Integrally Formed Paper Straw with Pointed Head

Huang; Chien-Ming

U.S. patent application number 16/131097 was filed with the patent office on 2020-03-19 for integrally formed paper straw with pointed head. The applicant listed for this patent is Chien-Ming Huang. Invention is credited to Chien-Ming Huang.

| Application Number | 20200085218 16/131097 |

| Document ID | / |

| Family ID | 69774558 |

| Filed Date | 2020-03-19 |

| United States Patent Application | 20200085218 |

| Kind Code | A1 |

| Huang; Chien-Ming | March 19, 2020 |

Integrally Formed Paper Straw with Pointed Head

Abstract

A pointed paper straw includes a paper straw (20) which is integrally formed with a pointed head (202) and an overlapping portion (201). The paper straw is formed by a paper mold sheet (220) which is formed by a residual edge (22) of a paper material (2). The residual edge has an end which has a left side and a right side that are cut symmetrically, with two triangular pieces (221) being removed, to form the paper mold sheet which includes a pointed portion (2201). The paper mold sheet has a left side and a right side that are curled inward and are overlapped and connected to form the overlapping portion.

| Inventors: | Huang; Chien-Ming; (Taichung City, TW) | ||||||||||

| Applicant: |

|

||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Family ID: | 69774558 | ||||||||||

| Appl. No.: | 16/131097 | ||||||||||

| Filed: | September 14, 2018 |

| Current U.S. Class: | 1/1 |

| Current CPC Class: | A47G 21/18 20130101; A47G 21/181 20130101 |

| International Class: | A47G 21/18 20060101 A47G021/18 |

Claims

1. A pointed paper straw comprising: a paper straw which is integrally formed with a pointed head; wherein: the paper straw is formed by a paper mold sheet; the paper mold sheet is formed by a residual edge of a paper material; the residual edge has an end formed with a pointed portion; the end of the residual edge has a left side and a right side that are cut symmetrically, with two triangular pieces being removed, to form the paper mold sheet which includes the pointed portion; the paper mold sheet has a left side and a right side that are curled inward and are overlapped and connected to form an overlapping portion; the overlapping portion is stuck to form the paper straw; and the paper straw includes the overlapping portion and the pointed head.

2. The pointed paper straw of claim 1, wherein the overlapping portion of the paper straw is stuck by a high frequency.

3. The pointed paper straw of claim 1, wherein the residual edge of the paper material is made of coated paper.

4. A pointed paper straw comprising: a paper straw which is integrally formed with a pointed head; the paper straw is formed by a paper mold sheet; the paper mold sheet is formed by a paper material; the paper material has an end formed with a pointed portion; the end of the paper material has a left side and a right side that are cut symmetrically, with two triangular pieces being removed, to form the paper mold sheet which includes the pointed portion; the paper mold sheet has a left side and a right side that are curled inward and are overlapped and connected to form an overlapping portion; the overlapping portion is stuck to form the paper straw; and the paper straw includes the overlapping portion and the pointed head.

5. The pointed paper straw of claim 4, wherein the overlapping portion of the paper straw is stuck by a high frequency.

6. The pointed paper straw of claim 4, wherein the paper material is made of coated paper.

Description

BACKGROUND OF THE INVENTION

1. Field of the Invention

[0001] The present invention relates to a paper product and, more particularly, to a paper straw used for drinking beverage.

2. Description of the Related Art

[0002] A straw has a tubular shape with a pointed head that pierces the film of a filmed cup to facilitate a user drinking the beverage in the filmed cup. However, the conventional straw is made of plastic material, thereby causing an environmental problem. Another conventional straw is made of stainless steel to replace the plastics. However, such a straw is not washed and cleaned easily. In addition, the straw made of stainless steel is hard and causes danger to the children. A conventional paper straw comprises a paper sheet that is wound and coiled to form a helical structure whose two axial ends are connected to each other. The helical structure has edges partially overlapping, and the overlapping portions are adhered by glue or adhesive. However, the conventional paper straw has complicated procedures of fabrication, thereby increasing the cost of production. In addition, the conventional paper straw has a smooth circular distal end that cannot pierce the film of the filmed cup, thereby causing inconvenience to the user when drinking the beverage in the filmed cup. Besides, a paper cup is formed by cutting a paper stuff. After the mold of the paper cup is removed from the paper stuff, the residual edges and the curled edges of the paper stuff are thrown away or recycled, thereby wasting the material.

BRIEF SUMMARY OF THE INVENTION

[0003] The primary objective of the present invention is to provide an integrally formed paper straw with a pointed head.

[0004] In accordance with one embodiment of the present invention, there is provided a pointed paper straw comprising a paper straw which is integrally formed with a pointed head. The paper straw is formed by a paper mold sheet. The paper mold sheet is formed by a residual edge of a paper material. The residual edge has an end formed with a pointed portion. The end of the residual edge has a left side and a right side that are cut symmetrically, with two triangular pieces being removed, to form the paper mold sheet which includes the pointed portion. The paper mold sheet has a left side and a right side that are curled inward and are overlapped and connected to form an overlapping portion. The overlapping portion is stuck to form the paper straw. The paper straw includes the overlapping portion and the pointed head.

[0005] Preferably, the overlapping portion of the paper straw is stuck by a high frequency.

[0006] Preferably, the residual edge of the paper material is made of coated paper.

[0007] In accordance with another embodiment of the present invention, there is provided a pointed paper straw comprising a paper straw which is integrally formed with a pointed head. The paper straw is formed by a paper mold sheet. The paper mold sheet is formed by a paper material. The paper material has an end formed with a pointed portion. The end of the paper material has a left side and a right side that are cut symmetrically, with two triangular pieces being removed, to form the paper mold sheet which includes the pointed portion. The paper mold sheet has a left side and a right side that are curled inward and are overlapped and connected to form an overlapping portion. The overlapping portion is stuck to form the paper straw. The paper straw includes the overlapping portion and the pointed head.

[0008] Preferably, the paper material is made of coated paper.

[0009] According to the primary advantage of the present invention, the recycled paper is worked simply and integrally formed with the paper straw which includes the pointed head, so that the paper straw is produced easily and quickly, thereby greatly reducing the cost of fabrication.

[0010] According to another advantage of the present invention, the paper straw is made of recycled paper and does not contain any plastics or glue so that the paper straw can be recycled completely to achieve the purpose of environment protection.

[0011] According to a further advantage of the present invention, the paper straw is integrally formed with the pointed head without needing a secondary working procedure.

[0012] Further benefits and advantages of the present invention will become apparent after a careful reading of the detailed description with appropriate reference to the accompanying drawings.

BRIEF DESCRIPTION OF THE SEVERAL VIEWS OF THE DRAWING(S)

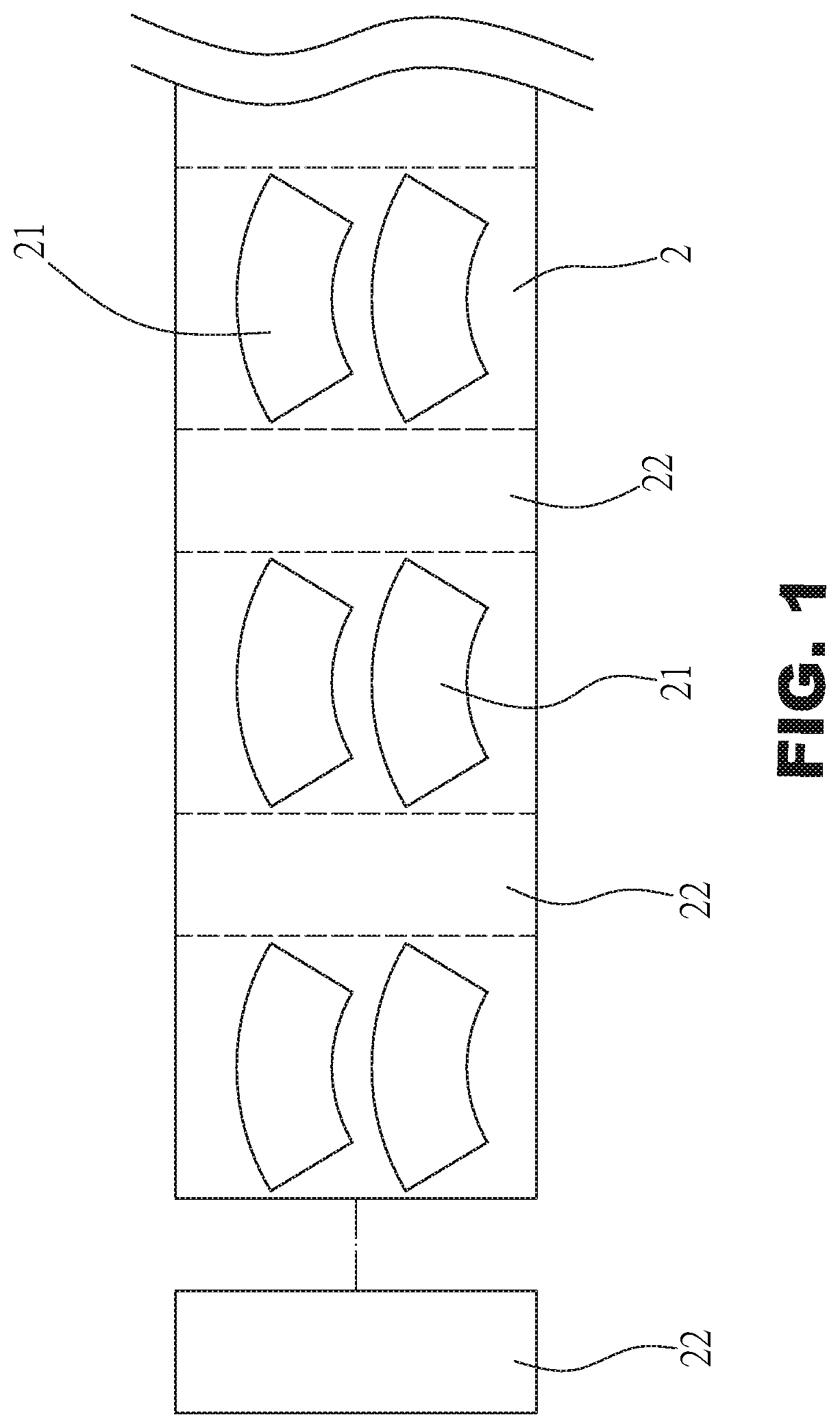

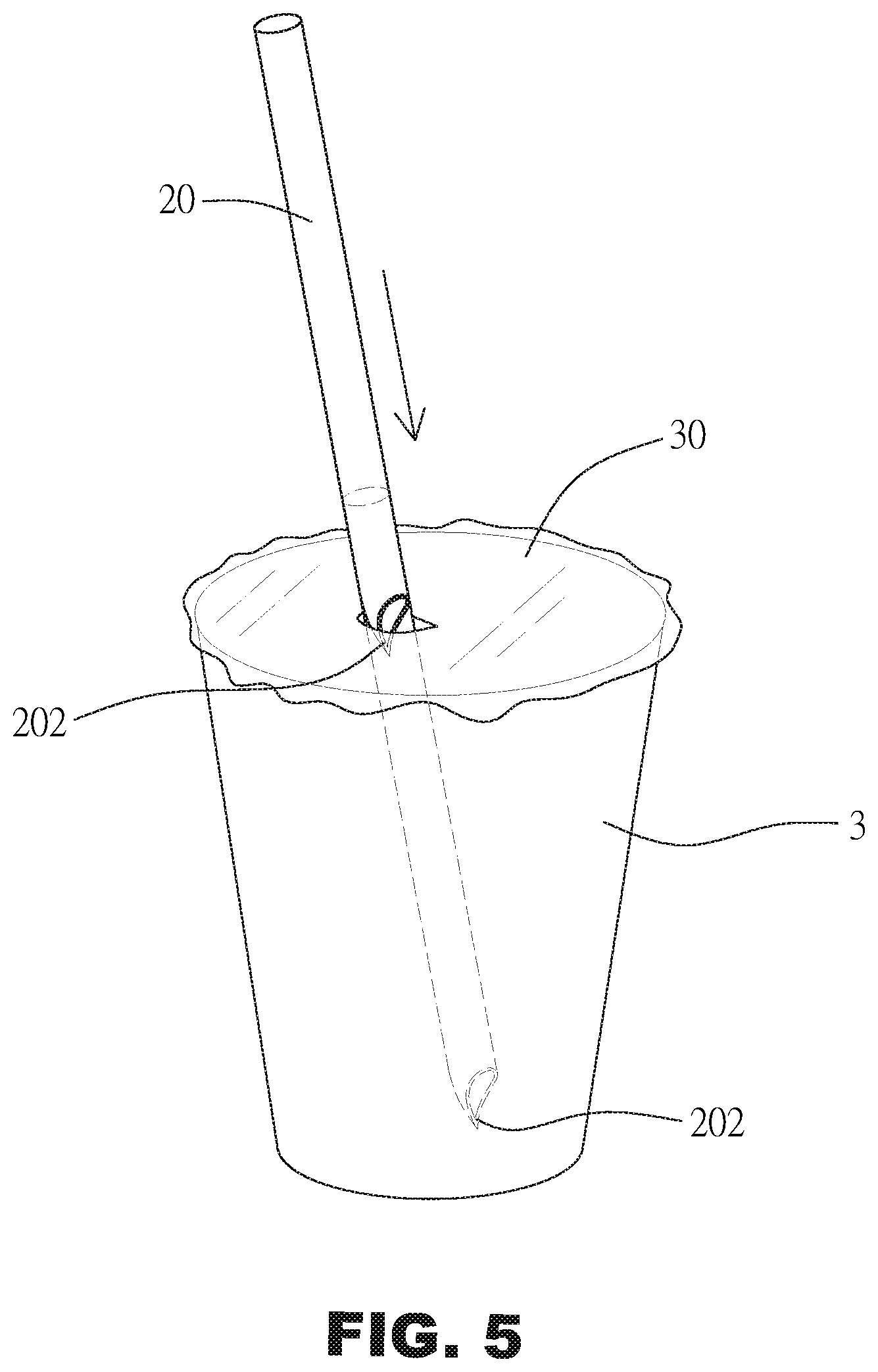

[0013] FIG. 1 is a schematic planar view showing a residual edge is cut and removed from a paper material.

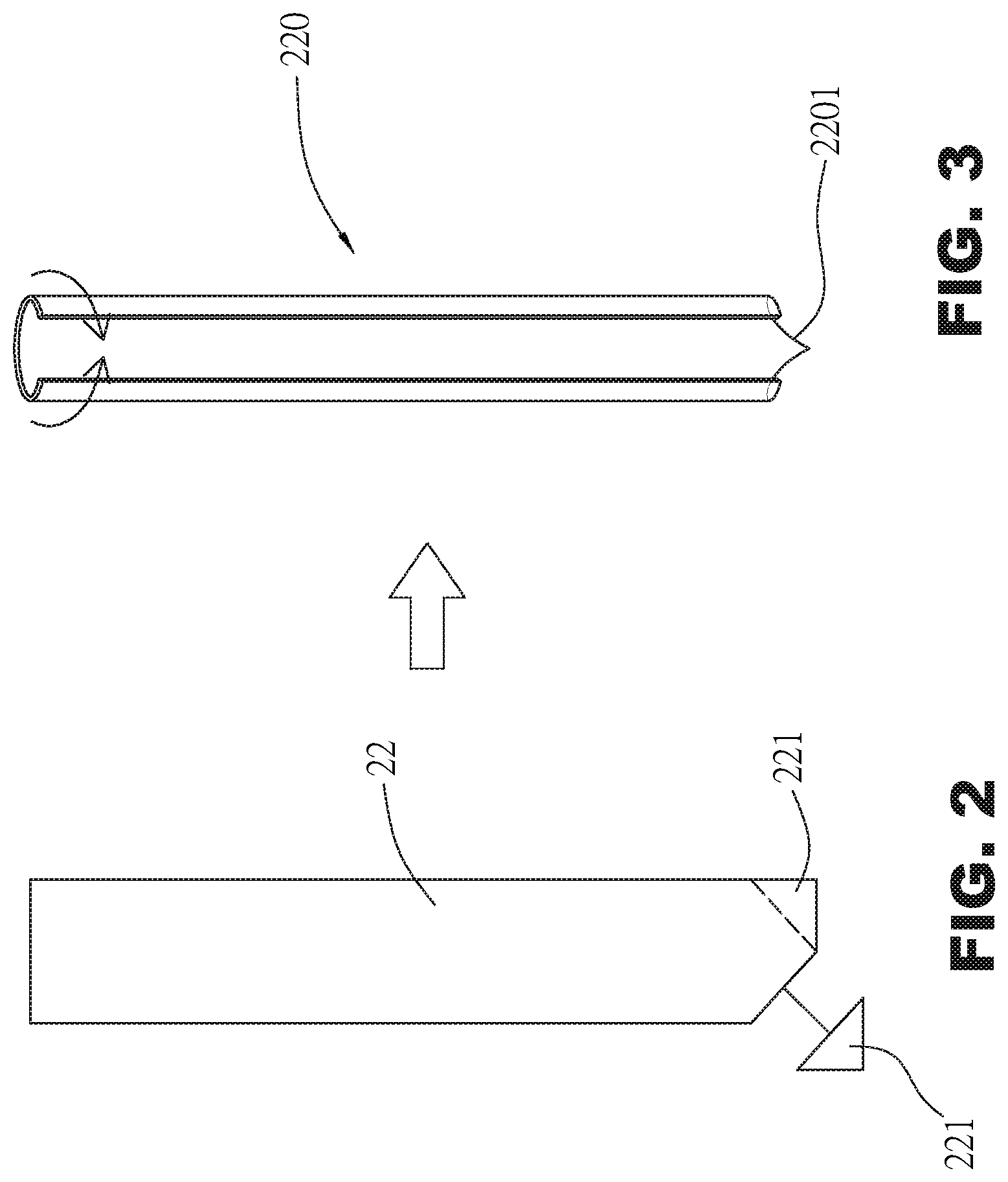

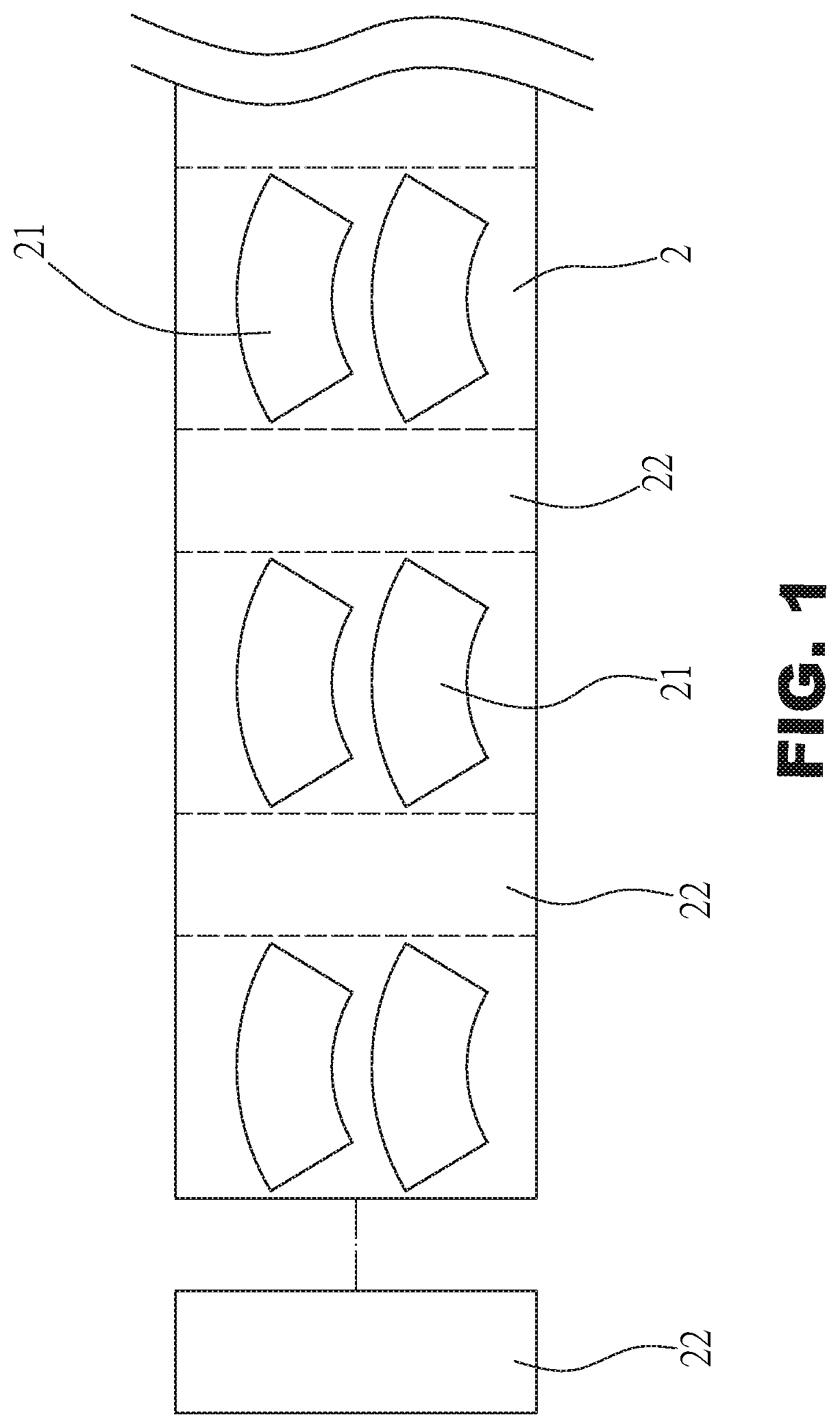

[0014] FIG. 2 is a schematic planar view showing a triangular piece is cut and removed from a residual edge.

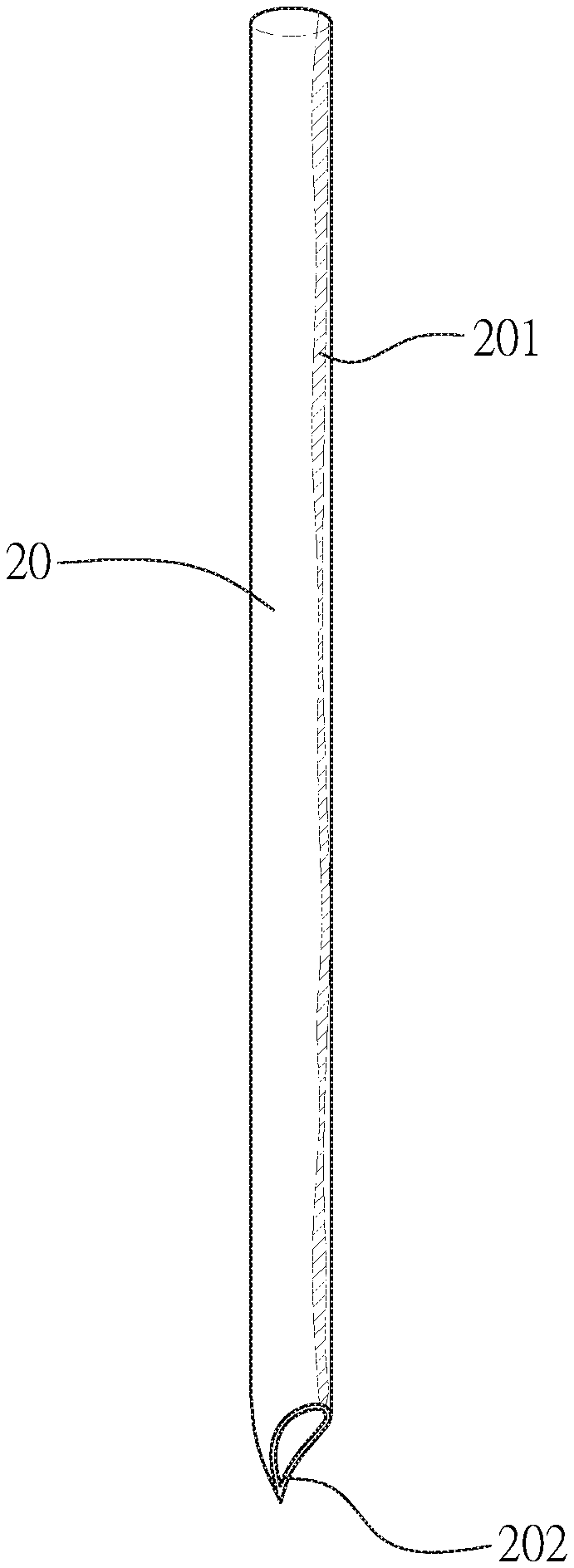

[0015] FIG. 3 is a perspective operational view showing the left side and the right side of the paper mold sheet are overlapped.

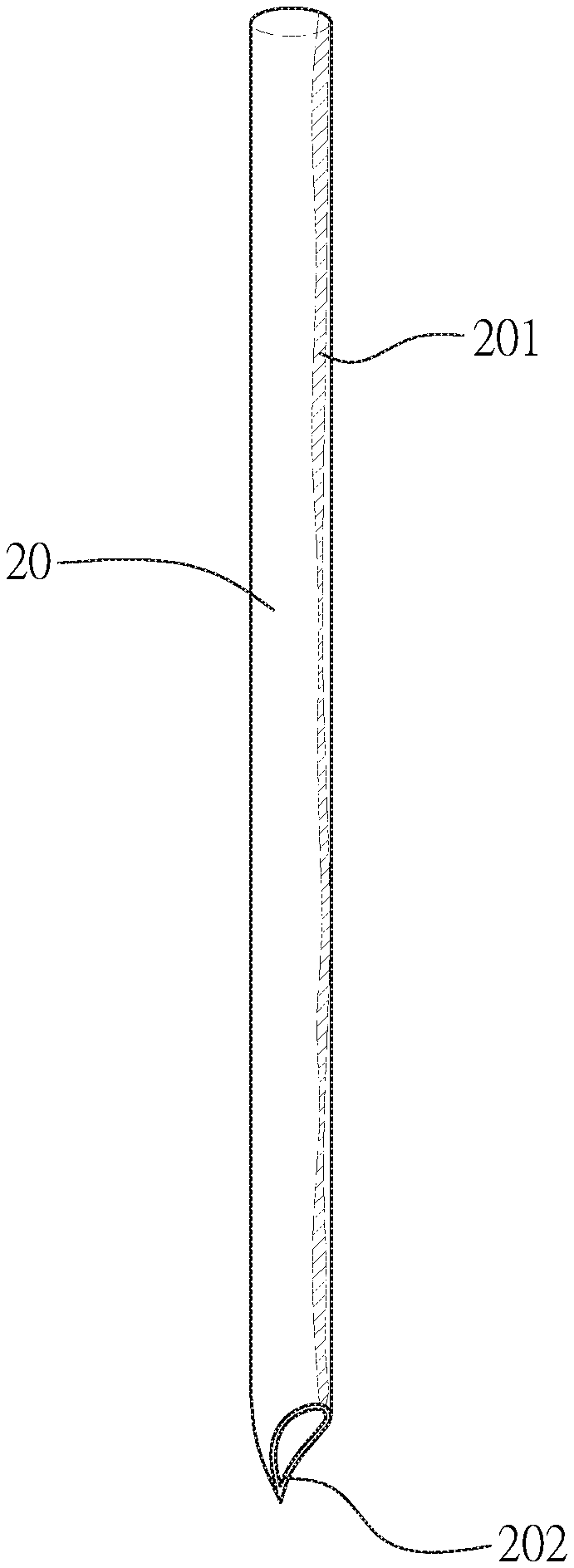

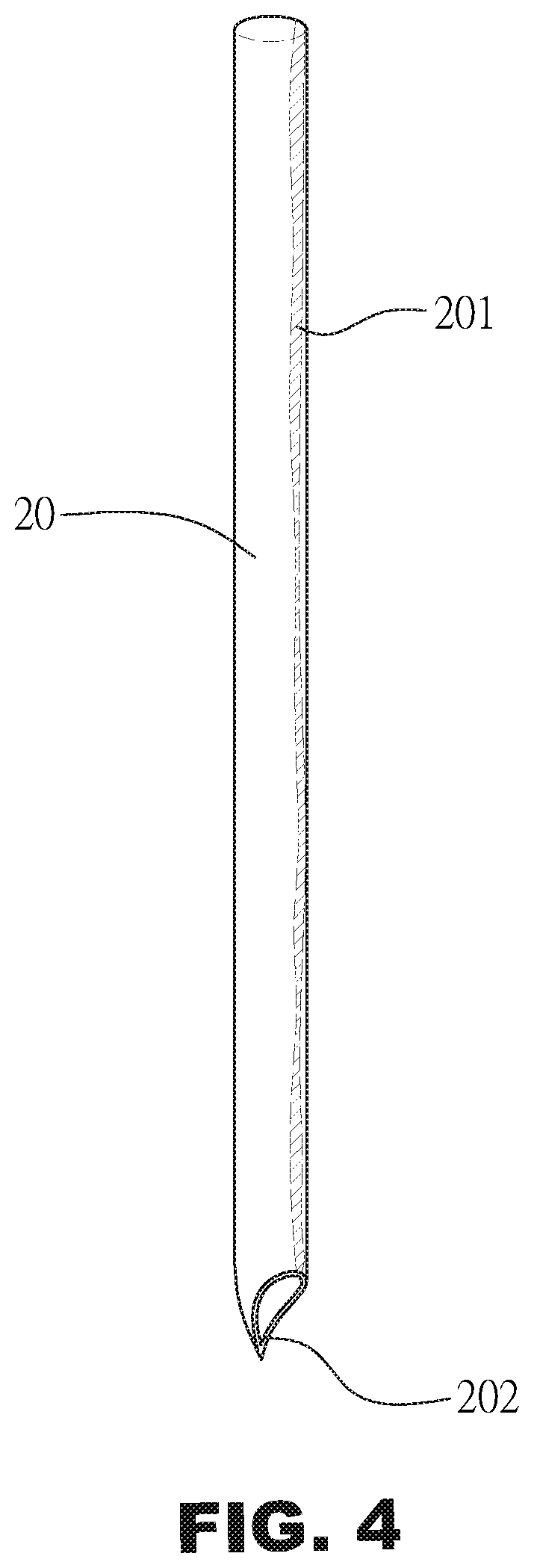

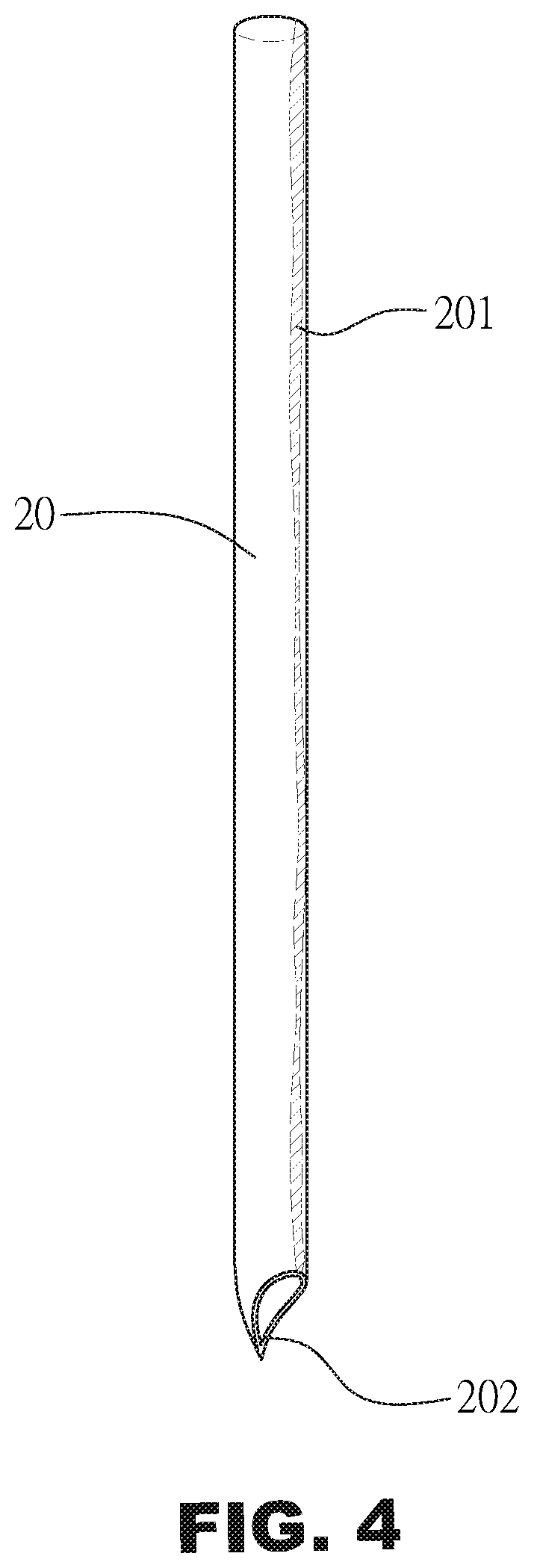

[0016] FIG. 4 is a perspective view of a paper straw in accordance with the preferred embodiment of the present invention.

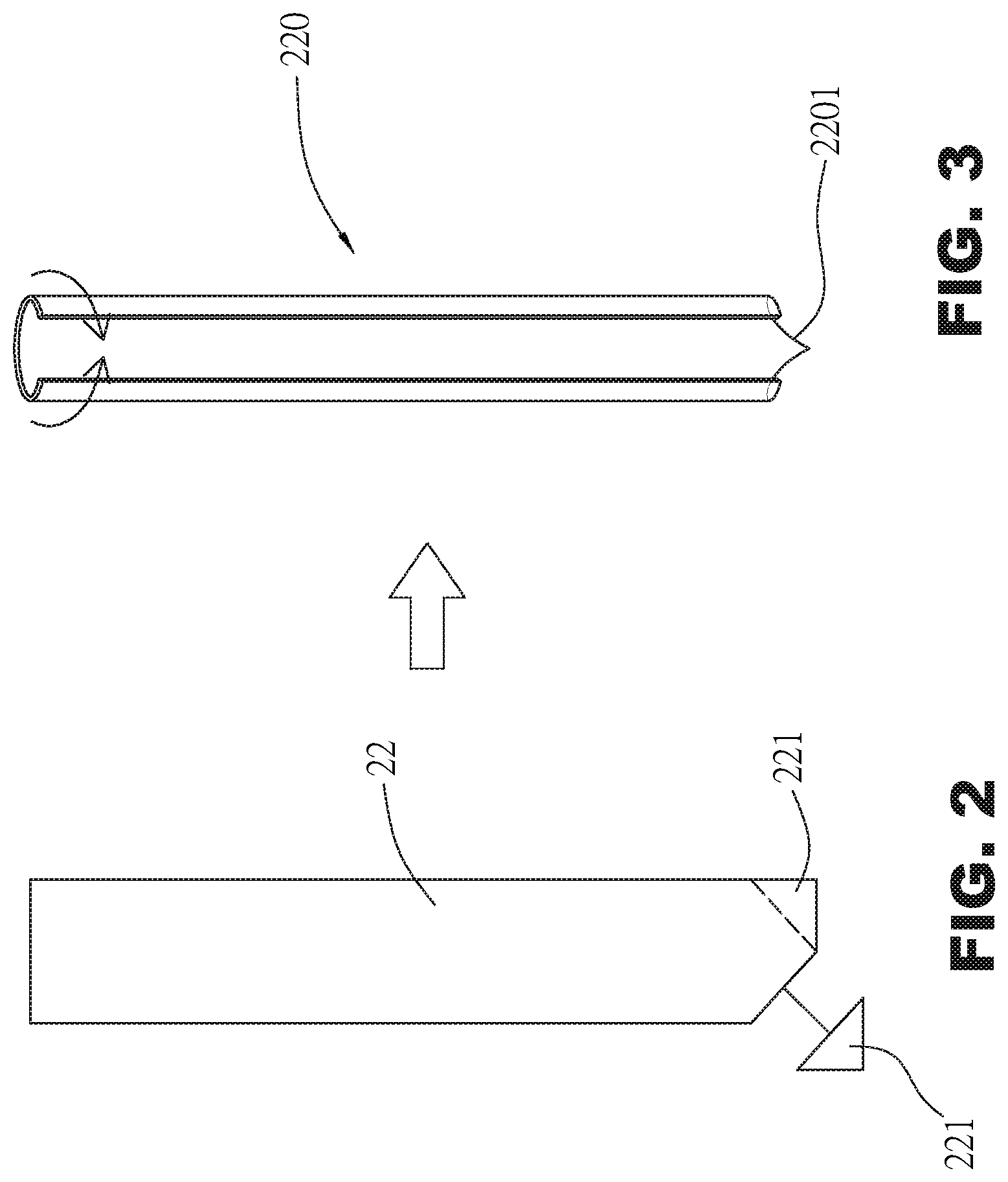

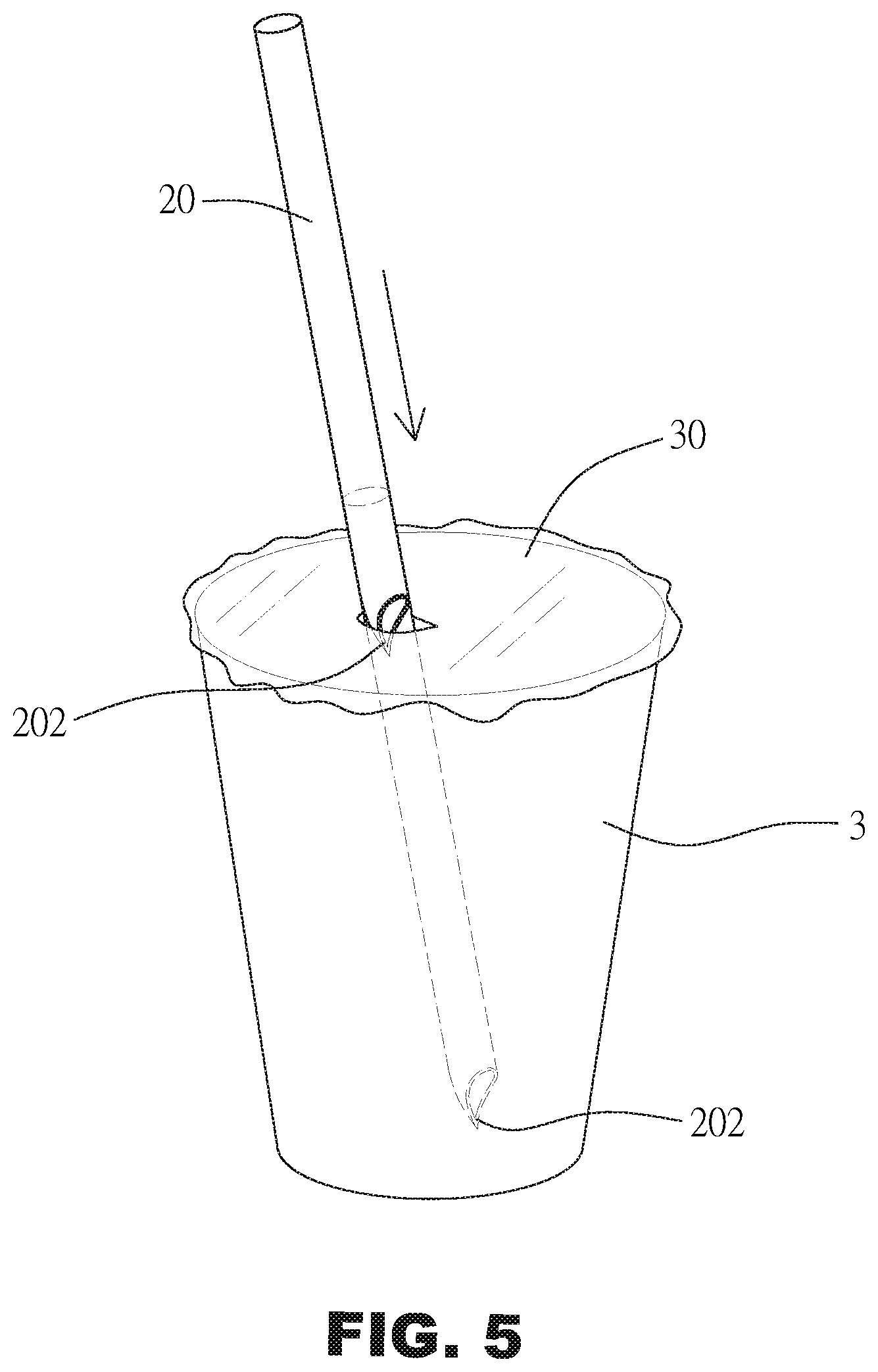

[0017] FIG. 5 is a schematic operational view of the paper straw in accordance with the preferred embodiment of the present invention.

DETAILED DESCRIPTION OF THE INVENTION

[0018] Referring to the drawings and initially to FIG. 1, a paper material 2 includes a plurality of container sheet molds 21 and a plurality of residual edges 22. Each of the container sheet molds 21 is a model of a container and may be cut to have the shape of the container. When the container sheet molds 21 are set, the residual edges 22 are kept on the paper material 2. After the container sheet molds 21 are cut, the residual edges 22 and the curled edges of the paper material 2 are recycled. Thus, the residual edges 22 and the curled edges of the paper material 2 are used to make a paper straw 20 as shown in FIG. 4. Preferably, the residual edges 22 and the curled edges of the paper material 2 are made of coated paper.

[0019] Referring to FIGS. 2 and 3, each of the residual edges 22 has an end formed with a pointed portion 2201. The end of each of the residual edges 22 has a left side and a right side that are cut symmetrically, with two triangular pieces 221 being removed, to form a paper mold sheet 220 with the pointed portion 2201 as shown in FIG. 3. Each of the two triangular pieces 221 forms a slope on the end of each of the residual edges 22.

[0020] Alternatively, the paper material 2 as shown in FIG. 1 is directly cut to remove the two triangular pieces 221, so as to form the paper mold sheet 220 with the pointed portion 2201. Thus, it is unnecessary to collect the residual edges 22 so that the paper mold sheet 220 satisfies the requirement of mass production.

[0021] Referring to FIGS. 3 and 4, the paper mold sheet 220 has a left side and a right side that are curled inward and are overlapped and connected to form an overlapping portion 201. Preferably, the overlapping portion 201 is hot pressed and stuck by a high frequency. Thus, the paper mold sheet 220 is made into a paper straw 20 which is integrally formed with a pointed head 202.

[0022] Accordingly, the paper straw 20 is made of recycled paper, such as the residual edges 22 or the curled edges of the paper material 2, thereby greatly reducing the cost of fabrication, and thereby achieving the purpose of environment protection. In addition, the overlapping portion 201 of the paper straw 20 is hot pressed by a high frequency, so that the paper straw 20 does not contain any plastics or glue and can be recycled completely to provide an environment friendly function.

[0023] Referring to FIG. 5, the paper straw 20 includes the pointed head 202 that easily pierces the plastic film 30 of a cup 3, thereby facilitating the user drinking the beverage contained in the cup 3.

[0024] In conclusion, the recycled paper is worked simply and integrally formed with the paper straw 20 which includes the pointed head 202, so that the paper straw 20 is produced easily and quickly, thereby greatly reducing the cost of fabrication. In addition, the paper straw 20 is made of recycled paper and does not contain any plastics or glue so that the paper straw 20 can be recycled completely to achieve the purpose of environment protection. Further, the paper straw 20 is integrally formed with the pointed head 202 without needing a secondary working procedure.

[0025] Although the invention has been explained in relation to its preferred embodiment(s) as mentioned above, it is to be understood that many other possible modifications and variations can be made without departing from the scope of the present invention. It is, therefore, contemplated that the appended claim or claims will cover such modifications and variations that fall within the scope of the invention.

* * * * *

D00000

D00001

D00002

D00003

D00004

XML

uspto.report is an independent third-party trademark research tool that is not affiliated, endorsed, or sponsored by the United States Patent and Trademark Office (USPTO) or any other governmental organization. The information provided by uspto.report is based on publicly available data at the time of writing and is intended for informational purposes only.

While we strive to provide accurate and up-to-date information, we do not guarantee the accuracy, completeness, reliability, or suitability of the information displayed on this site. The use of this site is at your own risk. Any reliance you place on such information is therefore strictly at your own risk.

All official trademark data, including owner information, should be verified by visiting the official USPTO website at www.uspto.gov. This site is not intended to replace professional legal advice and should not be used as a substitute for consulting with a legal professional who is knowledgeable about trademark law.