Extraction Method

Auerbach; Michael I. ; et al.

U.S. patent application number 15/919040 was filed with the patent office on 2019-06-13 for extraction method. This patent application is currently assigned to Entheo Gardens Inc. The applicant listed for this patent is Entheo Gardens Inc. Invention is credited to Michael I. Auerbach, William L. Reilly.

| Application Number | 20190176052 15/919040 |

| Document ID | / |

| Family ID | 61600182 |

| Filed Date | 2019-06-13 |

| United States Patent Application | 20190176052 |

| Kind Code | A1 |

| Auerbach; Michael I. ; et al. | June 13, 2019 |

EXTRACTION METHOD

Abstract

A method for extraction of desirable comounds from cannabis provides for high-cannabinoid full spectrum (HCFSE) extractions, using CO.sub.2 at low temperature to extract the compounds in an extraction vessel. The CO.sub.2 with extracted compounds is transferred to a heated vessel which converts the CO.sub.2 to a gas, allowing the desired compounds to drop out and be removed.

| Inventors: | Auerbach; Michael I.; (Oak Grove, OR) ; Reilly; William L.; (Portland, OR) | ||||||||||

| Applicant: |

|

||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Assignee: | Entheo Gardens Inc Portland OR |

||||||||||

| Family ID: | 61600182 | ||||||||||

| Appl. No.: | 15/919040 | ||||||||||

| Filed: | March 12, 2018 |

Related U.S. Patent Documents

| Application Number | Filing Date | Patent Number | ||

|---|---|---|---|---|

| 15634933 | Jun 27, 2017 | 9919241 | ||

| 15919040 | ||||

| Current U.S. Class: | 1/1 |

| Current CPC Class: | C07D 311/80 20130101; C07C 2602/42 20170501; C07C 7/005 20130101; B01D 11/0284 20130101; C07C 17/08 20130101; C07C 7/10 20130101; B01D 11/0215 20130101; B01D 11/0203 20130101; C07C 17/08 20130101; C07C 13/39 20130101; C07C 17/08 20130101; C07C 11/21 20130101 |

| International Class: | B01D 11/02 20060101 B01D011/02; C07D 311/80 20060101 C07D311/80; C07C 7/00 20060101 C07C007/00; C07C 7/10 20060101 C07C007/10 |

Claims

1. A method of extracting from cannabis, comprising the steps of: a) placing cannabis in an extraction vessel; b) introducing CO.sub.2 into the extraction vessel at an extraction pressure and at an extraction temperature, c) thereby extracting components from the cannabis; d) moving the CO.sub.2 with extracted components from the extraction vessel to a first separator held at a first separator pressure of between 500 and 900 psi and a separation temperature thereby dropping out extracted terpenes, cannabinoids or THC; and e) removing the extracted terpenes, cannabinoids or THC from the first separator.

2. The method according to claim 1, wherein the separation temperature is between 60 to 600 degrees F.

3. The method according to claim 1, wherein the extraction pressure is between 500 to 2000 psi

4. The method according to claim 1, wherein the extraction temperature is between -50 to 80 F.

5. The method according to claim 1, wherein the cannabis is dried cannabis.

6. The method according to claim 1, wherein the cannabis is not-dried cannabis.

7. The method according to claim 1, further comprises the steps of moving the CO.sub.2 with any remaining extracted components from the first separator to a second separator; and removing any additional extracted terpenes, cannabinoids or THC from the second separator.

8. The method according to claim 1, wherein the extraction pressure is between 500 to 700 psi to extract high terpene low cannabinoid components.

9. The method according to claim 1, wherein the first separator pressure is between 500 to 600 psi to extract high terpene low cannabinoid components.

10. The method according to claim 1, wherein the extraction pressure is between 500 to 700 psi and the first separator pressure is between 500 to 600 psi to extract high terpene low cannabinoid components

11. The method according to claim 1, wherein the extraction pressure is between 900 to 2000 psi to extract high terpene high cannabinoid components.

12. The method according to claim 1, wherein the first separator pressure is between 600 to 900 psi to extract high terpene high cannabinoid components.

13. The method according to claim 1, wherein the extraction pressure is between 900 to 2000 psi and the first separator pressure is between 600 to 900 psi to extract high terpene high cannabinoid components

14. The method according to claim 1, further comprising f) cooling the CO.sub.2 after the second separator to return it to a liquid state.

15. The method according to claim 14, comprising g) reintroducing the cooled CO.sub.2 to the extraction vessel at an extraction pressure of between 500 to 2000 psi and at temperatures between -50 to 80 F, and cycling through the steps c through g for a period of 1 to 24 hours.

16. The method according to claim 1, wherein the first separator is held at a temperature of 120 to 130 degrees F.

17. A method of extracting from cannabis, comprising the steps of: a) placing cannabis in an extraction vessel; b) introducing CO.sub.2 into the extraction vessel at an extraction pressure and at an extraction temperature, c) thereby extracting components from the cannabis; d) moving the CO.sub.2 with extracted components from the extraction vessel to a first separator held at a first separator pressure and a separation temperature of 100 to 600 degrees F. thereby dropping out extracted terpenes, cannabinoids or THC; and e) removing the extracted terpenes, cannabinoids or THC from the first separator.

18. The method according to claim 17, wherein the first separator pressure is between 500 and 900 psi.

19. The method according to claim 17, wherein the cannabis is dried cannabis.

20. The method according to claim 17, wherein the cannabis is not-dried cannabis.

Description

CROSS-REFERENCE TO RELATED APPLICATIONS

[0001] This application is a continuation of U.S. patent application Ser. No. 15/634,933 filed Jun. 27, 2017, entitled EXTRACTION METHOD.

BACKGROUND

[0002] This disclosure relates to extraction of substances from botanical specimens, and more particularly to high-cannabinoid full spectrum (HCFSE) extractions from cannabis.

[0003] In the cannabis industry, extracts of cannabis plants are desirable to allow uses other than direct use of the plant material. A commonly used method of extraction is hydrocarbon extraction, using propane or butane (or possibly pentane or hexane) to remove cannabinoids and terpenes from the plant material. This method of extraction can be cheaper to operate than other methods, but the process must be done in a carefully prepared environment to avoid explosion and injury.

[0004] Other extractors use supercritical CO.sub.2 methods, which avoid the danger of explosion, but have much higher equipment costs.

[0005] Both hydrocarbon and supercritical and subcritical CO.sub.2 extraction result in an output material that can include both desired and undesired compounds from the cannabis (such as residual hydrocarbon, wax, etc.), requiring post processing, to remove the hydrocarbons or to remove wax and other components that remain.

SUMMARY

[0006] In accordance with the disclosure, a subcritical CO.sub.2 process is employed to obtain high-cannabinoid full spectrum (HCFSE) extractions from cannabis.

[0007] The subject matter of the present technology is particularly pointed out and distinctly claimed in the concluding portion of this specification. However, both the organization and method of operation, together with further advantages and embodiments thereof, may best be understood by reference to the following description taken in connection with accompanying drawings wherein like reference characters refer to like elements.

BRIEF DESCRIPTION OF THE DRAWING

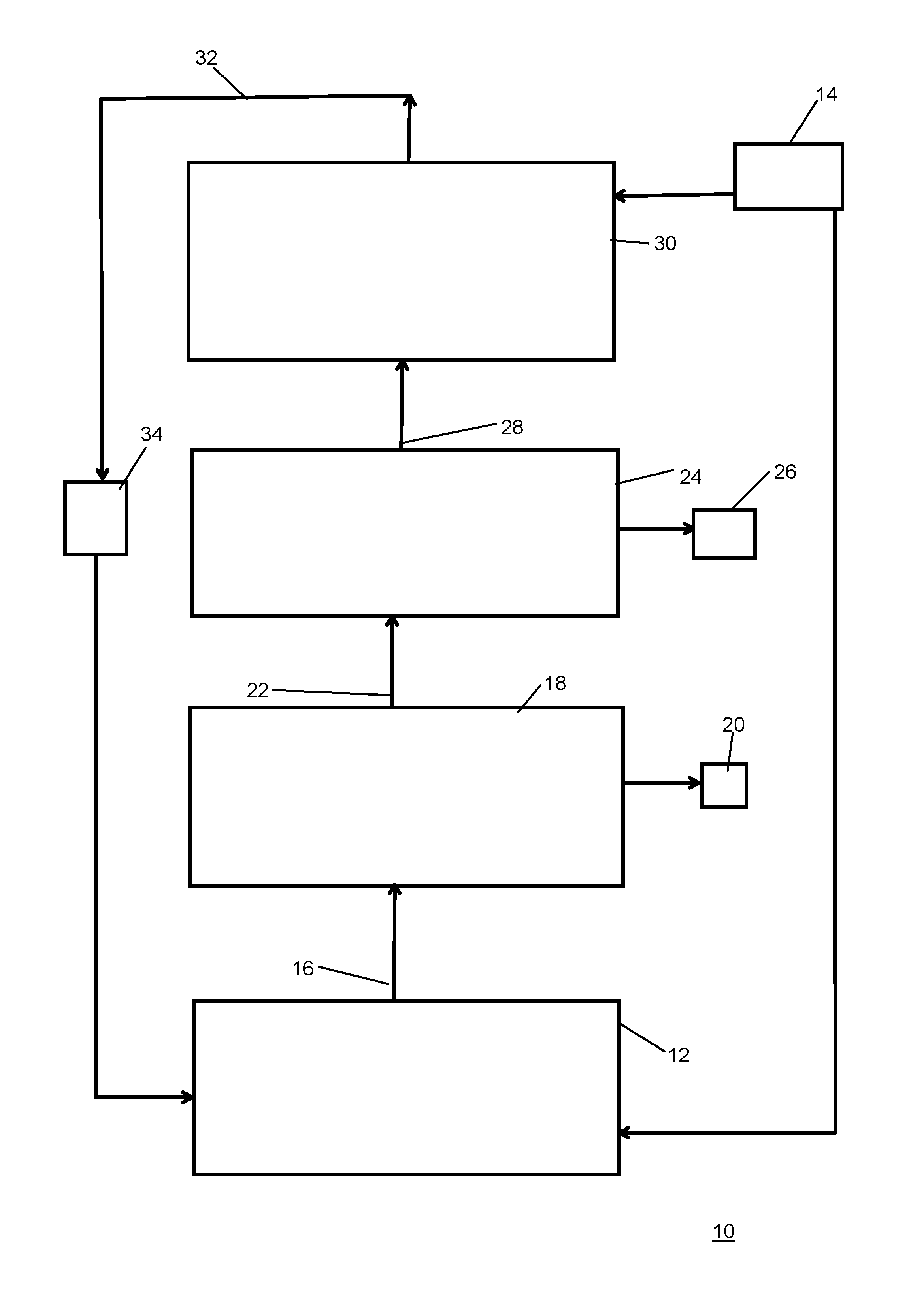

[0008] The FIGURE is a block diagram of the extraction system in accordance with the disclosure.

DETAILED DESCRIPTION

[0009] The method according to a preferred embodiment of the present disclosure comprises processing an amount of dried cannabis in an extraction device using a subcritical CO.sub.2 process at pressure and temperature values to extract high-cannabinoid full spectrum (HCFSE) components.

[0010] The preferred manner of performing the process, involves, with reference to FIG. 1, a block diagram of the extraction device employed, using an extraction device 10 that comprises an extraction vessel 12. The extraction vessel is jacketed so that the temperature thereof can be controlled and maintained at a desired level. The extraction vessel is connected by pipe 16 to a collection vessel 18. The collection vessel may have a collection valve 20. Vessel 18 is connected by pipe 22 to an optional overflow vessel 24, which may have a collection valve 26. Vessel 24 connects via pipe 28 to gas/liquid phase change jacketed vessel 30, which is connected to extraction vessel 12 via pipe 32, through pump 34. Vessel 30 can receive CO.sub.2 from a CO.sub.2 supply 14 as desired, which can also supply vessel 12 with CO.sub.2. The device thereby provides a looped extraction system.

[0011] In use, the specimen which is to have high-cannabinoid full spectrum material extracted therefrom is loaded into extraction vessel 12, the vessel is sealed and the pressure in the vessel is raised to between 500 to 5000 psi by the introduction of fresh CO.sub.2 at a temperature of between -60 to +80 degrees F. In a particular example, the specimen will be a quantity of dried or wet (not dried) cannabis such that desirable high-cannabinoid full spectrum (HCFSE) components can be extracted therefrom.

[0012] The CO.sub.2, which will suitably be in a liquid state in vessel 12 will cause the high-cannabinoid full spectrum (HCFSE) components and other compounds to be extracted from the cannabis, and operation of pump 34 will move the HCFSE containing CO.sub.2 from vessel 12 into vessel 18. Vessel 18 is suitably maintained at 500 psi at a temperature of 130 degrees F. in a particular embodiment. Other embodiments can vary the temperature between 60 to 600 degrees F. Vessel 24 is maintained at 120 to 130 degrees F. and 500 psi, and the high temperature of vessel 18 (and vessel 24) relative to the extraction vessel will cause the CO.sub.2 to become a gas, allowing the extracted high-cannabinoid full spectrum components to drop out of the CO.sub.2, this dropping out occurring mainly in the extraction vessel 18. The gaseous CO.sub.2 with most of the high-cannabinoid full spectrum components removed is then pumped from vessel 18 to vessel 24, vessel 24 operating as an overflow to allow removal of any residual high-cannabinoid full spectrum components remaining with the CO.sub.2 gas, to minimize gumming up the rest of the device. Operation of pump 34 then moves the gaseous CO.sub.2 from vessel 24 into phase change jacketed vessel 30, which is suitably maintained to 1000 psi (although the pressure can be fluctuated between 300 to 5000 psi) at 40 degrees F. This temperature and pressure returns the CO.sub.2 to a liquid state, and the now liquid CO.sub.2 is pumped (via operation of pump 34) back into the extraction vessel 12, completing the extraction loop. Each cycle during of operation of the pump moves the CO.sub.2 and extracts through the system.

[0013] The device is operated for a period of time, such as 2 to 3 hours or as much as 24 hours or more, to allow extraction of a sufficient amount of the desired high-cannabinoid full spectrum (HCFSE) components.

[0014] Valve 20 may be opened a slight amount during operation of the device so that the extracted high-cannabinoid full spectrum (HCFSE) components may be continuously collected outside of the device, or may be occasionally opened to allow a quantity of extracted high-cannabinoid full spectrum (HCFSE) components built up in vessel 18 to be removed. Any overflow collected in vessel 24 may be removed via valve 26.

[0015] Operation of the device for 2 to 3 hours results in output that is substantially higher in terpenes. Operation for 24 hours results in higher cannabinoid content in the output.

[0016] The operational parameters of the device (temperatures and pressures of the various vessels) can be adjusted such that the viscosity of the extracted high-cannabinoid full spectrum (HCFSE) components is at a desired level. For example, if the high-cannabinoid full spectrum (HCFSE) components are to be used as liquid for filling e-cigarette cartridges, a certain consistency range may be desirable. Setting operation of the device to produce the desired consistency can thereby remove the need for post processing to dilute or thicken so that the end product flows as desired.

[0017] Use of the system and process, thus provides a high-cannabinoid full spectrum (HCFSE) extraction that is ready to use and that does not require post processing. It is noted that lower pressure and colder temperatures results in higher terpene values in the output.

EXAMPLES

[0018] Table 1 provides examples of results from various pressure levels in the different vessels of the device, illustrating variation of the resulting extractions.

TABLE-US-00001 Consistency Extraction Separator Separator Vessel of output Vessel 12 18 24 30 from vessels (psi) (psi) (psi) (psi) 18 or 24 500 500 500 400 Thin oil No wax HTLC 700 500 500 600 Thin oil No wax HTLC 900 600 600 700 Thin oil No wax HTHC 1050 600 600 800 Thin oil No wax HTHC 1400 650 650 900 Little thicker No wax HTHC 1700 700 700 1000 Little thicker Little wax HTHC 2000 900 900 1200 Little thicker Little wax HTHC What if scenario continue pattern ##STR00001## 2500 1200 1200 1400 Thicker More wax HTHC 3000 1500 1500 2000 Thicker More wax HTHC 4000 2000 2000 3000 Very thick Heavy wax HTHC 5000 2000 2000 4000 Very thick Heavy wax HTHC HTLC = High Terpene Low Cannabinoid HTHC = High Terpene High Cannabinoid

[0019] From the table it can be seen that operation in the lower ranges of pressures results in an output oil that is thinner, with high terpene content and low cannabinoid content with no wax present. Somewhat higher pressures increase the cannabinoid extraction so that both high terpene and cannabinoid levels are present. As the pressures increase, the resulting output is somewhat thicker, but still without wax. Further pressure increases start to increase the amount of wax present, and still higher pressures result in a thicker output. Extractions have been run with extraction vessel 12 up to 2000 psi, but the results can be predicted that as the pressures are increased, as illustrated in the lower portions of the table, the thickness of the output will increase and the amount of wax extracted will increase.

[0020] Variations on the temperatures and pressures (as noted above in table 1) can be made. For example, vessel 12 is typically held to between -60 to +80 degrees F. Vessels 18 and 24 can be operated at between 84 to 200 degrees F.

[0021] Typical operational ranges that have been employed are:

[0022] Vessel 12: -60 to 80 degrees F., 500 to 2000 psi. Keeping this vessel cold allows extraction to occur without requiring the post processing of the prior art. -10 to -60 is the range most often used.

[0023] Vessel 18--130 degrees F., 500 psi. The warmer temperature of this vessel causes the CO.sub.2 to return to a gas state, dropping out the extracted terpenes, cannabinoids and THC

[0024] Vessel 24--120-130 degrees F., 500 psi. The bulk of the extraction takes place in vessel 18, this vessel acts as `overflow` to extract most of the remaining elements not gathered in vessel 18

[0025] Vessel 30--40 degrees F., .about.1000 psi

[0026] Vessels 18 and 24 will typically have the same parameters.

[0027] Thus the device can be operated to provide a high terpene output with low cannabinoid, or a high terpene high cannabinoid output, as desired, with no or little wax content. High terpene can mean between 5 to 100% terpene content in the output, with the terpene content varying on a single extraction run depending on the time, temperature and pressure values employed.

[0028] While a preferred embodiment of the technology has been shown and described, it will be apparent to those skilled in the art that many changes and modifications may be made without departing from the broader aspects. The appended claims are therefore intended to cover all such changes and modifications as fall within the true spirit and scope of the technology.

* * * * *

uspto.report is an independent third-party trademark research tool that is not affiliated, endorsed, or sponsored by the United States Patent and Trademark Office (USPTO) or any other governmental organization. The information provided by uspto.report is based on publicly available data at the time of writing and is intended for informational purposes only.

While we strive to provide accurate and up-to-date information, we do not guarantee the accuracy, completeness, reliability, or suitability of the information displayed on this site. The use of this site is at your own risk. Any reliance you place on such information is therefore strictly at your own risk.

All official trademark data, including owner information, should be verified by visiting the official USPTO website at www.uspto.gov. This site is not intended to replace professional legal advice and should not be used as a substitute for consulting with a legal professional who is knowledgeable about trademark law.