be used in conjunction with a vector. If a vector is used then the choice of vector can be dependent upon the method that will be used to transform host cells as is well known to those skilled in the art. For example, a plasmid vector can be used. The skilled artisan is well aware of the genetic elements that must be present on the vector in order to successfully transform, select and propagate host cells comprising any of the isolated nucleic acid fragments of the disclosure. The skilled artisan will also recognize that different independent transformation events will result in different levels and patterns of expression (Jones et al., (1985) EMBO J. 4:2411-2418; De Almeida et al., (1989) Mol. Gen. Genetics 218:78-86), and thus that multiple events must be screened in order to obtain lines displaying the desired expression level and pattern. Such screening may be accomplished by Southern analysis of DNA, Northern analysis of mRNA expression, immunoblotting analysis of protein expression, or phenotypic analysis, among others. Vectors can be plasmids, viruses, bacteriophages, pro-viruses, phagemids, transposons, artificial chromosomes, and the like, that replicate autonomously or can integrate into a chromosome of a host cell. A vector can also be a naked RNA polynucleotide, a naked DNA polynucleotide, a polynucleotide composed of both DNA and RNA within the same strand, a poly-lysine-conjugated DNA or RNA, a peptide-conjugated DNA or RNA, a liposome-conjugated DNA, or the like, that is not autonomously replicating. As used herein, the term "expression" refers to the production of a functional end-product e.g., an mRNA or a protein (precursor or mature).

[0050] "Operably linked" or "functionally linked" can mean in this context the sequential arrangement of the promoter polynucleotide according to the disclosure with a further oligo- or polynucleotide (e.g., glucose permease gene and/or glucokinase gene), resulting in transcription of said further polynucleotide (e.g., glucose permease gene and/or glucokinase gene). In other words, "operably linked" or "functionally linked" can mean the promoter controls the transcription of the gene (e.g. glucose permease gene and/or glucokinase gene) adjacent or downstream or 3' to said promoter.

[0051] The term "carbon source" generally can refer to a substance suitable to be used as a source of carbon for cell growth. Carbon sources can include, but are not limited to, biomass hydrolysates, starch, sucrose, cellulose, hemicellulose, xylose, and lignin, as well as monomeric components of these substrates. Carbon sources can comprise various organic compounds in various forms, including, but not limited to polymers, carbohydrates, acids, alcohols, aldehydes, ketones, amino acids, peptides, etc. These can include, for example, various monosaccharides such as glucose, dextrose (D-glucose), maltose, oligosaccharides, polysaccharides, saturated or unsaturated fatty acids, succinate, lactate, acetate, ethanol, etc., or mixtures thereof. Photosynthetic organisms can additionally produce a carbon source as a product of photosynthesis. In some embodiments, carbon sources may be selected from biomass hydrolysates and glucose.

[0052] The term "feedstock" can be defined as a raw material or mixture of raw materials supplied to a microorganism or fermentation process from which other products can be made. For example, a carbon source, such as biomass or the carbon compounds derived from biomass can be a feedstock for a microorganism that produces a product of interest (e.g. small molecule, peptide, synthetic compound, fuel, alcohol, etc.) in a fermentation process. However, a feedstock may contain nutrients other than a carbon source.

[0053] The term "volumetric productivity" or "production rate" can be defined as the amount of product formed per volume of medium per unit of time. Volumetric productivity can be reported in gram per liter per hour (g/L/h).

[0054] The term "specific productivity" can defined as the rate of formation of the product. To describe productivity as an inherent parameter of the microorganism and not of the fermentation process, productivity can herein further be defined as the specific productivity in gram product per gram of cell dry weight (CDW) per hour (g/g CDW/h). Using the relation of CDW to OD.sub.600 for the given microorganism specific productivity can also be expressed as gram product per liter culture medium per optical density of the culture broth at 600 nm (OD) per hour (g/L/h/OD)

[0055] The term "yield" can be defined as the amount of product obtained per unit weight of raw material and may be expressed as g product per g substrate (g/g). Yield may be expressed as a percentage of the theoretical yield. "Theoretical yield" is defined as the maximum amount of product that can be generated per a given amount of substrate as dictated by the stoichiometry of the metabolic pathway used to make the product.

[0056] The term "titre" or "titer" can be defined as the strength of a solution or the concentration of a substance in solution. For example, the titre of a product of interest (e.g. small molecule, peptide, synthetic compound, fuel, alcohol, etc.) in a fermentation broth can be described as g of product of interest in solution per liter of fermentation broth (g/L).

[0057] The term "total titer" can be defined as the sum of all product of interest produced in a process, including but not limited to the product of interest in solution, the product of interest in gas phase if applicable, and any product of interest removed from the process and recovered relative to the initial volume in the process or the operating volume in the process.

[0058] As used herein, the term "glucose permease" can refer to any transporter (e.g., myo-inositol transporter and/or glucose permease) that exhibits an affinity for glucose and subsequently facilitates its transport across the cell membrane of a host cell. The glucose permease can be a transmembrane protein. The transport can be passive transport whereby glucose diffuses in or out of the host cell as facilitated by the glucose permease. The glucose permease can be derived from a prokaryotic cell (i.e., Bacteria or Archaea) or a eukaryotic cell (e.g., a fungal cell). The prokaryotic glucose permease protein can be from any genus and species of bacteria or Archaea known in the art. The eukaryotic glucose permease protein can be, for example, from any genus and species of fungus known in the art. The term "bacterial glucose permease" as used herein can refer to a glucose permease as described herein derived from a bacteria.

[0059] As used herein, the term "glucose permease gene" can refer to any nucleic acid (e.g., genomic DNA, cDNA and/or mRNA) that when transcribed and/or translated encodes a glucose permease protein as described herein. The term "bacterial glucose permease gene" as used herein can refer to a bacterial glucose permease protein as described herein derived from a bacteria.

[0060] As used herein, the term "hexokinase" can refer to any protein derived from a prokaryotic cell (i.e., Bacteria or Archaea) or a eukaryotic cell (e.g., a fungal cell) that is an enzyme that can facilitate the phosphorylation of a hexose (six-carbon sugar). As provided herein, a hexokinase can be a glucokinase. As used herein, the term "glucokinase" can refer to any protein derived from a prokaryotic cell (i.e., Bacteria or Archaea) or a eukaryotic cell (e.g., a fungal cell) that is an enzyme that can facilitate the phosphorylation of glucose to glucose-6-phosphate. The prokaryotic hexokinase or glucokinase protein can be from any genus and species of bacteria or Archaea known in the art. The eukaryotic hexokinase or glucokinase protein can be, for example, from any genus and species of fungus known in the art. The term "bacterial hexokinase" as used herein can refer to a hexokinase as described herein derived from a bacteria. The term "bacterial glucokinase" as used herein can refer to a glucokinase as described herein derived from a bacteria.

[0061] As used herein, the "hexokinase gene" can refer to any nucleic acid (e.g., genomic DNA, cDNA and/or mRNA) that when transcribed and/or translated encodes a hexokinase protein as described herein. As used herein, the "glucokinase gene" can refer to any nucleic acid (e.g., genomic DNA, cDNA and/or mRNA) that when transcribed and/or translated encodes a glucokinase protein as described herein. The term "bacterial hexokinase gene" as used herein can refer to a bacterial hexokinase protein as described herein derived from a bacteria. The term "bacterial glucokinase gene" as used herein can refer to a bacterial glucokinase protein as described herein derived from a bacteria.

[0062] The term "product of interest" or "biomolecule" as used herein refers to any product produced by microbes from feedstock. In some cases, the product of interest may be a small molecule, enzyme, peptide, amino acid, organic acid, synthetic compound, fuel, alcohol, etc. For example, the product of interest or biomolecule may be any primary or secondary extracellular metabolite. The primary metabolite may be, inter alia, ethanol, citric acid, lactic acid, glutamic acid, glutamate, lysine, threonine, tryptophan and other amino acids, vitamins, polysaccharides, etc. The secondary metabolite may be, inter alia, an antibiotic compound like penicillin, or an immunosuppressant like cyclosporin A, a plant hormone like gibberellin, a statin drug like lovastatin, a fungicide like griseofulvin, etc. The product of interest or biomolecule may also be any intracellular component produced by a microbe, such as: a microbial enzyme, including: catalase, amylase, protease, pectinase, glucose isomerase, cellulase, hemicellulase, lipase, lactase, streptokinase, and many others. The intracellular component may also include recombinant proteins, such as: insulin, hepatitis B vaccine, interferon, granulocyte colony-stimulating factor, streptokinase and others.

Overview

[0063] The present disclosure provides a microbial genomic engineering method that does not suffer from the myriad of problems associated with traditional microbial strain improvement programs.

[0064] One aspect provided herein is a method for generating a microorganism (e.g., bacteria) that is capable of increased production of a biomolecule or product of interest. In general, the methods for generating a microorganism for use in producing any biomolecule as provided herein can entail genetically modifying a host microorganism by introducing a member of a library of target genes into said host microorganism to generate a genomically engineered strain of said microorganism, culturing said engineered strain under conditions suitable to produce the biomolecule or product of interest, and selecting said engineered strain if said engineered strain produces an increased amount of the biomolecule or product of interest. The increased amount can be as compared to a wild-type strain of the host microorganism. The increased amount can be as compared to a strain of the host microorganism that does not contain a member of the library of target genes. The library of target genes can comprise a plurality of vectors, wherein each vector in the library comprises a chimeric construct comprising at least one promoter polynucleotide functionally linked or coupled to a target gene.

[0065] An exemplary workflow of one of the embodiments of the invention entails selecting a target gene, acquiring or synthesizing nucleic acid (e.g., DNA) for the target gene, and cloning said acquired or synthesized target gene into a suitable vector. Any method known in the art and/or provided herein can be used to assemble or clone the target gene or target genes into a suitable vector. The vector can be any vector known in the art and/or provided herein that is compatible with the host microorganism to be utilized. Once the vector comprising the target gene(s) is assembled, it can be introduced into the host microorganism. The introduction of the vector can be using any method known in the art and/or provided herein. The host microorganism can be any host microorganism provided herein. Once introduced into the host microorganism, genetically modified hosts can be selected and the insertion of the target gene(s) can be evaluated. The target gene(s) can be engineered to be inserted into specific locations of the host microorganism's genome. In some cases, the target gene(s) is inserted into a neutral site of the genome that facilitates expression of the target gene(s) without perturbing unintended pathways/processes within the host microorganism. In some cases, the target gene(s) replace specific gene(s) within the host microorganism. The specific gene can be the homologous target gene normally present in the host microorganism. The integration site, such as, for example, the neutral integration site can be determined empirically such that various sites can tested and a site that permits expression of the integrated target gene(s) without being detrimental to the host cell can be chosen. Integration into a desired site (e.g., neutral site) can be facilitated by cloning the target gene(s) into a vector comprising portions of sequence homologous to the desired integration site (i.e., homologous arms) and subsequently performing a recombination event in the host cell. The target gene(s) can be inserted between the portions of homologous sequence. In one embodiment, the vector comprises about 2 kb of sequence homologous to the desired integration site. The sequence homologous to the desired site can flank a glucose permease gene insert and/or glucose permease-glucokinase gene insert such that a first portion of the sequence is upstream (i.e., 5') of the gene insert and a second portion of the sequence is downstream (i.e., 3') of the gene insert. In another embodiment, the vector comprises about 4 kb of sequence homologous to the desired integration site. In this embodiment, the vector comprises about 2 kb of sequence homologous to the desired integration site upstream (i.e., 5') to a glucose permease gene insert and/or glucose permease-glucokinase gene insert and about 2 kb of sequence homologous to the desired integration site downstream (i.e., 3') to a glucose permease gene insert and/or glucose permease-glucokinase gene insert. In one embodiment, integration is performed by a single-cross-over integration and subsequent loop out of the plasmid backbone facilitated by counter-selection on a marker present in the vector backbone. In one embodiment, the target gene is any bacterial glucose permease gene known in the art and/or provided herein. In one embodiment, the target gene is any bacterial glucokinase gene known in the art and/or provided herein. In one embodiment, target genes are any bacterial glucose permease gene known in the art and/or provided herein and any bacterial glucokinase gene known in the art and/or provided herein.

[0066] Evaluation of the insertion can be performed using any method know in the art such as, for example, amplifying and/or sequencing of the genetically modified microorganism's genome or portions thereof. In some cases, the methods provided herein also entail the removal or looping out of selection markers through counter selection as described herein. The looping out can be performed using any of the methods provided herein.

[0067] Following the evaluation of the insertion of the target gene(s) and, optional, removal of selection markers, the genetically modified strain can be evaluated for its ability to produce a biomolecule or product of interest. Prior to evaluation an optional step can be expanding the strain. Expansion can entail culturing the genetically modified strain on plates or in wells in a multi-well plate in growth media suitable for expansion. The evaluation step can entail culturing the genetically modified strain on plates or in wells in a multi-well plate comprising growth media/conditions designed to mimic actual conditions for producing a biomolecule or product of interest. In some cases, the growth media in this step is suitable for the production of biomolecules or products of interest derived from the metabolic processing of glucose. If the genetically modified strain possesses or is predicted to produce a desired or threshold rate of production or yield of the biomolecule or product of interest as determined from the evaluation step, the strain can be selected and placed in cold storage. The prediction can be based on measuring the amount of product of interest and biomass formed at various time points during culturing of the strain and using said measurements to predict how said strain will perform under expanded or larger scale conditions (e.g., fermentation conditions). In one embodiment, the prediction is based on a linear regression analysis of the performance of the strain during the evaluation method.

[0068] In some cases, a genetically modified strain possessing or predicted to produce a desired or threshold rate of production or yield of the biomolecule or product of interest is transferred to or grown in a larger culture under conditions for producing the biomolecule or product of interest (e.g., fermentation conditions). This step can be used in order to determine if the selected strain can perform as predicted under actual conditions for the production of the biomolecule or product of interest. In some cases, the steps provided herein for the introduction and evaluation of each target gene from a library of target genes such as those provided herein are repeated for each target gene from the library in order to select one or more strains of genetically modified microorganisms that produce a desired or threshold yield and/or productivity rate of a biomolecule or product of interest.

[0069] In one embodiment, the biomolecule or product of interest is derived from glucose and the metabolic processing thereof by the microorganism such that the methods provided herein entail the generation of a strain or strains of microorganisms that produce an increased amount of a biomolecule or product of interest derived from the metabolic processing of glucose by the strain or strains. In one embodiment, the methods provided herein entail the introduction of one or more target genes involved in glucose transport and/or metabolism. In one embodiment, the one or more target genes are utilized in a phosphotransferase system (PTS). In one embodiment, the target gene is a glucose permease gene such that a glucose permease gene is introduced into the host microorganism in the methods provided herein. The glucose permease gene can be a heterologous gene in the host microorganism. In one embodiment, the target gene is a hexokinase gene such that a hexokinase gene is introduced into the host microorganism in the methods provided herein. In one embodiment, both a glucose permease gene and a hexokinase gene are introduced into the host microorganism in the methods provided herein. In one embodiment, the introduction of a glucose permease gene and/or hexokinase gene into the host microorganism produces a non-PTS recombinant glucose uptake system in the host microorganism. The recombinant glucose uptake system can serve to uncouple glucose transport from phosphoenolpyruvate (PEP) utilization, thereby producing more PEP for the synthesis of biomolecules or products of interest. The biomolecules or products of interest produced by the methods provided herein can be any commercial product produced from glucose. In some cases, the biomolecule or product of interest is a small molecule, an amino acid, an organic acid, or an alcohol. The amino acid can be tyrosine, phenylalanine, tryptophan, aspartic acid, asparagine, threonine, isoleucine, methionine, or lysine. The organic acid can be succinate, lactate or pyruvate. The alcohol can be ethanol or isobutanol.

[0070] In one embodiment, the disclosed microbial genomic engineering method utilizes a library of glucose permease genes and/or hexokinase genes. A glucose permease gene can be selected based on the glucose permeases affinity for glucose and/or glucose transport rate. In some cases, the microbes are engineered utilizing a glucose permease library, a hexokinase (e.g., glucokinase) library or a combination of glucose permease and hexokinase (e.g., glucokinase) libraries. In one embodiment, the library contains a plurality of chimeric construct inserts such that each insert in the library comprises a glucose permease gene and a hexokinase (e.g., glucokinase) gene. Following engineering, the microbes can be efficiently screened or evaluated for resultant outcome, e.g. production of a product from glucose as provided herein. This process of utilizing the libraries provided herein to define particular genomic alterations and then testing/screening host microbial genomes harboring the alterations can be implemented in an efficient and iterative manner and can be used to identify specific combinations of glucose permease/hexokinase genes (e.g., glucokinase genes) whose expression in a host cell produces a desired or threshold level of a biomolecule or product of interest form glucose.

[0071] In one embodiment, each glucose permease gene or hexokinase gene (glucokinase gene) as provided herein for use in the methods provided herein is under the control of or functionally linked to a native promoter or any of the promoter polynucleotides provided herein. A "promoter polynucleotide" or a "promoter" or a "polynucleotide having promoter activity" can mean a polynucleotide, preferably deoxyribopolynucleotide, or a nucleic acid, preferably deoxyribonucleic acid (DNA), which when functionally linked to a polynucleotide to be transcribed determines the point and frequency of initiation of transcription of the coding polynucleotide (e.g., glucose permease gene or glucokinase gene), thereby enabling the strength of expression of the controlled polynucleotide to be influenced. In one embodiment, each glucose permease gene and/or hexokinase gene (e.g., glucokinase gene) in a library comprising glucose permease genes and/or hexokinase genes (e.g., glucokinase genes) is under the control of the same or an identical promoter. In one embodiment, each glucose permease gene and/or hexokinase gene (e.g., glucokinase gene) in a library comprising glucose permease genes and/or hexokinase genes (e.g., glucokinase genes) is under the control of separate or different promoter. In yet another embodiment, each target gene in a chimeric construct in a library of chimeric constructs comprising the target genes are under the control of the same or an identical promoter. In a further embodiment, each target gene in a chimeric construct in a library of chimeric constructs comprising the target genes are under the control of a separate or different promoter.

[0072] In one embodiment, provided herein is a promoter ladder for use in generating a library of glucose permease genes or hexokinase genes or glucokinase genes. The term "promoter ladder" as used herein refers to a plurality of promoters with incrementally increasing levels of promoter activity. The term "promoter activity" as used herein refers to the ability of the promoter to initiate transcription of a polynucleotide sequence into mRNA. Methods of assessing promoter activity are well known to those of skill in the art and can include, for example the methods described in Example 2 of U.S. 62/264,232, filed on Dec. 7, 2015 and PCT/US16/65464 (i.e., PCT Publication No. WO2017/100376), each of which is herein incorporated by references in its entirety. The term "constitutive promoter" as used herein can refer to a promoter that directs the transcription of its associated genes at a constant rate regardless of the internal or external cellular conditions.

Promoters

[0073] In some embodiments, the present disclosure teaches methods of selecting promoters with optimal expression properties to modulate RNA degradation function and produce beneficial effects on overall-host strain productivity.

[0074] Promoters regulate the rate at which genes are transcribed and can influence transcription in a variety of ways. Constitutive promoters, for example, direct the transcription of their associated genes at a constant rate regardless of the internal or external cellular conditions, while regulatable promoters increase or decrease the rate at which a gene is transcribed depending on the internal and/or the external cellular conditions, e.g. growth rate, temperature, responses to specific environmental chemicals, and the like. Promoters can be isolated from their normal cellular contexts and engineered to regulate the expression of virtually any gene, enabling the effective modification of cellular growth, product yield and/or other phenotypes of interest.

[0075] In some embodiments, the present disclosure teaches methods of identifying one or more promoters and/or generating variants of one or more promoters within a host cell, which exhibit a range of expression strengths (e.g. promoter ladders discussed infra), or superior regulatory properties (i.e., tighter regulatory control for selected genes). A particular combination of these identified and/or generated promoters can be grouped together as a promoter ladder for use in the RNA degradation perturbation experiments explained in more detail below.

[0076] In some embodiments, promoter ladders are created by identifying natural, native, or wild-type promoters associated with a target gene of interest that have a range of expression strengths. These identified promoters can be grouped together as a promoter ladder.

[0077] In some embodiments, promoter ladders are created by: identifying natural, native, or wild-type promoters associated with a target gene of interest and then mutating said promoter to derive multiple mutated promoter sequences. Each of these mutated promoters is tested for effect on target gene expression. In some embodiments, the edited promoters are tested for expression activity across a variety of conditions, such that each promoter variant's activity is documented/characterized/annotated and stored in a database. The resulting edited promoter variants are subsequently organized into promoter ladders arranged based on the strength of their expression (e.g., with highly expressing variants near the top, and attenuated expression near the bottom, therefore leading to the term "ladder").

[0078] In some embodiments, the present disclosure teaches promoter ladders that are a combination of identified naturally occurring promoters and mutated variant promoters.

[0079] In some embodiments, the present disclosure teaches methods of identifying natural, native, or wild-type promoters that satisfied both of the following criteria: 1) represented a ladder of constitutive promoters; and 2) could be encoded by short DNA sequences, ideally less than 100 base pairs. In some embodiments, constitutive promoters of the present disclosure exhibit constant gene expression across two selected growth conditions (typically compared among conditions experienced during industrial cultivation). In some embodiments, the promoters of the present disclosure will consist of a .about.60 base pair core promoter, and a 5' UTR between 26- and 40 base pairs in length.

[0080] In some embodiments, one or more of the aforementioned identified naturally occurring promoter sequences are chosen for gene editing. In some embodiments, the natural promoters are edited via any known genetic mutation methods. In other embodiments, the promoters of the present disclosure are edited by synthesizing new promoter variants with the desired sequence.

[0081] The entire disclosures of U.S. Patent Application No. 62/264,232, filed on Dec. 7, 2015, and PCT/US16/65464 (PCT Publication No. WO2017/100376), filed Dec. 7, 2016 are each hereby incorporated by reference in its entirety for all purposes.

[0082] A non-exhaustive list of the promoters of the present disclosure is provided in Table 1 below. Each of the promoter sequences in Table 1 can be referred to as a heterologous promoter or heterologous promoter polynucleotide.

TABLE-US-00001 TABLE 1 Selected promoter sequences of the present disclosure. SEQ ID Promoter Short No. Name 1 P1 2 P2 3 P3 4 P4 5 P5 6 P6 7 P7 8 P8

[0083] In some embodiments, the promoters of the present invention exhibit at least 100%, 99%, 98%, 97%, 96%, 95%, 94%, 93%, 92%, 91%, 90%, 89%, 88%, 87%, 86%, 85%, 84%, 83%, 82%, 81%, 80%, 79%, 78%, 77%, 76%, or 75% sequence identity with a promoter sequences from Table 1.

Glucose Permeases

[0084] Provided herein is a library of glucose permease genes for use in the methods provided herein. The library of glucose permease genes can comprise one or more glucose permease genes. Each glucose permease gene in the library can be a native form of the glucose permease gene or a mutated form. The mutated form can comprise one or more mutations selected from an insertion, deletion, single nucleotide polymorphism (SNP), or translocation. Each glucose permease gene in the library can be a bacterial glucose permease gene. The glucose permease gene can be any glucose permease gene from a prokaryotic cell (i.e., Bacteria and/or Archaea) known in the art. The glucose permease gene can be any glucose permease gene from a eukaryotic cell (e.g., fungal) known in the art. A glucose permease can be considered any protein comprising glucose permease activity. For example, a glucose permease for use herein can be any transporter (e.g., myo-inositol transporter) that exhibits an affinity for glucose and subsequently facilitates its transport across the cell membrane of a host cell. The host cell can be any host cell provided herein. In one embodiment, the library of glucose permease genes comprises glucose permease genes from any strain/species/sub-species of Mycobacterium (e.g., Mycobacterium smegmatis), Streptomyces (e.g., Streptomyces coelicolor), Zymomonas (e.g., Zymomonas mobilis), Synechocystis (e.g., Synechocystis sp. PCC6803), Bifidobacterium (e.g., Bifidobacterium longum), Escherichia (e.g., Escherichia coli), Bacillus (e.g., Bacillus subtilis), Corynebacterium (e.g., Corynebacterium glutamicum), Saccharomyces (e.g., S. cerevisiae) or a combination thereof. In one embodiment, the library of glucose permease genes comprises glucose permease genes that encode polypeptide sequences selected from SEQ ID NO: 9, SEQ ID NO: 10, SEQ ID NO: 11, SEQ ID NO: 12, SEQ ID NO: 13, SEQ ID NO: 14 or a combination thereof.

[0085] In some embodiments, the permeases of the present invention exhibit at least 100%, 99%, 98%, 97%, 96%, 95%, 94%, 93%, 92%, 91%, 90%, 89%, 88%, 87%, 86%, 85%, 84%, 83%, 82%, 81%, 80%, 79%, 78%, 77%, 76%, or 75% sequence identity with a permease provided herein.

[0086] In one embodiment, the library of glucose permease genes comprises glucose permease genes selected from SEQ ID NO: 19, SEQ ID NO: 20, SEQ ID NO: 21, SEQ ID NO: 22, SEQ ID NO: 23, SEQ ID NO: 24 or a combination thereof.