Extended Reach Tool

KLETZEL; Robert

U.S. patent application number 16/566447 was filed with the patent office on 2020-01-02 for extended reach tool. This patent application is currently assigned to COIL SOLUTIONS, INC.. The applicant listed for this patent is COIL SOLUTIONS, INC.. Invention is credited to Robert KLETZEL.

| Application Number | 20200003020 16/566447 |

| Document ID | / |

| Family ID | 64014533 |

| Filed Date | 2020-01-02 |

| United States Patent Application | 20200003020 |

| Kind Code | A1 |

| KLETZEL; Robert | January 2, 2020 |

EXTENDED REACH TOOL

Abstract

An extended reach tool includes two or more separate flow paths, wherein each of the flow paths has multiple hollow chambers connected in series. Each of the hollow chambers includes a first constricted chamber with a fluid entry, a first expansion chamber located adjacent to the lower end of the first constricted chamber, and a second constricted chamber with the upper end of connected to the lower end of the first expansion chamber. A separate second expansion chamber is connected to the lower end of a plurality of the second constricted chambers. A single port is located adjacent to the lower end of the second expansion chamber.

| Inventors: | KLETZEL; Robert; (Medicine Hat, CA) | ||||||||||

| Applicant: |

|

||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Assignee: | COIL SOLUTIONS, INC. ALICE TX |

||||||||||

| Family ID: | 64014533 | ||||||||||

| Appl. No.: | 16/566447 | ||||||||||

| Filed: | September 10, 2019 |

Related U.S. Patent Documents

| Application Number | Filing Date | Patent Number | ||

|---|---|---|---|---|

| 15970691 | May 3, 2018 | |||

| 16566447 | ||||

| 62500870 | May 3, 2017 | |||

| Current U.S. Class: | 1/1 |

| Current CPC Class: | E21B 31/005 20130101; E21B 28/00 20130101 |

| International Class: | E21B 31/00 20060101 E21B031/00 |

Claims

1. An extended reach tool configured to be coupled to at least one of a bottom hole assembly, a tubing, and of a motor, the extended reach tool comprising: at least two separate flow paths extending through the extended reach tool, wherein each flow path of the at least two separate flow paths includes: a first constricted chamber with an upper end and a lower end spaced apart from the upper end of the first constricted chamber, the first constricted chamber including a first constricted chamber diameter; a first expansion chamber with an upper end and a lower end spaced apart from the upper end of the first expansion chamber, the first expansion chamber including a first expansion chamber diameter, wherein the first expansion chamber diameter is greater than the first constricted chamber diameter; a second constricted chamber with an upper end and a lower end spaced apart from the upper end of the second constricted chamber, the second constricted chamber including a second constricted chamber diameter, wherein the first expansion chamber diameter is greater than the second constricted chamber diameter; and, a second expansion chamber with a top end and a bottom end spaced apart from the top end, wherein the top end of the second expansion chamber is fluidly coupled to the lower end of the second constricted chamber of each of the at least two separate flow paths.

2. The extended reach tool of claim 1, further comprising a single port located proximate to the bottom end of the second expansion chamber.

3. The extended reach tool of claim 1, wherein the single port is one of a) a hollow-cylinder and b) a hollow-conical structure with a first width proximate the second expansion chamber and a second width spaced apart from the first width, wherein the first width is smaller than the second width.

4. The extended reach tool of claim 1, further comprising at least one of a) a top side with a threaded box configured to receive a threaded pin of the bottom hole assembly and b) a bottom end with a threaded pin wherein the threaded pin is configured to be received in a threaded box of one of the tubing and the motor.

5. The extended reach tool of claim 1, wherein each of the at least two separate flow paths are configured such that when a fluid flows through the extended reach tool the fluid flows sequentially through the first constricted chamber, the first expansion chamber, the second constricted chamber, and the second expansion chamber.

6. The extended reach tool of claim 1, wherein the first constricted chamber and the first expansion chamber are configured such that when a fluid flows through the extended reach tool the fluid flow becomes turbulent upon entering the first expansion chamber from the first constricted chamber.

7. The extended reach tool of claim 1, wherein the first expansion chamber and the second constricted chamber are configured such that when a fluid flows through the extended reach tool a portion of the fluid flow within the first expansion chamber becomes turbulent as another portion of the fluid flow exits the first expansion chamber and enters the second constricted chamber.

8. The extended reach tool of claim 1, wherein the first constricted chamber, the first expansion chamber, and the second constricted chamber are configured such that when a fluid flows through the extended reach tool a portion of the fluid within the first expansion chamber becomes turbulent and propagates through the first expansion chamber.

9. The extended reach tool of claim 1, wherein a cross-section of at least one of the first constricted chamber, the first expansion chamber, and the second constricted chamber of at least one of the at least two separate flow paths, and the second expansion chamber is one of a columnar hollow shape, a rectangular shape, a square shape, a triangular shape, a rhomboidal shape, an elliptical shape, and a circular shape.

10. The extended reach tool of claim 1, wherein a cross-sectional area of the second expansion chamber decreases from the top end to the bottom end of the second expansion chamber.

11. The extended reach tool of claim 1, wherein a longitudinal section of the second expansion chamber is a trapezoidal section.

12. The extended reach tool of claim 11, wherein the trapezoidal section includes a top base proximate the top of the second expansion chamber and a bottom base proximate the bottom of the second expansion chamber, wherein the top base is longer than the bottom base.

13. The extended reach tool of claim 1, wherein the second expansion chamber and each second constricted chamber of the at least two flow paths are configured such that when a fluid flows through the extended reach tool a portion of the fluid flow within each of second constricted chamber enters the second expansion chamber, thereby causing the flow of fluid to become turbulent within the second expansion chamber and amplify a pulsation of the fluid flowing through the second expansion chamber.

14. A method of delivering a pulsing fluid, comprising: positioning the extended reach tool of claim 1 in a well bore; providing a fluid to the extended reach tool; separating the fluid into the at least two separate flow paths in the extended reach tool.

15. A drill string comprising: at least one of a tubing and a motor; a bottom hole assembly; and, the extended reach tool of claim 1.

Description

RELATED APPLICATIONS

[0001] This application is a continuation of U.S. Non-provisional patent application Ser. No. 15/970,691 entitled Extended Reach Tool filed May 3, 2018, which claims the benefit of U. S. Provisional Patent Application No. 62/500,870 entitled Extended Reach Tool filed on May 3, 2017, each of which are specifically incorporated by reference in its entirety herein.

FIELD

[0002] The disclosure relates generally to apparatus and methods for creating a vibration within a wellbore. The disclosure relates specifically to a vibrating downhole tool configured to vibrate equipment located within a wellbore.

BACKGROUND

[0003] In the drilling of oil and gas wells as well as other downhole activities, it is common to use a downhole system which provides a percussive or hammer effect to the drill string to increase drilling rate. For example, in the process of drilling a wellbore, frictional forces acting against the drill pipe or other component running through the wellbore limit the maximum length or depth to which the wellbore may be drilled. Solutions of this problem include mechanisms for vibrating the drill pipe during drilling in order to convert static frictional forces on the drill pipe to dynamic frictional forces between the drill pipe and the wall of the wellbore.

[0004] Various types of vibrator devices have been employed with pipe strings in order to provide vibration. Some such vibrator devices typically employ reciprocating impact elements that move back and forth along the axis of the pipe string to induce vibration in the pipe string. Other such vibrator devices employ the use of eccentrically weighted rotating masses, eccentric shafts or rods, or rotatable impact elements that rotate about the longitudinal axis of the drill or pipe string to strike an impact anvil in order to apply a rotational or torsional vibration to the pipe string.

[0005] Still other types of vibrator devices utilize Moineau power sections that are generally used in downhole mud motors or pumps. Moineau power sections typically utilize rubber or rubber-like elastomers as seals which are negatively affected by elevated wellbore temperatures and pressures, certain drilling fluids and or chemicals, and contaminants or debris in the wellbore or drilling fluids.

[0006] Apparatus utilizing one or both of these principles is described in U.S. Pat. No. 5,165,438 to David M. Facteau. Two fluidic oscillators are achieved by employing wedge-shaped splitters to route the flow of a fluid down diverging diffuser legs. The oscillators connect to a source of fluid flow, provide a mechanism for oscillating the fluid flow between two different locations within the oscillator, and emit fluid pulses downstream of the source of the fluid flow. In one vibrator, a feedback passageway from each leg is routed back to the flow path upstream of the splitter to create a condition establishing oscillating flow through the legs. In a second vibrator, a passageway between the legs downstream of the upstream end of the splitter creates a condition establishing oscillating flow through the legs. A disadvantage of this kind of oscillator is that the diverging diffuser legs required to establish oscillation are expensive to fabricate and prone to clogging from debris in the fluid because of the relative incline between the leg and the axial of the pipe string.

[0007] Consequently, there is a need to provide an even more effective fluid oscillator for down hole tools which is reliable, long-lived and economical.

SUMMARY

[0008] The present invention is directed to a helix oscillating delivery system that creates an erratic helical pulsating stream within a circular cylindrical structure. The helix oscillating delivery system connects to a source of fluid flow at its upper end and has a plurality of separate flow paths that are constricted and expanded repeatedly. The erratic helical pulsating stream is caused by the flow paths and strengthened by an expansion chamber.

[0009] In one embodiment, the helix oscillating delivery system comprises two or more separate flow paths. Each of the flow paths has multiple hollow chambers connected in series. Each of the hollow chambers comprises a first constricted chamber 6 with a fluid entry, a first expansion chamber located adjacent to the lower end of the first constricted chamber, a second constricted chamber with an upper end connected to the lower end of the first expansion chamber; a separate second expansion chamber connected to the lower ends of a plurality of the second constricted chambers; and a single port located adjacent to the lower end of the second expansion chamber.

[0010] The cross-section area of the first constricted chamber is smaller than that of the first expansion chamber and the cross-section area of the first expansion chamber is larger than that of the second constricted chamber.

[0011] The cross-section area of the second expansion chamber gradually decreases from a top end to a bottom end of the second expansion chamber.

[0012] In a preferred embodiment, the shape of the cross-section of the second expansion chamber is circular, and the longitudinal section of the second expansion chamber is a trapezoidal section with a large top base and a small bottom base.

[0013] In another aspect, the invention is directed to an extended reach tool. The tool comprises two or more separate flow paths. Each of the flow paths has multiple hollow chambers connected in series. Each of the hollow chambers comprises a first constricted chamber with a fluid entry, a first expansion chamber located adjacent to the lower end of the first constricted chamber, a second constricted chamber with the upper end connected to the lower end of the first expansion chamber; a separate second expansion chamber connected to the lower ends of a plurality of the second constricted chambers; and a single port located adjacent to the lower end of the second expansion chamber.

[0014] In one embodiment, the extended reach tool can be attached to a tubing or motor on a top side of the extended reach tool and attached to a bottom hole assembly on a bottom end of the extended reach tool.

[0015] In one embodiment, the extended reach tool comprises a thread pin adapted to engage a threaded box of a tubing or motor, and a threaded box end to receive male threaded pin end of a bottom hole assembly.

[0016] In another aspect, the invention is direct to a method of delivering an erratic helical pulsating jet stream within an extended reach tool connected to a drill string pipe/coil tubing or a bottom hole assembly. The tool receives fluid from the drill string pipe or coil tubing into a hollow interior of the tool, wherein the fluid is separated into two or more separate flow paths. The fluid is repeatedly compressed and expanded, which will create a pulsating flow with erratic helical flow, and the pulsating flow passes out of the tool through ports in the tool to create pulsing and erratic helical jets of fluid. The erratic, helically pulsating jets of fluid will cause the extended reach tool to vibrate and pulsate a bottom hole assembly and coil tubing/tubing to release friction around them so as to move the bottom hole assembly freely downhole and up hole.

[0017] In one embodiment, the fluid is separated into two separate paths.

[0018] The foregoing has outlined rather broadly the features of the present disclosure in order that the detailed description that follows may be better understood. Additional features and advantages of the disclosure will be described hereinafter, which form the subject of the claims.

BRIEF DESCRIPTION OF THE DRAWINGS

[0019] In order that the manner in which the above-recited and other enhancements and objects of the disclosure are obtained, a more particular description of the disclosure briefly described above will be rendered by reference to specific embodiments thereof which are illustrated in the appended drawings. Understanding that these drawings depict only typical embodiments of the disclosure and are therefore not to be considered limiting of its scope, the disclosure will be described with additional specificity and detail through the use of the accompanying drawings in which:

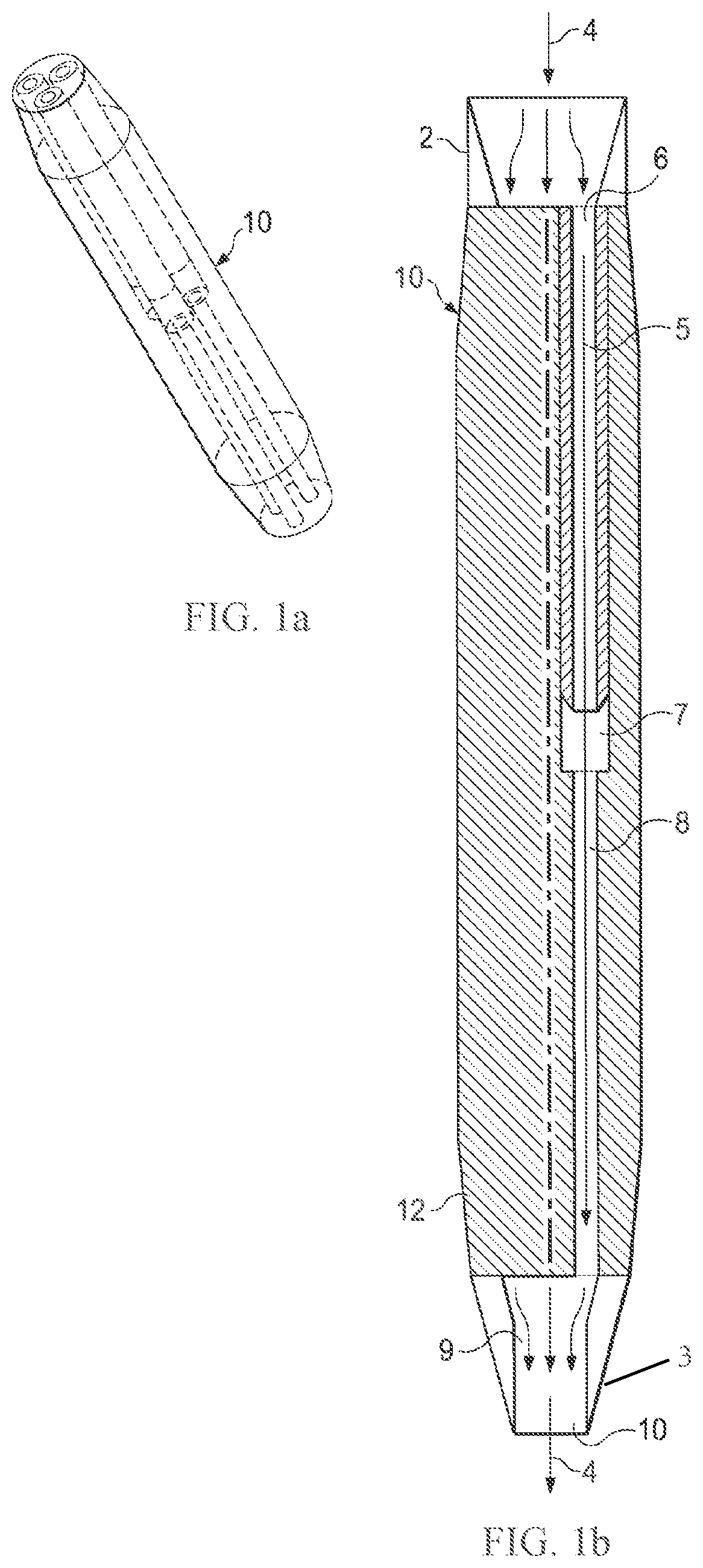

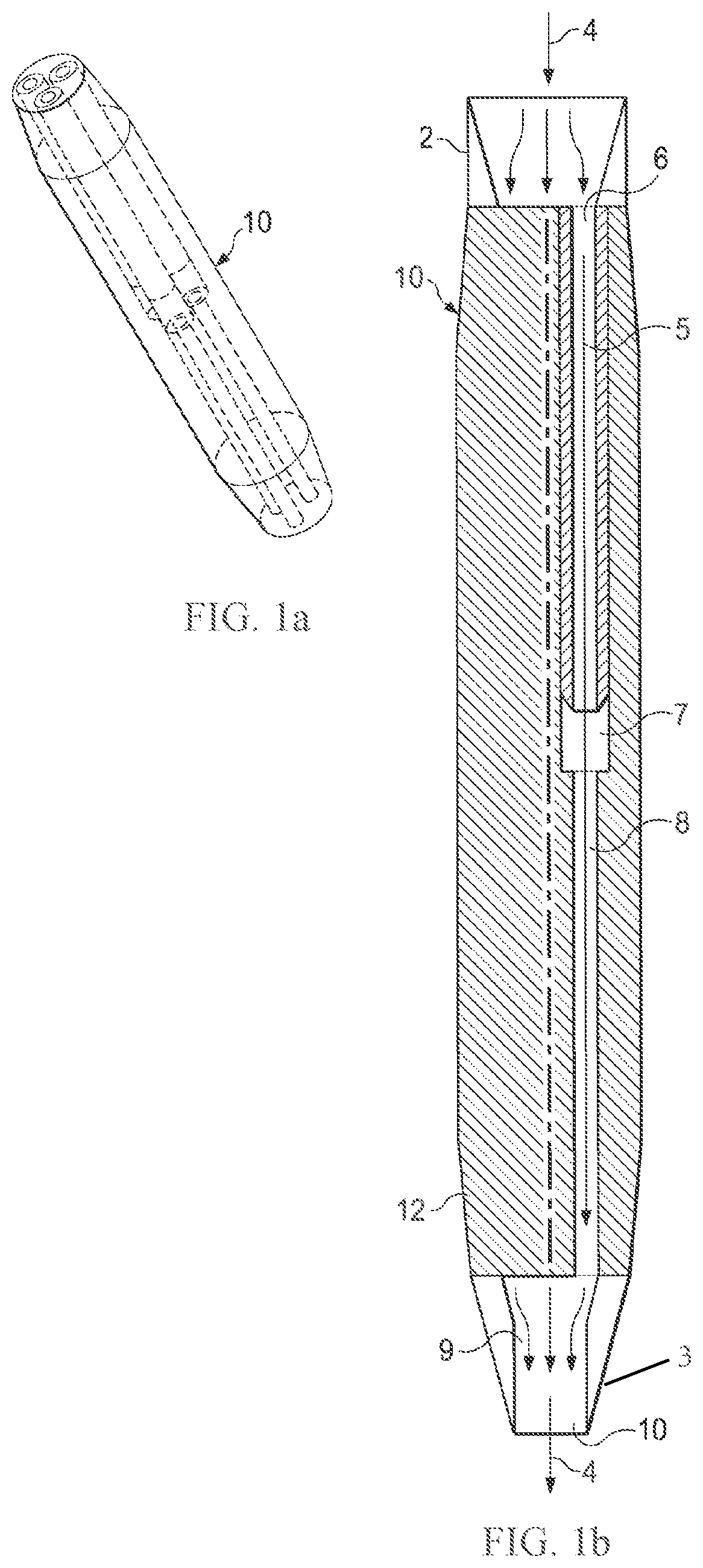

[0020] FIG. 1a is a transparent perspective view of an extended reach tool in accord with one possible embodiment of the present invention;

[0021] FIG. 1b is a cross-sectional view of the extended reach tool in FIG. 1a in accord with one possible embodiment of the present invention;

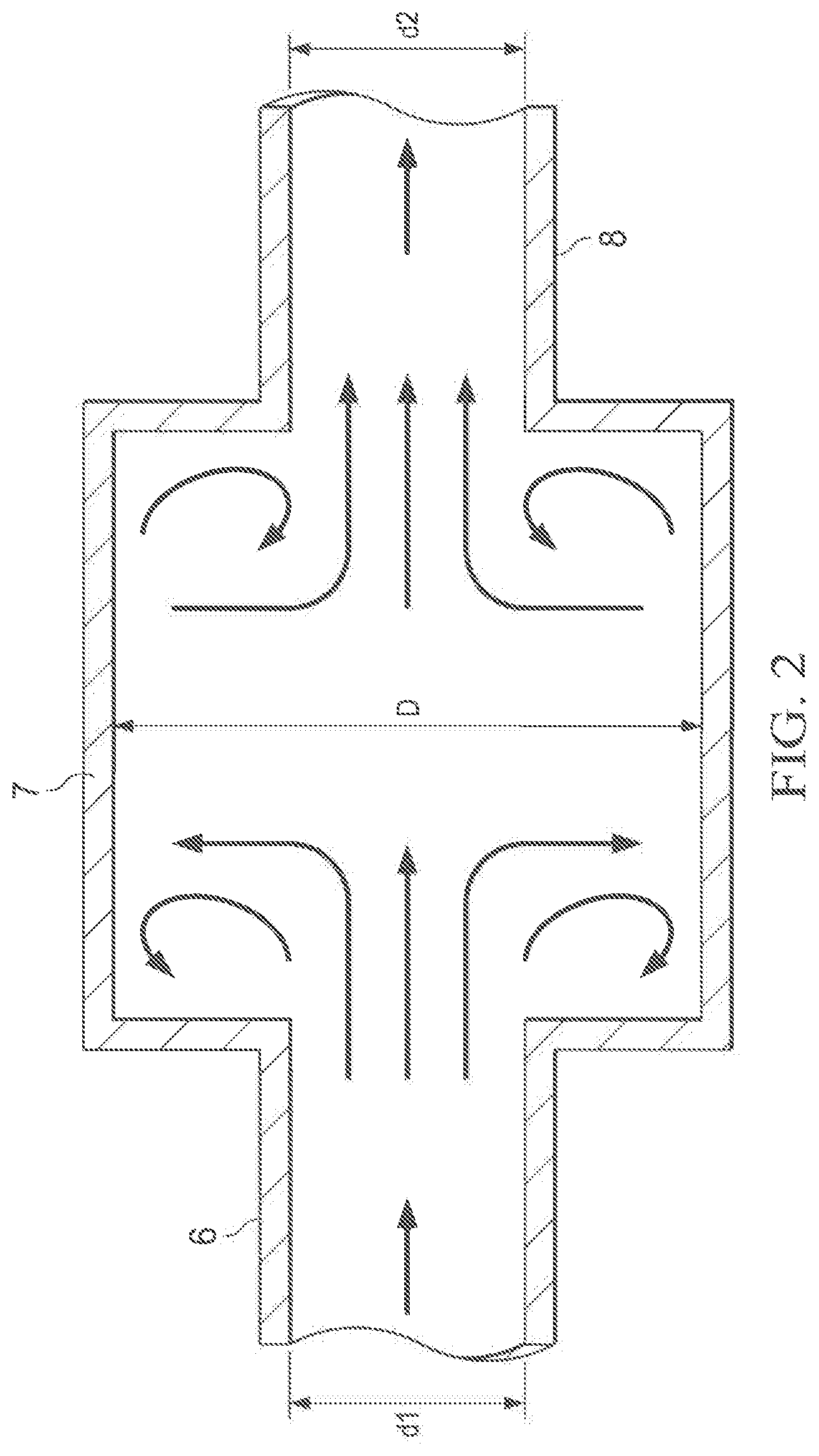

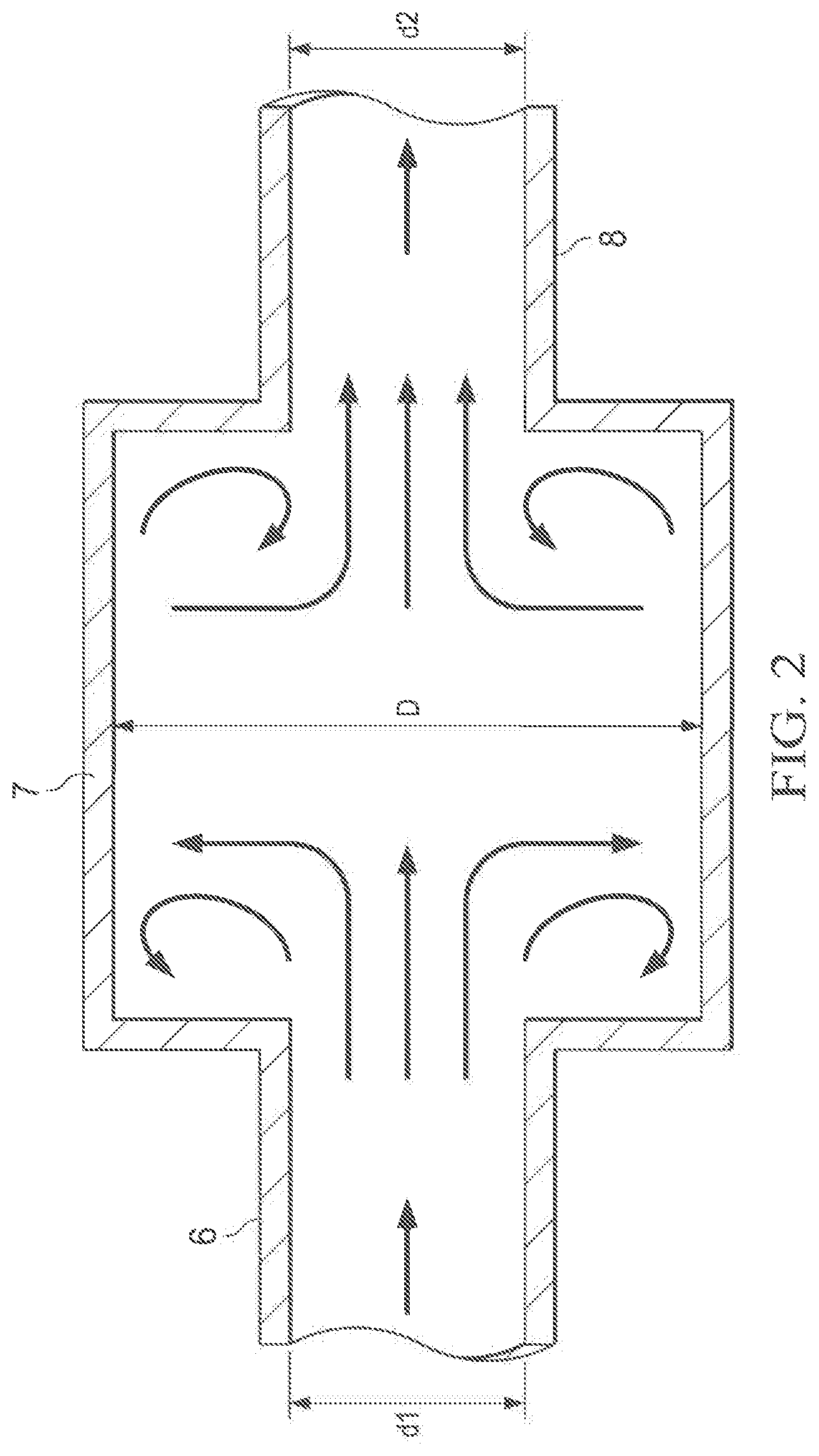

[0022] FIG. 2 is a view to show the fluid flowing in chambers of a flow path in a helix oscillating delivery system.

DETAILED DESCRIPTION

[0023] The particulars shown herein are by way of example and for purposes of illustrative discussion of the preferred embodiments of the present disclosure only and are presented in the cause of providing what is believed to be the most useful and readily understood description of the principles and conceptual aspects of various embodiments of the disclosure. In this regard, no attempt is made to show structural details of the disclosure in more detail than is necessary for the fundamental understanding of the disclosure, the description taken with the drawings making apparent to those skilled in the art how the several forms of the disclosure may be embodied in practice.

[0024] The following definitions and explanations are meant and intended to be controlling in any future construction unless clearly and unambiguously modified in the following examples or when application of the meaning renders any construction meaningless or essentially meaningless. In cases where the construction of the term would render it meaningless or essentially meaningless, the definition should be taken from Webster's Dictionary 3.sup.rd Edition.

[0025] The present invention pertains to a helix oscillating delivery system that creates a pulsating flow within a circular cylindrical structure. The helix oscillating delivery system connects to a source of fluid flow at its upper end and has a plurality of separate flow paths that are constricted and expanded repeatedly. The flow paths enter into an expanded area and the expanded area connects to a single port on its lower end. Referring to FIG. 1, the helix oscillating delivery system comprises two or more separate flow paths 5, each of the flow paths 5 has multiple hollow chambers connected in series. For example, a flow path has a first constricted chamber 6 with a fluid entry, a first expansion chamber 7 is located adjacent to a lower end of the first constricted chamber 6. An upper end of the second constricted chamber 8 is connected to a lower end of the first expansion chamber 7. There is a separate second expansion chamber 9 connected to the lower ends of a plurality of the second constricted chambers 8 of the flow paths 5. Then a single port 10 is located adjacent to a lower end of the second expansion chamber 9. The chambers 6, 7, and 8 are columnar hollow structures and the shapes of the cross-section of the chambers are arbitrary. In some embodiments, the cross-sectional shapes can be rectangular, squares, triangular, rhomboid, and ellipse. In a preferred embodiment, the shapes of the cross-section of the chambers are circular in order to reduce the effects of resistance and drag applied to the fluid flow in the chambers.

[0026] The cross-section area of the first constricted chamber 6 is smaller than that of the first expansion chamber 7 and the cross-section area of the first expansion chamber 7 is larger than that of the second constricted chamber 8. FIG. 2 illustrate fluid flowing in chambers 6, 7 and 8 which are connected in series. The arrows indicate the direction of the movement of the fluid. In FIG. 2, chamber 6, 7 and 8 are of cylinder shapes and have inner diameters d1, D and d2 respectively, where d1<D and D>d2. The fluid is compressed in chamber 6 because of the restriction in flow and decrease in diameter, and the velocity of the fluid will increase. When the fluid enters into chamber 7, it will expand and the velocity of the fluid will decrease because of the increase in diameter of the chamber 7. Then when the fluid enters into chamber 8 from chamber 7, the fluid will be compressed and the velocity of it will increase, which will create a pulsing flow. The fluid near the section between chamber 6 and chamber 7 will be subject to high shear forces because of the density and viscosity of the fluid and the sudden expansion of the fluid. The shear forces cause vortex turbulence in the chamber 7. Similarly, shear forces near the section between chamber 7 and chamber 8 cause vortex turbulence in the chamber 7 because of the sudden contraction of the fluid. The vortex turbulence is propagated in the chamber 7, which induces an erratic helical flow. The erratic helical flow amplifies the pulsation of the pulsing flow.

[0027] In some embodiments, the shape of the cross-section of the expanded chamber 9 can be rectangles, squares, triangles, rhomboid, ellipse. The cross-section area of the expanded chamber 9 gradually decreases from a top end to a bottom end of it. In a preferred embodiment the shape of the cross-section of the expanded chamber 9 is circular, the longitudinal section of the expanded chamber 9 is a trapezoidal section with a large top base and a small bottom base. With this construction, the pulsing flows from a plurality of chambers 8 will expand and generate vortex turbulence which will interfuse with each other, such that the erratic helical flows from a plurality of chambers 8 will interfere with each other to generate stronger erratic helical flow. And at the same time, the fluid will be concentrated because of the gradually decreased cross-section area of the expanded chamber 9. The erratic helical flow further amplifies the pulsation of the pulsing flow in the expanded chamber 9. Then the pulsing flow is deflected and forced into the single port 10. The single port 10 can be a hollow cylinder or a conical structure with an up-narrow and down-wide configuration to form a flow path for the erratic helical pulsating stream.

[0028] As a result, a strong pulsating stream with erratic helical flow is developed in the helix oscillating delivery system without any external excitation, and no moving parts or valve arrangements are required to bring about a pulse flow.

[0029] The helix oscillating delivery system can be used in a downhole system to provide pulsation. In one embodiment, it can be used as an extended reach tool to prevent stick-slip incidences with coil tubing or lock-up of jointed pipe between cased hole/open hole, and with tubing or coil tubing while milling, drilling or performing service work.

[0030] The extended reach tool can be used to vibrate and pulsate coil tubing/tubing and milling, drilling, or service work bottom hole assemblies to eliminate friction of the coil tubing or tubing in cased hole or open hole, so as to allow the bottom hole assembly to reach the depth in the cased hole or open hole well to complete the desired milling, drilling, or service job.

[0031] Referring back to FIG. 1, the extended reach tool 10 will be attached to a tubing or motor (not shown) on top side 2 and attached to a bottom hole assembly (not shown) on the bottom end 3. The extended reach tool 10 can be used on any size tubing. The top side 2 may have a male threaded box adapted to receive a female threaded pin of the tubing, and the bottom end 3 may comprise a female threaded pin end to engage a male threaded box end of the bottom hole assembly.

[0032] Fluid flow 4 enters from the top side 2 into the extended reach tool 10. The entry of the flow into the tool can be through an inclusive box or pin of said tool or a crossover that can be attached to the tool. The tool is provided internally with two or more separate flow paths 5, each of the flow paths 5 has multiple hollow chamber connected in series. A flow path 5 has a first constricted chamber 6 with a fluid entry, a first expansion chamber 7 is located adjacent to a lower end of the first constricted chamber 6. An upper end of the second constricted chamber 8 is connected to a lower end of the first expansion chamber 7. Fluid flow 4 is alternatingly constricted in chamber 6, then expanded in chamber 7 and then constricted in chamber 8 to cause itself to pulsate in a flow pattern with erratic helical flow. The flow paths are all arranged in a case 12. The flow 4 from the chamber 8 enters into the second expansion chamber 9 and is forced into the single port 10 which can be part of the tool or an add on, extending through the extended reach tool 10 on a lower end for delivering erratic helically pulsating jets of fluid out of the tool. The erratic helically pulsating jets of fluid will cause the extended reach tool 10 to vibrate and pulsate the bottom hole assembly and coil tubing/tubing to release friction around them to move the bottom hole assembly freely downhole and up hole.

[0033] Yet another aspect of the current invention is a method of delivering an erratic helical pulsating jet stream within an extended reach tool connected to a drill string pipe/coil tubing or a bottom hole assembly, so that the tool receives fluid from the drill string pipe or coil tubing into a hollow interior of the tool, wherein the fluid is separated into two or more separate flow paths, causing the fluid to be repeatedly compressed and expanded which in turn will create a pulsating flow with erratic helical flow, and causing the pulsating flow to pass out of the tool through ports in the tool to create pulsing and erratic helical jets of fluid. The erratic helically pulsating jets of fluid will cause the extended reach tool to vibrate and pulsate a bottom hole assembly and coil tubing/tubing to release friction around them to move the bottom hole assembly freely downhole and up hole.

[0034] Referring back to FIG. 1, the extended reach tool 10 is provided internally with two or more separate flow paths that are repeatedly compressed and expanded to cause the fluid to pulsate in an erratic helical flow pattern, and a single port extending through the extended reach tool 10 that is deflected back to one flow path on a lower end of the tool for delivering erratic helical pulsating jets of fluid out of the tool. The erratic helically pulsating jets of fluid will cause the tool to vibrate and pulsate the bottom hole assembly and coil tubing/tubing.

[0035] All of the compositions and methods disclosed and claimed herein can be made and executed without undue experimentation in light of the present disclosure. While the compositions and methods of this disclosure have been described in terms of preferred embodiments, it will be apparent to those of skill in the art that variations may be applied to the compositions and methods and in the steps or in the sequence of steps of the methods described herein without departing from the concept, spirit and scope of the disclosure. More specifically, it will be apparent that certain agents which are both chemically related may be substituted for the agents described herein while the same or similar results would be achieved. All such similar substitutes and modifications apparent to those skilled in the art are deemed to be within the spirit, scope and concept of the disclosure as defined by the appended claims.

* * * * *

D00000

D00001

D00002

XML

uspto.report is an independent third-party trademark research tool that is not affiliated, endorsed, or sponsored by the United States Patent and Trademark Office (USPTO) or any other governmental organization. The information provided by uspto.report is based on publicly available data at the time of writing and is intended for informational purposes only.

While we strive to provide accurate and up-to-date information, we do not guarantee the accuracy, completeness, reliability, or suitability of the information displayed on this site. The use of this site is at your own risk. Any reliance you place on such information is therefore strictly at your own risk.

All official trademark data, including owner information, should be verified by visiting the official USPTO website at www.uspto.gov. This site is not intended to replace professional legal advice and should not be used as a substitute for consulting with a legal professional who is knowledgeable about trademark law.