Inflatable Stand Up Board

HUANG; Shuiyong

U.S. patent application number 16/047005 was filed with the patent office on 2019-02-07 for inflatable stand up board. The applicant listed for this patent is Bestway Inflatables & Material Corp.. Invention is credited to Shuiyong HUANG.

| Application Number | 20190039698 16/047005 |

| Document ID | / |

| Family ID | 61796054 |

| Filed Date | 2019-02-07 |

| United States Patent Application | 20190039698 |

| Kind Code | A1 |

| HUANG; Shuiyong | February 7, 2019 |

INFLATABLE STAND UP BOARD

Abstract

An inflatable stand up board, comprising: a top layer having a first perimeter; a bottom layer having a second perimeter; a drop stitch layer disposed between the top layer and the bottom layer; a first sealing sheet coupled in an airtight configuration to the first perimeter and the second perimeter; a second sealing sheet disposed at least at one of a front end or a tail end of the inflatable stand up board. The second sealing sheet is coupled in an airtight configuration to the first and second perimeters, and overlaps at least part of the first sealing sheet. The top layer, the bottom layer and the first sealing sheet define an inflatable chamber of the inflatable stand up board. The side of the inflatable stand up board is not easily broken and a double sealing effect is achieved, preventing air leakage.

| Inventors: | HUANG; Shuiyong; (Shanghai, CN) | ||||||||||

| Applicant: |

|

||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Family ID: | 61796054 | ||||||||||

| Appl. No.: | 16/047005 | ||||||||||

| Filed: | July 27, 2018 |

| Current U.S. Class: | 1/1 |

| Current CPC Class: | B63B 32/51 20200201; B63B 32/57 20200201 |

| International Class: | B63B 35/79 20060101 B63B035/79 |

Foreign Application Data

| Date | Code | Application Number |

|---|---|---|

| Aug 4, 2017 | CN | 201720968926.9 |

Claims

1. An inflatable stand up board, comprising: a top layer having a first perimeter; a bottom layer having a second perimeter; a drop stitch layer coupled to and disposed between the top layer and the bottom layer; a first sealing sheet coupled in an airtight fashion to the first perimeter and the second perimeter; and a second sealing sheet disposed at least at one of a front end and a tail end of the inflatable stand up board, the tail end being opposite the front end; wherein the top layer, the bottom layer, and the first sealing sheet define an inflatable chamber of the inflatable stand up board; and wherein the second sealing sheet is coupled to the first perimeter and the second perimeter and overlaps at least part of the first sealing sheet.

2. The inflatable stand up board of claim 1, wherein the second sealing sheet comprises a front sealing sheet disposed at the front end of the inflatable stand up board and a tail sealing sheet disposed at the tail end of the inflatable stand up board.

3. The inflatable stand up board of claim 1, wherein the second sealing sheet spans the first perimeter and the second perimeter.

4. The inflatable stand up board of claim 1, wherein the first sealing sheet has a first lip and a second lip; wherein the first lip overlaps the first perimeter, forming a first border and the second lip overlaps the second perimeter forming a second border; and wherein the second sealing sheet overlaps the first and second borders.

5. The inflatable stand up board of claim 4, wherein an adhesive layer is disposed between the first sealing sheet and the second sealing sheet.

6. The inflatable stand up board of claim 5, wherein the adhesive layer comprises: a first adhesive strip disposed proximate the first border, creating a first airtight connection at the first boarder; and a second adhesive strip disposed proximate the second border, creating a second airtight connection at the second border.

7. The inflatable stand up board of claim 4, wherein an adhesive layer is disposed between the first perimeter and the first lip, creating an airtight connection; and wherein an additional adhesive layer is disposed between the second perimeter and the second lip, creating an additional airtight connection.

8. The inflatable stand up board of claim 1, wherein the drop stitch layer comprises an upper base layer coupled to the top layer, a lower base layer coupled to the bottom layer, and tensioning members disposed between and coupled to the upper base layer and the lower base layer.

9. The inflatable stand up board of claim 8, wherein the upper base layer is coupled to the top layer via an adhesive layer disposed between the upper base layer and the top layer, and the lower base layer is coupled to the bottom layer via a separate adhesive layer disposed between the lower base layer and the bottom layer.

10. The inflatable stand up board of claim 5, wherein the adhesive layer is formed by curing a complex glue, wherein the complex glue comprises a glue and a fixing agent having a mass ratio between 5% and 10%.

11. The inflatable stand up board of claim 6, wherein at least one adhesive layer is formed by curing a complex glue, wherein the complex glue comprises a glue and a fixing agent having a mass ratio between 5% and 10%.

12. The inflatable stand up board of claim 7, wherein the adhesive layer is formed by curing a complex glue, wherein the complex glue comprises a glue and a fixing agent having a mass ratio between 5% and 10%.

13. The inflatable stand up board of claim 9, wherein the adhesive layer is formed by curing a complex glue, wherein the complex glue comprises a glue and a fixing agent having a mass ratio between 5% and 10%.

14. An inflatable stand up board, comprising: a top layer having a first perimeter; a bottom layer having a second perimeter; a drop stitch layer coupled to and disposed between the top layer and the bottom layer; a first sealing sheet coupled in an airtight fashion to the first perimeter and the second perimeter; a first sealing strip coupled to the top layer and the first sealing sheet; a second sealing strip coupled to the bottom layer and the first sealing sheet; wherein the top layer, the bottom layer, and the first sealing sheet define an inflatable chamber of the inflatable stand up board.

15. The inflatable stand up board of claim 14, wherein the first sealing sheet has a first lip and a second lip; and wherein, the first lip overlaps the first perimeter, forming a first border, and the second lip overlaps the second perimeter forming a second border; wherein the first sealing strip overlaps the first border and the second sealing strip overlaps the second border.

16. The inflatable stand up board of claim 15, wherein a first adhesive layer is disposed between the first sealing strip and the first sealing sheet, creating a first airtight connection proximate the first border; and a second adhesive layer is disposed between the second sealing strip and the first sealing sheet, creating a second airtight connection proximate the second border.

Description

CROSS-REFERENCE TO RELATED APPLICATIONS

[0001] This application claims the priority of Chinese Patent Application No. 201720968926.9, filed Aug. 4, 2017, which is incorporated herein by reference in its entirety.

TECHNICAL FIELD

[0002] The present disclosure generally relates to products for aquatic sports and, more particularly, to an inflatable stand up board.

BACKGROUND

[0003] Inflatable stand up boards provide boarders with access to numerous aquatic activities. Surfboarders can stand or sit on the inflatable board and participate in numerous aquatic sports. The inflatable stand up board can be designed to encompass various shapes, as needed, to achieve various functions. For example, the inflatable stand up board can be a surfboard for surfing, can be used with a paddle for paddleboarding when waves are not present, and can further be used as a flotation device for aided swimming.

[0004] The inflatable stand up board has the ability to support boarders and float on water due to air filled chambers therein. Unfortunately, due to collisions or impacts with external objects, inflation chambers can be damaged during use, causing air leakage and loss of buoyancy. This air leakage and loss of buoyancy presents a dangerous scenario for those using the board. Accordingly, there is a need to provide an inflatable stand up board that can prevent air leakage during use.

SUMMARY

[0005] The above mentioned problems are solved according to the present invention, which provides an inflatable stand up board comprising: a top layer with a first perimeter; a bottom layer with a second perimeter; a drop stitch layer coupled to and disposed between the top layer and the bottom layer, which is uniquely adapted to maintain the predetermined shape of the inflatable stand up board upon inflation; a first sealing sheet circumferentially surrounding the top layer and the bottom layer and coupled in an airtight fashion to the first perimeter and the second perimeter; and a second sealing sheet. The second sealing sheet is disposed at least at the front end and the tail end of the inflatable stand up board (the two ends being on opposing sides of the board), and is coupled to at least a portion of the first perimeter and the second perimeter. The second sealing sheet also overlaps at least part of the first sealing sheet. The board's inflatable chamber is defined by the top layer, the bottom layer, and the first sealing sheet.

[0006] Alternatively, the second sealing sheet may comprise a front sealing sheet disposed at the front end of the inflatable stand up board and a tail sealing sheet which is disposed at the tail end of the inflatable stand up board. Ideally, however, the second sealing sheet will surround the circumference of the board such that the second sealing sheet spans the first perimeter and the second perimeter of the top and bottom layers respectively.

[0007] Alternatively, the first sealing sheet has a first lip and a second lip. The first lip overlaps the first perimeter, forming a first border and the second lip overlaps the second perimeter forming a second border. Furthermore, the second sealing sheet can overlap the first and second borders to provide additional securement.

[0008] In one embodiment, an adhesive layer is disposed between the first sealing sheet and the second sealing sheet; the adhesive may cover all or a portion of the inner surface of the second sealing sheet.

[0009] Alternatively, the adhesive layer disposed between the first and second sheets may comprise: a first adhesive strip disposed proximate the first border, creating a first airtight connection at the first boarder; and a second adhesive strip disposed proximate the second border, creating a second airtight connection at the second border.

[0010] In another embodiment, an adhesive layer is disposed between the first perimeter and the first lip, all of which overlap, creating an airtight connection. Similarly, another adhesive layer may be disposed between the second perimeter and the second lip, all of which overlap, creating another airtight connection.

[0011] In a particularly advantageous embodiment, the drop stitch layer comprises an upper base layer coupled to the top layer, a lower base layer coupled to the bottom layer, and tensioning members disposed between and coupled to the upper and lower base layers.

[0012] In yet another embodiment, the upper base layer is coupled to the top layer via an adhesive layer disposed between the upper base layer and the top layer. Similarly, the lower base layer is coupled to the bottom layer via a separate adhesive layer disposed between the lower base layer and the bottom layer.

[0013] In an advantageous embodiment, at least one of the adhesive layers is formed by curing a complex glue, which comprises a glue and a curing agent. Ideally, the cuing agent has a mass ratio between 5% and 10%.

[0014] The present disclosure also provides an inflatable stand up board, comprising: a top layer with a first perimeter; a bottom layer with a second perimeter; a drop stitch layer disposed between the top layer and the bottom layer, which is uniquely adapted to maintain the predetermined shape of the inflatable stand up board upon inflation; a first sealing sheet circumferentially surrounding the top layer and the bottom layer and coupled in an airtight fashion to the first perimeter and the second perimeter; a first sealing strip coupled to the top layer and the first sealing sheet; and a second sealing strip coupled to the bottom layer and the first sealing sheet. The top layer, the bottom layer, and the first sealing sheet define the inflatable chamber of the inflatable stand up board.

[0015] Alternatively, the first sealing sheet has a first lip and a second lip wherein the first lip overlaps the first perimeter forming a first border, and the second lip overlaps the second perimeter forming a second border. Additionally, the first sealing strip overlaps the first border and the second sealing strip overlaps the second border.

[0016] In an advantageous embodiment, a first adhesive layer is disposed between the first sealing strip and the first sealing sheet, creating a first airtight connection proximate the first border. Furthermore, a second adhesive layer is disposed between the second sealing strip and the first sealing sheet, creating a second airtight connection proximate the second border.

[0017] The above listed embodiments present numerous advantages over the prior art including an airtight connection between the first and second sealing sheets and the top layer and the bottom layer. Accordingly, the inflatable stand up board achieves a double sealing effect, preventing air leakage. The double sealing effect makes it difficult to puncture or damage the air seals or the side surface of the inflatable stand up board, meaning users can avoid dangerous conditions presented during deflation of an inflatable stand up board.

BRIEF DESCRIPTION OF THE DRAWINGS

[0018] The above-mentioned and other features and advantages of this disclosure, and the manner of attaining them, will become more apparent and better understood by reference to the following detailed description taken in conjunction with the accompanying drawings, wherein:

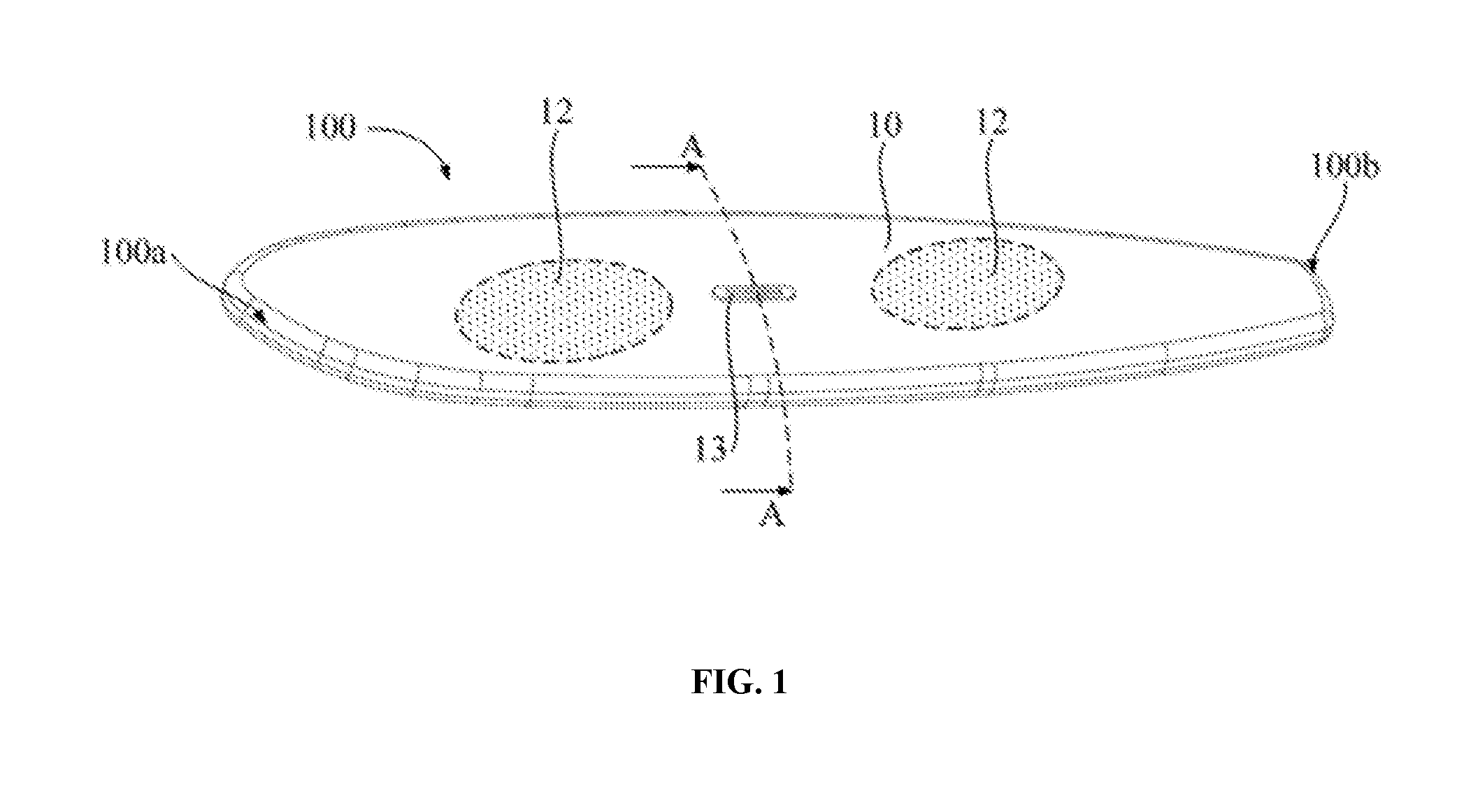

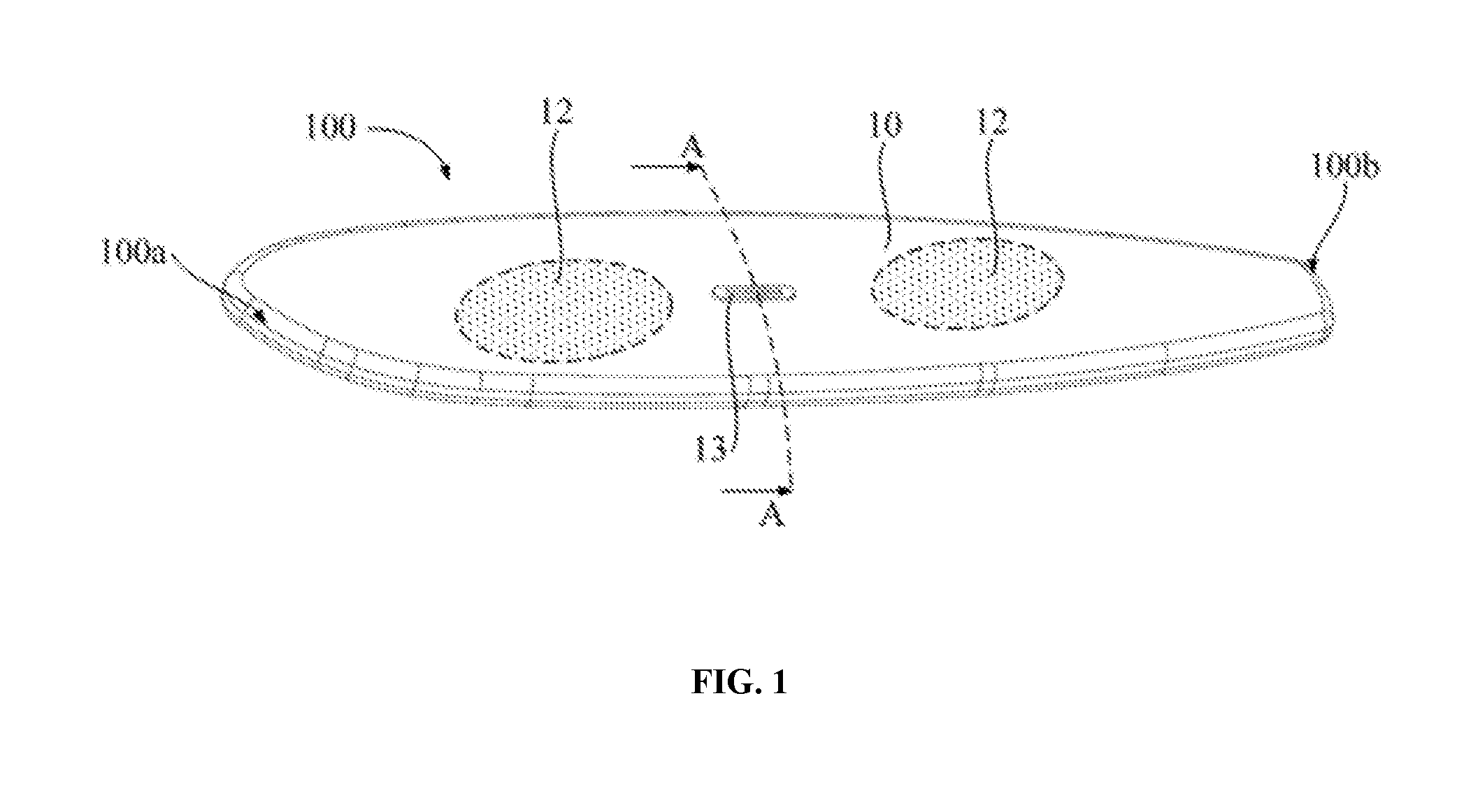

[0019] FIG. 1 is a perspective view of the inflatable stand up board.

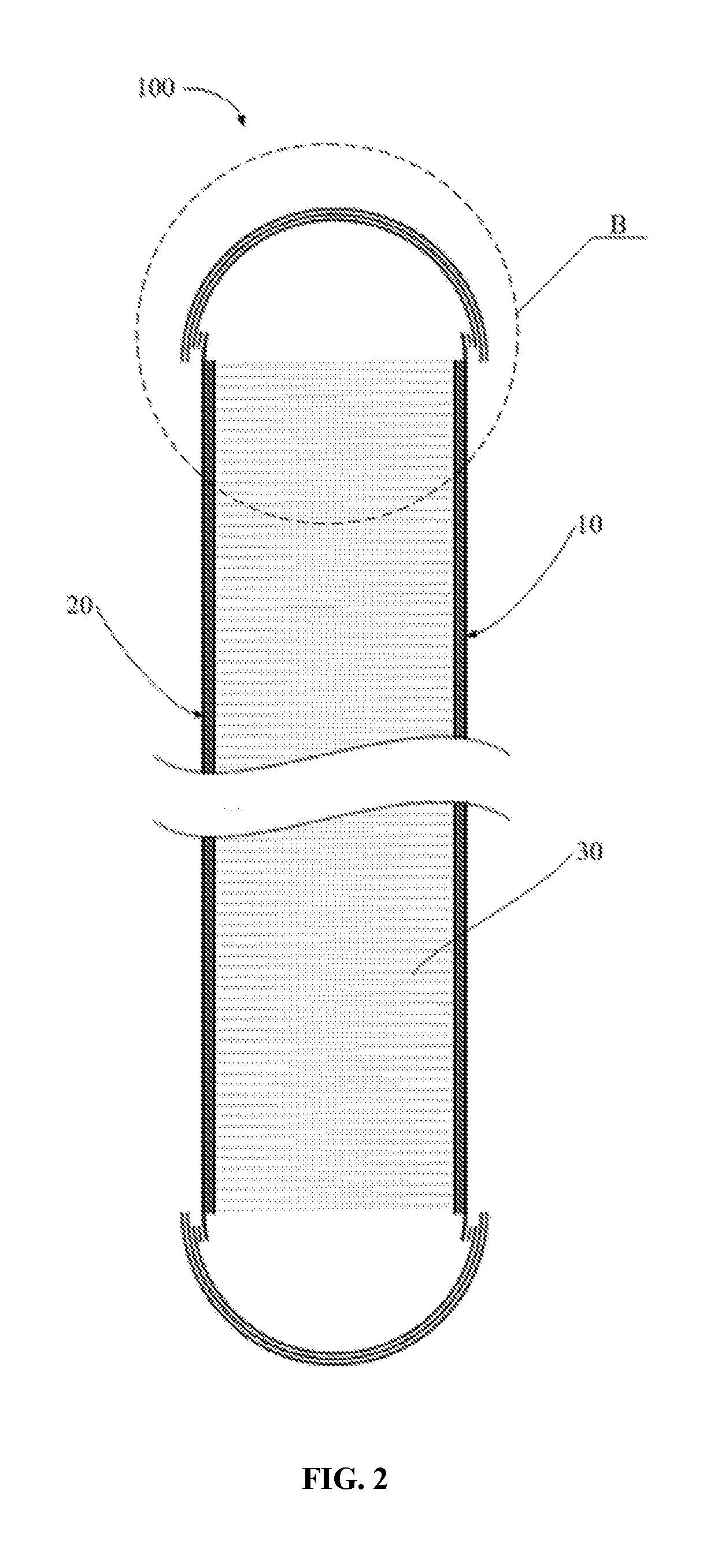

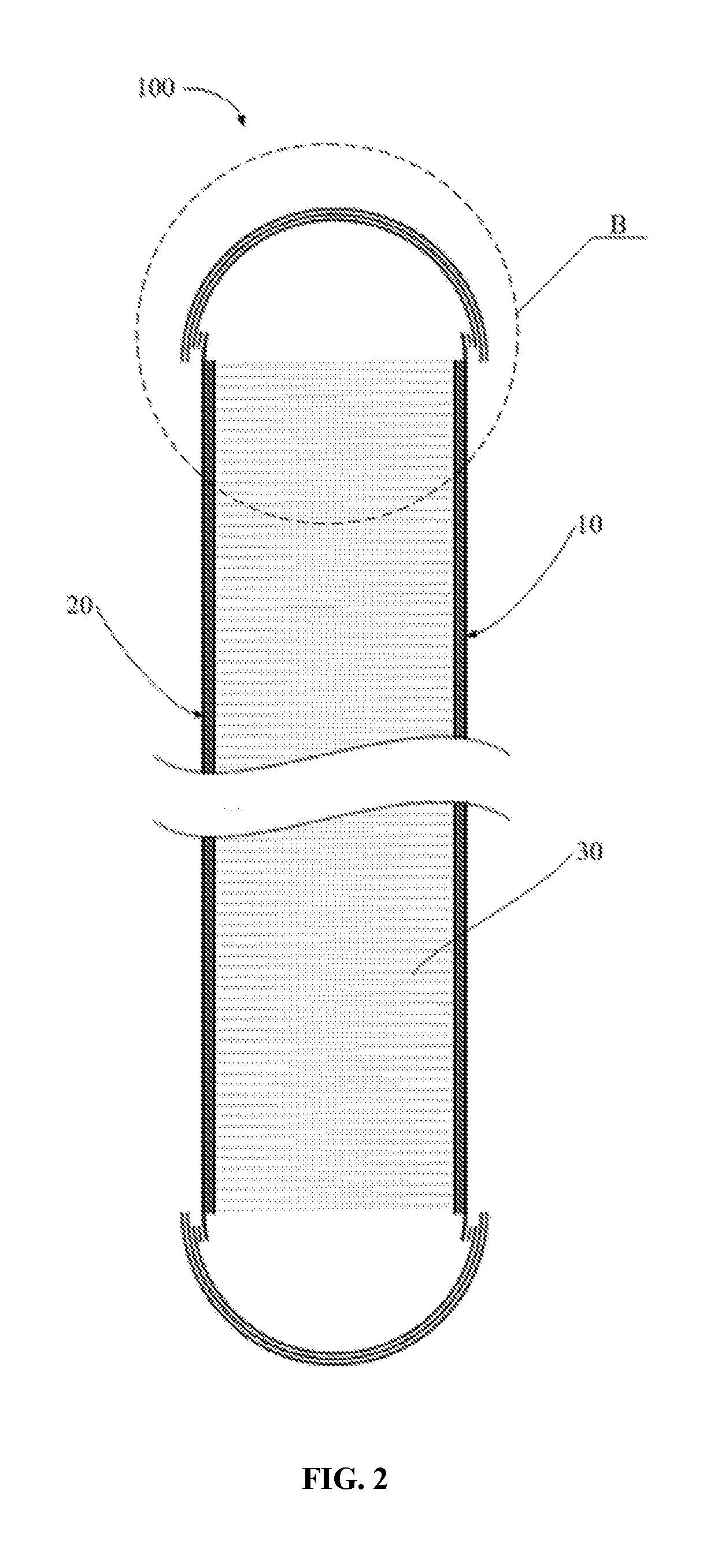

[0020] FIG. 2 is a cross-sectional view taken along Line A-A, shown in FIG. 1.

[0021] FIG. 3 is an enlarged view of Area B, as shown in FIG. 2, according to one embodiment of the present disclosure.

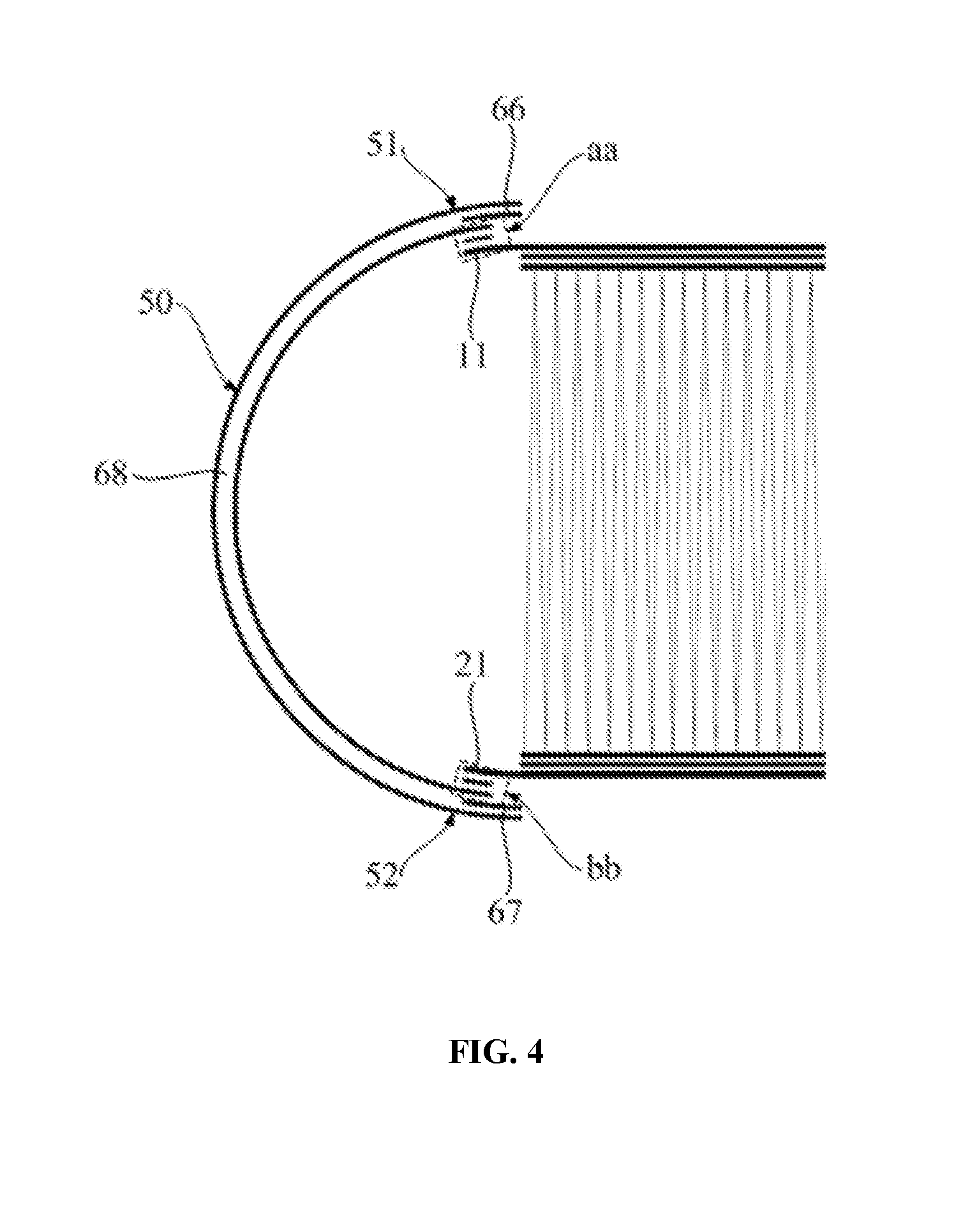

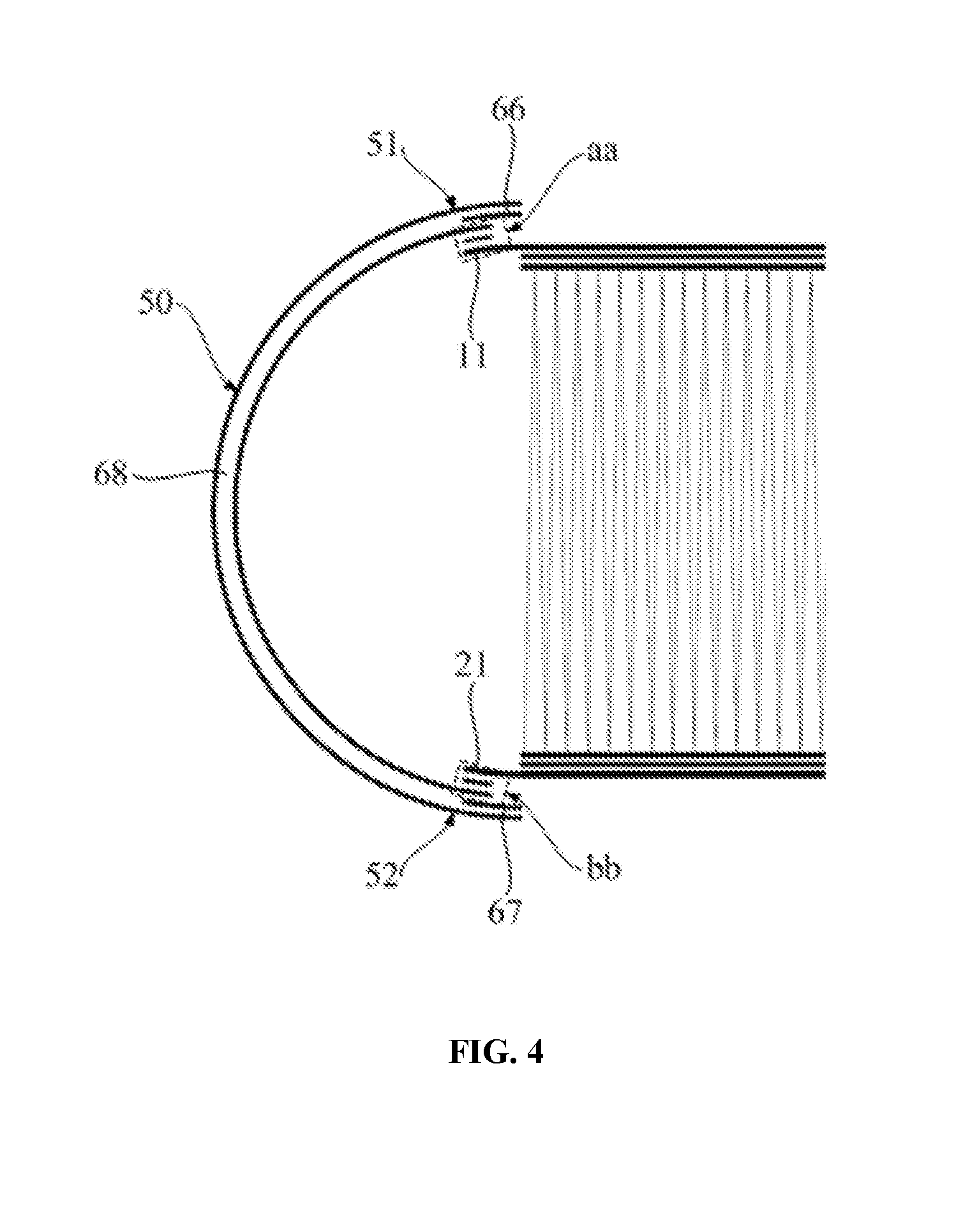

[0022] FIG. 4 is an alternate enlarged view of Area B, as shown in FIG. 2, according to an alternate embodiment.

[0023] FIG. 5 is another alternate enlarged view of Area B, as shown in FIG. 2, according to another alternate embodiment.

DETAILED DESCRIPTION

[0024] Detailed examples are provided below for the purpose of ease of understanding the present disclosure. The exemplary embodiments of the present disclosure are described below with reference to the drawings for illustration. It should be understood that, the description of the exemplary embodiments should not be construed as limiting the scope of the present disclosure in any manner.

[0025] Referring to FIGS. 1 to 3, an inflatable stand up board 100 is shown. The board 100 comprises a top layer 10, a bottom layer 20, a drop stitch layer 30, and a first sealing sheet 40. The top and bottom layers 10, 20 are generally parallel to each other. The top layer 10, the bottom layer 20, and the first sealing sheet 40 are preferably constructed of waterproof material. In particular, the top layer 10, the bottom layer 20, and the first sealing sheet 40 can be formed from PVC (polyvinyl chloride) material, thermoplastic elastomer (TPE) material, polyester or polyether thermoplastic polyurethanes elastic rubber PU, or other suitable materials.

[0026] When in use, the top layer 10 is typically in contact with the boarder's body. Referring to FIG. 1, the inflatable stand up board 100 may further utilize an anti-slipping layer 12 disposed on the top layer 10. The anti-slipping layer 12 is designed to contact a boarder's body and can be used to increase the friction coefficient between the board 100 and the body, decreasing the likelihood of slipping off the board during use. The top layer 10 has a first perimeter 11 surrounding the circumference of the top layer 10. The bottom layer 20 is typically in contact with the water, when in use, and has a second perimeter 21 surrounding the circumference of the bottom layer 20. The first sealing sheet 40 acts as side surface of the inflatable stand up board, coupled to the top layer 10 and the bottom layer 20 at the first perimeter 11 and the second perimeter 21, thus forming airtight seals in both locations.

[0027] As a result of the affixation, an inflatable chamber is formed in the board 100 which is defined by the top layer 10, the bottom layer 20, and the first sealing sheet 40. The drop stitch layer 30 is disposed within the inflatable chamber and is uniquely adapted to maintaining a predetermined shape of the inflatable stand up board 100 upon inflation.

[0028] In addition, the inflatable stand up board 100 may include a fixing base 13. The fixing base 13 is disposed on the top layer 10 and is depressed toward the bottom layer 20. The fixing base 13 is used for affixing a mast, fishing pole, camera stand, or the like to the board 100, enabling the boarder to fish or take photos while boarding.

[0029] In one embodiment, a rear control (not shown) may also be provided, that is disposed on the bottom layer 20. In particular, a mounting hole for the rear control is disposed on the bottom layer 20 of the inflatable stand up board 100, in which the rear control is disposed. The rear control is adapted to provide additional stability to the inflatable stand up board 100 during flotation. The rear control may also be used to adjust the floating direction of the inflatable stand up board 100.

Example 1

[0030] In a first example, with reference to FIG. 3, the inflatable stand up board 100 further comprises a second sealing sheet 50 in a ring shape, surrounding the top layer 10 and the bottom layer 20, and coupled in an airtight manner to the first perimeter 11 and the second perimeter 21. The second sealing sheet 50 covers the first sealing sheet 40. The second sealing sheet 50 is ideally constructed of the same or similar material as that of the first sealing sheet 40.

[0031] Both the first sealing sheet 40 and the second sealing sheet 50 are affixed in an airtight manner to the first and second perimeters 11 and 21, achieving a double sealing effect for the inflatable stand up board 100. This double sealing effect prevents damage or puncture to the sidewalls of the board 100, thereby avoiding the dangerous condition of air leakage during use.

[0032] It should be noted that, in other modified embodiments, a plurality of sealing sheets can be disposed. For example, three or more sealing sheets can be disposed at the sides of the inflatable stand up board, such that the inner sealing sheets are covered by the outer sealing sheets, thus achieving an improved sealing effect.

[0033] As shown in FIG. 3, the first sealing sheet 40 has a first lip 41 disposed on a first end of an inner side of the first sealing sheet, proximate the first perimeter 11 and a second lip 42 disposed on a second end of an inner side of the first sealing sheet, proximate the second perimeter 21. The first lip 41 overlaps the first perimeter 11 to form a first border aa. Similarly, the second lip 42 overlaps the second perimeter 21 to form a second border bb. The second sealing sheet 50 overlaps the first and second borders aa and bb.

[0034] According to a particularly advantageous embodiment, a first adhesive layer 61 is disposed between the first lip 41 and the first perimeter 11. The adhesive has the effect of forming an airtight seal between the first lip 41 and the first perimeter 11. The first border aa is the connection site of the first sealing sheet 40 and the top layer 10. Similarly, a second adhesive layer 62 is disposed between the second lip 42 and the second perimeter 21, again forming an airtight seal between the second lip 42 and the second perimeter 21. The second border bb is the connection site of the first sealing sheet 40 and the bottom layer 20.

[0035] The first border aa and the second border bb are protected from exposure to the outside environment via the second sealing sheet 50, which overlaps the first border aa and the second border bb (i.e., the second sealing sheet 50 covers the first sealing sheet 40 and the top layer 10 at the first border aa and the second sealing sheet 50 and bottom layer 20 at the second border bb). This overlapping feature prevents external substances from contacting and damaging the first border aa and the second border bb, further preventing air leakage of the inflatable stand up board.

[0036] As is additionally shown in FIG. 3, a third adhesive layer 63 is disposed between the first sealing sheet 40 and the second sealing sheet 50, which covers the inner surface of the second sealing sheet 50. The result of the third adhesive layer 63 is such that the first sealing sheet 40 is fixedly coupled to the second sealing sheet 50. In comparison to utilizing only the first sealing sheet 40, the side thickness of the inflatable stand up board as described in this example is increased, further protecting the side from damage and air leakage.

[0037] In addition, since the first sealing sheet 40 is covered by the second sealing sheet 50 and the third adhesive layer 63 covers the inner surface of the second sealing sheet 50, the third adhesive layer 63 circumferentially overlaps the top layer 10 and the bottom layer 20. The second sealing sheet 50 covers the third adhesive layer 63, resulting in an airtight connection amongst the second sealing sheet 50, the top layer 10, and the bottom layer 20.

[0038] Referring again to FIG. 3, the drop stitch layer 30 is shown which comprises an upper base layer 31, a lower base layer 32, and tensioning members 33 disposed between the upper base layer 31 and the lower base layer 32. The tensioning members 33 are coupled to the upper and lower base layers 31 and 32 at both ends thereof, and ensure a constant distance between the upper and lower base layers 31 and 32 upon inflation. Ideally, the inflatable stand up board 100 is formed as a flat plate shape upon inflation, though other shapes are anticipated. The tensioning members may consist of any form of string, wire, or other lightweight, durable, material.

[0039] In order to ensure the shape of the board 100, the upper base layer 31 of the drop stitch layer 30 is coupled to the top layer 10 of the board 100. Additionally, the lower base layer 20 is coupled to the bottom layer 20, effectively connecting the top layer 10 with the bottom layer 20 via the drop stitch layer 30. In order to achieve this connection, a fourth adhesive layer 64 is disposed between the upper base layer 31 and the top layer 10, which serves as an affixation means between the upper base layer 31 and the top layer 10. Additionally, a fifth adhesive layer 65 is disposed between the lower base layer 32 and the bottom layer 20, which serves as the affixation means between the upper base layer 31 and the top layer 10.

[0040] In a particular embodiment, the first, second, third, fourth, and/or fifth adhesive layers 61, 62, 63, 64, and/or 65 are formed by curing a complex glue. The complex glue preferably comprises a glue and a fixing agent. The fixing agent has a mass ratio between 5% and 10%, preferably 6%; though other ratios are anticipated, depending on the type of glue used. Exemplary glue types include polyurethane or other glues. The fixing agent can be isocyanate or any other suitable fixing agent.

Example 2

[0041] In another example board, a second sealing sheet is provided that does not completely surround the top layer 10 or the bottom layer 20. The second sealing sheet only partially encompasses the first perimeter 11 and the second perimeter 21.

[0042] Referring to FIG. 1, the inflatable stand up board 100 has a front end 100a and a tail end 100b. The front end 100a and tail end 100b are generally located on opposing sides of the board 100. This embodiment is particularly advantageous when viewed from a board use perspective. While using the inflatable stand up board 100, more collisions occur at the front end 100a and the tail end 100b than occur at the sides of the inflatable stand up board 100, thus it is advantageous to reinforce the front end 100a and tail end 100b to ensure adequate protection from air leakage.

[0043] Accordingly, in the present embodiment, the second sealing sheet comprises a front sealing sheet (not shown) which is disposed at the head end 100a of the inflatable stand up board and a tail sealing sheet (not shown) which is disposed at the tail end 100b of the inflatable stand up board. Particularly, at the head end 100a and the tail end 100b of the inflatable stand up board, the first sealing sheet 40 is covered by the front and tail sealing sheets from a portion of the first perimeter to a portion of the second perimeter.

[0044] The front and tail sealing sheets are respectively disposed at the head end 100a and the tail end 100b, such that double protection and sealing effects are produced at the head end 100a and the tail end 100b of the inflatable stand up board, thus reducing the risk of damage and air leakage from the inflatable chamber.

[0045] In other modified examples, only the front sealing sheet is disposed at the head end 100a of the inflatable stand up board 100. Alternately, only the tail sealing sheet is disposed at the tail end 100b of the inflatable stand up board 100.

Example 3

[0046] In another exemplary embodiment and referring to FIG. 4, less than all of the inner surface of the second sealing sheet 50 is coated with the adhesive layer between the first sealing sheet 40 and the second sealing sheet 50. In particular, the second sealing sheet 50 comprises a third lip 51 covering the first border aa and a fourth lip 52 covering the second border bb. A sixth adhesive layer 66 is disposed between the third lip 51 and the first border aa to achieve an airtight connection. A seventh adhesive layer 67 is disposed between the fourth lip 52 and the second border bb to achieve an airtight connection.

[0047] Other than the sixth and seventh adhesive layers, 66 and 67, no adhesive is disposed between the first sealing sheet 40 and the second sealing sheet 50. The adhesive layers 66 and 67 are merely disposed proximate the first perimeter of the top layer 10 and the second perimeter of the bottom layer 20 (i.e., proximate the first border aa and the second border bb). This configuration creates a hollow cavity 68, defined between the first and second sealing sheets 40 and 50.

[0048] Exposure of the first and second borders aa and bb to the external environment can be avoided through covering the first border aa by the third lip 51 and covering the second border bb by the fourth lip 52, such that the first and second borders aa and bb are protected from damage. The third and fourth lips 51 and 52 also add to the double sealing effect, further preventing air leakage of the inflatable stand up board 100.

Example 4

[0049] In yet another example and with reference to FIG. 5, the second sealing sheet of the inflatable stand up board comprises a first and second sealing strip 71 and 72. The first sealing strip is coupled to the first perimeter 11 of the top layer and a second sealing strip 72 is coupled to the second perimeter 21 of the bottom layer.

[0050] In this example, the first sealing strip 71 is in a ring shape, surrounding the first perimeter of the top layer 10. The first sealing strip 71 couples the top layer 10 and the first sealing strip 40 in an airtight configuration. The second sealing strip 72 is additionally in a ring shape, surrounding the second perimeter of the bottom layer 20. Similarly, the second sealing strip 72 couples the bottom layer 20 and the first sealing sheet 40 in another airtight configuration.

[0051] In particular, the first sealing sheet 40 has a first lip 41 disposed on a first end of an inner side of the first sealing sheet, proximate the first perimeter 11 and a second lip 42 disposed on a second end of an inner side of the first sealing sheet, proximate the second perimeter 21. The first lip 41 overlaps the first perimeter 11 to form a first border aa. Similarly, the second lip 42 overlaps the second perimeter 21 to form a second border bb. The first sealing strip 71 overlaps the first border aa and the second sealing strip 72 overlaps the second border bb.

[0052] A first adhesive layer 61 is disposed between the first lip 41 and the first perimeter 11, securing the two in an airtight manner at the first border aa. A second adhesive layer 62 is disposed between the second lip 42 and the second perimeter 21, securing the two in an airtight manner at the second border bb.

[0053] Exposure of the first border aa to the external environment can be avoided through covering the first border aa by the first sealing strip 71, such that external substances are prevented from contacting and damaging the first border aa. Similarly, exposure of the second border bb to the external environment can be avoided through covering the second border bb by the second sealing strip 72, such that external substances are prevented from contacting and damaging the second border bb.

[0054] Furthermore, with reference to FIG. 5, a sixth adhesive layer 66 is disposed between the first sealing strip 71 and the first border aa to achieve an airtight connection. A seventh adhesive layer 67 is disposed between the second sealing strip 72 and the second border bb to achieve an additional airtight connection. As such, a double sealing effect is achieved, further preventing air leakage from the inflation chamber.

[0055] In this example, both first and second sealing strips 71 and 72 are in a ring shape to surrounding the top layer 10 and bottom layer 20. In other modified examples the first and second sealing strips 71 and 72 can be in a band shape for affixation to the front end or the tail end of the inflatable stand up board (examples of which are provided at least in Example 2 herein). Additional shapes are anticipated, depending on the shape of the board's perimeter.

[0056] While the particular embodiments of the present disclosure have been described, a person skilled in the art should understand that these are merely illustrative, and that the scope of protection of the present invention is defined by the appended claims. Various alterations or modifications can be made by a person skilled in the art to these embodiments without departing from the principle and substance of the present disclosure; however, these alterations and modifications all fall within the scope of protection of the present disclosure.

* * * * *

D00000

D00001

D00002

D00003

D00004

D00005

XML

uspto.report is an independent third-party trademark research tool that is not affiliated, endorsed, or sponsored by the United States Patent and Trademark Office (USPTO) or any other governmental organization. The information provided by uspto.report is based on publicly available data at the time of writing and is intended for informational purposes only.

While we strive to provide accurate and up-to-date information, we do not guarantee the accuracy, completeness, reliability, or suitability of the information displayed on this site. The use of this site is at your own risk. Any reliance you place on such information is therefore strictly at your own risk.

All official trademark data, including owner information, should be verified by visiting the official USPTO website at www.uspto.gov. This site is not intended to replace professional legal advice and should not be used as a substitute for consulting with a legal professional who is knowledgeable about trademark law.