Rod reducer, compressor, distractor system

McClintock , et al. October 13, 2

U.S. patent number RE48,250 [Application Number 16/545,644] was granted by the patent office on 2020-10-13 for rod reducer, compressor, distractor system. This patent grant is currently assigned to K2M, Inc.. The grantee listed for this patent is K2M, Inc.. Invention is credited to Clint Boyd, Larry E. McClintock.

View All Diagrams

| United States Patent | RE48,250 |

| McClintock , et al. | October 13, 2020 |

Rod reducer, compressor, distractor system

Abstract

A compressor/distractor system for operating on a spine is disclosed. The system includes two rod reducers which each advance a spinal rod into the shoulder portion of a pedicle screw. Each rod reducer includes an inner member, an outer member, and a pair of gripping members. Each outer member receives and advances the spinal rod into the pedicle screw. The outer member also includes a through slot which receives the proximal end of each of the pair of gripping members which may limit the longitudinal translation of the outer member with respect to the inner member. The compressor/distractor system may include a compressor/distractor device which has a compressing, a distracting, and a neutral configuration. A method for using the minimally invasive rod reducers with the compressor/distractor system to secure at least two pedicle screws in desired positions on a spinal rod is also disclosed.

| Inventors: | McClintock; Larry E. (Gore, VA), Boyd; Clint (Winchester, VA) | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Applicant: |

|

||||||||||

| Assignee: | K2M, Inc. (Leesburg,

VA) |

||||||||||

| Family ID: | 48780504 | ||||||||||

| Appl. No.: | 16/545,644 | ||||||||||

| Filed: | August 20, 2019 |

Related U.S. Patent Documents

| Application Number | Filing Date | Patent Number | Issue Date | ||

|---|---|---|---|---|---|

| 13741934 | Sep 8, 2015 | 9125703 | |||

| 61586928 | Jan 16, 2012 | ||||

| Reissue of: | 14828909 | Aug 18, 2015 | 9737351 | Aug 22, 2017 | |

| Current U.S. Class: | 1/1 |

| Current CPC Class: | A61B 17/7086 (20130101); A61B 17/7077 (20130101); A61B 17/7079 (20130101); A61B 17/708 (20130101); A61B 17/88 (20130101); A61B 17/88 (20130101); A61B 17/7085 (20130101); A61B 17/7079 (20130101); A61B 17/708 (20130101); A61B 17/7085 (20130101); A61B 17/7086 (20130101) |

| Current International Class: | A61B 17/88 (20060101); A61B 17/70 (20060101) |

References Cited [Referenced By]

U.S. Patent Documents

| 1920821 | August 1933 | Wassenaar |

| 3244170 | April 1966 | McElvenny |

| 3997138 | December 1976 | Crock et al. |

| 4263899 | April 1981 | Burgin |

| 4382438 | May 1983 | Jacobs |

| 4409968 | October 1983 | Drummond |

| 4411259 | October 1983 | Drummond |

| 4957495 | September 1990 | Kluger |

| 5010879 | April 1991 | Moriya et al. |

| 5059194 | October 1991 | Michelson |

| 5167662 | December 1992 | Hayes |

| 5242443 | September 1993 | Kambin |

| 5281223 | January 1994 | Ray |

| 5385565 | January 1995 | Ray |

| 5478340 | December 1995 | Kluger |

| 5487743 | January 1996 | Laurain et al. |

| 5529571 | June 1996 | Daniel |

| 5591167 | January 1997 | Laurain et al. |

| 5672175 | September 1997 | Martin |

| 5685826 | November 1997 | Bonutti |

| 5704937 | January 1998 | Martin |

| RE36221 | June 1999 | Breard et al. |

| 5944658 | August 1999 | Koros et al. |

| 6090113 | July 2000 | Le Couedic et al. |

| 6123707 | September 2000 | Wagner |

| 6146386 | November 2000 | Blackman et al. |

| 6200322 | March 2001 | Branch et al. |

| 6485518 | November 2002 | Cornwall et al. |

| 6506151 | January 2003 | Estes et al. |

| 6530929 | March 2003 | Justis et al. |

| 6616605 | September 2003 | Wright et al. |

| 6616666 | September 2003 | Michelson |

| 6616667 | September 2003 | Steiger et al. |

| 6712818 | March 2004 | Michelson |

| 6849064 | February 2005 | Hamada |

| 6929606 | August 2005 | Ritland |

| 7008422 | March 2006 | Foley et al. |

| 7011660 | March 2006 | Sherman et al. |

| 7083621 | August 2006 | Shaolian et al. |

| 7160300 | January 2007 | Jackson |

| 7179261 | February 2007 | Sicvol et al. |

| 7188626 | March 2007 | Foley et al. |

| 7250052 | July 2007 | Landry et al. |

| 7462182 | December 2008 | Lim |

| 7491208 | February 2009 | Pond, Jr. et al. |

| 7591836 | September 2009 | Dick et al. |

| 7625379 | December 2009 | Puno et al. |

| 7651502 | January 2010 | Jackson |

| 7655008 | February 2010 | Lenke et al. |

| 7666189 | February 2010 | Gerber et al. |

| 7794464 | September 2010 | Bridwell et al. |

| 7854751 | December 2010 | Sicvol et al. |

| 7922749 | April 2011 | Dewey |

| 7927334 | April 2011 | Miller et al. |

| 7946982 | May 2011 | Hamada |

| 7951168 | May 2011 | Chao et al. |

| 7951175 | May 2011 | Chao et al. |

| 7955355 | June 2011 | Chin |

| 7981115 | July 2011 | Justis |

| 7988694 | August 2011 | Barrus et al. |

| 8002798 | August 2011 | Chin et al. |

| 8007516 | August 2011 | Chao et al. |

| 8147524 | April 2012 | Piza Vallespir |

| 8157809 | April 2012 | Butters et al. |

| 8192438 | June 2012 | Garamszegi |

| 8206395 | June 2012 | McLean et al. |

| 8221426 | July 2012 | Justis |

| 8221474 | July 2012 | Bridwell et al. |

| 8230863 | July 2012 | Ravikumar et al. |

| 8277453 | October 2012 | Kave et al. |

| 8298138 | October 2012 | Gorek et al. |

| 8303595 | November 2012 | Jones |

| 8308729 | November 2012 | Nunley et al. |

| 8308774 | November 2012 | Hoffman et al. |

| 8506574 | August 2013 | Butters et al. |

| 8545505 | October 2013 | Sandstrom et al. |

| 8702713 | April 2014 | Nayet et al. |

| 8764757 | July 2014 | Tumialan |

| 8784424 | July 2014 | Tsuang |

| 8894655 | November 2014 | Fallin et al. |

| 8915925 | December 2014 | Butters et al. |

| 9125703 | September 2015 | McClintock et al. |

| 9179947 | November 2015 | Bass |

| 9345463 | May 2016 | Butters et al. |

| 2002/0052603 | May 2002 | Nichols et al. |

| 2003/0055430 | March 2003 | Kim |

| 2003/0073998 | April 2003 | Pagliuca et al. |

| 2003/0187436 | October 2003 | Bolger et al. |

| 2004/0034351 | February 2004 | Sherman et al. |

| 2004/0138662 | July 2004 | Landry et al. |

| 2004/0143265 | July 2004 | Landry et al. |

| 2004/0147928 | July 2004 | Landry et al. |

| 2004/0172022 | September 2004 | Landry et al. |

| 2004/0215190 | October 2004 | Nguyen et al. |

| 2004/0230191 | November 2004 | Frey et al. |

| 2004/0260287 | December 2004 | Ferree |

| 2004/0267275 | December 2004 | Cournoyer et al. |

| 2005/0010220 | January 2005 | Casutt et al. |

| 2005/0010221 | January 2005 | Dalton |

| 2005/0021030 | January 2005 | Pagliuca et al. |

| 2005/0021031 | January 2005 | Foley et al. |

| 2005/0038436 | February 2005 | Michelson |

| 2005/0070917 | March 2005 | Justis |

| 2005/0090822 | April 2005 | DiPoto |

| 2005/0090833 | April 2005 | DiPoto |

| 2005/0131421 | June 2005 | Anderson et al. |

| 2005/0131422 | June 2005 | Anderson |

| 2005/0154389 | July 2005 | Selover et al. |

| 2005/0245928 | November 2005 | Colleran |

| 2006/0004380 | January 2006 | DiDomenico |

| 2006/0111714 | May 2006 | Foley |

| 2006/0200132 | September 2006 | Chao |

| 2006/0200135 | September 2006 | Sherman et al. |

| 2006/0247645 | November 2006 | Wilcox |

| 2006/0247649 | November 2006 | Rezach |

| 2006/0264934 | November 2006 | Fallin |

| 2007/0055247 | March 2007 | Jahng |

| 2007/0162009 | July 2007 | Chao et al. |

| 2007/0162010 | July 2007 | Chao et al. |

| 2007/0213715 | September 2007 | Bridwell |

| 2007/0233079 | October 2007 | Fallin |

| 2008/0015601 | January 2008 | Castro et al. |

| 2008/0077155 | March 2008 | Diederich |

| 2008/0119862 | May 2008 | Wicker |

| 2008/0125789 | May 2008 | Butters |

| 2008/0172062 | July 2008 | Donahue |

| 2009/0018593 | January 2009 | Barrus et al. |

| 2009/0062857 | March 2009 | Ramsay |

| 2009/0082775 | March 2009 | Altarac |

| 2009/0138056 | May 2009 | Anderson |

| 2009/0143828 | June 2009 | Stad |

| 2009/0149892 | June 2009 | Stad |

| 2009/0157125 | June 2009 | Hoffman |

| 2009/0171391 | July 2009 | Hutton |

| 2009/0228053 | September 2009 | Kolb |

| 2009/0259262 | October 2009 | Nayet |

| 2009/0326586 | December 2009 | Duarte |

| 2010/0024487 | February 2010 | Khoo |

| 2010/0030283 | February 2010 | King |

| 2010/0036443 | February 2010 | Hutton |

| 2010/0324610 | December 2010 | Bridwell et al. |

| 2010/0331849 | December 2010 | Riesinger |

| 2011/0077690 | March 2011 | Shin |

| 2011/0106082 | May 2011 | Kave |

| 2011/0130793 | June 2011 | Woolley |

| 2011/0137358 | June 2011 | Manninen |

| 2011/0152940 | June 2011 | Frigg |

| 2011/0172714 | July 2011 | Boachie-Adjei et al. |

| 2011/0172723 | July 2011 | Miller |

| 2011/0196426 | August 2011 | Peukert |

| 2011/0257692 | October 2011 | Sandstrom |

| 2011/0282402 | November 2011 | Chao et al. |

| 2011/0295328 | December 2011 | Woolley et al. |

| 2011/0313477 | December 2011 | McLean |

| 2011/0319938 | December 2011 | Piza Vallespir |

| 2012/0031792 | February 2012 | Petit |

| 2012/0035668 | February 2012 | Manninen |

| 2012/0078308 | March 2012 | Dziedzic |

| 2012/0083853 | April 2012 | Boachie-Adjei |

| 2012/0116467 | May 2012 | King et al. |

| 2012/0191137 | July 2012 | Butters et al. |

| 2012/0191143 | July 2012 | Nayet |

| 2012/0197297 | August 2012 | Bootwala |

| 2012/0239096 | September 2012 | Gleeson |

| 2012/0239097 | September 2012 | Garamszegi |

| 2012/0271365 | October 2012 | Daubs |

| 2012/0323279 | December 2012 | Tsuang |

| 2013/0012999 | January 2013 | Petit |

| 2013/0046345 | February 2013 | Jones |

| 2013/0096635 | April 2013 | Wall |

| 2013/0096637 | April 2013 | Richelsoph |

| 2013/0110184 | May 2013 | Wing |

| 2013/0172947 | July 2013 | Greenberg |

| 2013/0184763 | July 2013 | McClintock |

| 2013/0238037 | September 2013 | Stad |

| 2013/0245692 | September 2013 | Hayes |

| 2013/0245694 | September 2013 | Choi |

| 2013/0274804 | October 2013 | Hutton et al. |

| 2013/0289633 | October 2013 | Gleeson |

| 2014/0018860 | January 2014 | Butters et al. |

| 2014/0031828 | January 2014 | Patel |

| 2014/0039557 | February 2014 | Stad et al. |

| 2014/0039567 | February 2014 | Hoefer |

| 2014/0046372 | February 2014 | Ibrahim |

| 2014/0052139 | February 2014 | Manninen |

| 2014/0074106 | March 2014 | Shin |

| 2014/0074171 | March 2014 | Hutton et al. |

| 2014/0100617 | April 2014 | Sandstrom et al. |

| 2014/0100618 | April 2014 | Kolb et al. |

| 2014/0107707 | April 2014 | Rovner |

| 2014/0114354 | April 2014 | May |

| 2014/0135855 | May 2014 | Jones |

| 2014/0163575 | June 2014 | Thoren |

| 2014/0188182 | July 2014 | Chao et al. |

| 2014/0249591 | September 2014 | Peultier |

| 2014/0257312 | September 2014 | Solitario, Jr. |

| 2014/0277151 | September 2014 | Fowler |

| 2014/0277198 | September 2014 | Stad |

| 2014/0316475 | October 2014 | Parikh |

| 2015/0238235 | August 2015 | Tuten |

| 2016/0106408 | April 2016 | Ponmudi |

| 2016/0262807 | September 2016 | Benson |

| 2016/0338683 | November 2016 | Butters et al. |

| 29710979 | Aug 1997 | DE | |||

| 19726754 | Feb 1999 | DE | |||

| 10027988 | Jan 2002 | DE | |||

| 0528117 | Feb 1993 | EP | |||

| 0611116 | Aug 1994 | EP | |||

| 665731 | Aug 1995 | EP | |||

| 839513 | Jun 1981 | SU | |||

| 9409726 | May 1994 | WO | |||

| 0141681 | Jun 2001 | WO | |||

| 04021899 | Mar 2004 | WO | |||

| 04037074 | May 2004 | WO | |||

| 04041100 | May 2004 | WO | |||

| 04080318 | Sep 2004 | WO | |||

| 05018466 | Mar 2005 | WO | |||

| 05023123 | Mar 2005 | WO | |||

| 05032358 | Apr 2005 | WO | |||

| 05060534 | Jul 2005 | WO | |||

| 2006060430 | Jun 2006 | WO | |||

Other References

|

Charles Hartjen; The Atavi System, Surgical Technique Brochure. Endius, p. 1-17, undated. cited by applicant . Diapason, Surgical Texchnique Catalog, Diapasan Spinal System, Jan. 2002. cited by applicant . Kambin et al, "Percutaneous Posterolateral Lumbar Discectomy and Decompression with a 6.9-millimeter cannula", The Journal of Bone and Joint Surgery, pp. 822-831, Jul. 1991. cited by applicant . Kambin, Minimally Invasive Techniques in Spinal Surgery Current Practice, Neurosurgical Focus, wwwspineuniversecom, 16 pages, printed Aug. 24, 2005. cited by applicant . Leu et al., Percutaneous Fusion of the Lumbar Spine, State of the Art Reviews, vol. 6, No. 3, pp. 593-604, Sep. 1992. cited by applicant . Pathfinder; Minimally Invasive Pedicie Fixation System. Spinal Concepts Product Brochure p. 1-4, May 2003. cited by applicant. |

Primary Examiner: Reip; David O

Attorney, Agent or Firm: Lerner, David, Littenberg, Krumholz & Mentlik, LLP

Parent Case Text

CROSS-REFERENCE TO RELATED APPLICATIONS

The present application is .Iadd.an application for the reissue of U.S. Pat. No. 9,737,351, which is .Iaddend.a divisional of U.S. patent application Ser. No. 13/741,934, filed .[.Jun..]. .Iadd.Jan. .Iaddend.15, 2013, which claims the benefit of, and priority to, U.S. Provisional Application Ser. No. 61/586,928, filed on Jan. 16, 2012. The entire contents of each of the above applications are incorporated herein by reference.

Claims

What is claimed:

1. A method for manipulating vertebrae comprising: accessing the spinal area of a patient having a pedicle screw secured to each of at least two vertebrae; engaging each pedicle screw with an inner member having distal and proximal ends defining a longitudinal axis therebetween, the distal end of each inner member receiving a head of the pedicle screw; advancing an outer member having distal and proximal ends distally along each of the inner members by rotating the proximal end of each of the outer members relative to each inner member, a pair of receiving slots on the distal end of each outer member receiving a portion of a spinal rod, each pair of receiving slots advancing the spinal rod into a saddle portion of the head of each pedicle screw; attaching a force applying device and a fulcrum to an outer surface of each outer member, the force applying device including first and second hook members and having a compressing configuration when the first and second hook members are attached to each outer member with each of the outer members between the first and second hook members and a distracting configuration when the first and second hook members are attached to each outer member with the first and second hook members between each of the outer members; manipulating each outer member with the force applying device until each of the pedicle screws is in a desired position with respect to the spinal rod; and securing each pedicle screw to the spinal rod with a set screw.

2. The method of claim 1, wherein the force applying device further includes a neutral configuration and the second hook member includes a switch assembly having a first, a second, and a third position, each position corresponding to a configuration of the force applying device.

3. The method of claim 1, wherein the first and second hook members each include a hook portion, each hook portion having a compressing hook and a distracting hook.

4. The method of claim 1, wherein the fulcrum is attached to a gripping portion of each outer member.

5. The method of claim 1, wherein the step of advancing further includes attaching an anti-torque handle to a distal segment of each outer member and attaching a turning handle to a proximal segment of each outer member.

6. The method of claim 1, wherein the method further includes the step of inserting at least one set screw through an inner member and at least partially locking the rod to at least one of the pedicle screws before the step of manipulating the each outer member.

7. A method for manipulating vertebrae comprising: securing a first elongate member to a first pedicle screw that is secured in a first vertebra; securing a second elongate member to a second pedicle screw that is secured in a second vertebra; and manipulating the first and second elongate members with a force applying device until the first and second pedicle screws are in a desired position, the force applying device having first and second hook members, each hook member having a distracting hook and a compressing hook.

8. The method according .[.of.]. .Iadd.to .Iaddend.claim 7, wherein manipulating the first and second elongate members with the force applying device includes positioning the first and second elongate members between the first and second hook members of the force applying device to compress the first and second elongate members towards one another.

9. The method according .[.of.]. .Iadd.to .Iaddend.claim 7, wherein manipulating the first and second elongate members with the force applying device includes positioning the first and second hook members of the force applying device between the first and second elongate members to distract the first and second elongate members away from one another.

10. The method according .[.of.]. .Iadd.to .Iaddend.claim 7, further comprising positioning a fulcrum over a .[.distal.]. .Iadd.proximal .Iaddend.end of each of the first and second elongate members before manipulating the first and second elongate members with the force applying device.

11. The method according to claim 10, wherein manipulating the elongate members with the force applying device includes engaging the first elongate member with the first hook member between the fulcrum and the pedicle screw and engaging the second elongate member with the second hook member between the fulcrum and the pedicle screw.

12. The method according .[.of.]. .Iadd.to .Iaddend.claim 7, further comprising: reducing a spinal rod into a head of the first pedicle screw with the first elongate member; and reducing the spinal rod into a head of the second pedicle screw with the second elongate member.

13. A method for manipulating vertebrae comprising: securing a first elongate member to a first pedicle screw that is secured in a first vertebra; securing a second elongate member to a second pedicle screw that is secured in a second vertebra; and manipulating the first and second elongate members with a force applying device until the first and second pedicle screws are in a desired position, the force applying device having a compressing configuration, a distracting configuration, and a neutral configuration and including two hook members, at least one of the two hook members including switch assembly for selecting a respective one of the compressing, distracting, and neutral configurations, the switch assembly defining detents which each correspond to a respective one of the compressing, distracting, and neutral configurations of the force applying device.

.Iadd.14. The method according to claim 10, wherein positioning the fulcrum over the proximal end of each of the first and second elongate members comprises positioning each of the first and second elongate members in a respective through hole of a plurality of through holes extending through the fulcrum..Iaddend.

.Iadd.15. The method according to claim 14, wherein the plurality of through holes extending through the fulcrum includes multiple through holes for each of the first and second elongate members, the through holes being spaced apart from one another such that each of the first and second elongate members can be selectively received within different ones of the multiple through holes, so as to thereby define a variable spacing between the first and second elongate members at a location where the fulcrum receives the first and second elongate members..Iaddend.

.Iadd.16. The method according to claim 15, wherein the plurality of first and second through holes are aligned along an axis of the fulcrum, the through holes being spaced apart along the axis..Iaddend.

.Iadd.17. The method according to claim 14, wherein each of the plurality of through holes includes a bearing ring received within the respective through hole..Iaddend.

.Iadd.18. The method of claim 1, wherein the fulcrum includes a plurality of through holes configured to receive each of the outer members therein..Iaddend.

.Iadd.19. The method of claim 18, wherein the plurality of through holes in the fulcrum includes multiple through holes for each of the outer members, the through holes being spaced apart from one another such that each outer member can be selectively received within different ones of the multiple through holes, so as to thereby define a variable spacing between the outer members at a location where the fulcrum receives the outer members..Iaddend.

.Iadd.20. The method of claim 19, wherein the plurality of through holes are aligned along an axis of the fulcrum, the through holes being spaced apart along the axis..Iaddend.

.Iadd.21. The method of claim 18, wherein each of the plurality of through holes includes a bearing ring received within the respective through hole..Iaddend.

.Iadd.22. The method of claim 13, further comprising engaging the first and second elongate members with a fulcrum by positioning each of the first and second elongate members in a respective through hole of a plurality of through holes extending through the fulcrum..Iaddend.

.Iadd.23. The method of claim 22, wherein the plurality of through holes extending through the fulcrum includes multiple through holes for each of the first and second elongate members, the through holes being spaced apart from one another such that each of the first and second elongate members can be selectively received within different ones of the multiple through holes, so as to thereby define a variable spacing between the first and second elongate members at a location where the fulcrum receives the first and second elongate members..Iaddend.

.Iadd.24. The method of claim 23, wherein the plurality of first and second through holes are aligned along an axis of the fulcrum, the through holes being spaced apart along the axis..Iaddend.

.Iadd.25. The method of claim 22, wherein each of the plurality of through holes includes a bearing ring received within the respective through hole..Iaddend.

.Iadd.26. A method for manipulating vertebrae comprising: securing a first elongate member to a first pedicle screw that is secured in a first vertebra; securing a second elongate member to a second pedicle screw that is secured in a second vertebra; selecting a selected spacing from a plurality of different possible spacings provided by a fulcrum having a plurality of receptacles configured to receive the first and second elongate members therein, the spacings each being characterized by a length dimension defined between any first one of the receptacles and any second one of the receptacles, such that the selected spacing is defined by the length dimension between a selected first one of the receptacles and a selected second one of the receptacles; engaging the first and second elongate members with the fulcrum by receiving the first elongate member within the selected first one of the receptacles and receiving the second elongate member within the selected second one of the receptacles so as to fix a distance between the first and second elongate members at a fulcrum location along the first and second elongate members, the distance being the length dimension defined between the selected first one of the receptacles and the selected second one of the receptacles; and applying compression and/or distraction forces to the first and second elongate members while the fulcrum fixes the distance between the first and second elongate members at the fulcrum location..Iaddend.

.Iadd.27. The method of claim 26, wherein the first and second receptacles are through holes extending through the fulcrum..Iaddend.

.Iadd.28. The method of claim 26, wherein the plurality of first and second receptacles are aligned along an axis of the fulcrum, the receptacles being spaced apart along the axis..Iaddend.

.Iadd.29. The method of claim 26, wherein each of the plurality of first and second receptacles includes a bearing ring received therein..Iaddend.

.Iadd.30. The method of claim 26, wherein each of the first and second elongate members is a rod reducer..Iaddend.

.Iadd.31. The method of claim 26, wherein each of the plurality of different possible spacings provided by the fulcrum corresponds to a different respective angle defined between the first and second elongate members when the first and second elongate members are secured to the respective first and second pedicle screws and when the first and second members are engaged with the fulcrum at the fulcrum location..Iaddend.

.Iadd.32. The method of claim 26, wherein the step of applying compression and/or distraction forces to the first and second elongate members comprises engaging a force applying device to the first and second elongate members, the force applying device being engageable to a plurality of force applying locations on each of the first and second elongate members..Iaddend.

.Iadd.33. The method of claim 32, wherein the step of engaging the force applying device to the first and second elongate members comprises engaging the force applying device to the first and second elongate members at a selected one of the force applying locations, the selected force applying location being between the fulcrum and the first and second pedicle screws..Iaddend.

.Iadd.34. The method of claim 26, wherein the fulcrum is engageable with the first and second elongate members by receiving the first and second elongate members at a variety of different fulcrum locations along a respective portion of each of the first and second elongate members..Iaddend.

Description

BACKGROUND

Technical Field

The present disclosure relates to a system and method for operating on the spine. More particularly, the present disclosure relates to a minimally invasive rod reducer, compressor/distractor system, and a method for using the compressor/distractor system to deliver a spinal rod to the head of a pedicle screw.

Background of Related Art

The spinal column is a complex system of bones and connective tissues that provide support for the human body and protection for the spinal cord and nerves. The adult spine is comprised of an upper and lower portion. The upper portion contains 24 discrete bones, which are subdivided into three areas including 7 cervical vertebrae, 12 thoracic vertebrae and 5 lumbar vertebrae. The lower portion is comprised of the sacral and coccygeal bones. The cylindrical shaped bones, called vertebral bodies, progressively increase in size from the upper portion downwards to the lower portion.

An intervertebral disc along with two posterior facet joints cushion and dampen the various translational and rotational forces exerted upon the spinal column. The intervertebral disc is a spacer located between two vertebral bodies. The facets provide stability to the posterior portion of adjacent vertebrae. The spinal cord is housed in the canal of the vertebral bodies. It is protected posteriorly by the lamina. The lamina is a curved surface with three main protrusions. Two transverse processes extend laterally from the lamina, while the spinous process extends caudally and posteriorly. The vertebral bodies and lamina are connected by a bone bridge called the pedicle.

The spine is a flexible structure capable of a large range of motion. There are various disorders, diseases, and types of injury which restrict the range of motion of the spine or interfere with important elements of the nervous system. The problems include, but are not limited to scoliosis, kyphosis, excessive lordosis, spondylolisthesis, slipped or ruptured discs, degenerative disc disease, vertebral body fracture, and tumors. Persons suffering from any of the above conditions typically experience extreme or debilitating pain and often times diminished nerve function. These conditions and their treatments can be further complicated if the patient is suffering from osteoporosis, or bone tissue thinning and loss of bone density.

Spinal fixation apparatuses are widely employed in surgical processes for correcting spinal injuries and diseases. When the disc has degenerated to the point of requiring removal, there are a variety of interbody implants that are utilized to take the place of the disc. These include polyetheretherketone ("PEEK") interbody spacers, metal cages, and cadaver and human bone implants. In order to facilitate stabilizing the spine and keeping the interbody in position, other implants are commonly employed, including longitudinally linked rods secured to coupling elements, which in turn are secured to the bone by spinal bone fixation fasteners such as pedicle screws, hooks, and others. The opposing pair of longitudinally linked rods is commonly disposed along the long axis of the spine via a posterior approach. Pedicle screws are utilized to capture these rods and can be manufactured from any biocompatible material, including cobalt chrome, stainless steel, titanium, and PEEK. It is desired to perform these procedures in a minimally invasive manner to minimize pain and reduce recovery time for the patient. Therefore, a need exists for a minimally invasive rod reducer, compressor, distractor system that can deliver the rod into the head of the pedicle screw or bone anchor while maintaining the proper screw and rod construct alignment.

A rod reducer that is small enough in diameter to work with a minimally invasive retractor, such as the rod reducer disclosed in U.S. Patent Publication No. 2013/0046345, the contents of which are hereby incorporated by reference in their entirety and a minimally invasive retractor, such as the minimally invasive retractor disclosed in U.S. Pat. No. 7,846,093, the contents of which are hereby incorporated by reference in their entirety, are also disclosed.

SUMMARY

The present disclosure is directed towards a system for operating on the spine. The system includes pedicle screws, rod reducers, and a force applying device.

According to one aspect, the rod reducers include a proximal end and a distal end and define a longitudinal axis between the proximal and distal ends. The rod reducer includes an outer member and an inner member. The inner member is selectively attachable to the housing of the pedicle screw. The outer member is axially movable relative to the inner member when the inner member is secured to the housing of the pedicle screw to secure the spinal rod within the saddle of the housing of the pedicle screw. The outer member includes a proximal segment and a distal segment. The proximal segment is rotatable for axially translating the distal segment. The distal segment is engageable with the spinal rod to secure the spinal rod within the saddle upon the axial translation of the distal segment. The proximal segment independently rotates relative to the distal segment. The rod reducer includes a pair of gripping members configured to engage the housing of the pedicle screw. The pair of gripping members is positioned between the inner and outer members of the rod reducer.

The handle assembly is selectively engageable with the rod reducer to move the outer member of the rod reducer axially relative to the inner member of the rod reducer. The handle assembly is configured to rotate the outer member so that the rotational movement of the outer member axially moves the outer member relative to the inner member. The handle assembly includes a turning handle and an anti-torque handle. The anti-torque handle is selectively engageable with the proximal end of the rod reducer and the turning handle is selectively engageable with a proximal end of the anti-torque handle.

In another aspect, an embodiment of the system includes two rod reducers, a force applying device, and a fulcrum. The force applying device is configured for selectively engaging each rod reducer. The system may also include at least one minimally invasive retraction device.

In yet another aspect, the force applying device is a compressor/distractor device including a first hook member, a second hook member, and a body portion. The body portion has a first end and a track extending from the first end. The first end includes the first hook member in a fixed position. The first end may slidably receive the first hook member in a fixed position. The track includes a set of teeth and is configured for slidably receiving the second hook member.

The second hook member includes a switch assembly and a gear assembly. The second hook member traverses the track when the gear assembly is rotated. The gear assembly may also retain the second hook member within the track. The switch assembly permits the second hook member to traverse the track in a desired direction, towards the first hook member or away from the first hook member. The switch assembly may also restrain the second hook member from traversing the track in an undesired direction.

The first and second hook members may be configured in a compressing configuration to engage the two rod reducers such that rod reducers are between the hook members. The first and second hook members may also be configured in a distracting configuration to engage the rod reducers such that the hook members are between the rod reducers.

The fulcrum is configured to receive the proximal segment of the outer member of each rod reducer and remain in a fixed position on the longitudinal axis of each rod reducer.

According to still another aspect, a method for compressing or distracting vertebrae including two minimally invasive rod reducers, a compressor/distractor system, a spinal rod, and two pedicle screws. The method includes the steps of accessing the spinal area of a patient having at least two pedicle screws secured to respective vertebrae, engaging each pedicle screw with a rod reducer, advancing the spinal rod into the head of each pedicle screw, attaching a compressor/distractor device to each rod reducer, inserting a set screw through each rod reducer, manipulating the compressor/distractor device, and securing the spinal rod to each pedicle screw.

The method may also include the step of attaching a fulcrum to the proximal segment of each outer member before rotating the gear assembly.

BRIEF DESCRIPTION OF THE DRAWINGS

The accompanying drawings, which are incorporated in and constitute a part of this specification, illustrate embodiments of the disclosure and, together with a general description of the disclosure given above, and the detailed description of the embodiments given below, serve to explain the principles of the disclosure, wherein:

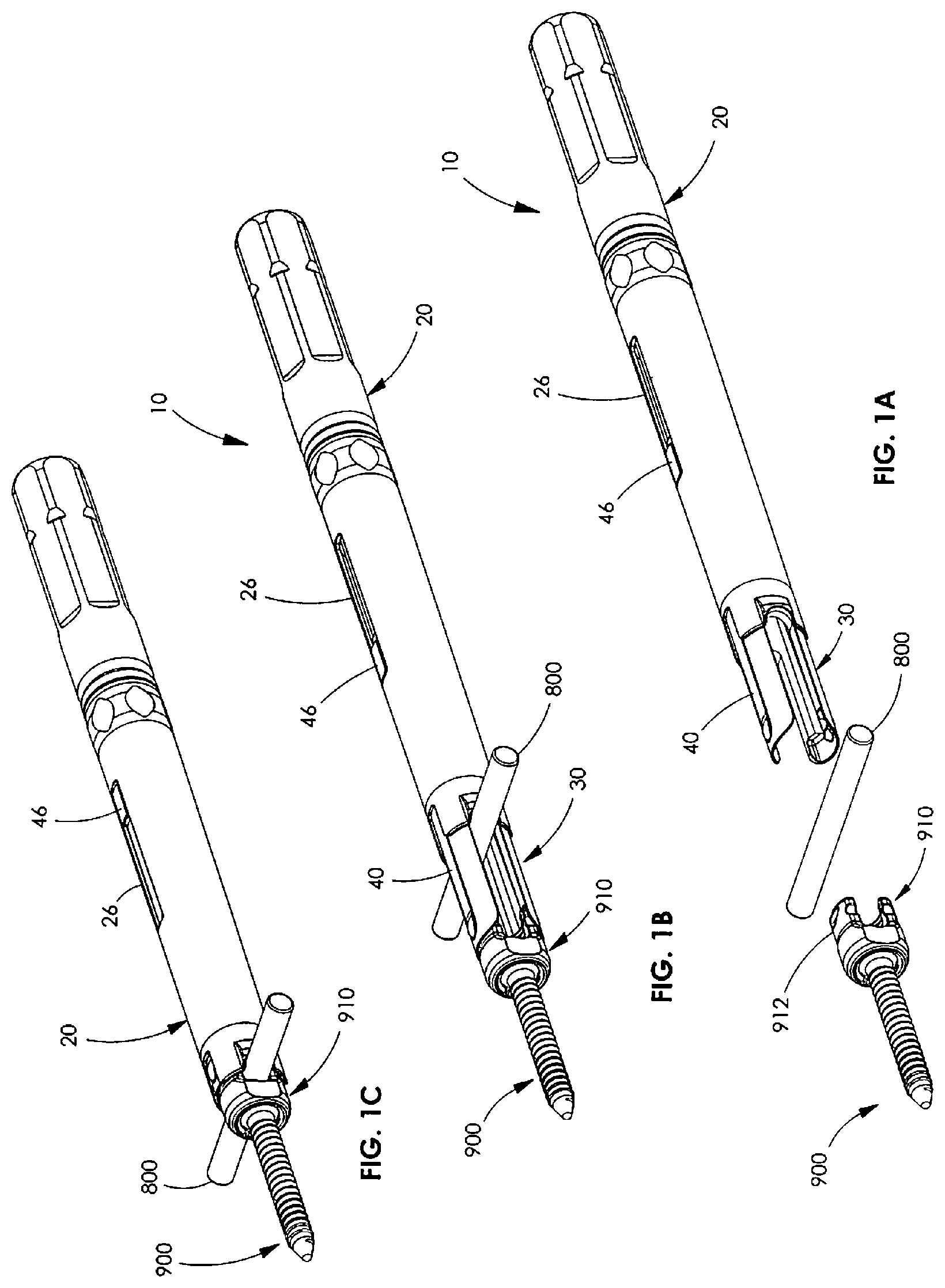

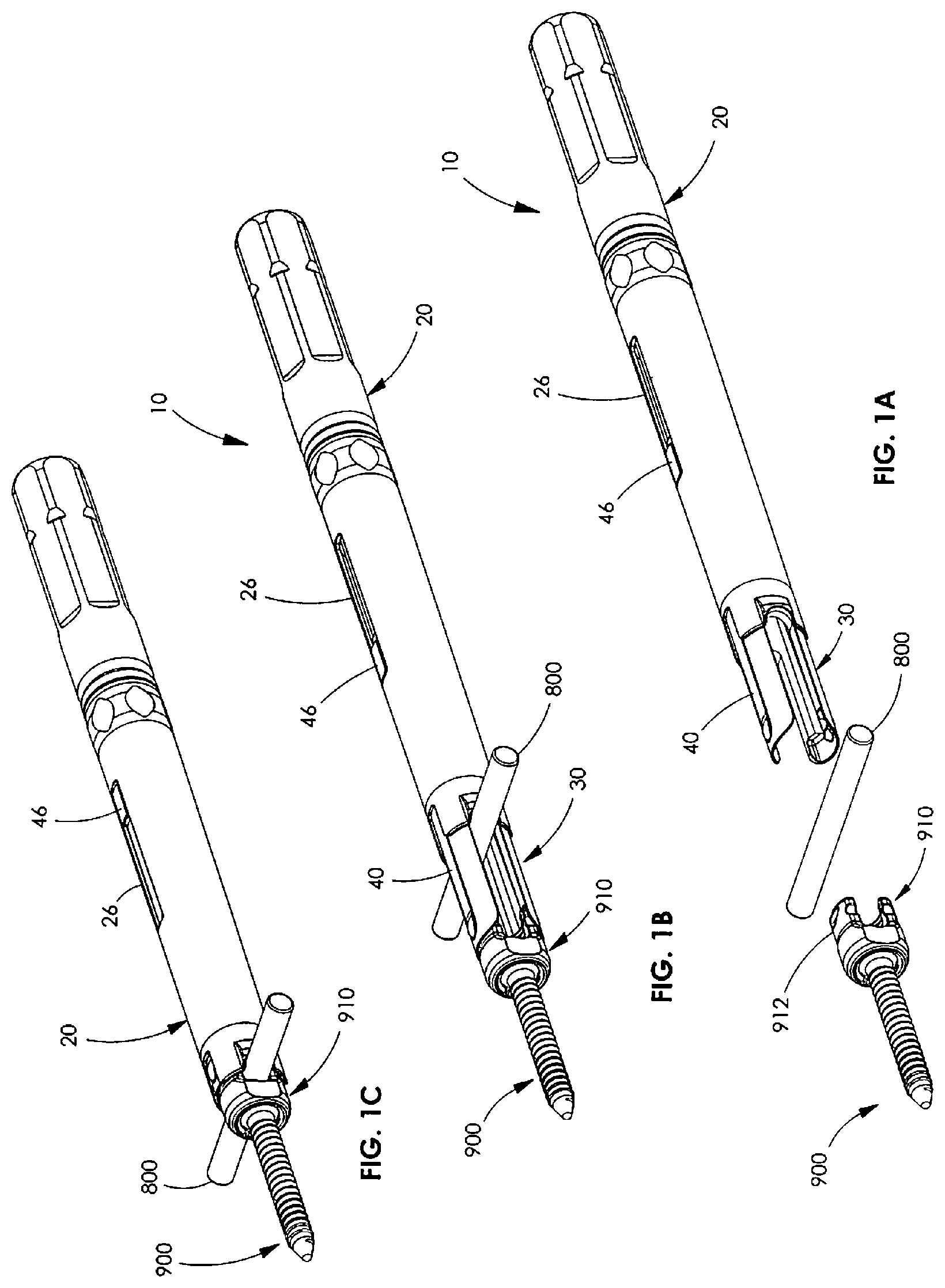

FIG. 1A is a perspective view of a minimally invasive rod reducer in accordance with the principles of the present disclosure before engagement with a rod and a pedicle screw;

FIG. 1B is a perspective view of the rod reducer of FIG. 1A after initial engagement of the rod and pedicle screw;

FIG. 1C is a perspective view of the rod reducer of FIG. 1B after the rod has been received by the shoulder portion of the pedicle screw

FIG. 2 is a perspective view of the outer member of FIG. 1A;

FIG. 3 is a exploded view of the outer member of FIG. 2;

FIG. 4 is a bottom cross-sectional view of the outer member of FIG. 2 taken along the section line 4-4;

FIG. 5 is an exploded view of the rod reducer of FIG. 1A;

FIG. 6 is a side cross-sectional view of the of the rod reducer of FIG. 1A;

FIG. 6A is an enlarged view of the detail area 6A of FIG. 6;

FIG. 7A is a perspective view of the outer member of FIG. 2 engaged with a turning handle and an anti-torque handle;

FIG. 7B is an exploded view of FIG. 7A;

FIG. 8 is a perspective view of an embodiment of a compressor/distractor system in accordance with the principles of the present disclosure in a compressing configuration;

FIG. 9 is a perspective view of the compressor/distractor system of FIG. 8 in a distracting configuration;

FIG. 10A is a perspective view of another embodiment of a compressor/distractor system in accordance with the principles of the present disclosure in a compressing configuration;

FIG. 10B is a perspective view of the compressor/distractor system of FIG. 10A in a distracting configuration;

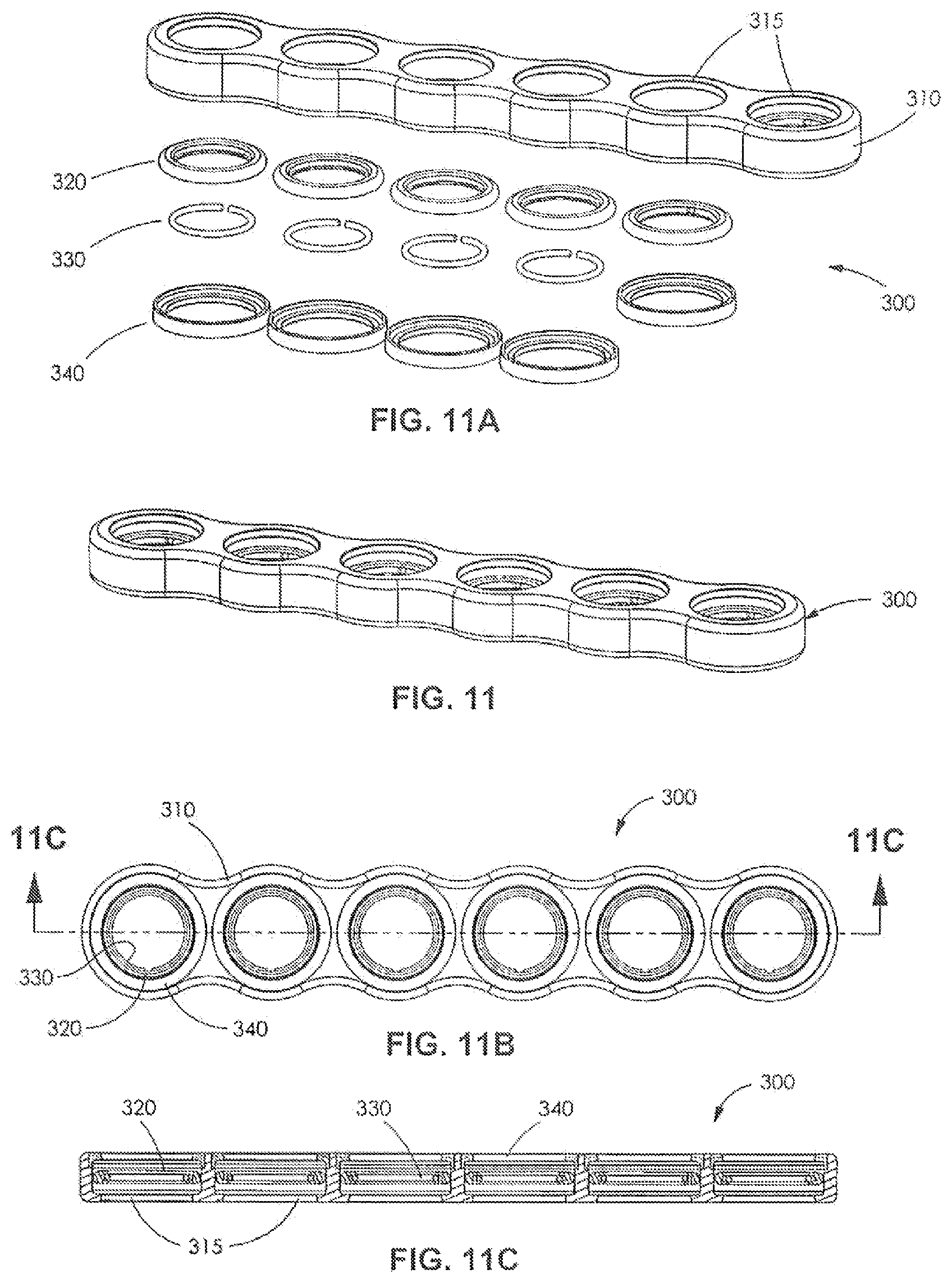

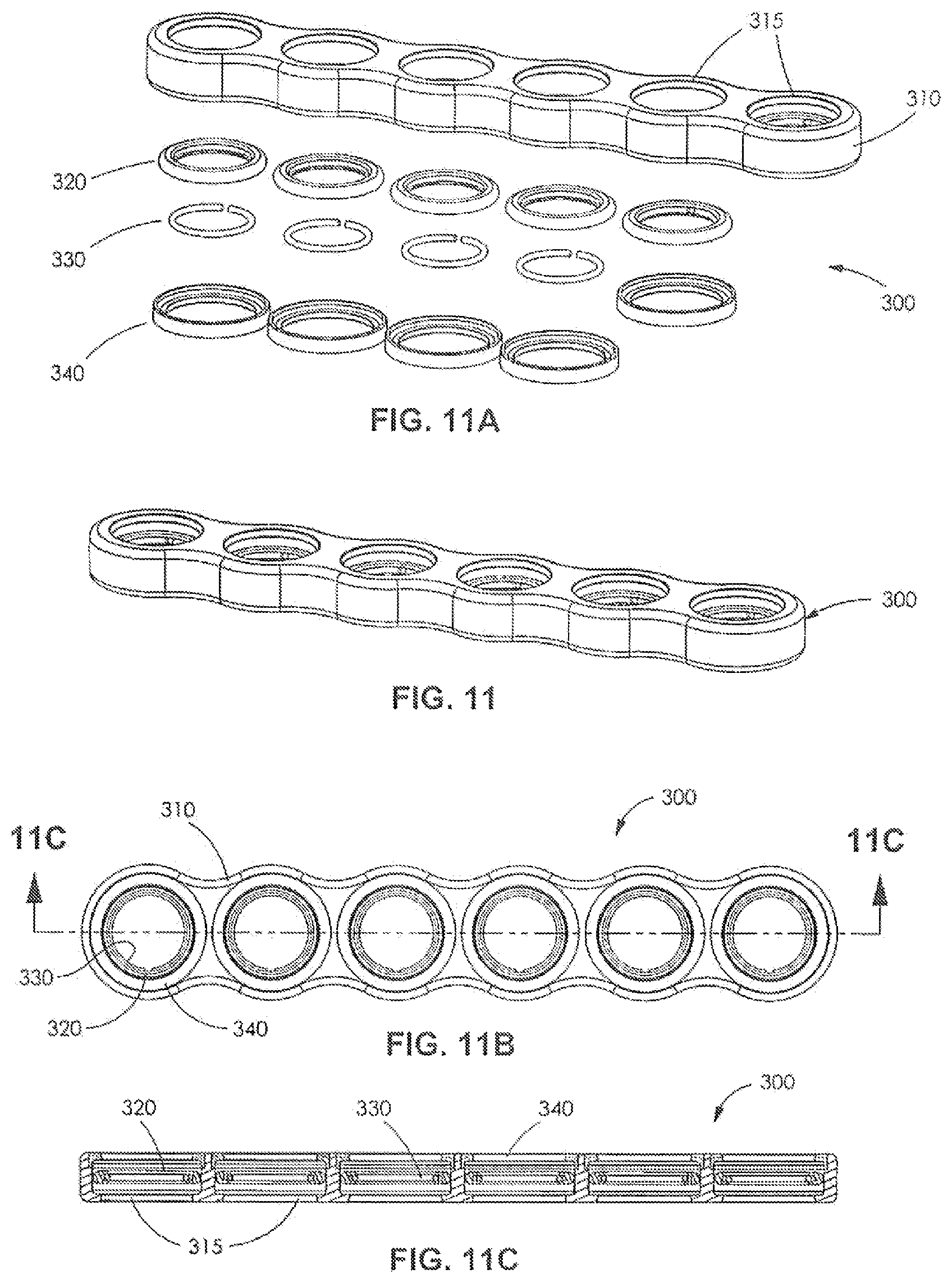

FIG. 11 is a perspective view of the fulcrum of FIG. 9;

FIG. 11A is an exploded view of the fulcrum of FIG. 11;

FIG. 11B is a top view of the fulcrum of FIG. 11;

FIG. 11C is a side cross-sectional view of the fulcrum taken along the section line 11C-11C in FIG. 11B;

FIG. 12 is an enlarged view of the compressor/distractor device of FIG. 9;

FIG. 13 is a top view of the compressor/distractor device of FIG. 12; and

FIG. 14 is an exploded view of the compressor/distractor device of FIG. 12.

DETAILED DESCRIPTION OF THE DRAWINGS

Particular embodiments of the present disclosure will be described herein with reference to the accompanying drawings. As shown in the drawings and as described throughout the following description, and as is traditional when referring to relative positioning on an object, the terms "proximal" and "trailing" may be employed interchangeably, and should be understood as referring to the portion of a structure that is closer to a clinician during proper use. The terms "distal" and "leading" may also be employed interchangeably, and should be understood as referring to the portion of a structure that is farther from the clinician during proper use. In addition, the term "cephalad" or "cranial" is used in this application to indicate a direction toward a patient's head, whereas the term "caudad" indicates a direction toward the patient's feet. Further still, the term "medial" indicates a direction toward the middle of the body of the patient, whilst the term "lateral" indicates a direction toward a side of the body of the patient (i.e., away from the middle of the body of the patient). The term "posterior" indicates a direction toward the patient's back, and the term "anterior" indicates a direction toward the patient's front. In the following description, well-known functions or constructions are not described in detail to avoid obscuring the present disclosure in unnecessary detail.

Turning now to FIGS. 2-6A, a rod reducer 10 includes an outer member 20, an inner member 30, and a pair of gripping members 40, such as the rod reducer disclosed in U.S. patent application Ser. No. 13/595,533 which is incorporated by reference. Outer member 20 includes a proximal segment 21, a distal segment 22, and a ring member 27 that is disposed between proximal and distal segments 21, 22. Proximal segment 21 includes an engaging portion 21a at a distal end of proximal segment 21 and a gripping portion 21b at a proximal end of proximal segment 21. An inner surface 28 of proximal segment 21 is threaded. Distal segment 22 defines a slot 26 therethrough and includes a reducing portion 22a at a distal end of distal segment 22 and a receiving portion 22b at a proximal end of distal segment 22. Receiving portion 22b includes a plurality of gripping features 22c on an outer surface of receiving portion 22b. A pair of rod engaging slots 25 and a pair of gripping member receiving slots 24 are defined through reducing portion 22a. Receiving portion 22b of distal segment 22 is configured to receive engaging portion 21a of proximal segment 21 so that ring member 27 is disposed between proximal and distal segments 21, 22. The components of outer member 20 may be integrally formed or assembled.

Inner member 30 includes an elongate body member 39 that defines an annular recess 33 configured to receive the pair of gripping members 40 so that the gripping members 40 are disposed in opposition on the elongate body member 39. Inner member 30 includes a pair of arms 32 supported on a distal end of elongate body member 39. A proximal end of elongate body member 39 has a threaded arrangement 38 that mates with threaded inner surface 28 of proximal segment 21 of outer member 20 to axially advance outer member 20 relative to inner member 30 as will be described in greater detail below.

Each gripping member 40 includes a body 47 having a supporting member 43, a proximal finger 46, and a distal finger 45. Supporting member 43 is configured to engage annular recess 33 of inner member 30 to support body 47 of each gripping member 40 on inner member 30. Proximal finger 46 extends proximally from supporting member 43 and is slidably positionable within slot 26 of outer member 20. Distal finger 45 extends distally from supporting member 43 and is positionable between an arm 32 of inner member 30 and reducing portion 22a of outer member 20 so that distal finger 45 is substantially aligned with a gripping member receiving slot 24 of reducing portion 22a.

As illustrated in FIGS. 1A-1C, outer member 20 of rod reducer 10 is disposed in a proximal position relative to inner member 30 of rod reducer 10, distal fingers 45 of gripping member 40 of rod reducer 10 are secured to an outer surface of pedicle screw head 910. Proximal segment 21 of outer member 20 may then be rotated by virtue of the threaded arrangement between outer member 20 and inner member 30 for axially advancing distal segment 22 of outer member 20 relative to inner member 30 and proximal segment 21. Proximal segment 21 remains axially fixed when rotated. Notably, as proximal segment 21 rotates, distal segment 22 remains radially fixed as distal segment 22 axially translates relative to inner member 30 and proximal segment 21. Outer member 20 approximates a spinal rod 800 positioned between rod reducer 10 and pedicle screw 900 as outer member 20 is advanced toward pedicle screw 900 to secure spinal rod 800 within a saddle 912 of pedicle screw 900. As outer member 20 advances distally, a proximal end of slot 26 of outer member 20 approximates a proximal end of proximal fingers 46 of gripping member 40.

Turning now to FIGS. 7A and 7B, a rod reducer and handle assembly 650 includes the rod reducer 10 and a handle assembly 652. Handle assembly 652 includes a turning handle 600 and an anti-torque handle 700 that are selectively connectable to gripping portion 21b and gripping features 22c respectively on rod reducer 10. Turning handle 600 includes a shaft 610, a handle 620, and a socket 630 that defines an opening 632. Opening 632 is configured to receive a proximal end of gripping portion 21b of rod reducer 10. Handle 620 is secured to a proximal end of shaft 610 and a socket 630 that may be integrally formed is secured to a distal end of shaft 610. Anti-torque handle 700 includes a shaft 720 and a handle 710 that may be integrally formed. Shaft 720 includes a socket 722 that defines an opening 722a at a distal end of socket 722. Opening 722a is disposed in communication with a lumen 725 defined within shaft 720 and another opening 724 disposed at a proximal end of shaft 720 so that anti-torque handle 700 may slide over gripping portion 21b of rod reducer 10 and engage with gripping feature 22c of rod reducer 10 to prevent rotational movement of distal segment 22 of outer member 20 of rod reducer 10.

Thus, if needed, either or both the turning handle 600 and the anti-torque handle 700 may be used to facilitate the rotational movement of outer member 20 relative to inner member 30. In particular, rotation of turning handle 600 imparts rotational movement to proximal segment 21 of outer member 20 and anti-torque handle 700 imparts counter rotational movement to distal segment 22 of outer member 20 so that proximal segment 21 rotates and distal segment 22 axially translates without rotating. As appreciated, anti-torque handle 700 is configured to limit the amount of torque imparted from the rotational movement imparted by turning handle 600 to prevent undesirable torquing of the outer member 20. More particularly, anti-torque handle 700 slides down over the outer surface of outer member 20 of rod reducer 10 so that a distal end of anti-torque handle 700 engages distal segment 22 of outer member 20 and a proximal end of proximal segment 21 of outer member 20 is exposed for engagement with turning handle 600. Meanwhile, since gripping member 40 is secured within annular recess 33 of inner member 30 such that proximal finger 46 of gripping member 40 is supported in slot 26 of distal segment 22 of outer member 20, the engagement of anti-torque handle 700 with gripping feature 22c of distal segment 22 of outer member 20 prevents rotation of both distal segment 22 of outer member 20 and inner member 30 as proximal segment 21 of outer member 20 is rotated with turning handle 600. After spinal rod 800 is fully reduced into the saddle 910 of pedicle screw 900, turning handle 600 and anti-torque handle 700 may be removed and a set screw (not shown) may be inserted down an inner diameter of rod reducer 10 to lock spinal rod 800 into place. Alternatively, anti-torque handle 700 may also be used to prevent rotation when tightening the set screw after spinal rod 800 has been fully reduced. Rod reducer 10 may then be removed.

Referring now to FIGS. 8 and 9, a compressor/distractor system 200 includes rod reducers 10, a compressor/distractor device 210, and a fulcrum 300. System 200 may further include one or more minimally invasive retraction devices 950, such as the retractor disclosed in U.S. Pat. No. 7,846,093, the entire contents of which is incorporated by reference. Each of the two rod reducers 10 engages a respective pedicle screw 900. Each pedicle screw 900 is inserted into a respective vertebra and is configured to receive spinal rod 800 in saddle portion 912 as shown in FIG. 1C. Compressor/distractor device 210 is configured for selective engagement with each rod reducer 10 when each rod reducer 10 is attached to pedicle screw 900.

FIGS. 10A and 10B illustrate other embodiments of compressor/distractor system 200a using compressor 400 and distractor 500 respectively as the force applying device. As shown in FIG. 10A, the compressor 400 has a handle assembly 410 with handles 402, 404 that are pivotably coupled together by pivot pin 406. Distal portions of handles 402, 404 have respective grippers 402a, 404a for engaging rod reducers 10. Each gripper 402a, 404a includes an arcuate recess configured for engaging an outer surface of rod reducer 10. Compressor 400 also includes an arm 420 having teeth 422 disposed thereon. Teeth 422 releasably engage a distal portion of handle 404 for maintaining a predetermined distance or spacing between handles 402, 404 during a compression stroke that moves rod reducers 10 towards each other. The arm 420 is pivotably coupled to a distal end of arm 402 such that it can be repositioned and allow handles 402, 404 to be moved away from each other once the desired amount of compression is achieved. Similarly, as shown in FIG. 10B, the distractor 500 has a handle assembly 510 with handles 502, 504 that are pivotably coupled together by pivot pin 506. Distal portions of handles 502, 504 have respective grippers 502a, 504a for engaging rod reducers 10. Each gripper 502a, 504a includes an arcuate recess configured for engaging an outer surface of rod reducer 10. Distractor 500 also includes an arm 520 having teeth 522 disposed thereon. Teeth 522 releasably engage a distal portion of handle 502 for maintaining a predetermined distance or spacing between handles 502, 504 during a distraction stroke that moves rod reducers 10 away from each other. The arm 520 is pivotably coupled to a distal end of arm 504 such that it can be repositioned and allow handles 502, 504 to be moved away from each other once the desired amount of distraction is achieved.

Now referring to FIGS. 11-11C illustrating fulcrum 300 including through holes 315 which receive inner bearing rings 320 which house retaining rings 330 that are prevented from falling out of fulcrum 300 by caps 340. Fulcrum 300 is an elongate structure and each through hole 315 includes an annular groove for retaining inner bearing rings 320 and their respective retaining rings 330.

Referring now to FIGS. 12-14, compressor/distractor device 210 has a first hook member 220, a second hook member 230, and a body portion 260. Body portion 260 includes first end 261 and track 262 extending from first end 261 along a length of body portion 260. Track 262 includes a set of teeth 263 and sidewall 264. First end 261 is insertable into a recess of the first hook member 220 and is fixed in position at first end 261 of body portion 260 by the cooperation of retaining pin 221 and first end retaining ring 222.

First and second hook members 220, 230 may each include hook portions 224, 234 for engaging rod reducers 10. Hook portions 224, 234 have respective distracting hooks 225, 235 and compressing hooks 226, 236. When rod reducers 10 are between first and second hook members 220, 230, each compressing hook 226, 236 engages a rod reducer 10 in a compressing configuration of compressor/distractor device 210 (FIG. 8). When first and second hook members 220, 230 are between rod reducers 10, each distracting hook 225, 235 engages a rod reducer 10 in a distracting configuration of compressor/distractor device 210 (FIG. 9). Compressor/distractor device 210 may also have a neutral configuration. Each hook member 220, 230 may engage gripping features 22c of each rod reducer 10.

Second hook member 230 may include a switch assembly 250 and a gear assembly 240. Switch assembly 250 may include a pawl 251, a pawl switch pin 252, a switch cap 253, a spring 254, a ball 255, ball detents 258, a switch 256, and a switch shaft 257. Switch assembly 250 is selectable amongst a first condition, a second condition, and a third condition. Each condition may correspond to a configuration of the compressor/distractor device 210. In the first condition, switch assembly 250 restrains second hook member 230 from traversing track 262 towards the first hook member 220, while permitting second hook member 230 to traverse track 262 away from the first hook member 220 (i.e., a distracting configuration). In the second condition, switch assembly 250 restrains second hook member 230 from traversing track 262 away from the first hook member 220, while permitting second hook member 230 to traverse track 262 towards the first hook member 220 (i.e., a compressing configuration). In the third condition, switch assembly 250 allows the second hook member 230 to freely move along track 262 in either direction (i.e., a neutral configuration), which allows for quick adjustment of compressor/distractor device 210.

Switch 256 rotates about switch shaft 257 causing pawl pivot pin 252 to rotate pawl 251 about switch shaft 257. Pawl pivot pin 252 acts on pawl 251 causing pawl 251 to engage set of teeth 263 which restrains second hook member from traversing in the undesired direction.

Second hook member 230 may include ball detents 258. Each ball detent 258 corresponds to a position of switch 256. Switch 256 may be retained in each position by spring 254 pressing ball 255 into a corresponding ball detent 258. Ball 255 selectively engages each ball detent 258 when the switch is in one of the positions corresponding to the compressing, distracting, and neutral configurations of the compressor/distractor device 210.

Gear assembly 240 engages set of teeth 263 causing second hook member 230 to traverse track 262. Rotation of traversing screw 244 rotates pinion 242. The cooperation of pinion 242 with set of teeth 263 induces the second hook member 230 to traverse track 262. A drive tool (not shown) may engage and rotate traversing screw 244.

A method for using system 200 to manipulate a vertebra into a desired position with respect to a second vertebra is discussed below. First, a surgeon accesses the spinal area of a patient having at least two pedicle screws 900 secured to adjacent vertebrae (not shown). Each pedicle screw 900 may be engaged by a minimally invasive retraction device 950. The surgeon then engages each pedicle screw 900 with a rod reducer 10 by attaching inner member 30 to pedicle screw head 910 as shown in FIG. 1B. Each inner member 30 receives a respective pedicle screw head 910 between arms 32. Next, the surgeon advances an outer member 20 along each inner member 30 by rotating the distal segment 21 of the outer member 20. The surgeon may use handle assembly 650 to rotate distal segment 21.

Rod engaging slots 25 of proximal segment 22 of each outer member 20 receives a portion of rod 800 and advances rod 800 into saddle portion 912 of each pedicle screw 900 as shown in FIGS. 1B and 1C. Once each outer member 20 is fully advanced with respect to each inner member 30 as shown in FIG. 1C, the surgeon engages each outer member 20 with a force applying device 210, 400, 500 as shown in FIGS. 8-10B. The force applying device may include gear assembly 240. Then the surgeon inserts a set screw (not shown) through each rod reducer 10 for securing the rod 800 to each pedicle screw 900. The surgeon may rotate at least one of the set screws to either partially or fully secure rod 800 to at least one of the pedicle screws 900.

Then the surgeon manipulates gear assembly 240 until each pedicle screw 900 is in a desired position on rod 800. Manipulation of gear assembly 240 may include rotating traversing screw 244. The surgeon may use a drive tool to manipulate gear assembly 240.

Then the surgeon rotates each set screw to fully secure rod 800 to each pedicle screw 900 in the desired position. Then the surgeon may remove compressor/distractor device 210 and each rod reducer 10.

The surgeon may also attach fulcrum 300 to gripping portion 21b of proximal segment 21 of each outer member 20 before manipulating gear assembly 240. Fulcrum 300 may then be removed with the compressor/distractor device 210 and each of the rod reducers 10.

While several embodiments of the disclosure have been shown in the drawings, it is not intended that the disclosure be limited thereto, as it is intended that the disclosure be as broad in scope as the art will allow and that the specification be read likewise. Therefore, the above description should not be construed as limiting, but merely as exemplifications of particular embodiments. Those skilled in the art will envision other modifications within the scope and spirit of the claims appended hereto.

* * * * *

D00000

D00001

D00002

D00003

D00004

D00005

D00006

D00007

D00008

D00009

D00010

D00011

XML

uspto.report is an independent third-party trademark research tool that is not affiliated, endorsed, or sponsored by the United States Patent and Trademark Office (USPTO) or any other governmental organization. The information provided by uspto.report is based on publicly available data at the time of writing and is intended for informational purposes only.

While we strive to provide accurate and up-to-date information, we do not guarantee the accuracy, completeness, reliability, or suitability of the information displayed on this site. The use of this site is at your own risk. Any reliance you place on such information is therefore strictly at your own risk.

All official trademark data, including owner information, should be verified by visiting the official USPTO website at www.uspto.gov. This site is not intended to replace professional legal advice and should not be used as a substitute for consulting with a legal professional who is knowledgeable about trademark law.