Water-cooled Mold For Casting Aluminum Alloy Wheel

ZHOU; Yule ; et al.

U.S. patent application number 16/188723 was filed with the patent office on 2019-05-30 for water-cooled mold for casting aluminum alloy wheel. This patent application is currently assigned to CITIC Dicastal CO., LTD. The applicant listed for this patent is CITIC Dicastal CO., LTD. Invention is credited to Changhai LI, Zhen LI, Shan MA, Peng ZHOU, Yule ZHOU, Lin ZHU.

| Application Number | 20190160523 16/188723 |

| Document ID | / |

| Family ID | 61776011 |

| Filed Date | 2019-05-30 |

| United States Patent Application | 20190160523 |

| Kind Code | A1 |

| ZHOU; Yule ; et al. | May 30, 2019 |

WATER-COOLED MOLD FOR CASTING ALUMINUM ALLOY WHEEL

Abstract

The present application provides a water-cooled mold for casting an aluminum alloy wheel, which is composed of a top mold, a side mold and a bottom mold, wherein a side mold insert is included between the side mold and the bottom mold, the inner surface of the side mold insert faces a cavity, and the upper surface and the lower surface are matched with the side mold frame respectively; the side mold insert is made of copper; the matching surface between the side mold insert and the side mold has a contact matching surface having a length of 10-15 mm at the edges of the inner ring and the outer ring respectively. And the side mold insert and the side mold form a gap which is 0.05-0.20 mm between the contact matching surfaces.

| Inventors: | ZHOU; Yule; (Qinhuangdao, CN) ; LI; Zhen; (Qinhuangdao, CN) ; ZHU; Lin; (Qinhuangdao, CN) ; ZHOU; Peng; (Qinhuangdao, CN) ; MA; Shan; (Qinhuangdao, CN) ; LI; Changhai; (Qinhuangdao, CN) | ||||||||||

| Applicant: |

|

||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Assignee: | CITIC Dicastal CO., LTD Qinhuangdao CN |

||||||||||

| Family ID: | 61776011 | ||||||||||

| Appl. No.: | 16/188723 | ||||||||||

| Filed: | November 13, 2018 |

| Current U.S. Class: | 1/1 |

| Current CPC Class: | B22D 18/04 20130101; B22D 11/055 20130101; B22C 9/28 20130101; B22C 9/065 20130101 |

| International Class: | B22C 9/06 20060101 B22C009/06; B22C 9/28 20060101 B22C009/28; B22D 18/04 20060101 B22D018/04 |

Foreign Application Data

| Date | Code | Application Number |

|---|---|---|

| Nov 30, 2017 | CN | 2017112356576 |

Claims

1. A water-cooled mold for casting an aluminum alloy wheel, comprising a top mold, a side mold and a bottom mold, wherein a side mold insert is arranged between the side mold and the bottom mold, the inner surface of the side mold insert faces a cavity, and the upper surface and the lower surface are matched with the side mold frame respectively; the side mold insert is made of copper; the matching surface between the side mold insert and the side mold has a contact matching surface having a length of 10-15 mm at the edges of the inner ring and the outer ring respectively, and a gap of 0.05-0.20 mm is formed between the side mold insert and the side mold.

2. The water-cooled mold according to claim 1, wherein the matching surface between the side mold insert and the side mold has a contact matching surface having a length of 12 mm at the edges of the inner ring and the outer ring of the matching surface respectively, and a gap of 0.10 mm is formed between the side mold insert and the side mold, and the gap is formed also between the contact matching surfaces.

3. The water-cooled mold according to claim 1, wherein in the water-cooled mold, a cooling water channel of the bottom mold is located on the outer side of the bottom mold.

Description

CROSS-REFERENCE TO RELATED APPLICATIONS

[0001] This application claims priority to Chinese Patent Application No. 201711235657.6, filed on Nov. 30, 2017, which is hereby incorporated by reference in its entirety.

TECHNICAL FIELD

[0002] The present application relates to a low-pressure casting mold for an aluminum wheel, specifically to a water-cooled side mold and a water-cooled bottom mold for improving the shrinkage porosity at spoke roots.

BACKGROUND ART

[0003] In the production process of low-pressure casting of aluminum wheels, spoke roots are very obvious hot spots where the shrinkage porosity and shrinkage cavity defect easily occurs. Therefore, whether the mold design and the artificially added cooling are reasonable will greatly affect the shrinkage porosity at the spoke roots, especially the shrinkage porosity of the spoke roots produced fast is a non-negligible defect. However, the present common design cannot thoroughly and effectively solve the shrinkage porosity at the spoke roots, which brings great difficulty to speeding up the production.

[0004] FIG. 1 shows the present common cooling design of spoke roots, the side mold insert 1 provided with a water channel is made of ordinary mold steel, which causes low thermal conductivity and slow cooling of the spoke roots. Although a cooling water channel 2 is arranged in the bottom mold to assist in cooling the spoke roots, the cooling water channel 2 often affects the feeding of spokes to the spoke roots; thus arranging cooling water channel in the bottom mold brings more adverse effects. Of course, the shrinkage porosity at the spoke roots can be fed by prolonging the production cycle, adding insulation to the spokes and other measures at the expense of production efficiency.

SUMMARY OF THE INVENTION

[0005] Accordingly, the purpose of the present application is to provide a water-cooled mold for casting an aluminum alloy wheel, thereby overcoming the above problems.

[0006] In one aspect, the present application provides a water-cooled mold for casting an aluminum alloy wheel. The water-cooled mold assembly is composed of a top mold, a side mold and a bottom mold, and wherein a side mold insert is arranged between the side mold and the bottom mold, the inner surface of the side mold insert faces a cavity, and the upper surface and the lower surface of the side mold insert are matched with the side mold and the bottom mold respectively; the side mold insert is made of copper; the matching surface between the side mold insert and the side mold has a contact matching surface having a length of 10-15 mm at the edges of the inner ring and the outer ring of the matching surface respectively. And the side mold insert and the side mold form a gap which is 0.05-0.20 mm, and it is formed also between the contact matching surfaces.

[0007] In a preferred aspect of the present application, the matching surface between the side mold insert and the side mold is a contact matching surface having a length of 12 mm at the edges of the inner ring and the outer ring of wheel respectively, and a gap of 0.10 mm is formed between the side mold insert and the side mold.

[0008] In a preferred aspect of the present application, in the water-cooled mold, a cooling water channel of the bottom mold is located on the outer side of the bottom mold.

[0009] The advantage of the technical solution in the present application is that by the above measures, the cooling on spoke roots is effectively improved and the influence of the cooling water channel on spokes is limited.

BRIEF DESCRIPTION OF DRAWINGS

[0010] The embodiments of the present invention will be described in detail below in combination with the accompanying drawings, in which:

[0011] FIG. 1 is a schematic diagram of a side mold insert for spoke roots in the prior art;

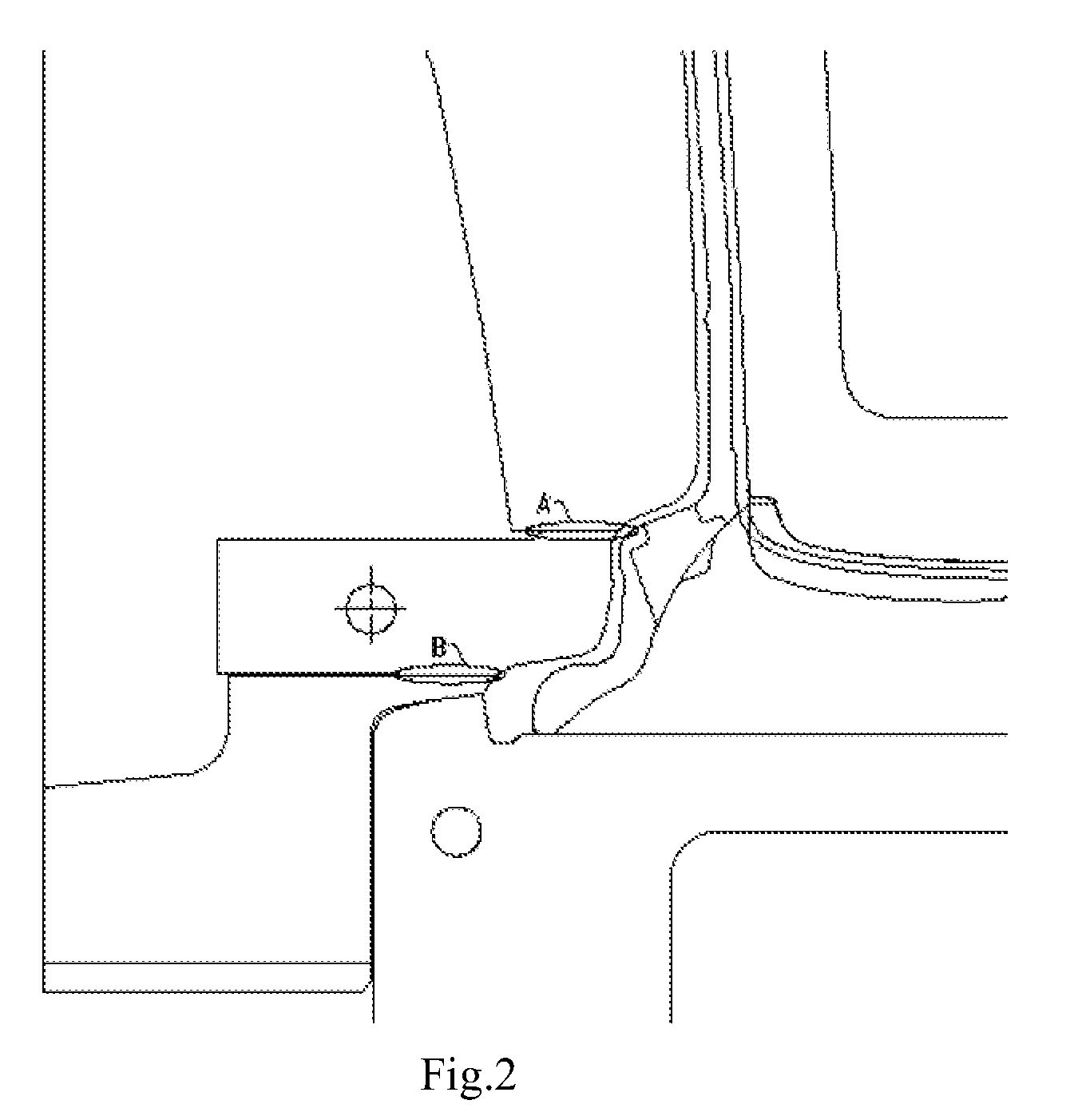

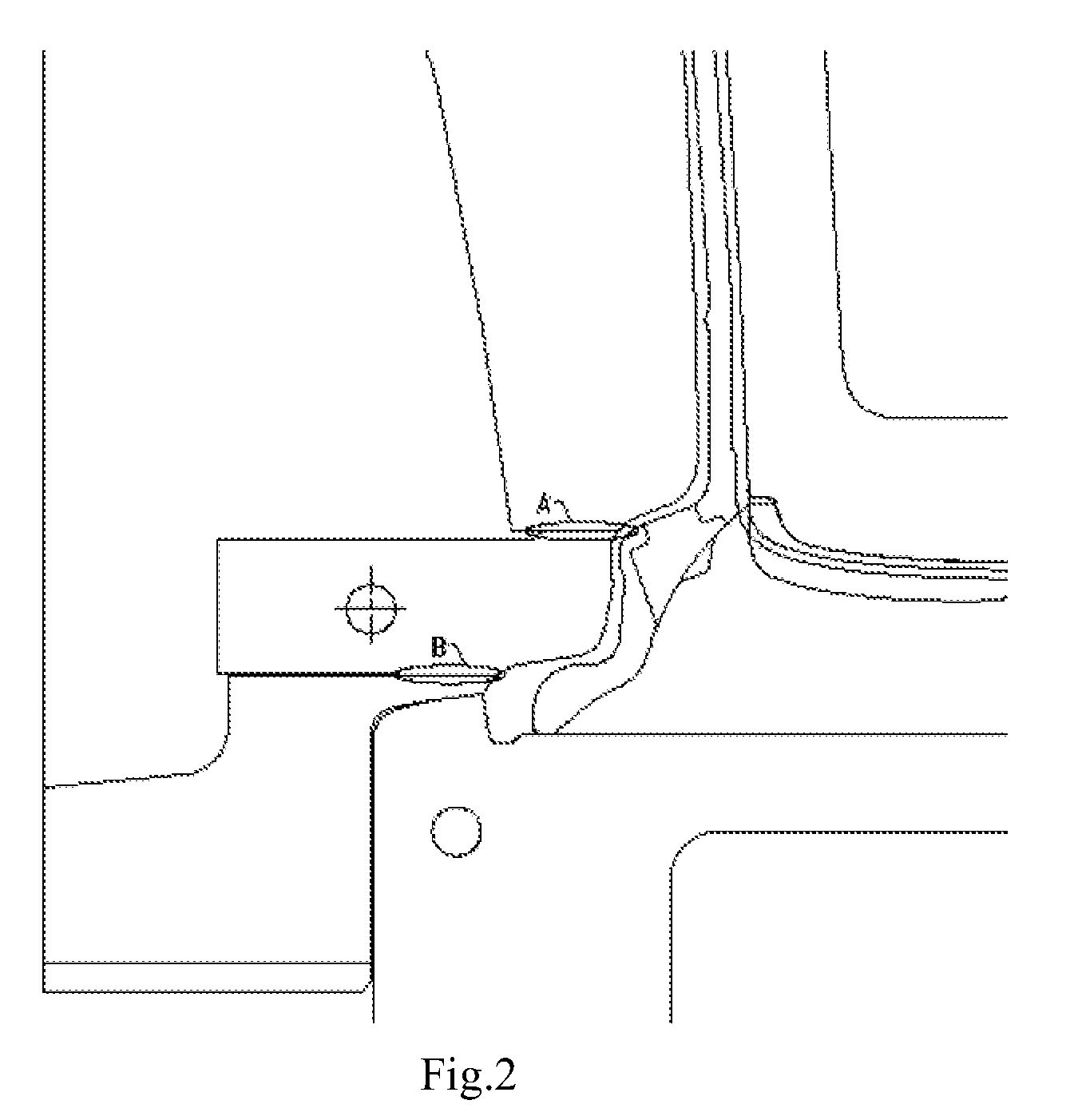

[0012] FIG. 2 is a schematic diagram of a side mold insert for spoke roots according to the present application;

[0013] FIG. 3 is a schematic diagram of a matching surface of the side mold insert and a side mold according to the present application.

[0014] In figures: 1--side mold insert, 2--bottom mold cooling water channel, A--upper surface of the side mold insert, B--lower surface of the side mold insert.

DETAILED DESCRIPTION OF THE INVENTION

Embodiment 1

[0015] A water-cooled mold for casting an aluminum alloy wheel is composed of a top mold, a side mold and a bottom mold, and a side mold insert is arranged between the side mold and the bottom mold, the inner surface of the side mold insert faces a cavity, the side mold insert upper surface A is matched with the lower surface of the side mold, and the side mold insert lower surface B is matched with the upper surface of the bottom mold; the side mold insert is made of copper; the matching surface between the side mold insert and the side mold has a contact matching surface having a length L.sub.1 at the edges of the inner ring and the outer ring of the matching surface respectively. And a gap L.sub.2 is formed between the side mold insert and the side mold. The gap is formed also between the contact matching surfaces.

[0016] In this embodiment, the following implementation scheme is adopted for test, and the test settings are recorded in Table 1:

TABLE-US-00001 TABLE 1 Parameters of each group of test device in this embodiment Group No. L.sub.1/mm L.sub.2/mm Test group 1 10 0.05 Test group 2 12 0.10 Test group 3 15 0.20 Control The side mold insert is made of mold steel and the entire group 1 matching surface is fully fitted Control The side mold insert is made of red copper and the entire group 2 matching surface is fully fitted.

[0017] The above five groups of water-cooled molds are used to produce five groups of hubs in the internal research and development workshop of CITIC Dicastal Co., Ltd., 1200 hubs constituting each group. In addition, the test results of the five test groups are measured by hub disqualification caused by the shrinkage porosity defect at spoke roots. The results show that the test group 2 has the best hub production quality, and the unqualified hubs caused by the shrinkage porosity defect at the spoke roots include 12 cases in test group 2, 37 cases in test group 1, 42 cases in test group 3, 81 cases in control group 1 and 54 cases in control group 2.

[0018] Hence, the mold of test group 2 reduces the ratio of the unqualified hubs caused by the shrinkage porosity defect at the spoke roots.

[0019] The foregoing descriptions of specific exemplary embodiments of the present application have been presented for purposes of illustration and description. They are not intended to be exhaustive or to limit the invention to the precise forms disclosed, and obviously many modifications and variations are possible in light of the above teachings. The exemplary embodiments were chosen and described in order to explain certain principles of the invention and their practical application, to thereby enable others skilled in the art to make and utilize various exemplary embodiments of the present invention, as well as various alternatives and modifications thereof. It is intended that the scope of the invention be defined by the Claims appended hereto and their equivalents.

* * * * *

D00000

D00001

D00002

D00003

XML

uspto.report is an independent third-party trademark research tool that is not affiliated, endorsed, or sponsored by the United States Patent and Trademark Office (USPTO) or any other governmental organization. The information provided by uspto.report is based on publicly available data at the time of writing and is intended for informational purposes only.

While we strive to provide accurate and up-to-date information, we do not guarantee the accuracy, completeness, reliability, or suitability of the information displayed on this site. The use of this site is at your own risk. Any reliance you place on such information is therefore strictly at your own risk.

All official trademark data, including owner information, should be verified by visiting the official USPTO website at www.uspto.gov. This site is not intended to replace professional legal advice and should not be used as a substitute for consulting with a legal professional who is knowledgeable about trademark law.