Electrocaloric Heat Transfer Modular Stack

Walker; Craig R. ; et al.

U.S. patent application number 16/064822 was filed with the patent office on 2019-01-03 for electrocaloric heat transfer modular stack. This patent application is currently assigned to UNITED TECHNOLOGIES CORPORATION. The applicant listed for this patent is UNITED TECHNOLOGIES CORPORATION. Invention is credited to Subramanyaravi Annapragada, Scott Alan Eastman, Joseph V. Mantese, Michael L. Perry, Jonathan Rheaume, Parmesh Verma, Craig R. Walker.

| Application Number | 20190003747 16/064822 |

| Document ID | / |

| Family ID | 55168430 |

| Filed Date | 2019-01-03 |

| United States Patent Application | 20190003747 |

| Kind Code | A1 |

| Walker; Craig R. ; et al. | January 3, 2019 |

ELECTROCALORIC HEAT TRANSFER MODULAR STACK

Abstract

A heat transfer system is disclosed including a plurality of modules arranged in a stack. The stack modules include electrocaloric element and electrodes on each side of the film. A fluid flow path is disposed between two or more electrocaloric elements. A first electrical bus element (18) in electrical contact with the first electrode (14), and a second electrical bus element (20) in electrical contact with second electrode (16). The first electrical bus element is electrically connected to at least one other electrical bus of another electrocaloric element in the stack at the same polarity as said first electrical bus, or the second electrical bus element is electrically connected to at least one other electrical bus of another electrocaloric element in the stack at the same polarity as said second electrical bus.

| Inventors: | Walker; Craig R.; (South Glastonbury, CT) ; Rheaume; Jonathan; (West Hartford, CT) ; Perry; Michael L.; (Glastonbury, CT) ; Eastman; Scott Alan; (Glastonbury, CT) ; Annapragada; Subramanyaravi; (Shrewsbury, MA) ; Verma; Parmesh; (South Windsor, CT) ; Mantese; Joseph V.; (Ellington, CT) | ||||||||||

| Applicant: |

|

||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Assignee: | UNITED TECHNOLOGIES

CORPORATION Farmington CT |

||||||||||

| Family ID: | 55168430 | ||||||||||

| Appl. No.: | 16/064822 | ||||||||||

| Filed: | December 21, 2015 | ||||||||||

| PCT Filed: | December 21, 2015 | ||||||||||

| PCT NO: | PCT/US15/67189 | ||||||||||

| 371 Date: | June 21, 2018 |

| Current U.S. Class: | 1/1 |

| Current CPC Class: | F25B 2321/001 20130101; F25B 21/00 20130101; Y02B 30/66 20130101; Y02B 30/00 20130101 |

| International Class: | F25B 21/00 20060101 F25B021/00 |

Claims

1. A heat transfer system, comprising a plurality of modules arranged in a stack, each of the modules comprising an electrocaloric element comprising an electrocaloric film, a first electrode on a first side of the electrocaloric film, and a second electrode on a second side of the electrocaloric film; a fluid flow path between two or more electrocaloric elements; a first electrical bus element in electrical contact with the first electrode; and a second electrical bus element in electrical contact with second electrode; wherein the first electrical bus element is electrically connected to at least one other electrical bus of another electrocaloric element in the stack at the same polarity as said first electrical bus, or the second electrical bus element is electrically connected to at least one other electrical bus of another electrocaloric element in the stack at the same polarity as said second electrical bus.

2. The heat transfer system of claim 1, wherein the first electrical bus element is electrically connected to at least one other electrical bus of another electrocaloric element in the stack at the same polarity as said first electrical bus, and the second electrical bus element is electrically connected to at least one other electrical bus of another electrocaloric element in the stack at the same polarity as said second electrical bus.

3. The heat transfer system of claim 1, wherein the first or second electrical bus is electrically connected to an electrical bus of an adjacent electrocaloric element in the stack at the same polarity as said first or second electrical bus.

4. The heat transfer system of claims 1, wherein the first and second electrical bus elements are each electrically connected to electrical bus elements of an adjacent electrocaloric element in the stack at the same polarities as said first and second electrical bus elements, respectively.

5. The heat transfer system of claim 1, wherein the first electrical bus element is in an interlocking configuration with an electrical bus of an adjacent electrocaloric element in the stack, or the second electrical bus element is in an interlocking configuration with an electrical bus of an adjacent electrocaloric element in the stack, or the first electrical bus element and the second electrical bus element are each in an interlocking configuration with an electrical bus of an adjacent electrocaloric element in the stack.

6. (canceled)

7. The heat transfer system of claim 1, wherein the first electrical bus element is electrically connected to a live electrode and the second electrical bus element is electrically connected to a ground electrode.

8. The heat transfer system of claim 1, wherein the first and second electrical bus elements are disposed along opposite edges of the electrocaloric element.

9. The heat transfer system of claim 8, wherein the first electrode extends from the first electrical bus element along the first side of the electrocaloric film to a position physically separated from the second electrical bus element, and the second electrode extends from the second electrical bus element along the second side of the electrocaloric film to a position physically separated from the first electrical bus element.

10. The heat transfer system of claim 1, wherein the first and second electrical bus elements are disposed along a common edge of the electrocaloric element.

11. The heat transfer system of claim 1, comprising at least two adjacent electrocaloric elements that share an electrode at least partially embedded between the electrocaloric films of the adjacent electrocaloric elements.

12. The heat transfer system of claim 11, wherein the embedded electrode is a live electrode, and comprising ground electrodes adjacent to the fluid flow path.

13. The heat transfer system of claim 1, further comprising one or more spacer elements between electrocaloric elements.

14. The heat transfer system of claim 13, wherein the one or more spacer elements extend axially along a direction of fluid flow along the fluid flow path or wherein the one or more axially-extending spacer elements extend linearly along a direction of fluid flow along the fluid flow path, or wherein the one or more axially-extending spacer elements extend non-linearly along a direction of fluid flow along the fluid flow path.

15. (canceled)

16. (canceled)

17. The heat transfer system of claim 13, wherein the one or more spacer elements are electrically non-conductive.

18. (canceled)

19. (canceled)

20. The heat transfer system of claim 1, wherein said plurality of modules further comprise an electrically non-conductive support member connected to the electrocaloric element.

21. The heat transfer system of claim 20, wherein the support includes header spaces at opposing ends of the electrocaloric elements in fluid communication with the fluid flow path.

22. The heat transfer system of claim 20, wherein the supports of the plurality of modules together form an enclosure within which the electrocaloric elements and the spacer elements are disposed.

23. (canceled)

24. (canceled)

25. (canceled)

26. The heat transfer system of claim 1, wherein the first and second electrodes each comprise a metalized layer deposited on the electrocaloric film.

27. The heat transfer system of claim 1, further comprising a first thermal flow path between the fluid flow path and a heat sink a second thermal flow path between the fluid flow path and a heat source; and a controller configured to control electrical current to the electrodes and to selectively direct transfer of heat energy from the fluid flow path in thermal communication with electrocaloric element to the heat sink along the first thermal flow path or from the heat source to the fluid flow path in thermal communication with the electrocaloric element along the second thermal flow path.

28. A method of fabricating the heat transfer system claim 1, comprising assembling repeating units of said modules in a stack configuration.

Description

BACKGROUND

[0001] A wide variety of technologies exist for cooling applications, including but not limited to evaporative cooling, convective cooling, or solid state cooling such as electrothermic cooling. One of the most prevalent technologies in use for residential and commercial refrigeration and air conditioning is the vapor compression refrigerant heat transfer loop. These loops typically circulate a refrigerant having appropriate thermodynamic properties through a loop that comprises a compressor, a heat rejection heat exchanger (i.e., heat exchanger condenser), an expansion device and a heat absorption heat exchanger (i.e., heat exchanger evaporator). Vapor compression refrigerant loops effectively provide cooling and refrigeration in a variety of settings, and in some situations can be run in reverse as a heat pump. However, many of the refrigerants can present environmental hazards such as ozone depleting potential (ODP) or global warming potential (GWP), or can be toxic or flammable. Additionally, vapor compression refrigerant loops can be impractical or disadvantageous in environments lacking a ready source of power sufficient to drive the mechanical compressor in the refrigerant loop. For example, in an electric vehicle, the power demand of an air conditioning compressor can result in a significantly shortened vehicle battery life or driving range. Similarly, the weight and power requirements of the compressor can be problematic in various portable cooling applications.

[0002] Accordingly, there has been interest in developing cooling technologies as alternatives to vapor compression refrigerant loops. Various technologies have been proposed such as field-active heat or electric current-responsive heat transfer systems relying on materials such as electrocaloric materials, magnetocaloric materials, or thermoelectric materials. However, many proposals have been configured as bench-scale demonstrations with limited capabilities for scalability or mass production.

BRIEF DESCRIPTION

[0003] In some embodiments of this disclosure, a heat transfer system comprises a plurality of modules arranged in a stack. The stack modules comprise an electrocaloric element comprising an electrocaloric film. A first electrode is disposed on a first side of the electrocaloric film, and a second electrode is disposed on a second side of the electrocaloric film. A fluid flow path is disposed between two or more electrocaloric elements. A first electrical bus element in electrical contact with the first electrode, and a second electrical bus element in electrical contact with second electrode. The first electrical bus element is electrically connected to at least one other electrical bus of another electrocaloric element in the stack at the same polarity as said first electrical bus, or the second electrical bus element is electrically connected to at least one other electrical bus of another electrocaloric element in the stack at the same polarity as said second electrical bus.

[0004] The first electrical bus element is electrically connected to at least one other electrical bus of another electrocaloric element in the stack at the same polarity as said first electrical bus, and the second electrical bus element is electrically connected to at least one other electrical bus of another electrocaloric element in the stack at the same polarity as said second electrical bus.

[0005] In any of the foregoing embodiments, the first or second electrical bus is electrically connected to an electrical bus of an adjacent electrocaloric element in the stack at the same polarity as said first or second electrical bus.

[0006] In any of the foregoing embodiments, the first and second electrical bus elements are each electrically connected to electrical bus elements of an adjacent electrocaloric element in the stack at the same polarities as said first and second electrical bus elements, respectively.

[0007] In any of the foregoing embodiments, the first or second electrical bus element is in an interlocking configuration with an electrical bus of an adjacent electrocaloric element in the stack.

[0008] In any of the foregoing embodiments, the first and second electrical bus elements are each in an interlocking configuration to electrical bus elements of an adjacent electrocaloric element in the stack.

[0009] In any of the foregoing embodiments, the first electrical bus element is electrically connected to a live electrode and the second electrical bus element is electrically connected to a ground electrode.

[0010] In any of the foregoing embodiments, the first and second electrical bus elements are disposed along opposite edges of the electrocaloric element.

[0011] In any of the foregoing embodiments, the first electrode extends from the first electrical bus element along the first side of the electrocaloric film to a position physically separated from the second electrical bus element, and the second electrode extends from the second electrical bus element along the second side of the electrocaloric film to a position physically separated from the first electrical bus element.

[0012] In any of the foregoing embodiments, the first and second electrical bus elements are disposed along a common edge of the electrocaloric element.

[0013] In any of the foregoing embodiments, at least two adjacent electrocaloric elements that share an electrode are at least partially embedded between the electrocaloric films of the adjacent electrocaloric elements.

[0014] In any of the foregoing embodiments, the embedded electrode is a live electrode, and comprising ground electrodes adjacent to the fluid flow path.

[0015] In any of the foregoing embodiments, one or more spacer elements are disposed between electrocaloric elements.

[0016] In any of the foregoing embodiments, the one or more spacer elements extend axially along a direction of fluid flow along the fluid flow path.

[0017] In any of the foregoing embodiments, the one or more axially-extending spacer elements extend linearly along a direction of fluid flow along the fluid flow path.

[0018] In any of the foregoing embodiments, the one or more axially-extending spacer elements extend non-linearly along a direction of fluid flow along the fluid flow path.

[0019] In any of the foregoing embodiments, the one or more spacer elements are electrically non-conductive.

[0020] In any of the foregoing embodiments, the electrocaloric element thickness is 1 .mu.m to 1000 .mu.m.

[0021] In any of the foregoing embodiments, the physical separation between electrocaloric elements in adjacent modules is from 1 .mu.m to 200 mm.

[0022] In any of the foregoing embodiments, the plurality of modules further comprise an electrically non-conductive support member connected to the electrocaloric element.

[0023] In any of the foregoing embodiments, the support includes header spaces at opposing ends of the electrocaloric elements in fluid communication with the fluid flow path.

[0024] In any of the foregoing embodiments, the supports of the plurality of modules together form an enclosure within which the electrocaloric elements and the spacer elements are disposed.

[0025] In any of the foregoing embodiments, the electrocaloric film comprises an electrocaloric polymer.

[0026] In any of the foregoing embodiments, the electrocaloric polymer comprises polyvinylidene fluoride (PVDF) or a liquid crystal polymer (LCP),

[0027] In any of the foregoing embodiments, the electrocaloric film comprises an inorganic electrocaloric material.

[0028] In any of the foregoing embodiments, the first and second electrodes each comprise a metalized layer deposited on the electrocaloric film.

[0029] In some embodiments, a heat transfer system comprises an electrocaloric element formed by the method of any of the above embodiments, a first thermal flow path between the electrocaloric element and a heat sink, a second thermal flow path between the electrocaloric element and a heat source, and a controller configured to control electrical current to the conductive layers and to selectively direct transfer of heat energy from the electrocaloric element to the heat sink along the first thermal flow path or from the heat source to the electrocaloric element along the second thermal flow path.

[0030] In another aspect, a method of fabricating the heat transfer system of any of the foregoing embodiments comprises assembling repeating units of the modules in a stack configuration.

BRIEF DESCRIPTION OF THE DRAWINGS

[0031] Subject matter of this disclosure is particularly pointed out and distinctly claimed in the claims at the conclusion of the specification. The foregoing and other features, and advantages of the present disclosure are apparent from the following detailed description taken in conjunction with the accompanying drawings in which:

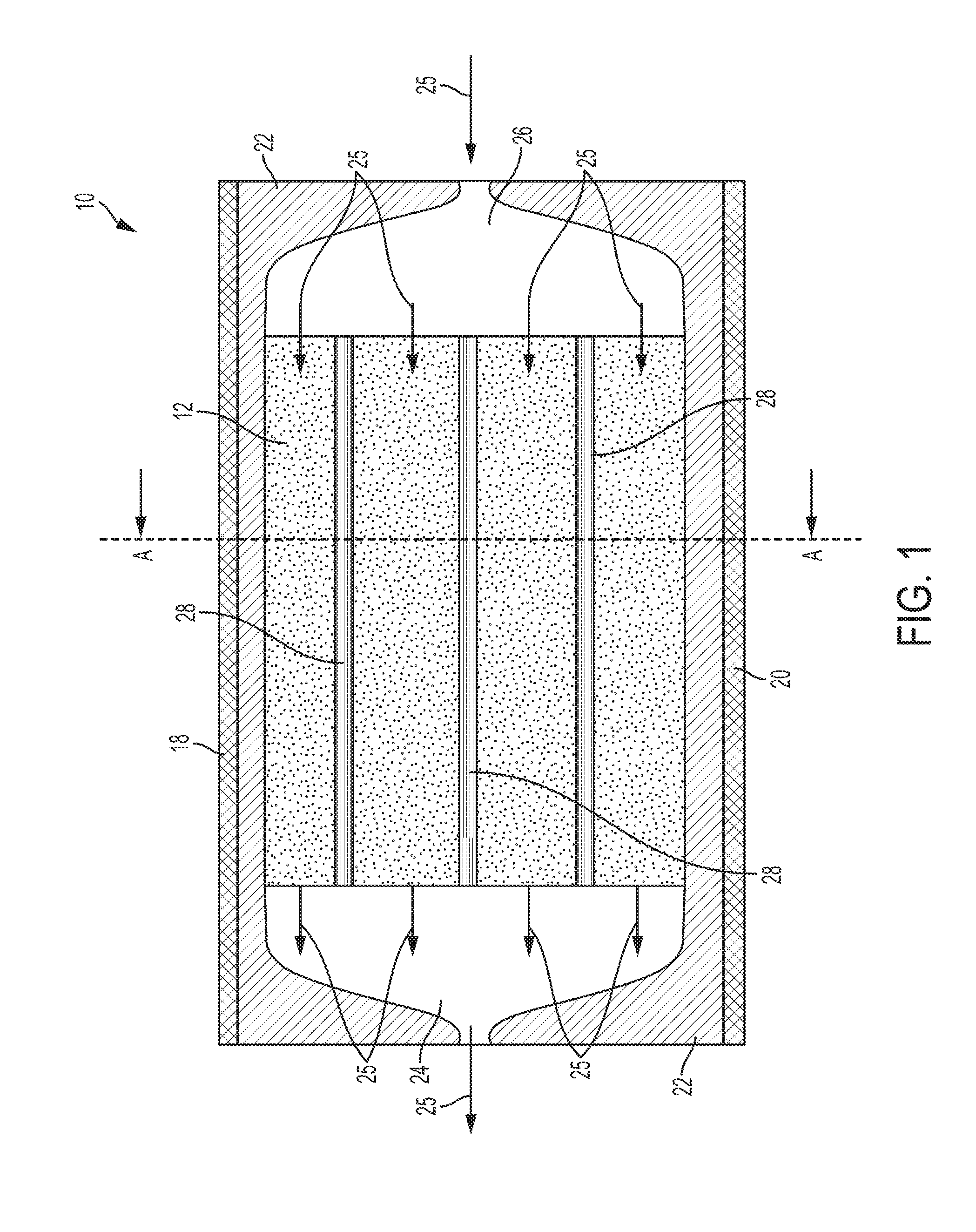

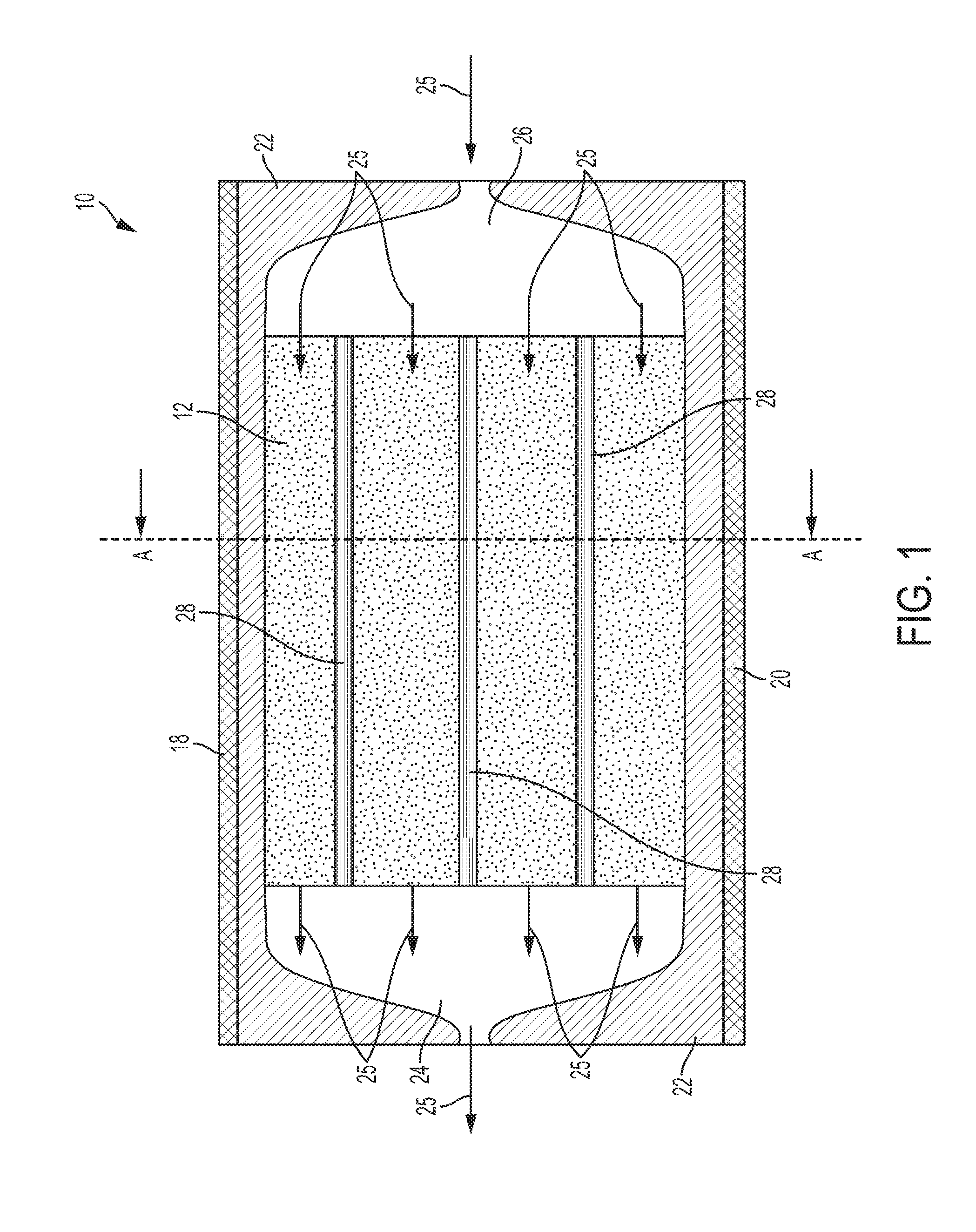

[0032] FIG. 1 is a schematic depiction of a top view of an example embodiment of an electrocaloric heat transfer module;

[0033] FIG. 2 is a schematic depiction of a cross-section side view of an example embodiment of an electrocaloric heat transfer module;

[0034] FIG. 3A is a schematic depiction of an exploded perspective view of an electrode and electrocaloric film configuration;

[0035] FIG. 3B is a top view of a portion of the configuration of FIG. 4 with an electric bus element:

[0036] FIG. 4 is a schematic depiction of an example embodiment of a stack assembly of a number of electrocaloric heat transfer modules;

[0037] FIG. 5 is a schematic depiction of an alternate example embodiment of a stack assembly of a number of electrocaloric heat transfer modules and

[0038] FIG. 6 is a schematic depiction of an example embodiment of heat transfer system comprising an electrocaloric stack and other components.

DETAILED DESCRIPTION

[0039] As mentioned above, a heat transfer system is disclosed that comprises a plurality of modules arranged in a stack. An example of an embodiment of a module is schematically depicted in FIGS. 1 and 2. Although any directions described herein (e.g., "up", "down", "top", "bottom", "left", "right", "over", "under", etc.) are considered to be arbitrary and to not have any absolute meaning but only a meaning relative to other directions, FIG. 1 can be described as a "top" view of an example embodiment of a module and FIG. 2 can be described as a "side" cross-section view taken along the line A4A shown in FIG. 1. As shown in FIGS. 1 and 2, a module 10 comprises an electrocaloric element comprises an electrocaloric film 12, a first electrode 14 on a first side of the film and a second electrode 16 on a second side of the film. It is noted that, for ease of illustration so that details of the electrocaloric film 12 and other components are not obscured, the electrodes 14, 16 are omitted from FIG. 1 and are only illustrated in FIG. 2.

[0040] The electrocaloric film 12 can comprise any of a number of electrocaloric materials. In some embodiments, electrocaloric film thickness can be in a range from having a lower limit of 0.1 .mu.m, more specifically 0.5 .mu.m, and even more specifically 1 .mu.m. In some embodiments, the film thickness range can and having an upper limit of 1000 .mu.m, more specifically 100 .mu.m, and even more specifically 10 .mu.m. It is understood that these upper and lower range limits can be independently combined to disclose a number of different possible ranges. Examples of electrocaloric materials for the electrocaloric film can include but are not limited to inorganic materials (e.g., ceramics), electrocaloric polymers, and polymer/ceramic composites. Examples of inorganics include but are not limited to PbTiO.sub.3 ("PT"), Pb(Mg.sub.1/3Nb.sub.2/3)O.sub.3 ("PMN"), PMN-PT, LiTaO.sub.3, barium strontium titanate (BST) or PZT (lead, zirconium, titanium, oxygen). Examples of electrocaloric polymers include, but are not limited to ferroelectric polymers, liquid crystal polymers, and liquid crystal elastomers.

[0041] Ferroelectric polymers are crystalline polymers, or polymers with a high degree of crystallinity, where the crystalline alignment of polymer chains into lamellae and/or spherulite structures can be modified by application of an electric field. Such characteristics can be provided by polar structures integrated into the polymer backbone or appended to the polymer backbone with a fixed orientation to the backbone. Examples of ferroelectric polymers include polyvinylidene fluoride (PVDF), polytriethylene fluoride, odd-numbered nylon, copolymers containing repeat units derived from vinylidene fluoride, and copolymers containing repeat units derived from triethylene fluoride. Polyvinylidene fluoride and copolymers containing repeat units derived from vinylidene fluoride have been widely studied for their ferroelectric and electrocaloric properties. Examples of vinylidene fluoride-containing copolymers include copolymers with methyl methacrylate, and copolymers with one or more halogenated co-monomers including but not limited to trifluoroethylene, tetrafluoroethylene, chlorotrifluoroethylene, trichloroethylene, vinylidene chloride, vinyl chloride, and other halogenated unsaturated monomers.

[0042] Liquid crystal polymers, or polymer liquid crystals comprise polymer molecules that include mesogenic groups. Mesogenic molecular structures are well-known, and are often described as rod-like or disk-like molecular structures having electron density orientations that produce a dipole moment in response to an external field such as an external electric field. Liquid crystal polymers typically comprise numerous mesogenic groups connected by non-mesogenic molecular structures. The non-mesogenic connecting structures and their connection, placement and spacing in the polymer molecule along with mesogenic structures are important in providing the fluid deformable response to the external field. Typically, the connecting structures provide stiffness low enough so that molecular realignment is induced by application of the external field, and high enough to provide the characteristics of a polymer when the external field is not applied.

[0043] In some exemplary embodiments, a liquid crystal polymer can have rod-like mesogenic structures in the polymer backbone separated by non-mesogenic spacer groups having flexibility to allow for re-ordering of the mesogenic groups in response to an external field. Such polymers are also known as main-chain liquid crystal polymers. In some exemplary embodiments, a liquid crystal polymer can have rod-like mesogenic structures attached as side groups attached to the polymer backbone. Such polymers are also known as side-chain liquid crystal polymers.

[0044] With continued reference to FIGS. 1 and 2, first electrode 14 is electrically connected to a first electrical bus element 18. Similarly, second electrode 16 is electrically connected to second electrical bus element 20. The electrodes can be any type of conductive material, including but not limited to metallized layers of a conductive metal such as aluminum or copper, or other conductive materials such as carbon (e.g., carbon nanotubes, graphene, or other conductive carbon). Noble metals can also be used, but are not required. Other conductive materials such as a doped semiconductor, ceramic, or polymer, or conductive polymers can also be used. In some embodiments, the electrical bus elements 18 and 20 of opposite polarity are disposed on opposite edges of the electrocaloric film 12 as shown in FIG. 2, which can in some embodiments provide a physical separation that can reduce the risk of short circuits. As also shown in FIG. 2, the electrodes 14 and 16 can extend from a position in contact with an electrical bus element on one edge of the film and extend across the film to a position that is not in contact with the electrical bus element of opposite polarity on the other edge of the film 12. In some embodiments, the electrical bus elements 18 and 20 can be disposed on the same side of the electrocaloric element as shown in FIGS. 3A and 3B. FIG. 3A is a schematic depiction of a perspective exploded view of an electrocaloric film 12 having a top electrode 14 and a bottom electrode 16. The top and bottom electrodes in FIGS. 3A and 3B have lead portions 14y and 16y for an electrical connection to an electrical bus element 19. The connection between the electrodes 14, 16 and the bus element 19 is depicted in a top view in FIG. 3B where only a portion of electrocaloric film 12 and the bus element 19 are shown. As shown in FIG. 3B, bus element has a first polarity portion 19a connected to the lead portion 14y of top electrode 14 and a second polarity portion 19b connected to the lead portion 16y of bottom electrode 16, and an electrically non-conductive portion 19c that electrically isolates the portions 19a and 19b of different polarities.

[0045] One or more support elements 22 can optionally be included for support and retention of the electrocaloric element. However, separate support elements are not required, as support and retention can also be provided by the bus elements as shown in FIG. 4 described below. As shown in FIG. 1, the support element(s) 22 can be configured to provide header spaces 24 and 26 for transport of working fluids to and from the electrocaloric element along fluid flow path 25. Although not required in all design configurations, in some embodiments, the support elements can be made from an electrically non-conductive material.

[0046] Spacer elements 28 can optionally be included to help maintain separation from adjacent electrocaloric elements for a fluid flow path for a working fluid (e.g., either a fluid to be heated or cooled directly such as air, or a heat transfer fluid such as a dielectric organic compound). Any configuration of spacer elements can be utilized, such as a set of discrete disk spacer elements. In some aspects, however, the spacer elements extend axially in a direction parallel to the direction of the fluid flow path 25. Such axial extension can be linear (i.e., in a straight line) as shown in FIG. 1, or can be non-linear (e.g., in a zig-zag or wavy pattern that extends generally in an axial direction. In some embodiments, the non-linearity can promote good fluid mixing while the general extension in the axial direction can help avoid excessive back-pressure to the flowing fluid.

[0047] Turning now to FIG. 4 where like numbering is used as FIGS. 1 and 2, a number of modules 10 are shown assembled together in a stack 30. As can be seen in FIG. 3, the spacers promote maintaining a physical separation between adjacent electrocaloric elements to provide a fluid flow path 25 between the spacers and the adjacent electrocaloric elements. Although not required in all design configurations, in design configurations where the spacer elements are disposed adjacent to electrodes of opposite polarity as shown in FIG. 3, the spacer elements can be made from an electrically non-conductive material. In some embodiments, spacing between adjacent electrocaloric elements can be in a range from having a lower limit of 1 .mu.m, more specifically 10 .mu.m, and even more specifically 50 .mu.m. In some embodiments, the separation spacing range can have an upper limit of 200 mm, more specifically 10 mm, even more specifically 2 mm. It is understood that these upper and lower range limits can be independently combined to disclose a number of different possible ranges.

[0048] In some embodiments, adjacent electrical bus elements 18, 20 can have an interlocking configuration as shown in FIG. 4. As used herein, interlocking means that adjacent elements have complementary contour of projections and recesses where a projection of one bus element projects is adjacent or projects into to a complementary recess of an adjacent bus element. Such an arrangement can in some embodiments facilitate assembly and promote structural integrity and electrical continuity of the assembled bus elements in the stack.

[0049] FIG. 4 depicts a stack with alternating electrocaloric elements and fluid flow passages; however, FIG. 4 represents only one example of a stack embodiment and is not limiting. An alternate embodiment is depicted in FIG. 5. With reference now to FIG. 5, a stack 30a is shown where bus elements 18b are connected to a bus bar 18a and bus elements 20b are connected to a bus bar 20a. As shown in FIG. 5 the electrodes 16a electrically connected to bus elements 20b are at least partially embedded between the electrocaloric films 12 of adjacent electrocaloric elements. In this embodiment, the electrode 16a serves as an electrode for two adjacent electrocaloric elements or, put another way, the two adjacent electrocaloric elements share a single electrode. The electrodes 14a of opposite polarity are disposed on the outside of the electrocaloric element `sandwich` and are not shared. This configuration can provide technical benefits by protecting the embedded electrode 16a from potential short circuits. In some embodiments, the at least partially embedded electrode is a live electrode, and the electrode exposed to the fluid flow path 25 is a ground electrode. It should be noted that although FIG. 5 depicts a sandwich of two films surrounding the embedded electrode, sandwiches of more than two films with embedded electrodes of alternating polarities are also contemplated.

[0050] An example embodiment of a heat transfer system and its operation are further described with respect to FIG. 6. As shown in FIG. 6, a heat transfer system 310 comprises an electrocaloric stack 311 has one or more electrically conductive liquids in thermal communication with a heat sink 317 through a first thermal flow path 318, and in thermal communication with a heat source 320 through a second thermal flow path 322. A controller 324 is configured to control electrical current to through a power source (not shown) to selectively activate electrocaloric elements (not shown) in the stack 311. The controller 324 is also configured to open and close control valves 326 and 328 to selectively direct the electrically conductive liquid along the first and second flow paths 318 and 322.

[0051] In operation, the system 310 can be operated by the controller 324 applying an electric field as a voltage differential across the electrocaloric elements in the stack 311 to cause a decrease in entropy and a release of heat energy by the electrocaloric elements. The controller 324 opens the control valve 326 to transfer at least a portion of the released heat energy along flow path 318 to heat sink 317. This transfer of heat can occur after the temperature of the electrocaloric elements has risen to a threshold temperature. In some embodiments, heat transfer to the heat sink 317 is begun as soon as the temperature of the electrocaloric elements increases to be about equal to the temperature of the heat sink 317. After application of the electric field for a time to induce a desired release and transfer of heat energy from the electrocaloric elements to the heat sink 317, the electric field can be removed. Removal of the electric field causes an increase in entropy and a decrease in heat energy of the electrocaloric elements. This decrease in heat energy manifests as a reduction in temperature of the electrocaloric elements to a temperature below that of the heat source 320. The controller 324 closes control valve 326 to terminate flow along flow path 318, and opens control device 328 to transfer heat energy from the heat source 320 to the colder electrocaloric elements.

[0052] In some embodiments, for example where a heat transfer system is utilized to maintain a temperature in a conditioned space or thermal target, the electric field can be applied to the electrocaloric elements to increase its temperature until the temperature of the electrocaloric element reaches a first threshold. After the first temperature threshold, the controller 324 opens control valve 326 to transfer heat from the electrocaloric elements to the heat sink 317 until a second temperature threshold is reached. The electric field can continue to be applied during all or a portion of the time period between the first and second temperature thresholds, and is then removed to reduce the temperature of the electrocaloric elements until a third temperature threshold is reached. The controller 324 then closes control valve 326 to terminate heat flow transfer along heat flow path 318, and opens control valve 328 to transfer heat from the heat source 320 to the electrocaloric elements. The above steps can be optionally repeated until a target temperature of the conditioned space or thermal target (which can be either the heat source or the heat sink) is reached.

[0053] While the present disclosure has been described in detail in connection with only a limited number of embodiments, it should be readily understood that the present disclosure is not limited to such disclosed embodiments. Rather, the present disclosure can be modified to incorporate any number of variations, alterations, substitutions or equivalent arrangements not heretofore described, but which are commensurate with the spirit and scope of the present disclosure. Additionally, while various embodiments of the present disclosure have been described, it is to be understood that aspects of the present disclosure may include only some of the described embodiments. Accordingly, the present disclosure is not to be seen as limited by the foregoing description, but is only limited by the scope of the appended claims.

* * * * *

D00000

D00001

D00002

D00003

D00004

D00005

D00006

XML

uspto.report is an independent third-party trademark research tool that is not affiliated, endorsed, or sponsored by the United States Patent and Trademark Office (USPTO) or any other governmental organization. The information provided by uspto.report is based on publicly available data at the time of writing and is intended for informational purposes only.

While we strive to provide accurate and up-to-date information, we do not guarantee the accuracy, completeness, reliability, or suitability of the information displayed on this site. The use of this site is at your own risk. Any reliance you place on such information is therefore strictly at your own risk.

All official trademark data, including owner information, should be verified by visiting the official USPTO website at www.uspto.gov. This site is not intended to replace professional legal advice and should not be used as a substitute for consulting with a legal professional who is knowledgeable about trademark law.