Methods to Reduce Chlorophyll Co-Extraction Through Extraction of Select Essential Oils and Aromatic Isolates

Galyuk; Yevgeniy

U.S. patent application number 16/605199 was filed with the patent office on 2020-02-06 for methods to reduce chlorophyll co-extraction through extraction of select essential oils and aromatic isolates. The applicant listed for this patent is CAPNA IP CAPITAL, LLC. Invention is credited to Yevgeniy Galyuk.

| Application Number | 20200038777 16/605199 |

| Document ID | / |

| Family ID | 60157310 |

| Filed Date | 2020-02-06 |

| United States Patent Application | 20200038777 |

| Kind Code | A1 |

| Galyuk; Yevgeniy | February 6, 2020 |

Methods to Reduce Chlorophyll Co-Extraction Through Extraction of Select Essential Oils and Aromatic Isolates

Abstract

A system, machine, and methods for selectively extracting chemicals from plant material without co-extracting chlorophyll, lipids and other undesirable constituents from plants, is described here. Extraction uses super-cooled solvents, such as 100% ethanol. The system and method provides plant extracts that are enriched in active compounds, and depleted in chlorophyll.

| Inventors: | Galyuk; Yevgeniy; (Sherman Oaks, CA) | ||||||||||

| Applicant: |

|

||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Family ID: | 60157310 | ||||||||||

| Appl. No.: | 16/605199 | ||||||||||

| Filed: | January 31, 2018 | ||||||||||

| PCT Filed: | January 31, 2018 | ||||||||||

| PCT NO: | PCT/US2018/016130 | ||||||||||

| 371 Date: | October 14, 2019 |

| Current U.S. Class: | 1/1 |

| Current CPC Class: | B01D 11/0296 20130101; B01D 11/0492 20130101; C11B 9/025 20130101; B01D 11/0292 20130101; B01D 11/0288 20130101; B01D 11/0219 20130101; B01D 11/028 20130101; F25B 7/00 20130101 |

| International Class: | B01D 11/02 20060101 B01D011/02; C11B 9/02 20060101 C11B009/02; F25B 7/00 20060101 F25B007/00; B01D 11/04 20060101 B01D011/04 |

Foreign Application Data

| Date | Code | Application Number |

|---|---|---|

| Apr 14, 2017 | US | 15488341 |

Claims

1. A system comprising a solvent tank (1.A), an extraction tank (1.H), a collection tank (1.I), and a plurality of fluid lines, wherein the system is capable of extracting plant matter with a solvent at an ultra-cold temperature, wherein this solvent is a fluid that does not contain chemicals extracted from the plant matter of the system, and wherein a solution is a solvent that comprises chemicals extracted from the plant matter of the system, wherein the system comprises: (i) An environment box (1.L) that is capable of maintaining an ultra-cold temperature of structures, solvents, and solutions that reside inside the environment box, wherein the environment box surrounds and envelops the solvent tank (1.A), the extraction tank (1.H), and the collection tank (1.I), wherein the environment box comprises an upper surface, a lower surface, and an interior region; (ii) Wherein the solvent tank (1.A) is operably linked to the extraction tank (1.H) with a fluid line; (iii) Wherein the system comprises a solvent flooding valve (1.C) that resides in a fluid line that is operably linked with the solvent tank (1.A) and the extraction tank (1.H), wherein opening solvent flooding valve permits transfer of solvent from the solvent tank (1.A) to the extraction tank (1.H); (iv) Wherein the extraction tank (1.H) comprises an interior, an extraction tank inlet (1.V), an extraction tank outlet (1.W), an extraction tank upper region (1.BB), wherein opening of solvent flooding valve (1.C) allows solvent from solvent tank (1.A) to pass through solvent flooding valve (1.C) and through extraction tank inlet and into extraction tank; (v) Wherein the extraction tank (1.H) comprises a lid, door, or aperture that is capable of allowing transfer of plant matter to interior of extraction tank; (vi) Wherein a first fluid line leads from solvent tank to extraction tank branching point (1.AA), and wherein a second fluid line leads from extraction tank outlet (1.W) to said extraction tank branching point, wherein the extraction tank branching point (1.AA) is operably linked to extraction tank inlet (1.V), wherein the extraction tank branching point is capable of directing solvent obtained from solvent tank into extraction tank for extracting plant matter with solvent, and wherein the extraction tank branching point is capable of directing solution obtained from collection tank outlet into extraction tank for extracting plant matter by recirculating the solution obtained from collection tank (1.I); (vii) Wherein the collection tank (1.I) comprising a collection tank inlet (1.Y) and a collection tank outlet (1.Z), wherein extraction tank outlet is operably linked to collection tank inlet by a fluid line, wherein flow of solution from extraction tank outlet to collection tank inlet is controllable by in-line valve (1.E), wherein the collection tank outlet is operably linked with a collection tank branching point that comprises a first branch and a second branch, wherein first branch of collection tank brandling point is operably linked by a fluid line that is capable of transmitting solution from collection tank to extraction tank, wherein flow of solution from extraction tank outlet to collection tank inlet is controllable by a solution return valve (1.D), wherein the second branch of collection tank branching point is operably linked by a fluid line that is capable of transmitting solution from collection tank (1.I) to evacuation line (1.P), wherein flow of solution from extraction tank outlet to evacuation line (1.P) is controllable by in-line valve (1.K) and, wherein flow of solution from extraction tank outlet to evacuation line (1.P) is configured for removing solution from environment box and configured for transmitting solution to the evacuation tank (1.R); (viii) Wherein regarding the solution return valve (1.D) and the evacuation valve (1.K), the opening of solution return valve (1.D) and closing evacuation valve (1.K) promotes or allows recirculating of solution from collection tank to extraction tank for the purpose of further extracting chemicals from plant matter; and wherein closing solution return valve (1.D) and opening evacuation valve (1.K) promotes or allows removal of solution from all tanks and fluid lines in said environment box; (ix) Wherein the system is capable of a first extraction of plant matter with solvent to produce a first extract, followed by one or more extractions of plant matter with solution that is recirculated from collection tank to produce at least a second extract, which is followed by a final extraction of plant matter with solvent to produce a final extract, and wherein the collection tank (1.I) is capable of receiving all of the first extract, the at least a second extract, and the final extract, and wherein the collection tank is capable of storing a mixture of the first extract, the second extract, and the final extract.

2. The system of claim 1 wherein the temperature in the environment box is maintainable to be in a temperature anywhere in the range of -60 degrees C. to -30 degrees C.

3. The system of claim 1 further comprising a vacuum pump (1.O) and a plurality of vacuum lines, wherein flow of solvent from solvent tank (1.A) to extraction tank (1.H), flow of solution from extraction tank outlet to collection tank (1.I), and flow of solution from collection tank outlet to evacuation line (1.P), are each driven by vacuum from said vacuum pump.

4. The system of claim 1 further comprising a vacuum pump and a plurality of vacuum lines, wherein flow of solvent from solvent tank (1.A) to extraction tank (1.H), flow of solution from extraction tank outlet to collection tank (1.I), and flow of solution from collection tank outlet to evacuation line (1.P), are each driven by vacuum from said vacuum pump, and wherein system further comprises: (i) Vacuum valve (1.M) that controls suction of vacuum from vacuum pump to upper region (1.BB) of extraction tank (1.H); (ii) Vacuum valve (1.N) that controls suction of vacuum from vacuum pump to upper region (1.CC) of collection tank (1.I); and (iii) Vacuum valve (1.Q) that control suction of vacuum from vacuum pump to evacuation tank (1.R).

5. The system of claim 1 further comprising a vacuum pump (1.O) and a plurality of vacuum lines, wherein flow of solvent from solvent tank (1.A) to extraction tank (1.H), flow of solution from extraction tank outlet to collection tank (1.I), and flow of solution from collection tank outlet to evacuation line (1.P), are each driven by vacuum front said vacuum pump, and wherein flow of solvent and flow of solution are not driven by any device other than a vacuum pump, and wherein flow of solvent and flow of solution are not driven by direct contact of solvent or solution with any rotor, propellor, or hose subjected to peristaltic forces.

6. The system of claim 1, wherein the extraction tank (1.H) comprises a tank liner and a false bottom, wherein the tank liner is configured to receive and secure plant matter, wherein the tank liner comprises a plurality of filtering apertures, optionally, apertures of about 10 micrometers in diameter, and wherein the false bottom is configured to secure the tank liner inside of extraction tank and to facilitate extraction of plant matter.

7. The system of claim 1, wherein exterior surface of one or more of solvent tank (1.A), extraction tank (1.H), and collection tank (1.I) are covered at least in part by a cooling jacket, wherein the cooling jacket is capable of receiving cold air or cold fluid from a freezer.

8. The system of claim 1 further comprising an evacuation tank (1.R), wherein the evacuation tank is outside of environment box (1.L), and wherein evacuation line (1.P) is operably linked with collection tank outlet and with evacuation tank (1.R), and wherein evacuation tank is capable of receiving solution that is transmitted from collection tank (1.I) via evacuation line (1.P) to evacuation tank (1.R), and wherein evacuation line passes from interior of environment box (1.L) to exterior of environment box.

9. The system of claim 1, wherein the extraction tank (1.H) comprises an inverted cone structure (narrow side up, wide side down), wherein the inverted cone structure is capable of supporting a false bottom, and wherein the false bottom is configured for supporting a tank liner, and wherein the inverted cone structure is configured to receive and collect solution generated by extracting plant matter with solvent, where solution falls from false bottom, and is capable of funneling the solution to extraction tank outlet.

10. The system of claim 1, further comprising a filter housing (1.J), wherein the filter housing resides in the evacuation line (1.P), wherein the evacuation line leads from collection tank outlet (1.Z) to evacuation tank (1.R), wherein the filter housing comprises a filter that is capable of removing particulate matter from the solution.

11. The system of claim 1, wherein the extraction tank comprises: (i) Plant matter; (ii) Plant matter derived from a cannabis plant; (iii) Plant matter derived from a cannabis plant and not any plant matter derived from any other type of plant.

12. The system of claim 1, wherein the solvent tank contains ethanol that is at least 95% ethanol, ethanol that is at least 98% ethanol, or 100% ethanol.

13. The system of claim 1, further comprising a cold air intake rube (1.T) and a cold air intake valve (1.B), wherein the cold air intake tube is substantially or completely located inside of the environment box, and wherein the cold air intake tube has an upper-end terminus and a lower-end terminus, wherein the lower-end terminus is constitutively open to air inside of the environment box, and wherein the lower-end terminus is positioned near interior bottom of environmental box, and wherein the lower-end terminus is capable of receiving cold air from interior of environment box, and (i) Wherein the upper-end terminus is secured to upper surface of environment box and is capable of directing passage of cold air from interior of environmental box to fluid lines located at exterior of environmental box, wherein cold air intake valve (1.B) is located exterior of environment box, and the cold air intake tube (1.T) is operably linked to a cold air intake valve (1.B), and (ii) Wherein the cold air intake valve (1.B) is capable of being closed in the situation where the solvent needs to be drawn out of solvent tank (1.A) and into extraction tank (1.H) and when vacuum from vacuum pump (1.O) is applied to top interior of extraction tank (1.BB), and (iii) Wherein the cold air intake valve (1.I) is capable of being opened in the situation where vacuum from vacuum pump (1.O) is applied to collection tank (1.I) in order to draw solution out of extraction tank outlet and to enter collection tank inlet, wherein in the situation when cold air intake valve (1.B) is open, and vacuum from vacuum pump (1.O) is applied to collection tank (1.I), the open cold air intake valve (1.B) is capable of acting as a vent to alleviate excess vacuum.

14. The system of claim 1 that comprises a plurality of solvent tanks, wherein each of said solvent tanks is operably linked with a corresponding solvent tank valve, wherein the system is configured to draw solvent from only one at a time of the solvent tanks for use in plant matter extraction, and wherein the system is configured to switch from an initial solvent tank to a subsequent solvent tank when the first solvent tank is emptied of solvent.

15. The system of claim 1 that includes at least one sight glass that is located in-line of at least one fluid line.

16. A method for selectively extracting a chemical from plant matter, wherein the extracting is accomplished by a system that comprises a solvent tank, an extraction tank, a collection tank, and fluid line capable of conveying solvent from solvent tank to extraction tank for initial extraction of plant matter, a fluid line capable of conveying a solution from extraction tank to collection tank wherein "solution" is defined as a solvent that contains chemicals extracted from plant matter, a fluid line capable of recirculating solution from collection tank back to extraction tank for further extraction of plant matter, and a fluid line capable of transmitting solution from collection tank to an evacuation line, wherein the system further comprises an extraction tank inlet, extraction tank outlet, collection tank inlet, and collection tank outlet, wherein the system further comprises fluid line valves that comprises a solvent flooding valve (1.C), a solution return valve (1.D), a solution collection valve (1.E), and an excavation valve (1.K), and wherein system further comprises a vacuum pump (1.O) that is operably linked to a plurality of vacuum line valves, wherein the vacuum line valves comprise an extraction tank vacuum valve (1.M), a collection tank vacuum valve (1.N), and an evacuation tank vacuum valve (1.Q), wherein said fluid line valves and vacuum line valves are capable of controlling the selective transmission of solvent from the solvent tank to the extraction tank, the selective transmission of solution from the extraction tank to the collection tank, the selective transmission of solution from the collection tank back to the extraction tank for recirculation, and the selective transmission of solution from the collection tank to the evacuation line (1.P), wherein the extracting is accomplished by a cold solvent that is at a temperature in the range of minus 60 degrees C. to minus 30 degrees C., wherein the temperature is measurable by probing solvent that resides in extraction tank, the method comprising: (i) The step of introducing plant matter into the extraction tank; (ii) The step of transmitting solvent from the solvent tank into the extraction tank, resulting in a mixture of solvent and plant matter; (iii) The step of allowing solvent to contact the plant matter that is in the extraction tank; (iv) The step of allowing solvent to extract chemicals from the plant matter resulting in the creating of the solution; (v) Wherein agitation is either applied to or is not applied to the mixture of solvent and plant matter; (vi) The step of draining at least a portion of the solution in the extraction tank and transmitting said at least a portion of the solution to the collection tank to produce a solution residing in the collection tank; (vii) The step of delivering at least a portion of the solution residing in the collection tank back to the extraction tank via a recirculating step; (viii) The step of allowing the solution delivered via the recirculating step to contact and further extract plant matter; (ix) The step of draining at least a portion of the solution in the extraction tank from the immediately previous step, and transmitting said at least a portion of the solution to the collection tank; (x) The step of controlling said fluid line valves and said vacuum line valves for allowing the transmission of solvent from solvent tank to extraction tank, followed by the step of controlling said fluid line valves and vacuum line valves for allowing the transmission of solution from extraction tank to collection tank, which is then followed by the step of controlling said fluid line valves and vacuum line valves for allowing the transmission and recirculation of solution from the collection tank to the extraction tank, and eventually followed by the step of controlling said fluid line valves and vacuum line valves for allowing transmission of solution from the collection tank to the evacuation line.

17. The method of claim 16, further comprising a final extraction step, wherein the final extraction step comprises transmitting solvent from solvent tank (1.A) to extraction tank (1.H) and allowing the solvent to extract any residual chemicals from the plant matter, followed by transmission of solution to the collection tank, and finally by transmission of solution from collection tank to the evacuation line.

18. The method of claim 16, further comprising the step of filling solvent tank (1.A) with ethanol that is at least 90% ethanol, at least 95% ethanol, or about 100% ethanol.

19. The method of claim 16, that excludes any agitation of the mixture of solvent and plant matter, and wherein agitation is not applied to the mixture of solvent and plant matter.

20. The method of claim 16, wherein transmissions of solvent and solution are driven by a force originating from a mechanical device, and where the only mechanical device that is used to drive transmission of solvent and solution is the vacuum pump.

21. The method of claim 16 that is batchwise, wherein the batchwise method comprises introducing plant matter into the extraction tank, filling extraction tank with a volume of solvent, followed by extraction of plant matter, and then followed by draining of at least 50%, at least 60%, at least 70%, at least 80%, at least 90%, or about 100%, of the volume of solution from extraction tank to produce a drained solution, wherein the drained solution is moved from extraction tank to collection tank, which is followed by transmission of at least 50%, at least 60%, at least 70%, at least 80%, at least 90%, or about 100%, of solution from collection tank back to extraction tank.

22. The method of claim 16 that is batchwise and not continuous.

23. The method of claim 16 that is continuous, wherein the continuous method comprises introducing plant matter into the extraction tank, filling extraction tank with a volume of solvent, followed by extraction of plant matter, which is then followed by a period of time wherein solution from extraction tank outlet is continuously circulated to inlet of extraction tank, to produce a recirculation duration, and where volume of solvent that is recirculated is equivalent to the volume of solvent, equivalent to two times the volume of the solvent, equivalent to about three times the volume of the solvent, equivalent to about four times the volume of the solvent, equivalent to about five times the volume of the solvent, or equivalent to greater than about five times the volume of the solvent.

24. The method of claim 16, wherein solution is emptied from collection tank and transmitted into the evacuation line where one of the following conditions precedent has been satisfied: (i) After performing the initial solvent extraction step and one or more solution extraction steps; (ii) After performing the initial solvent extraction step, and one or more solution extraction steps, and the final solvent extraction step; (iii) After performing the initial solvent extraction step and one or more solution extraction steps, followed by emptying the collection tank, and then performing the final solvent extraction step.

25. The method of claim 16, further comprising the step of purging solvent out of a solution produced by the steps of initial extraction of plant matter with solvent to produce a solution, followed by one or more steps of re-extraction of plant matter with solution via one or more recirculation steps, and finally followed by extracting the previously extracted plant matter with fresh solvent to produce a final solution, wherein the final solution is purged to remove at least 50%, at least 60%, at least 70%, at least 80%, at least 90%, or at least 95% of solvent that is present in the final solution.

26. A solution produced by the method of claim 16.

Description

CROSS REFERENCE TO RELATED CASES

[0001] This application claims the benefit of, and priority to, U.S. Provisional Patent Application Ser. No. 62/322,751 filed Apr. 14, 2016, and U.S. Ser. No. 15/488,341 filed Apr. 14,2017, the content of which is incorporated herein by reference herein in its entirety.

FIELD OF THE DISCLOSURE

[0002] The disclosure relates to systems and methods for extracting oil-containing substances such as plant matter and to oil compositions prepared by those systems and methods.

BACKGROUND OF THE DISCLOSURE

[0003] This present disclosure relates to ways of extracting and concentrating cannabinoids and terpenes from plant substrates including hemp, and particularly modifying the characteristics of the solvent to by-pass undesired constituents of plants throughout the extraction process.

[0004] Extraction of industrial hemp and cannabis can be done via many methods, using a wide array of FDA-approved food grade solvents. The most commonly used solvents are hydrocarbons such as hexane, pentane, butane or propane. Lipid based solvents such as canola oil, soybean oil, olive oil, flax seed oil, hemp oil are also commonly used in hemp and cannabis extraction methods. Supercritical carbon dioxide is also commonly used in cannabis extraction, but the expensive machinery and the post-extraction steps required to purify a supercritical fluid extraction (SFE) extract of undesired plant lipids, makes SFE the least desirable method for any commercial processor.

[0005] Several drawbacks of hydrocarbon extraction methods have been recognized. The most prominent of these drawbacks is the volatility of hydrocarbon solvents. The cost associated with retrofitting a laboratory with explosion proof electronics, ventilation fans, and the like, create enormous start-up costs. Second, pure hydrocarbon solvents such as N-butane or N-hexane are extremely difficult to obtain and therefore are hardly ever used for cannabis extract production. The majority of extracts are created with inferior, low quality butane that contains additives and impurities.

[0006] Lipid-based extractions are safer and less hazardous to health than hydrocarbon-based extractions, but separating the cannabinoids or flavonoids from a lipid emulsion requires a more thorough training in chemistry, as well as more expensive distillation devices.

[0007] Various states and local governments are now legalizing cannabis for medical and recreational use. This has created an expanding market for DIY extractions which are obtained through low quality, impure, hydrocarbons such as butane and propane. Unsafe practices by DIY manufacturers have resulted in explosions and fires resulting from use of hydrocarbon solvents such as butane and propane.

SUMMARY OF THE DISCLOSURE

[0008] The present disclosure provides the following system. What is provided is a system comprising a solvent tank (1.A), an extraction tank (1.H), a collection tank (1.I), and a plurality of fluid lines, wherein the system is capable of extracting plant matter with a solvent at an ultra-cold temperature, wherein this solvent is a fluid that does not contain chemicals extracted from the plant matter of the system, and wherein a solution is a solvent that comprises chemicals extracted from the plant matter of the system, wherein the system comprises:

[0009] (i) An environment box (1.L) that is capable of maintaining an ultra-cold temperature of structures, solvents, and solutions that reside inside the environment box, wherein the environment box surrounds and envelops the solvent tank (1.A), the extraction tank (1.H), and the collection tank (1.I), wherein the environment box comprises an upper surface, a lower surface, and an interior region;

[0010] (ii) Wherein the solvent tank (1.A) is operably linked to the extraction tank (1.H) with a fluid line;

[0011] (iii) Wherein the system comprises a solvent flooding valve (1.C) that resides in a fluid line that is operably linked with the solvent tank (1.A) and the extraction tank (1.H), wherein opening solvent flooding valve permits transfer of solvent from the solvent tank (1.A) to the extraction tank (1.H);

[0012] (iv) Wherein the extraction tank (1.H) comprises an interior, an extraction tank inlet (1.V), an extraction tank outlet (1.W), an extraction tank upper region (1.BB), wherein opening of solvent flooding valve (1.C) allows solvent from solvent tank (1.A) to pass through solvent flooding valve (1.C) and through extraction tank inlet and into extraction tank;

[0013] (v) Wherein the extraction tank (1.H) comprises a lid, door, or aperture that is capable of allowing transfer of plant matter to interior of extraction tank;

[0014] (vi) Wherein a first fluid line leads from solvent tank to extraction tank branching point (1.AA), and wherein a second fluid line leads from extraction tank outlet (1.W) to said extraction tank branching point, wherein the extraction tank branching point (1.AA) is operably linked to extraction tank inlet (1.V), wherein the extraction tank branching point is capable of directing solvent obtained from solvent tank into extraction tank for extracting plant matter with solvent, and wherein the extraction tank branching point is capable of directing solution obtained from collection tank outlet into extraction tank for extracting plant matter by recirculating the solution obtained from collection tank (1.I);

[0015] (vii) Wherein the collection tank (1.I) comprising a collection tank inlet (1.Y) and a collection tank outlet (1.Z), wherein extraction tank outlet is operably linked to collection tank inlet by a fluid line, wherein flow of solution from extraction tank outlet to collection tank inlet is controllable by in-line valve (1.E), wherein the collection tank outlet is operably linked with a collection tank branching point that comprises a first branch and a second branch, wherein first branch of collection tank branching point is operably finked by a fluid line that is capable of transmitting solution from collection tank to extraction tank, wherein flow of solution from extraction tank outlet to collection tank inlet is controllable by a solution return valve (1.D), wherein the second branch of collection tank branching point is operably linked by a fluid line that is capable of transmitting solution from collection tank (1.I) to evacuation line (1.P), wherein flow of solution from extraction tank outlet to evacuation line (1.P) is controllable by in-line valve (1.K) and, wherein flow of solution from extraction tank outlet to evacuation line (1.P) is configured for removing solution from environment box and configured for transmitting solution to the evacuation tank (1.R);

[0016] (viii) Wherein regarding the solution return valve (1.D) and the evacuation valve (1.K), the opening of solution return valve (1.D) and closing evacuation valve (1.K) promotes or allows recirculating of solution from collection tank to extraction tank for the purpose of further extracting chemicals from plant matter; and wherein closing solution return valve (1.D) and opening evacuation valve (1.K) promotes or allows removal of solution from all tanks and fluid lines in said environment box;

[0017] (ix) Wherein the system is capable of a first extraction of plant matter with solvent to produce a first extract, followed by one or more extractions of plant matter with solution that is recirculated from collection tank to produce at least a second extract, which is followed by a final extraction of plant matter with solvent to produce a final extract, and wherein the collection tank (1.I) is capable of receiving all of the first extract, the at least a second extract, and the final extract, and wherein the collection tank is capable of storing a mixture of the first extract, the second extract, and the final extract.

[0018] In a temperature embodiments, what is provided is the above system wherein the temperature in the environment box is maintainable in the range of -60 to -50, -60 to -45, -60 to -40, -60 to -35, -60 to -30, -60 to -25, -60 to -20, or where the temperature is maintainable in the range of -55 to -45, -55 to -40, -55 to -35, -55 to -30, -55 to -25, or where the temperature is in the range of -50 to -40, -50 to -35, -50 to -30, -50 to -25, -50 to -20, or where the temperature is maintainable in the range of -45 to -40, -45 to -35, -45 to -30, -45 to -25, -45 to -20, or where temperature is maintainable in the range of -40 to -30, -40 to -25, -40 to -20, -40 to -15, and the like.

[0019] In vacuum embodiments, what is provided is the above system, further comprising a vacuum pump (1.O) and a plurality of vacuum lines, wherein flow of solvent from solvent tank (1.A) to extraction tank (1.H), flow of solution from extraction tank outlet to collection tank (1.I), and flow of solution from collection tank outlet to evacuation line (1.P), are each driven by vacuum from said vacuum pump.

[0020] In vacuum valve embodiments, what is embraced is the above system, further comprising a vacuum pump and a plurality of vacuum lines, wherein flow of solvent from solvent tank (1.A) to extraction tank (1.H), flow of solution from extraction tank outlet to collection tank (1.I), and flow of solution from collection tank outlet to evacuation line (1.P), are each driven by vacuum from said vacuum pump, and wherein system further comprises: (i) Vacuum valve (1.M) that controls suction of vacuum from vacuum pump to upper region (1.BB) of extraction tank (1.H); (ii) Vacuum valve (1.N) that controls suction of vacuum from vacuum pump to upper region (1.CC) of collection tank (1.I); and (iii) Vacuum valve (1.Q) that control suction of vacuum from vacuum pump to evacuation tank (1.R).

[0021] In vacuum pump embodiments, what is contemplated is the above system, further comprising a vacuum pump (1.O) and a plurality of vacuum lines, wherein flow of solvent from solvent tank (1.A) to extraction tank (1.H). How of solution from extraction tank outlet to collection tank (1.I), and flow of solution from collection tank outlet to evacuation line (1.P), are each driven by vacuum from said vacuum pump, and wherein flow of solvent and flow of solution are not driven by any device other than a vacuum pump, and wherein flow of solvent and flow of solution are not driven by direct contact of solvent or solution with any rotor, propeller, or hose subjected to peristaltic forces.

[0022] In tank liner embodiments, the present disclosure embraces the above system, wherein the extraction tank (1.H) comprises a tank liner and a false bottom, wherein the tank liner is configured to receive and secure plant matter, wherein the tank liner comprises a plurality of filtering apertures, optionally, apertures of about 10 micrometers in diameter, and wherein the false bottom is configured to secure the tank liner inside of extraction tank and to facilitate extraction of plant matter. Apertures can be about 5 micrometers, about 10, about 15, about 20, about 25, about 30, about 35, about 40, about 50, about 60 about 70, about 80, about 90, or about 100 micrometers in diameter, or any range consisting of what is bracketed by any two of these numbers.

[0023] In cooling jacket embodiments, what is provided is the above system, wherein exterior surface of one or more of solvent tank (1.A), extraction tank (1.H), and collection tank (1.I) are covered at least in part by a cooling jacket, wherein the cooling jacket is capable of receiving cold air or cold fluid from a freezer.

[0024] In evacuation embodiments, what is provided is the above system, that further comprising an evacuation tank (1.R), wherein the evacuation tank is outside of environment box (1.L), and wherein evacuation line (1.P) is operably linked with collection tank outlet and with evacuation tank (1.R), and wherein evacuation tank is capable of receiving solution that is transmitted from collection tank (1.I) via evacuation line (1.P) to evacuation tank (1.R), and wherein evacuation line passes from interior of environment box (1.L) to exterior of environment box.

[0025] In tank liner and cone embodiments, what is provided is the above system, wherein the extraction tank (1.H) comprises an inverted cone structure (narrow side up, wide side down), wherein the inverted cone structure is capable of supporting a false bottom, and wherein the false bottom is configured for supporting a tank liner, and wherein the inverted cone structure is configured to receive and collect solution generated by extracting plant matter with solvent, where solution falls from false bottom, and is capable of tunneling the solution to extraction tank outlet.

[0026] In filter embodiments, what is provided is the above system, further comprising a filter housing (1.J), wherein the filter housing resides in the evacuation line (1.P), wherein the evacuation line leads from collection tank outlet (1.Z) to evacuation tank (1.R), wherein the filter housing comprises a filter that is capable of removing particulate matter from the solution.

[0027] In plant matter embodiments, it is understood that the "plant matter" is the workpiece of the system of the present disclosure. What is encompassed is the above system in combination with the workpiece, where wherein the extraction tank comprises: (i) Plant matter; (ii) Plant matter derived from a cannabis plant; (iii) Plant matter derived from a cannabis plant and not any plant matter derived from any other type of plant. Moreover, for all embodiments that are described herein, what is provided are embodiments where the workpiece is other than "plant matter," for example, where the workpiece is a synthetic composition, where the workpiece takes the form of bacteria or fungus, where the workpiece takes the form of animal matter, and so on.

[0028] In solvent embodiments, the solvent tank contains ethanol that is at least 95% ethanol, ethanol that is at least 98% ethanol, or 100% ethanol.

[0029] In cold air intake embodiments, the present disclosure provides a cold air intake tube (1.T) and a cold air intake valve (1.B), wherein the cold air intake tube is substantially or completely located inside of the environment box, and wherein the cold air intake tube has an upper-end terminus and a lower-end terminus, wherein the lower-end terminus is constitutively open to air inside of the environment box, and wherein the lower-end terminus is positioned near interior bottom of environmental box, and wherein the lower-end terminus is capable of receiving cold air from interior of environment box, and (i) Wherein the upper-end terminus is secured to upper surface of environment box and is capable of directing passage of cold air from interior of environmental box to fluid lines located at exterior of environmental box, wherein cold air intake valve (1.B) is located exterior of environment box, and the cold air intake tube (1.T) is operably linked to a cold air intake valve (1.B), and (ii) Wherein the cold air intake valve (1.B) is capable of being closed in the situation where the solvent needs to be drawn out of solvent tank (1.A) and into extraction tank (1.H) and when vacuum from vacuum pump (1.O) is applied to top interior of extraction tank (1.BB), and (iii) Wherein the cold air intake valve (1.I) is capable of being opened in the situation where vacuum from vacuum pump (1.O) is applied to collection tank (1.I) in order to draw solution out of extraction tank outlet and to enter collection tank inlet, wherein in the situation when cold air intake valve (1.B) is open, and vacuum from vacuum pump (1.O) is applied to collection tank (1.I), the open cold air intake valve (1.B) is capable of acting as a vent to alleviate excess vacuum.

[0030] In solvent tank embodiments, the present disclosure provides a plurality of solvent tanks, wherein each of said solvent tanks is operably linked with a corresponding solvent tank valve, wherein the system is configured to draw solvent from only one at a time of the solvent tanks for use in plant matter extraction, and wherein the system is configured to switch from an initial solvent tank to a subsequent solvent tank when the first solvent tank is emptied of solvent.

[0031] In sight glass embodiments, the system includes at least one sight glass that is located in-line of at least one fluid line.

[0032] In methods embodiments, the present disclosure provides the following method, as well as compositions, extracts, solutions, and purged solutions, provided by the following method. What is encompassed is a method for selectively extracting a chemical from plant matter, wherein the extracting is accomplished by a system that comprises a solvent tank, an extraction tank, a collection tank, and fluid line capable of conveying solvent from solvent tank to extraction tank for initial extraction of plant matter, a fluid line capable of conveying a solution from extraction tank to collection tank wherein "solution" is defined as a solvent that contains chemicals extracted from plant matter, a fluid line capable of recirculating solution from collection tank back to extraction tank for further extraction of plant matter, and a fluid line capable of transmitting solution from collection tank to an evacuation line, wherein the system further comprises an extraction tank inlet, extraction tank outlet, collection tank inlet, and collection tank outlet, wherein the system further comprises fluid line valves that comprises a solvent flooding valve (1.C), a solution return valve (1.D), a solution collection valve (1.E), and an excavation valve (1.K), and wherein system further comprises a vacuum pump (1.O) that is operably linked to a plurality of vacuum line valves, wherein the vacuum line valves comprise an extraction tank vacuum valve (1.M), a collection tank vacuum valve (1.N), and an evacuation tank vacuum valve (1.Q), wherein said fluid line valves and vacuum line valves are capable of controlling the selective transmission of solvent from the solvent tank to the extraction tank, the selective transmission of solution from the extraction tank to the collection tank, the selective transmission of solution from the collection tank back to the extraction tank for recirculation, and the selective transmission of solution from the collection tank to the evacuation line (1.P), wherein the extracting is accomplished by a cold solvent that is at a temperature in the range of minus 60 degrees C. to minus 30 degrees C., wherein the temperature is measurable by probing solvent that resides in extraction tank, the method comprising:

[0033] (i) The step of introducing plant matter into the extraction tank;

[0034] (ii) The step of transmitting solvent from the solvent tank into the extraction tank, resulting in a mixture of solvent and plant matter;

[0035] (iii) The step of allowing solvent to contact the plant matter that is in the extraction tank;

[0036] (iv) The step of allowing solvent to extract chemicals from the plant matter resulting in the creating of the solution;

[0037] (v) Wherein agitation is either applied to or is not applied to the mixture of solvent and plant matter;

[0038] (vi) The step of draining at least a portion of the solution in the extraction tank and transmitting said at least a portion of the solution to the collection tank to produce a solution residing in the collection tank;

[0039] (vii) The step of delivering at least a portion of the solution residing in the collection tank back to the extraction tank via a recirculating step;

[0040] (viii) The step of allowing the solution delivered via the recirculating step to contact and further extract plant matter;

[0041] (ix) The step of draining at least a portion of the solution in the extraction tank from the immediately previous step, and transmitting said at least a portion of the solution to the collection tank;

[0042] (x) The step of controlling said fluid line valves and said vacuum line valves for allowing the transmission of solvent from solvent tank to extraction tank, followed by the step of controlling said fluid line valves and vacuum line valves for allowing the transmission of solution from extraction tank to collection tank, which is then followed by the step of controlling said fluid line valves and vacuum line valves for allowing the transmission and recirculation of solution from the collection tank to the extraction tank, and eventually followed by the step of controlling said fluid line valves and vacuum line valves for allowing transmission of solution from the collection tank to the evacuation line.

[0043] In a final extraction method embodiment, what is provided is the above method, further comprising a final extraction step, wherein the final extraction step comprises transmitting solvent from solvent tank (1.A) to extraction tank (1.H) and allowing the solvent to extract any residual chemicals from the plant matter, followed by transmission of solution to the collection tank, and finally by transmission of solution from collection tank to the evacuation line.

[0044] In solvent embodiments, what is provided is the above method, further comprising the step of filling solvent tank (1.A) with ethanol that is at least 90% ethanol, at least 95% ethanol, or about 100% ethanol.

[0045] In agitation-free embodiments, what is provided is the above method that excludes any agitation of the mixture of solvent and plant matter, and wherein agitation is not applied to the mixture of solvent and plant matter.

[0046] In vacuum-activated embodiments, what is provided is the above method, wherein transmissions of solvent and solution are driven by a force originating from a mechanical device, and where the only mechanical device that is used to drive transmission of solvent and solution is the vacuum pump.

[0047] In batchwise embodiments, what is provided is the above method, that is batchwise, wherein the batchwise method comprises introducing plant matter into the extraction tank, filling extraction tank with a volume of solvent, followed by extraction of plant matter, and then followed by draining of at least 50%, at least 60%, at least 70%, at least 80%, at least 90%, or about 100%, of the volume of solution from extraction tank to produce a drained solution, wherein the drained solution is moved from extraction tank to collection tank, which is followed by transmission of at least 50%, at least 60%, at least 70%, at least 80%, at least 90%, or about 100%, of solution from collection tank back to extraction tank. Also provided is the above method that is batchwise and not continuous.

[0048] In a contrasting continuous method, the present disclosure also encompasses a continuous (non-batchwise) method, wherein the continuous method comprises introducing plant matter into the extraction tank, filling extraction tank with a volume of solvent, followed by extraction of plant matter, which is then followed by a period of time wherein solution from extraction tank outlet is continuously circulated to inlet of extraction tank, to produce a recirculation duration, and where volume of solvent that is recirculated is equivalent to the volume of solvent, equivalent to two times the volume of the solvent, equivalent to about three times the volume of the solvent, equivalent to about four times the volume of the solvent, equivalent to about five times the volume of the solvent, or equivalent to greater than about five times the volume of the solvent.

[0049] In embodiments where there are alternate times when collection tank is emptied, what is provided is the above method, wherein solution is emptied from collection tank and transmitted into the evacuation line where one of the following conditions precedent has been satisfied: (i) After performing the initial solvent extraction step and one or more solution extraction steps; (ii) After performing the initial solvent extraction step, and one or more solution extraction steps, and the final solvent extraction step; (iii) After performing the initial solvent extraction step and one or more solution extraction steps, followed by emptying the collection tank, and then performing the final solvent extraction step.

[0050] In a purging embodiment, what is provided is the above method, further comprising the step of purging solvent out of a solution produced by the steps of initial extraction of plant matter with solvent to produce a solution, followed by one or more steps of re-extraction of plant matter with solution via one or more recirculation steps, and finally followed by extracting the previously extracted plant matter with fresh solvent to produce a final solution, wherein the final solution is purged to remove at least 50%, at least 60%, at least 70%, at least 80%, at least 90%, or at least 95% of solvent that is present in the final solution.

[0051] In composition embodiments, what is provided is a solution, purged solution, filtered solution, colorless solution, de-colorized solution, produced by the above method. Also, provided is a solution provided by the above method, to which a fragrance has been added, to which a color or dye has been added, to which a pharmaceutical agent has been added, and the like.

[0052] In embodiments, the present disclosure provides an improved system comprising a modular ultra low, cascade type refrigeration compressor system. What is also provided is the above system, wherein the ultra-low refrigeration compressor unit circulates Freon.RTM. through a coil which lines an insulated compartment, further comprising at least a refrigerated compartment capable of achieving temperatures between -1 degrees C. and -81 degrees C. The refrigerant can be a Freon.RTM. compound, dichlorodifluoromethane (Freon 12), trichlorofluoromethane (Freon 11), chlorodifluoromethane (Freon 22), dichlorotetrafluoroethane (Freon 114), and trichlorotrifluoroethane (Freon 113).

[0053] What is also embraced is the above system, wherein the refrigerated compartment houses a vessel in which plant material is stored for extraction, and wherein the refrigerated compartment houses a vessel which serves as an intermittent storage ballast for extract rich solution, and the refrigerated compartment houses an inline filter strainer assembly. Also contemplated is the above system, wherein the filter housing assembly is in line with the evacuation plumbing of the system, and wherein a 10 micron nylon, polyethylene (PE), polypropylene (PP), or stainless steel material filter bag is housed within the filter strainer assembly.

[0054] In another aspect, the present disclosure provides the above system, wherein the refrigerated compartment houses at least four solvent storage tanks. Also provided is the above system, wherein the refrigerated compartment (Environment Box (1.L)) houses six solvent storage tanks. Also provided is the above system, wherein the solvent storage tanks hold 1 gallon, 2 gallons, 3 gallons, 4 gallons, 5 gallons, or 6 gallons.

[0055] Also embraced is the above system, wherein the refrigerated compartment houses stainless steel plumbing and the plumbing connects all of the vessels within the refrigerated compartment. Also provided is the above system, wherein valves are positioned onto the plumbing. Also contemplated, is the above system, wherein the valves are positioned outside of the refrigerated compartment. Also provided is the above system, wherein the plumbing inside the refrigerated compartment allows for the transfer of solvent from vessel to vessel. Also embraced is the above system, wherein the transfer of fluid happens at ultra-low temperatures -1 degrees C. to -81 degrees C.

[0056] In yet another aspect, the present disclosure provides the above system, wherein the transfer of fluid happens via vacuum. Also provided is the above system, further comprising a vacuum pump, vacuum plumbing, and valving. Also provided is the above system, which comprises of a vacuum pump and vacuum plumbing positioned on the outside of the refrigerated compartment. Also embraced is the above system, that further comprises a cold trap container inside the refrigerated compartment, in line with the plumbing connected to the vacuum pump.

[0057] In yet another embodiment, the present disclosure provides a safer and more reliable extraction process, comprising, in combination, a pre-processing step; a contacting step; a filtration step; an evaporation step; a recovery step; and a purging step as described whereby the resultory extract is substantially free of any lipids and chlorophyll. Another aspect of the above safer and more reliable extraction process, what is provided is that process wherein the term solvent is defined to be 100% grain ethanol. Also provided is that above process that includes a solvent recovery step which can be accomplished via simple distillation or rotary evaporator apparatus. Also provided is the above process, that further includes a purging step under vacuum to remove remaining solvent from the extract.

BRIEF DESCRIPTIONS OF THE DRAWINGS

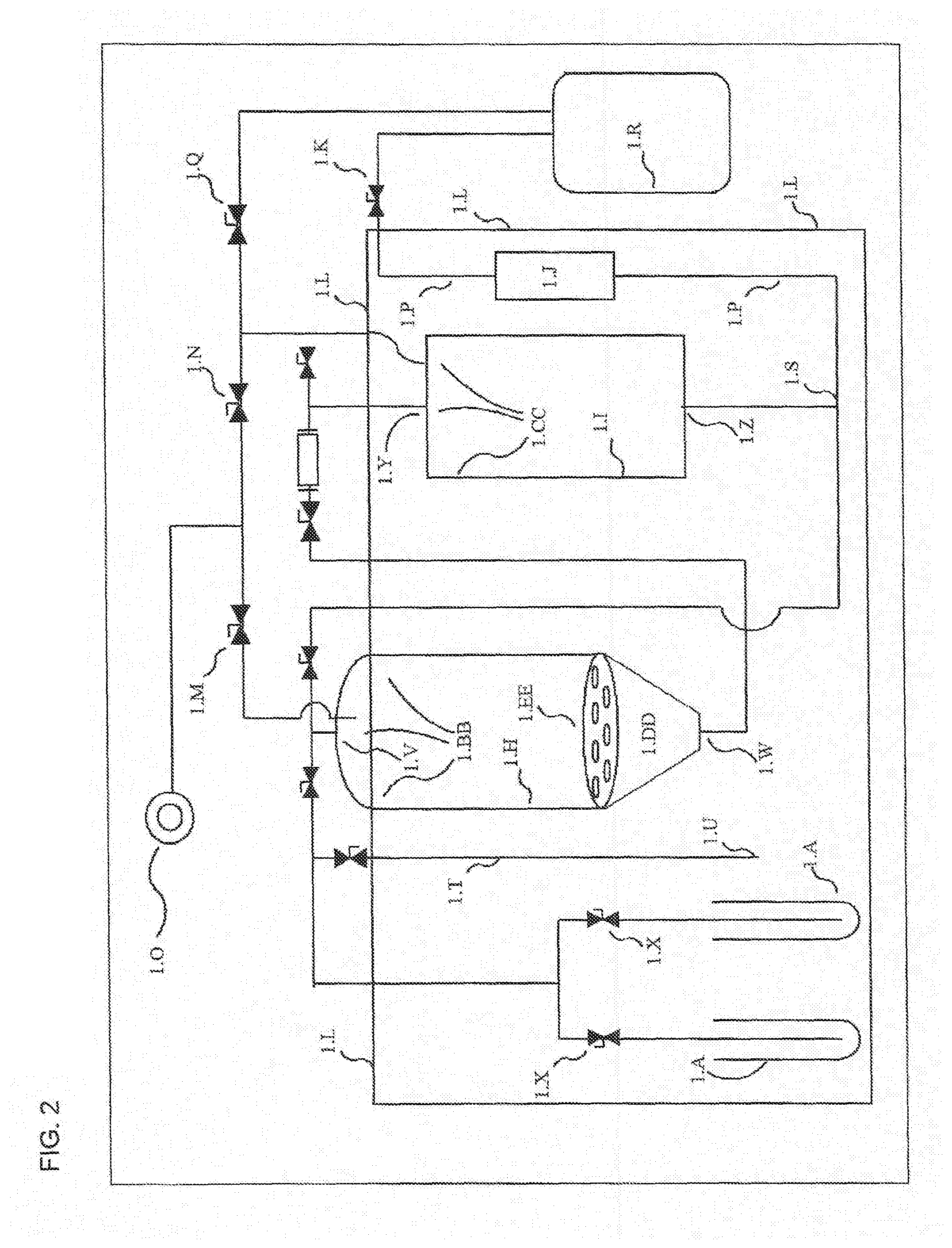

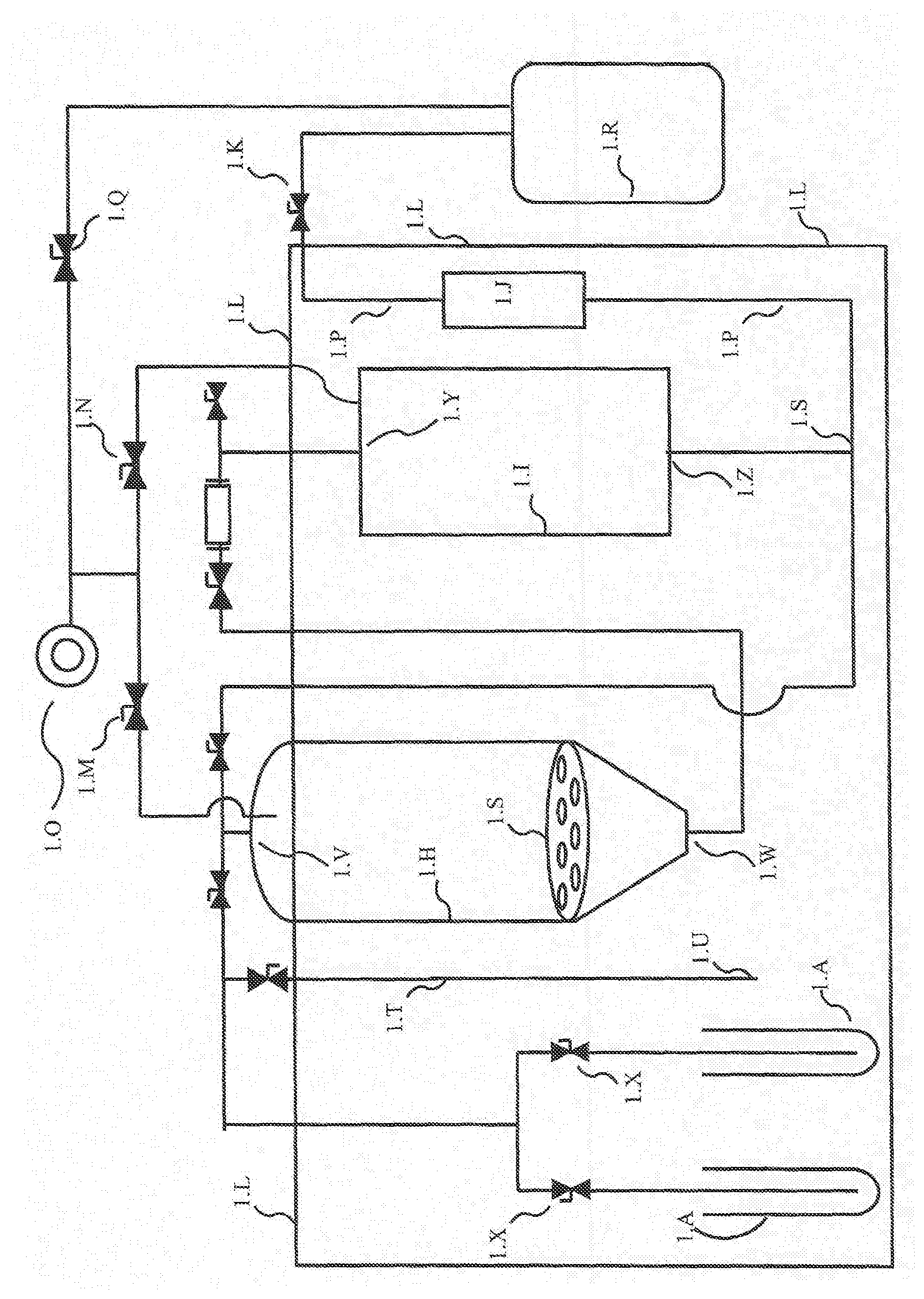

[0058] FIG. 1 discloses a system, where the system includes extraction tank, collection tank, various fluid lines, and evacuation tank.

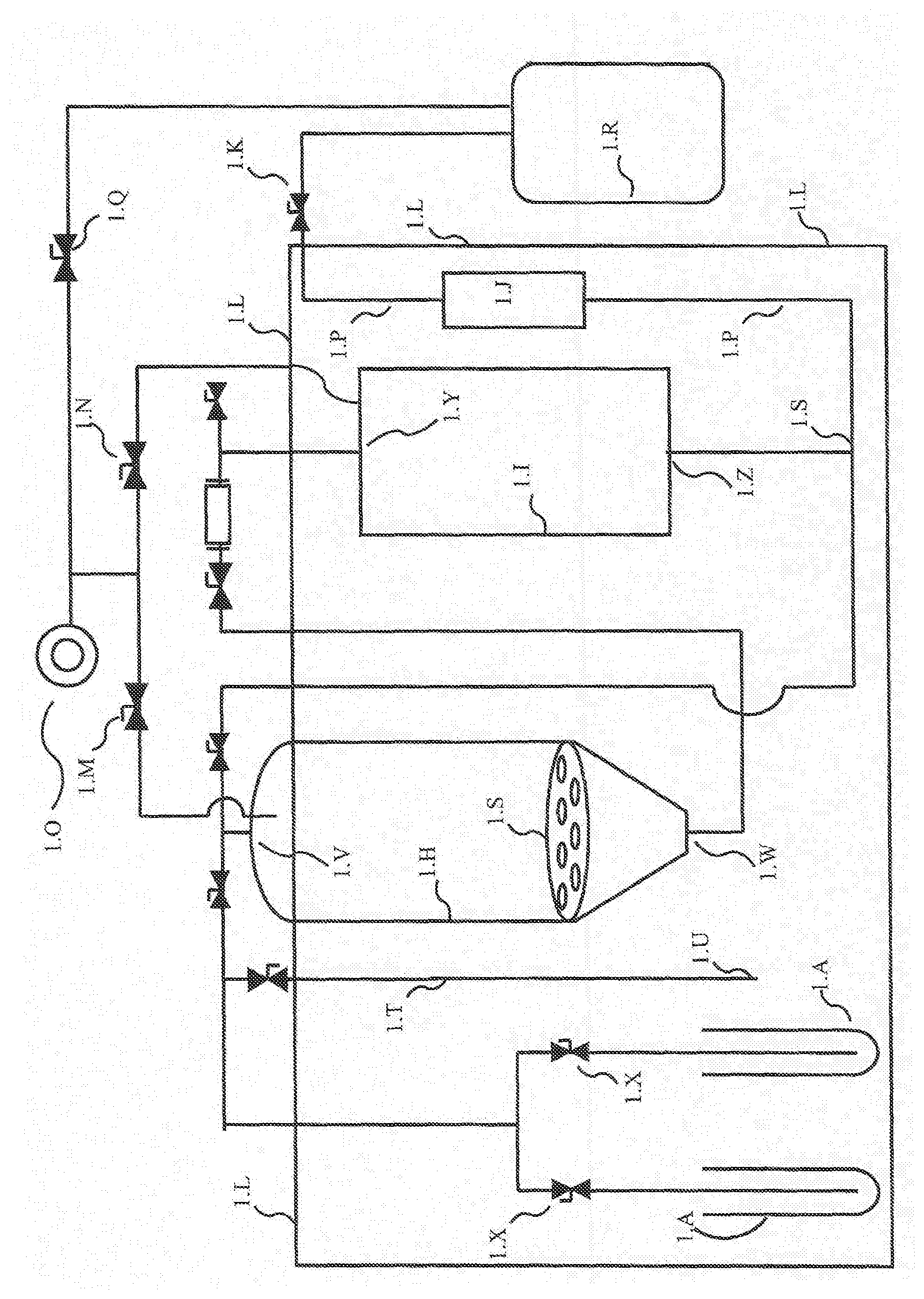

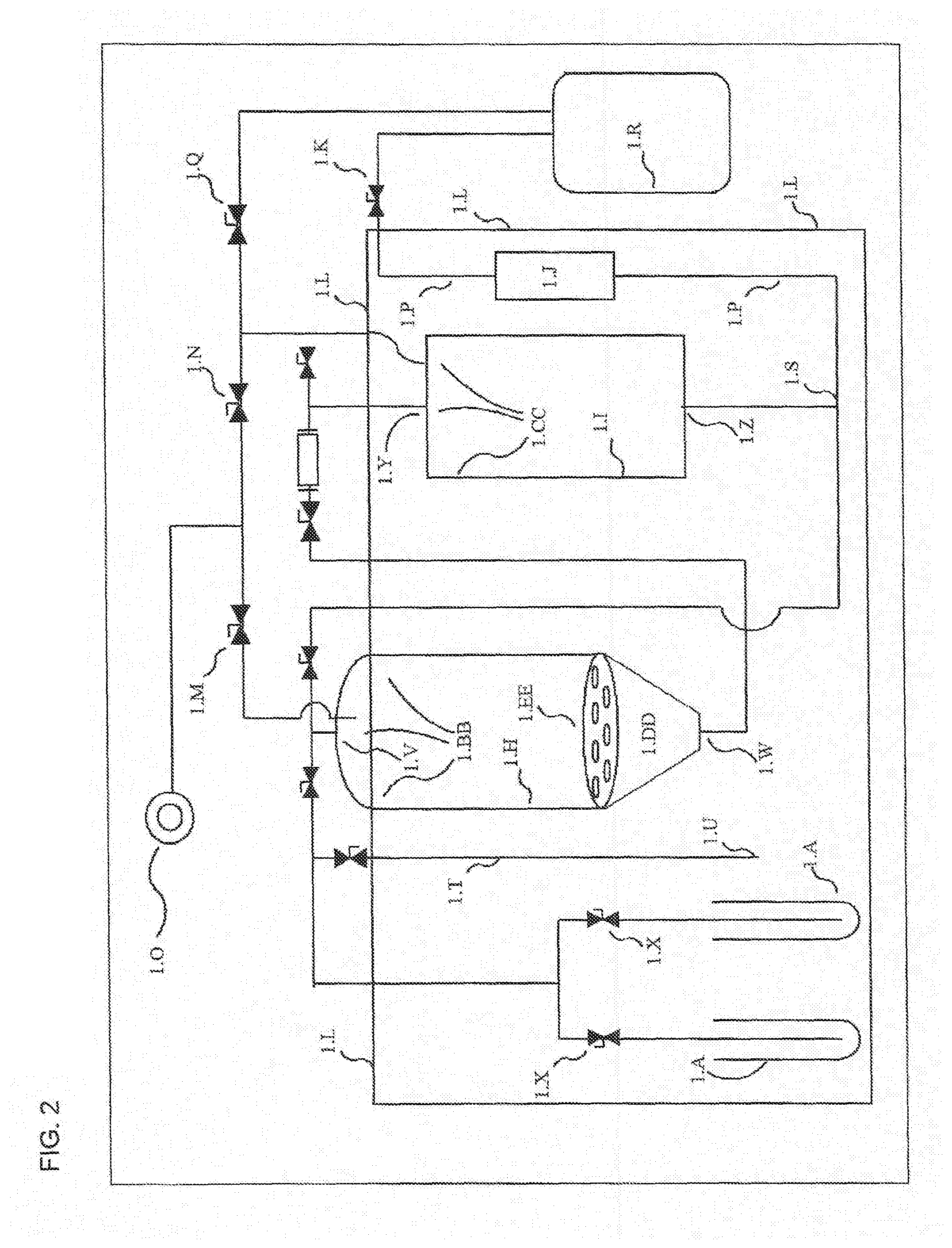

[0059] FIG. 2 discloses the same system as shown in FIG. 1, but with additional structures that are exterior of environmental box, where these additionally disclosed structures include vacuum pump and several valves.

[0060] FIG. 3 discloses a variation of the system shown in FIG. 2, where the variation occurs in the positioning of the vacuum line and valve relating to vacuum pump and evacuation tank.

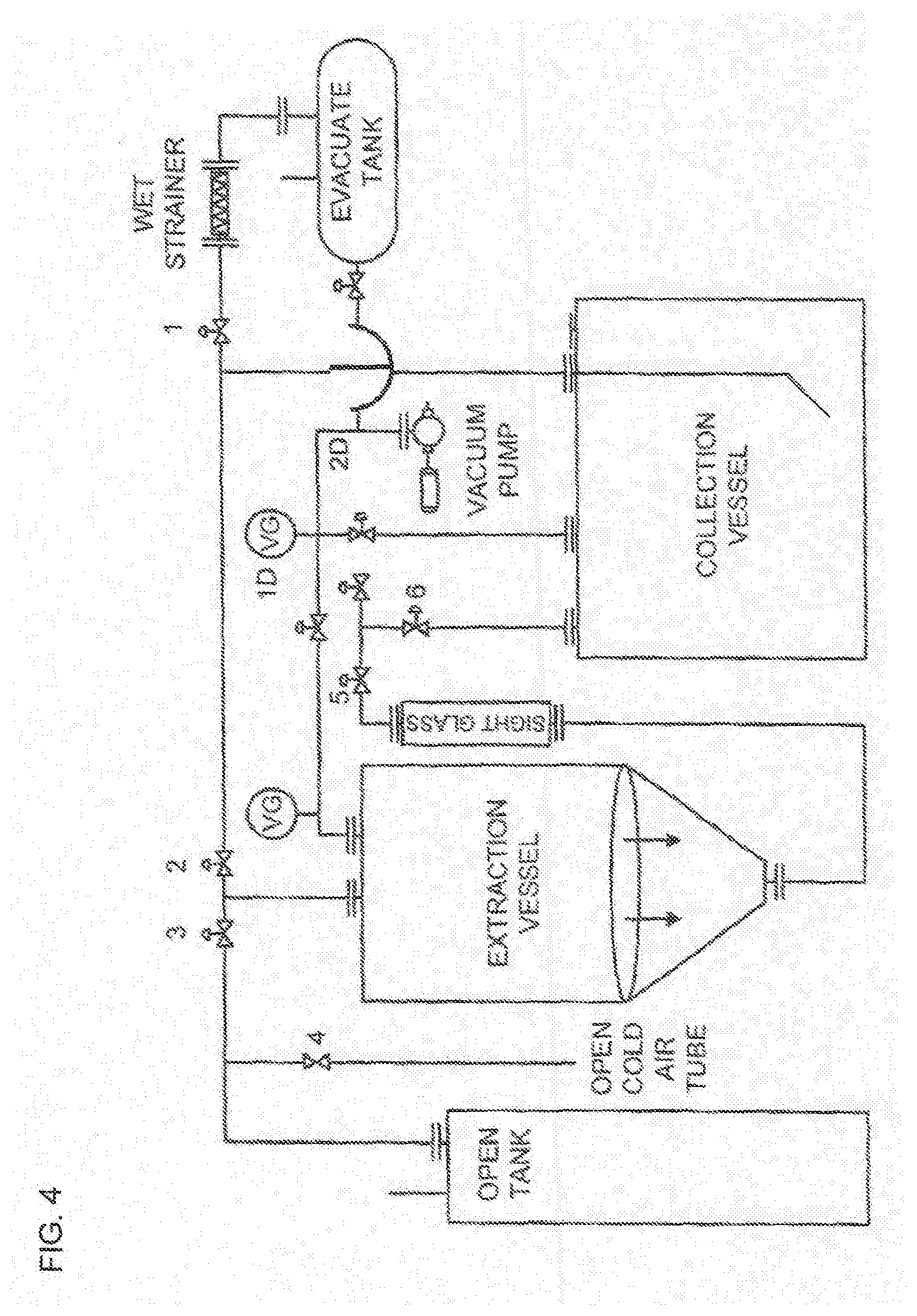

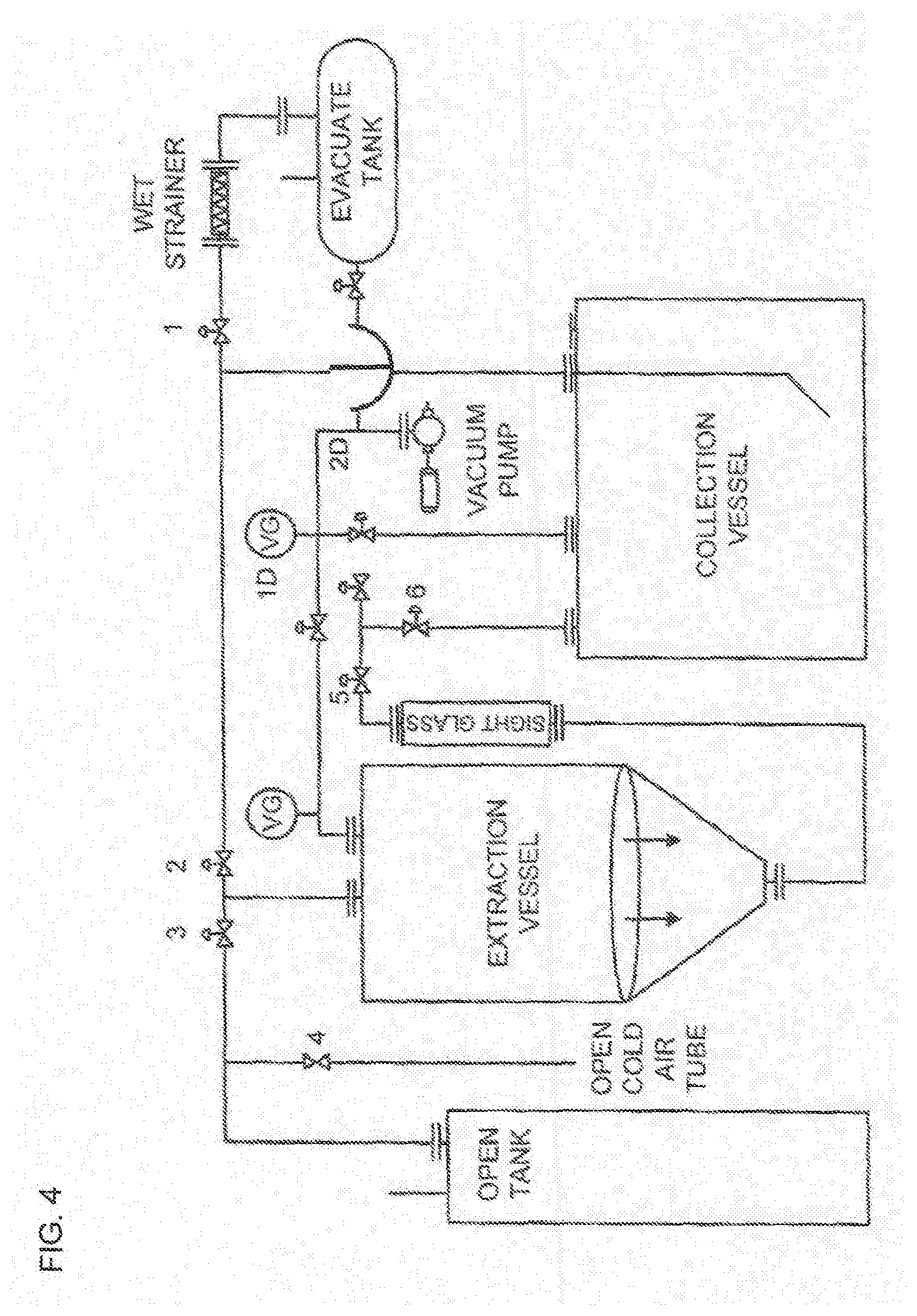

[0061] FIG. 4 discloses a variation of the system shown in FIG. 1 and FIG. 2.

[0062] FIG. 5 discloses a variation of the system shown in FIG. 1 and FIG. 2.

DETAILED DESCRIPTION

[0063] As used herein, including the appended claims, the singular forms of words such as "a," "an," and "the" include their corresponding plural references unless the context clearly dictates otherwise. All references cited herein are incorporated by reference to the same extent as if each individual patent, and published patent application, as well as figures, drawings, sequence listings, compact discs, and the like, was specifically and individually indicated to be incorporated by reference.

[0064] Meanings of Terms

[0065] The present disclosure provides a system that has structures enclosed by a low temperature freezer, where the freezer maintains low temperatures of devices within the freezer, such as solvent tanks, extraction tank, collection tank, and fluid transmission lines that connect these devices. The fluid transmission lines may take the form of pipes, hoses, tubing, and the like. Also, the system includes structures that reside outside of the freezer, such as lines leading from a vacuum pump to extraction tank, to collection tank, and to an evacuation tank. The evacuation tank is preferably outside of the freezer. The terms "fluid line," "line," and "fluid transmission line," and the like are synonymous, unless defined otherwise or indicated otherwise by the context.

[0066] "Derived" as in plant matter "derived" from a given plant, refers to plant matter that is derived by one or more of harvesting, chopping, drying, grinding, slicing, folding, desiccating, and so on. Preferred methods of deriving are methods that minimally damage the plant or that minimally release one or more of oils, resins, aromatics, fat-soluble chemicals, and water-soluble chemicals, from the plant.

[0067] A goal of the system is to extract plant matter at a sub-zero temperature, where extraction is via a solvent such as ethanol, and where the sub-zero temperature enables the selective extraction of certain chemicals, but not of other chemicals, from plant matter. The plant matter may be cannabis, and the chemicals to be extracted are cannabinoids, and the chemicals to be left behind and not extracted include chlorophyll. The freezer is named "environment box." The "environment box" can take various forms, where all of these forms are encompassed by this term, unless expressly stated otherwise or dictated by the context. The environment box can be an insulated box with a built-in refrigeration unit. Alternatively, the environment box can be an insulated box where the interior is cooled by a separate refrigeration unit, for example, where the separate refrigeration unit delivers cold air that is circulated throughout environment box (or where a separate refrigeration unit delivers cold fluid via pipeline, where pipeline is connected to a network of pipes, serving as a heat exchanger, that reside in environment box).

[0068] In the present disclosure, the terms "extraction tank" and "extraction vessel" refer to the same thing. Also, the terms "collection tank" and "collection vessel" refer to the same thing. The term "plant matter" and "plant material" refer to the same thing, unless specified otherwise.

[0069] Table 1 provides a legend that identifies structures in the figures. Where a structure is illustrated and identified in one figure, and where a corresponding structure is illustrated (but not identified) in another figure, the skilled artisan will be able to compare the figures, and by referring to the legend will be able to identify the corresponding structure in the other figure.

TABLE-US-00001 TABLE 1 Legend Identifying Structures in the Figures Table 1. Legend identifies structures in the figures 1.A Solvent storage tank 1.B Cold air intake valve (airlock valve) 1.C Solvent flooding valve 1.D Solution return valve 1.E Solution collection valve 1.F Sight glass 1.G Ambient atmosphere sucking valve 1.H Extraction tank 1.I Collection tank 1.J Inline filter housing 1.K Evacuation valve 1.L Environment box 1.M Extraction tank vacuum valve 1.N Collection tank vacuum valve 1.O Evacuation tank vacuum pump 1.P Evactuation line 1.Q Vacuum valve 1.R Evacuation tank 1.S Collection tank branching point 1.T Cold air intake tube 1.U Cold air intake tube air inlet 1.V Extraction tank inlet 1.W Extraction tank outlet 1.X Solvent tank valve 1.Y Collection tank inlet 1.Z Collection tank outlet 1.AA Extraction tank inlet branching point 1.BB Extraction tank upper region that, when in use, comprises air (or gas) and not any fluid 1.CC Collection tank upper region that, when in use, comprises air (or gas) and not any fluid 1.DD Cone-shaped portion of extraction tank. Cone-shaped portion may be an integrated part of extraction tank, or it may be an "add-on" that is attached to bottom of extraction tank 1.EE False bottom

[0070] Workpieces and Solvents

[0071] A preferred workpiece of the present disclosure takes the form of plant matter. The plant substrate is preferably dry. Drying methods are not crucial for the extraction process. Typically the plant matter is gently ground to a particle size below 0.5 cm.sup.2. Mechanical grinding or chopping is not recommended as it opens up cells anti undesired co-extracted chemicals can enter the solution. Lignans, sugars, and chlorophyll are some of the co-extracted chemicals found in machine ground plant material extracts. The process for grinding, preferably non-mechanical grinding, should be as gentle as possible. The present disclosure provides an extract produced by processing plant matter by the system and method of the present disclosure. Also, the present disclosure provides composition comprising one or more refined chemicals, as derived from and produced by processing plant matter by the system and method of the present disclosure.

[0072] For extraction, 100% ethanol is preferred. Our data has shown that at a ratio of 90% ethanol/10% water, a hydrosol begins to form during the reduction phase (evaporation of ethanol from oil). Although this is not a problem for the extraction process itself, it is a problem for extract post processing. The water must then be separated from the oil. Likewise, the water content in the extract tends to trap some of the water soluble essentials such as terpenes. This can be a problem for operators who intend to produce a full spectrum extract and do not want to lose any essential oils to post processing.

[0073] In exclusionary embodiments, the present system, method, and compositions produced by the system, can exclude any system and method where ethanol is not used for extracting, and can exclude any system and method where ethanol is used for extracting but where the ethanol is not 100% ethanol. Also the present system and method can exclude any system and method, where a hydrosol is formed.

[0074] Contact time is typically limited to how long it takes to build ideal vacuum for collection procedure, and this is preferably about 30 seconds. The recirculation procedure requires 5-7 recirculations of the solution over the plant material, this would equate to 30 seconds.times.7 equals about 4 minutes of actual contact time. But, since the solution is constantly poured over the plant material, and about 20% of the ethanol introduced into the material is actually retained in the material, the plant material is constantly soaked in solution. Once that material is thoroughly wetted through recirculation procedures, it is then rinsed with a fresh batch of ethanol. The clean rinse volume is determined by the operator based on the amount of material placed in the extraction vessel. Usually that is 30% of ethanol to overall weight of material based on a ratio of 1 gallon=1 pounds of plant material.

[0075] Extraction preferably batchwise. In exclusionary embodiments, the system and methods of the present disclosure can exclude any extraction method, any system that performs an extraction method, and any composition prepared by that system, where extraction is by a process other than batchwise.

[0076] The time for extraction is only determined by the operator and his familiarity with the system. A skilled extraction operator can turn an extraction around in about 15-20 minutes. Turnaround time is limited by how long it takes to get to an appropriate amount of vacuum in a vessel to engage a strong flow. This can vary with different vacuum pumps. A 8 cfm vacuum pump will take longer to reach optimal vacuum than a 16 cfm vacuum pump.

[0077] Ideal vacuum for Hooding procedure: -20 inches of mercury (inhg). Ideal vacuum for recirculation procedure: -20 inches of mercury. Ideal vacuum for collection procedure: -28 inches of mercury. Ideal vacuum for evacuation procedure: -28 inches of mercury.

[0078] Plurality of Solvent Storage Tanks

[0079] System of the present disclosure can comprise one or more solvent storage tanks, where each solvent storage tank is operably linked with a corresponding solvent storage tank valve. In use, only one solvent storage tank is used at a time, that is, for providing solvent to Extraction Tank (1.H). Preferably, each solvent storage tank holds six U.S. gallons. Preferably, system of the present disclosure includes four solvent storage tanks, each with a corresponding storage tank valve. In one aspect, all solvent storage tanks are situated inside of Environment Box (1.L), thereby ensuring that the solvent is kept at the same temperature as that inside the environment box. For initiating delivery of solvent to Extraction Tank (1.T) and for continuing delivery of solvent to extraction tank, cold air intake valve (1.B) is closed, solvent flooding valve (1.C) is opened, and vacuum from vacuum pump is applied to Extraction Tank. In a preferred embodiment, vacuum applied to Extraction Tank is minus 20 inches of mercury.

[0080] Cold air intake valve (1.B) is alternatively called, airlock valve or gate valve.

[0081] In embodiments, the present disclosure provides a system that comprises one solvent storage tank, two, three, four, five, six, seven, eight, nine, or ten, and the like, solvent storage tanks. The one or more solvent storage tanks of the present disclosure are all housed inside of Environment Box (1.L). In exclusionary embodiments, the present disclosure can exclude any system, device, apparatus, or method, that comprises one or more solvent storage tanks and where at least one of the solvent storage tanks is not enclosed by an environment box. Regarding the present disclosure, an environment box is an airtight enclosure, optionally shaped like a box, that substantially prevents exchange of environmental air with air inside of environment box, and substantially reduces warming of objects, fluids, and plant matter inside of environment box. This reduced warming is accomplished by reducing transfer of heat originating from environmental air to air inside of environment box. Environmental air refers, for example, to room-temperature air that occurs in parts of the laboratory where laboratory personnel conduct their work. "Environmental air" is not the same as air inside of environment box. This definition of air does not refer to molecules and atoms that constitute the air, but instead refers to the location of the air.

[0082] Branching Points Residing at Extraction Tank Inlet and at Collection Tank Outlet

[0083] Regarding flow of solution downstream of collection tank outlet, the relative flow at collection tank branching point, that is, towards the left branch or to the right branch, is controlled by evacuation valve (1.K) and solution return valve (1.D). Closing evacuation valve (1.K) and opening solution return valve (1.D) allows or promotes recirculation of solution from collection tank back to extraction tank. Regarding the flow of solvent and the flow of solution through extraction tank inlet and into extraction tank (1.H), the relative flow at extraction tank branching point, that is, from solvent tank to extraction tank inlet or from collection tank to extraction tank inlet, is controlled by solution flooding valve (1.C) and solution return valve (1.D). In short, opening solution flooding valve (1.C) and closing solution return valve (1.D) promotes or allows transmission of solvent from solvent tank into extraction tank. Conversely, closing solution flooding valve (1.C) and opening solution return valve (1.D) promotes recirculation of solution from collection tank into the extraction tank, for the purpose of further extracting plant matter.

[0084] Alternative to Branching Point Structures

[0085] Instead of using the branching point structure, the present disclosure provides system where extraction tank branching point and extraction tank inlet is replaced by two extraction tank inlets, where the first extraction tank inlet is dedicated to receiving solvent from solvent tank, and the second extraction tank inlet is dedicated to receiving solution from collection tank. Also the present disclosure provides system where collection rank branching tank and collection tank outlet is replaced by two collection tank outlets, where first collection tank outlet is dedicated to transmitting solution from collection tank back to extraction tank (recirculating the solution), and the second collection tank outlet is dedicated to transmitting solution from collection tank to evacuation line. In exclusionary embodiments, the present disclosure can exclude a system or device that comprises a branching point.

[0086] Generally Regarding Valves

[0087] The valves shown in the figures include 3/4 inch compression valves, 1/2 inch compression valves, and 1.5 inch sanitary butterfly valves. For the sake of the PID, it may not be critical to utilize any particular design of the valves. In a preferred embodiment, all of the valves are hand powered. The system is manual and requires an operator to perform the extraction. The jacketed system built by the inventors is an automated system and has pneumatic actuators on the valves. The actuators are powered by compressed air, passed through a solenoid actuated by a PLC.

[0088] The valves act to either isolate or engage flow. The flow can be of air, vacuum, or liquid. All valves are quarter turn valves that either open or close. No metering is done by the valves on these systems. The direction of flow is determined by the vacuum being applied. If vacuum is applied to extraction vessel, opening a valve on a wet line will draw solution or ethanol into that extraction tank. Likewise, if vacuum is applied to collection vessel, a valve will start or stop the flow of liquid to that tank.

[0089] Preferred Uses Inside of Environment Box and Outside of Environment box

[0090] In embodiments, the temperature of the internal cold compartment of the environment box is displayed on a LCD screen on the HMI of the compressors. This temperature reading is enough for an operator to know that the machine is ready for operation. Optionally, thermocouples can be placed into the various tanks and plumbing to monitor the temperatures at every step. A system and method that employs thermocouples is not preferred. The present disclosure can exclude any system and method that employs thermocouples, for example, to monitor the temperature of fluids inside fluid lines and inside tanks or vessels.

[0091] If the overall temperature of the system is below -50C we know that it is ready for operation. The typical temperature setting on the system is -60C. Having the freezer compartment set below -45C (ideal temperature for extraction) allows for cooling compensation. Some of the wet plumbing must be externalized due to the positioning of the valves. As we recirculate the solution throughout the system, it tends to warm ever so slightly. We always set the freezer component to a lower temperature to compensate for that warming.

[0092] Referring to FIG. 1, illustrated is an inventive vessel--wet plumbing and freezer compartment assembly which has produced advantageous results. Super-cooling processes have driven these advantageous results with this system. Solvent Storage Tank (1.A) is operatively and communicatively linked to cold air intake valve (1.B) via known lines to those skilled in the art as shown. Solvent flooding valve (1.C) then runs via lines to the solution return valve (1.D) as shown above Extraction Tank (1.H). Solution collection valve (1.E) is then ported through sight glass (1.F) and down to Extraction Tank (1.I) and is connected to inline filter housing (1.J) along to evacuation valve (1.K).

[0093] FIG. 1 shows an inlet at the top of Extraction Tank (1.H). Extraction tank inlet can receive solvent from solvent flooding valve (1.C) is open (and solution return valve (1.D) is closed), and it can receive solution when solution return valve (1.D) is open (and solvent flooding valve (1.C) is closed). The term "solvent" or "clean solvent" refer to solvent prior to exposure to any plant material. The term "solution" refers to any solvent that has been contacted with any plant material. Where any "solution" is recirculated and used to extract a partially extracted plant material, this "solution" is still called a "solution" and is not called a "solvent."

[0094] The following explains what controls the proportion of material passing through solvent flooding valve (1.C) versus material passing through solution return valve (1.D). The plumbing is arranged in such a way that two wet lines are connected to a single port at the top of the lid. Once vacuum is built in the Extraction Tank (1.H), valve (1.C) will open the flow of clean ethanol from a Solvent Storage Tank. Likewise, valve (1.D) will engage the flow of solution from the Collection Tank (1.I), back into the Extraction Tank for what is called the "recirculation procedure." The detailed arrangement of the plumbing allows a single port to double as the flooding and recirculating channel. These valves work independently of one another and are never used to flood the Extraction Tank with BOTH, clean ethanol and solution at the same time.

[0095] The following concerns the proportion of material passing through valve (1.C) versus material passing through valve (1.D). There is never a time when BOTH clean ethanol and solution are delivered into the Extraction Tank at the same time. Clean ethanol introduction and solution recirculation happen at different stages of the extraction process. Clean solvent is introduced into the Extraction tank as very FIRST step in the extraction process. Afterwards, a recirculation of the solution over the plant material is what allows maximum extraction efficiency. After a thorough recirculation procedure, another clean batch of ethanol can be introduced into the Extraction Tank to perform a "final cleanse" or "final wash" of the plant substrate. This "final wash" frees up any solution saturated in actives from the plant substrate.

[0096] Accordingly, the present disclosure provides a system and method, where clean solvent, such as clean ethanol, is delivered as an "initial batch" into an Extraction Tank as the very first step in the extraction process, followed by one or more steps where clean solvent is not delivered into the Extraction Tank but instead there is a recirculation of solution (solution comprising substances extracted from the plant matter) over the plant material, and where this recirculation provides for maximum extraction of chemicals from the plant matter. After the one or more steps where there is recirculation of solution comprising substances extracted from the plant matter, in some embodiments there is not any further extraction using clean solvent, while in other embodiments, there is a final extraction (final cleanse, final wash) of the plant matter with a "final batch" of clean solvent. The "initial batch" can be delivered all at once, or as more than one consecutive smaller batches, or as two consecutive smaller batches, or as three consecutive smaller batches, and so on. The "final batch" can be delivered all at once, or as more than one consecutive smaller batches, or as two consecutive smaller batches, or as three consecutive smaller batches, and so on.

[0097] Introducing Plant Matter into the Extraction Tank

[0098] Extraction Tank has a lid. This lid is attached to Extraction Tank via a hinge. The lid opens, allowing tank liner to be inserted into Extraction Tank. Plant material can be top fed, or it can be placed into the tank liner prior to inserting into Extraction Tank. The tank liner is a combination of two polyester materials: a rough, 70 US mesh outer shell, and a fine 508 US mesh inner lining that acts as the filter. The tank liner can be cylindrical, where it resembles in general form and function, a cylindrical coffee filter that is placed into an extraction chamber that has a cylindrical conformation. More familiar are conical coffee filters with a conical extraction chamber, and the tank liner of the present disclosure can also be conical, where it is placed inside a chamber having a conical conformation. Whatever the overall shape, the tank liner is porous, and optionally has both an inner shell and an outer shell.

[0099] In the flooding procedure, super-cooled ethanol is drawn from Solvent Tank by vacuum into Extraction Tank at a preferred vacuum of minus 20 inches mercury. After passage of solvent (e.g., ethanol) or solution through extraction tank outlet, solvent or solution can be dispersed over plant matter out of one aperture, out of 2, 3, 4, 5, 6, 7, 8, 9, or 10 apertures, out of 10-20 apertures, out of 100-200 apertures, out of 200-1000 apertures, or out of a plurality of apertures, or out of greater than 10 apertures, or greater than 100 apertures, or greater than 1000 apertures. System can be configured so that the solvent or the solution is dispensed as a gushing fluid, as a dripping fluid, as a spray, as a mist, or as any combination of the above, as any of the above in a continuous manner or as any of the above in an intermittent manner.

[0100] For each extraction step, that is, with either solvent or with solution, available volume in Extraction Tank can be filled to about 2%, about 4%, about 6%, about 8%, about 10%, about 15%, about 20%, about 30%, about 40%, about 50%, about 60%, about 70%, about 80%, about 90%, about 95%, about 100%, or to a volume that consists of a range defined by any two of the above percent values.

[0101] For transfer of solution from Extraction Tank to Collection Tank, preferred vacuum is minus 28 inches mercury. For recirculating step, solution from Collection Tank is drawn to Extraction Tank at a preferred vacuum of minus 20 inches mercury. For filling Evacuation Tank, preferred vacuum is minus 28 inches mercury. For the step of filling Evacuation Tank, solution can be drawn from only Collection Tank (in the situation where solution from Extraction Tank has already been transferred to Collection Tank). Alternatively, for filling Evacuation Tank, solution can be simultaneously drawn from both Extraction Tank via valve (1.E) to Collection Tank, and finally to Evacuation Tank.

[0102] Regarding the false bottom that is used to support tank liner, FIG. 1 shows a false bottom in the shape of a disc. Alternatively, or in addition, false bottom can take the form of an inverted cone (pointy side up, broad circular end down). False bottom has apertures or perforations that are preferably 2 millimeters in diameter. The liner, which contains plant matter, can reside directly on top of disc-shaped false bottom or directly on top of inverted cone false bottom.

[0103] Branching Points in Flow Lines and Coordinated Opening and Closing of Valves

[0104] This concerns the branching point at the outlet to Collection Tank (1.I), and it concerns valve (1.D) and valve (1.K). Direction of flow is controlled only by whichever direction vacuum is applied. Transfer of solution from Collection Tank (1.I) to Extraction Tank (1.H) is propelled by vacuum in Extraction Tank (1.H) and by opening of valve (1.D). Here, this vacuum and valve opening drives flow to the leftward direction at the branching point. But if vacuum is applied at valve (1.K) and if valve (1.K) is open, then flow is driven at the branching point to the right.

[0105] In embodiments, the system and method of the present disclosure is capable of simultaneously opening valve (1.D) and closes valve (1.K). Also, the system and method of the present disclosure is capable of simultaneously closing valve (1.D) and opening valve (1.K). In some embodiments, the vacuum coming from Extraction Tank (1.H) is continuous where opening of valve (1.D) is the sole control that forces solution at the branching point to the left. But in other embodiments, vacuum coming from Extraction Tank (1.H) is turned on, or is increased, and where opening of valve (1.D) allows solution at the branching point to travel to the left. In exclusionary embodiments, the present invention can exclude any system, method, or composition made by the system or method, that does not include one or both of the above mechanisms that control flow at the branching point.

[0106] Regarding valve (1.K) and vacuum applied downstream of valve (1.K), in some embodiments vacuum is continuous and the sole control that forces solution at the branching point to the right is opening of valve (1.K). But in other embodiments, vacuum applied downstream of valve (1.K) is turned on, or is increased, and where opening of valve (1.K) allows solution at the branching point to travel to the right. In exclusionary embodiments, the present invention can exclude any system, method, or composition made by the system or method, that does not include one or both of the above mechanisms that control flow at the branching point.

[0107] Recirculating Solution from Collecting Tank Back to Extraction Tank

[0108] This concerns use of Collection Tank (1.I) as an "intermittent holding vessel that allows for closed loop recirculation." In exclusionary embodiments, the present disclosure can exclude any system, method, or products made with the system or method, where the system or method does not have any "intermittent holding vessel that allows for closed loop recirculation." In detail, vacuum can be applied to Collection Tank (1.I) which draws solution from Extraction Tank (1.H). The reverse of this flow can be accomplished, by creating a vacuum in Extraction Tank (1.H) which pulls or draws solution from Collection Tank (1.I). Flow from Extraction Tank (1.H) to Collection Tank (1.I) is via the pipe (or hose, conduit) that communicates from bottom (outlet) of Extraction Tank (1.H) to top (inlet) Collection Tank (1.H). The reverse flow, is via the pipe (hose, conduit) that communicates from bottom (outlet) of Collection Tank (1.H) to top (inlet) of Extraction Tank (1.H).

[0109] This concerns recirculation. Once the clean ethanol enters Collection Tank (1.H) and contacts plant material, it immediately becomes a "solution." Any time we refer to "recirculating" it must be a recirculation of a solution and not of a clean solvent. The solution stays chilled as it is housed in a controlled environment which maintains a temp below -50 degrees C. The entire process happens at these temperatures. Flooding of plant material with solvent, recirculation of the solution over the plant material, and filtration happen at a pre-determined temperature which allows us to lock out water-soluble molecules.