Extraction Device For Extracting A Detergent From A Dispensing Compartment Of A Washing Machine

Sudkemper; Andrea ; et al.

U.S. patent application number 16/134991 was filed with the patent office on 2019-03-21 for extraction device for extracting a detergent from a dispensing compartment of a washing machine. The applicant listed for this patent is Miele & Cie. KG. Invention is credited to Michael Finke, Andrea Sudkemper.

| Application Number | 20190085496 16/134991 |

| Document ID | / |

| Family ID | 63557262 |

| Filed Date | 2019-03-21 |

| United States Patent Application | 20190085496 |

| Kind Code | A1 |

| Sudkemper; Andrea ; et al. | March 21, 2019 |

EXTRACTION DEVICE FOR EXTRACTING A DETERGENT FROM A DISPENSING COMPARTMENT OF A WASHING MACHINE

Abstract

An extraction device for extracting a detergent from a dispensing compartment of a washing machine includes: an extraction channel having a channel opening that is or can be arranged in the dispensing compartment so as to form an inlet region; and an injection apparatus for injecting a diluting agent into the dispensing compartment, the injection apparatus having a nozzle opening which is arranged adjacent to the channel opening when the extraction device is in an operating state, so as to dilute the detergent with the diluting agent.

| Inventors: | Sudkemper; Andrea; (Delbrueck-Hagen, DE) ; Finke; Michael; (Hoevelhof, DE) | ||||||||||

| Applicant: |

|

||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Family ID: | 63557262 | ||||||||||

| Appl. No.: | 16/134991 | ||||||||||

| Filed: | September 19, 2018 |

| Current U.S. Class: | 1/1 |

| Current CPC Class: | D06F 39/028 20130101; D06F 39/088 20130101; D06F 39/02 20130101; D06F 39/022 20130101 |

| International Class: | D06F 39/02 20060101 D06F039/02; D06F 39/08 20060101 D06F039/08 |

Foreign Application Data

| Date | Code | Application Number |

|---|---|---|

| Sep 20, 2017 | DE | 10 2017 121 814.9 |

Claims

1. An extraction device for extracting a detergent from a dispensing compartment of a washing machine, comprising: an extraction channel comprising a channel opening that is configured to be arranged in the dispensing compartment so as to form an inlet region; and an injection apparatus configured to inject a diluting agent into the dispensing compartment, the injection apparatus comprising a nozzle opening which is arranged adjacent to the channel opening when the extraction device is in an operating state, so as to dilute the detergent with the diluting agent.

2. The extraction device according to claim 1, wherein the nozzle opening is configured to form the diluting agent into a jet, and wherein the nozzle opening is aimed at the inlet region of the channel opening.

3. The extraction device according to claim 1, wherein the channel opening and the inlet region are spaced apart from one another at a maximum of 3 cm when the extraction device is in the operating state.

4. The extraction device according to claim 1, wherein the extraction channel comprises a siphon.

Description

CROSS-REFERENCE TO PRIOR APPLICATION

[0001] Priority is claimed to German Patent Application No. DE 10 2017 121 814.9, filed on Sep. 20, 2017, the entire disclosure of which is hereby incorporated by reference herein.

FIELD

[0002] The invention relates to an extraction device for extracting a detergent from a dispensing compartment of a washing machine.

BACKGROUND

[0003] In order to be extracted from a dispensing compartment of a washing machine, viscous textile treatment agents can for example be mixed with water. A relatively large amount of water is generally required to rinse out the dispensing compartment.

SUMMARY

[0004] In an embodiment, the present invention provides an extraction device for extracting a detergent from a dispensing compartment of a washing machine, comprising: an extraction channel comprising a channel opening that is configured to be arranged in the dispensing compartment so as to form an inlet region; and an injection apparatus configured to inject a diluting agent into the dispensing compartment, the injection apparatus comprising a nozzle opening which is arranged adjacent to the channel opening when the extraction device is in an operating state, so as to dilute the detergent with the diluting agent.

BRIEF DESCRIPTION OF THE DRAWINGS

[0005] The present invention will be described in even greater detail below based on the exemplary figures. The invention is not limited to the exemplary embodiments. Other features and advantages of various embodiments of the present invention will become apparent by reading the following detailed description with reference to the attached drawings which illustrate the following:

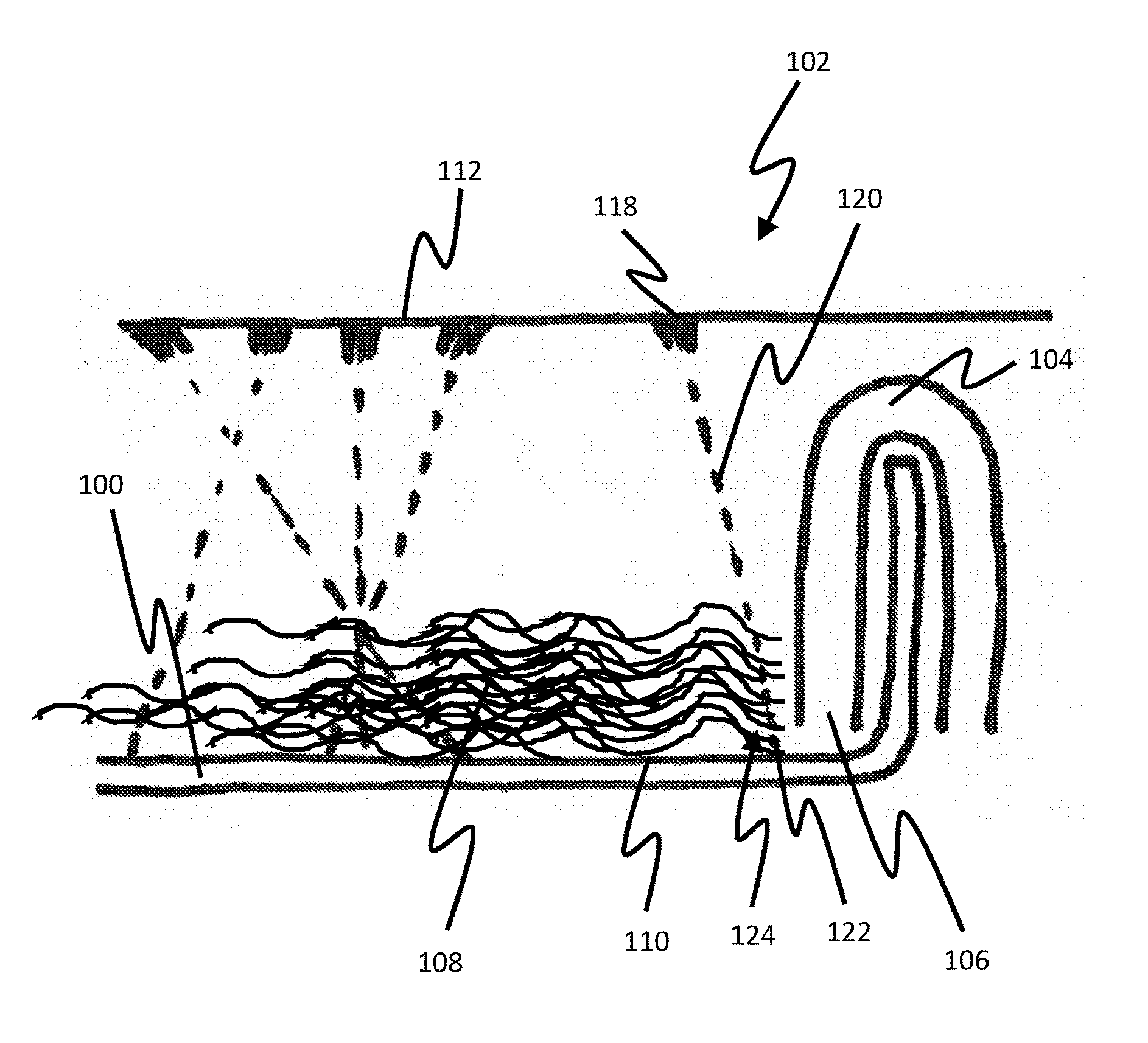

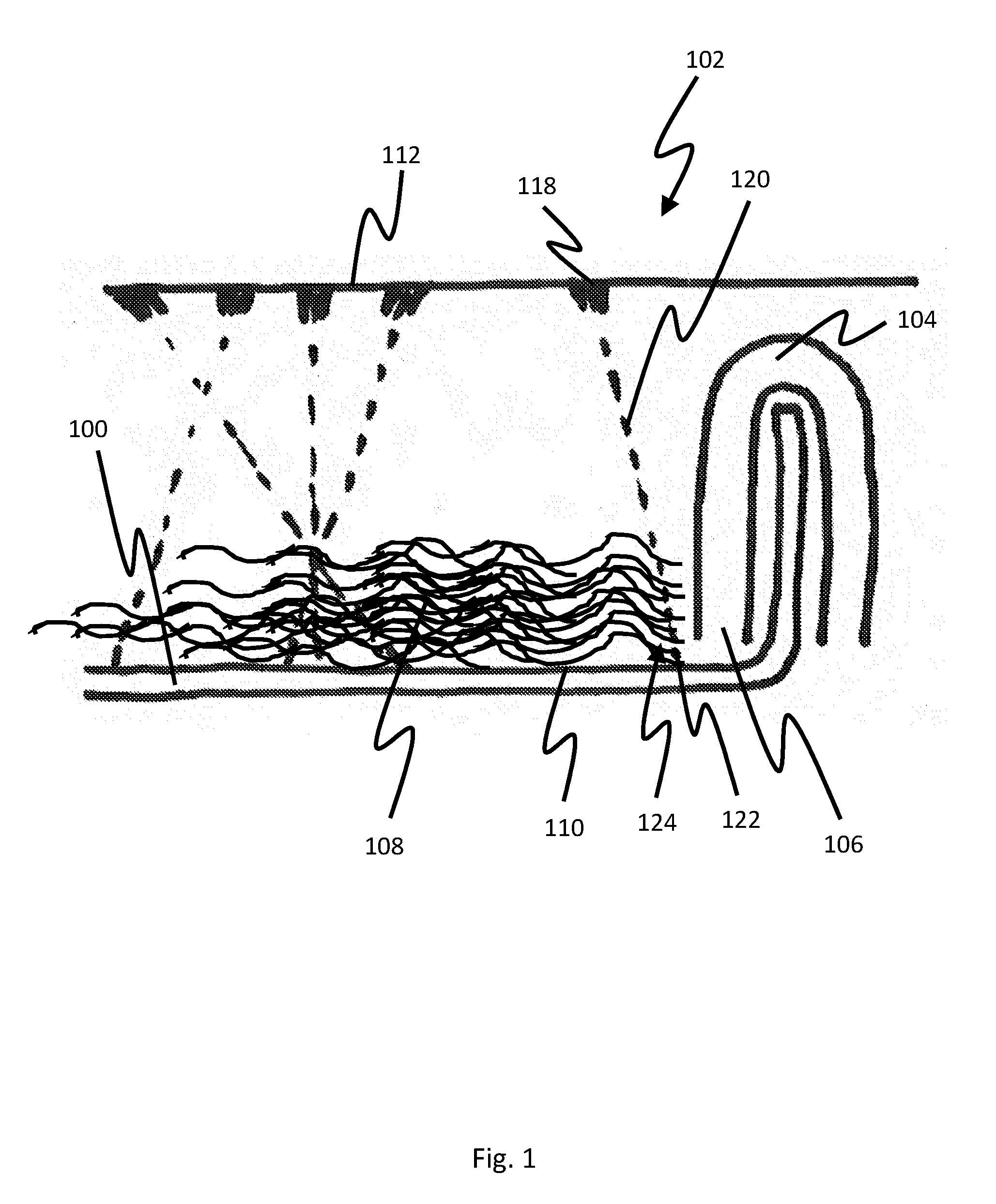

[0006] FIG. 1 is a schematic view of a portion of a dispensing compartment of a washing machine that comprises an extraction device according to one embodiment.

DETAILED DESCRIPTION

[0007] Against this background, the present invention provides an improved extraction device for extracting a detergent from a dispensing compartment of a washing machine.

[0008] The invention is advantageous in that, by injecting a directed water jet into a region of a dispensing compartment in which a siphon for extracting the detergent ends, the detergent is efficiently mixed and can be sufficiently diluted before extraction. This prevents the siphon from becoming clogged by detergent.

[0009] An extraction device for extracting a detergent from a dispensing compartment of a washing machine is presented, wherein the extraction device has the following features:

[0010] an extraction channel comprising a channel opening that is or can be arranged in the dispensing compartment so as to form an inlet region; and

[0011] an injection apparatus for injecting a diluting agent into the dispensing compartment, wherein the injection apparatus comprises a nozzle opening which is arranged adjacent to the channel opening when the extraction device is in the operating state, in order to dilute the detergent with the diluting agent.

[0012] A detergent can generally be understood to mean a textile treatment agent, for example in liquid or viscous form or even in powder form, such as a liquid detergent or a fabric softener. A dispensing compartment can be understood to mean, for example, a detergent dispensing compartment that has a prewash, main wash or softener compartment. A washing machine can alternatively also be understood to mean a washer-dryer. The extraction channel can be part of a siphon, for example. When the extraction device is in the operating state, the extraction opening can be facing a base of the dispensing compartment. The injection apparatus can comprise a nozzle for producing a directed jet, in particular a single jet. The diluting agent can be water or suds, for example.

[0013] The inlet region is formed by arranging the channel opening of the extraction channel such that the inlet region surrounds and adjoins the channel opening. The medium to be extracted flows from the inlet region towards the channel opening and through said opening into the extraction channel.

[0014] The nozzle opening of the injection apparatus is arranged adjacent to the channel opening when in the operating state. In this case, adjacent signifies that the nozzle is arranged inside the injection apparatus in such a way that the diluting agent can reach the inlet region from this nozzle.

[0015] According to one embodiment, the nozzle opening can be designed to form the diluting agent into a jet, wherein the nozzle opening is aimed at the inlet region of the channel opening. As a result, the diluting agent can be specifically directed towards the channel opening.

[0016] The jet of the diluting agent occurring in the inlet region of the channel opening and the inlet region adjoining the channel opening means that the diluting agent jet on the channel opening ensures mixing and therefore counteracts the channel opening clogging.

[0017] In particular, the channel opening and the inlet region can be spaced apart from one another at a maximum of 3 cm when the extraction device is in the operating state. As a result, the diluting agent can be injected in front of the channel opening in a very targeted manner, in order to liquefy the washing agent in front of the channel opening and very effectively prevent the extraction channel from clogging.

[0018] According to a further embodiment, the extraction channel can be a siphon. As a result, the extraction channel can be laid so as to be particularly space-saving and without using a pump.

[0019] FIG. 1 is a schematic view of a portion of a dispensing compartment 100 of a washing machine that comprises an extraction device 102 according to one embodiment. The extraction device 102 comprises an extraction channel 104, in this case by way of example in the form of a U-shaped siphon that is curved around a wall portion of the dispensing compartment 100, the channel opening 106 of which channel is arranged in the dispensing compartment 100 so as to form the inlet region 124.

[0020] When the extraction device 102 is in the operating state, the channel opening 106 is located below a surface of the detergent 108, in particular at a short distance from a base 110 of the dispensing compartment 100. The inlet region 124 is located in front of or around the channel opening 106.

[0021] Furthermore, the extraction device 102 comprises an injection apparatus 112, which comprises nozzle openings according to this embodiment. By way of example, the nozzle opening 118 is designed and oriented so as to form the diluting agent, in this case water, into a jet 120, the nozzle opening 118 being aimed at the inlet region 124 of the channel opening 106.

[0022] The injection apparatus 112 is designed to conduct a diluting agent, such as water, through the nozzle opening 118 at a particular pressure in order to form the diluting agent into a directed jet 120, in particular a single jet, upon exiting the nozzle opening 118. The end 122 of the jet 120 thereby occurs in the inlet region 124 directly in front of the channel opening 106.

[0023] As a result of the directed jet 120 from the nozzle opening 118, which jet occurs in the inlet region 124 directly in front of the channel opening 106, the detergent 108, which can for example be a viscous textile treatment agent or a powder detergent mixed with liquid, is diluted or liquefied or mixed through or mixed up by means of the jet 120 to such an extent that it can be readily extracted through the extraction channel 104 and can do so without clogging said channel.

[0024] By injecting for example water as a diluting agent, in the form of an individual water jet 120, via the injection apparatus 112 and nozzle opening 118 and specifically in front of the extraction channel 104, the detergent 108 can be well mixed and liquefied directly in front of the extraction channel 104 and can thus be extracted effectively. This prevents the extraction channel 104 from becoming clogged. Even viscous textile treatment agents can therefore be very effectively extracted via a siphon without this becoming clogged or detergent residues remaining in the dispensing compartment 100. Advantageously, comparatively less water is required by the single jet 120, which reduces the water consumption of the washing machine.

[0025] While the invention has been illustrated and described in detail in the drawings and foregoing description, such illustration and description are to be considered illustrative or exemplary and not restrictive. It will be understood that changes and modifications may be made by those of ordinary skill within the scope of the following claims. In particular, the present invention covers further embodiments with any combination of features from different embodiments described above and below. Additionally, statements made herein characterizing the invention refer to an embodiment of the invention and not necessarily all embodiments.

[0026] The terms used in the claims should be construed to have the broadest reasonable interpretation consistent with the foregoing description. For example, the use of the article "a" or "the" in introducing an element should not be interpreted as being exclusive of a plurality of elements. Likewise, the recitation of "or" should be interpreted as being inclusive, such that the recitation of "A or B" is not exclusive of "A and B," unless it is clear from the context or the foregoing description that only one of A and B is intended. Further, the recitation of "at least one of A, B and C" should be interpreted as one or more of a group of elements consisting of A, B and C, and should not be interpreted as requiring at least one of each of the listed elements A, B and C, regardless of whether A, B and C are related as categories or otherwise. Moreover, the recitation of "A, B and/or C" or "at least one of A, B or C" should be interpreted as including any singular entity from the listed elements, e.g., A, any subset from the listed elements, e.g., A and B, or the entire list of elements A, B and C.

* * * * *

D00000

D00001

XML

uspto.report is an independent third-party trademark research tool that is not affiliated, endorsed, or sponsored by the United States Patent and Trademark Office (USPTO) or any other governmental organization. The information provided by uspto.report is based on publicly available data at the time of writing and is intended for informational purposes only.

While we strive to provide accurate and up-to-date information, we do not guarantee the accuracy, completeness, reliability, or suitability of the information displayed on this site. The use of this site is at your own risk. Any reliance you place on such information is therefore strictly at your own risk.

All official trademark data, including owner information, should be verified by visiting the official USPTO website at www.uspto.gov. This site is not intended to replace professional legal advice and should not be used as a substitute for consulting with a legal professional who is knowledgeable about trademark law.