Revision connector for spinal constructs

Montello , et al. May 18, 2

U.S. patent number 11,006,978 [Application Number 15/349,509] was granted by the patent office on 2021-05-18 for revision connector for spinal constructs. This patent grant is currently assigned to DePuy Synthes Products, Inc.. The grantee listed for this patent is DePuy Synthes Products, Inc.. Invention is credited to Thomas Kueenzi, Oleg Levin, Albert Montello, William Strausbaugh.

View All Diagrams

| United States Patent | 11,006,978 |

| Montello , et al. | May 18, 2021 |

Revision connector for spinal constructs

Abstract

An extender system is configured to couple a vertebral bone anchor that has been previously implanted in a vertebra, or is newly implantable in a vertebra, to an adjacent bone, which can be an additional spinal level or an occiput, for example. The extender system includes an extension member having a body and an engagement member coupled to the body. The extension member defines an aperture extending through the engagement member. A screw is configured to attach the extension member to the vertebral bone anchor. The extension member can be fastened to the adjacent bone.

| Inventors: | Montello; Albert (Duxbury, MA), Levin; Oleg (Chester Springs, PA), Strausbaugh; William (Newmanstown, PA), Kueenzi; Thomas (Magden, CH) | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Applicant: |

|

||||||||||

| Assignee: | DePuy Synthes Products, Inc.

(Raynham, MA) |

||||||||||

| Family ID: | 1000005557640 | ||||||||||

| Appl. No.: | 15/349,509 | ||||||||||

| Filed: | November 11, 2016 |

Prior Publication Data

| Document Identifier | Publication Date | |

|---|---|---|

| US 20170112540 A1 | Apr 27, 2017 | |

Related U.S. Patent Documents

| Application Number | Filing Date | Patent Number | Issue Date | ||

|---|---|---|---|---|---|

| 12817920 | Jun 17, 2010 | 9510862 | |||

| 61187902 | Jun 17, 2009 | ||||

| Current U.S. Class: | 1/1 |

| Current CPC Class: | A61B 17/7049 (20130101); A61B 17/7025 (20130101); A61B 17/7011 (20130101); A61B 17/7007 (20130101); A61B 17/7032 (20130101); A61B 17/7001 (20130101); A61B 17/7002 (20130101) |

| Current International Class: | A61B 17/70 (20060101) |

| Field of Search: | ;606/246-264,278,280,283,286,287,290,291,300-321 |

References Cited [Referenced By]

U.S. Patent Documents

| 405546 | June 1889 | Frist |

| 513630 | January 1894 | Beard |

| 802896 | October 1905 | Webb |

| 2005348 | June 1935 | Michell |

| 2338659 | January 1944 | Morehouse |

| 2396925 | March 1946 | Morehouse |

| 3173987 | March 1965 | Potruch |

| 3463427 | August 1969 | Fisher |

| 4447934 | May 1984 | Anscher |

| 4601491 | July 1986 | Bell, Jr. et al. |

| 4719905 | January 1988 | Steffee |

| 4805602 | February 1989 | Puno et al. |

| 4846614 | July 1989 | Steinbock |

| 4863383 | September 1989 | Grafelmann |

| 4936851 | June 1990 | Fox et al. |

| 4944475 | July 1990 | Ono et al. |

| 4946458 | August 1990 | Biedermann |

| 5005562 | April 1991 | Cotrel |

| 5116337 | May 1992 | Johnson |

| 5129388 | July 1992 | Vignaud et al. |

| 5207678 | May 1993 | Harms et al. |

| 5242446 | September 1993 | Steffee et al. |

| 5270678 | December 1993 | Gambut et al. |

| 5282825 | February 1994 | Chan |

| 5304178 | April 1994 | Stahurski |

| 5306275 | April 1994 | Bryan |

| 5306285 | April 1994 | Miller et al. |

| 5312410 | May 1994 | Miller et al. |

| 5360431 | November 1994 | Puno et al. |

| 5383882 | January 1995 | Buess et al. |

| 5395374 | March 1995 | Miller et al. |

| 5413576 | May 1995 | Rivard |

| 5413602 | May 1995 | Metz-Stavenhagen |

| 5417684 | May 1995 | Jackson et al. |

| 5443467 | August 1995 | Biedermann et al. |

| 5449361 | September 1995 | Preissman |

| 5466237 | November 1995 | Byrd, III et al. |

| 5468241 | November 1995 | Metz-Stavenhagen et al. |

| 5474555 | December 1995 | Puno et al. |

| 5476464 | December 1995 | Metz-Stavenhagen et al. |

| 5486174 | January 1996 | Fournet-Fayard et al. |

| 5496321 | March 1996 | Puno et al. |

| 5498262 | March 1996 | Bryan |

| 5501684 | March 1996 | Schlapfer et al. |

| 5520689 | May 1996 | Schlapfer et al. |

| 5520690 | May 1996 | Errico et al. |

| 5527183 | June 1996 | O'Brien |

| 5531746 | July 1996 | Errico et al. |

| 5534001 | July 1996 | Schlapfer et al. |

| 5536268 | July 1996 | Griss |

| 5536270 | July 1996 | Songer et al. |

| 5540698 | July 1996 | Preissman |

| 5549608 | August 1996 | Errico et al. |

| 5549677 | August 1996 | Kirsch |

| 5554157 | September 1996 | Errico et al. |

| 5562661 | October 1996 | Yoshimi et al. |

| 5575792 | November 1996 | Errico et al. |

| 5578033 | November 1996 | Errico et al. |

| 5584832 | December 1996 | Schlapfer |

| 5584834 | December 1996 | Errico et al. |

| 5586984 | December 1996 | Errico et al. |

| 5601261 | February 1997 | Koike |

| 5601429 | February 1997 | Blacklock |

| 5605457 | February 1997 | Bailey et al. |

| 5605458 | February 1997 | Bailey et al. |

| 5607304 | March 1997 | Bailey et al. |

| 5607426 | March 1997 | Ralph et al. |

| 5609593 | March 1997 | Errico et al. |

| 5609594 | March 1997 | Errico et al. |

| 5624442 | April 1997 | Mellinger et al. |

| 5643260 | July 1997 | Doherty |

| 5643262 | July 1997 | Metz-Stavenhagen et al. |

| 5643265 | July 1997 | Errico et al. |

| 5645544 | July 1997 | Tai et al. |

| 5647873 | July 1997 | Errico et al. |

| 5662651 | September 1997 | Tornier et al. |

| 5667508 | September 1997 | Errico et al. |

| 5669911 | September 1997 | Errico et al. |

| 5672175 | September 1997 | Martin |

| 5683390 | November 1997 | Metz-Stavenhagen et al. |

| 5683392 | November 1997 | Richelsoph et al. |

| 5683404 | November 1997 | Johnson |

| 5688273 | November 1997 | Errico et al. |

| 5690630 | November 1997 | Errico et al. |

| 5694760 | December 1997 | Baxter |

| 5704939 | January 1998 | Justin |

| 5725582 | March 1998 | Bevan et al. |

| 5725588 | March 1998 | Errico et al. |

| 5728098 | March 1998 | Sherman et al. |

| 5733285 | March 1998 | Errico et al. |

| 5738685 | April 1998 | Halm et al. |

| 5772663 | June 1998 | Whiteside et al. |

| 5782831 | July 1998 | Sherman et al. |

| 5782833 | July 1998 | Haider |

| 5797911 | August 1998 | Sherman et al. |

| 5810818 | September 1998 | Errico et al. |

| 5817094 | October 1998 | Errico et al. |

| 5860987 | January 1999 | Ratcliff et al. |

| 5863293 | January 1999 | Richelsoph |

| 5868748 | February 1999 | Burke |

| 5876402 | March 1999 | Errico et al. |

| 5879350 | March 1999 | Sherman et al. |

| 5882350 | March 1999 | Ralph et al. |

| 5885286 | March 1999 | Sherman et al. |

| 5888204 | March 1999 | Ralph et al. |

| 5891145 | April 1999 | Morrison et al. |

| 5899940 | May 1999 | Carchidi et al. |

| 5902305 | May 1999 | Beger et al. |

| 5938663 | August 1999 | Petreto |

| 5951287 | September 1999 | Hawkinson |

| 5961329 | October 1999 | Stucki-Mccormick |

| 5964760 | October 1999 | Richelsoph |

| 6001098 | December 1999 | Metz-Stavenhagen et al. |

| 6010503 | January 2000 | Richelsoph et al. |

| 6015409 | January 2000 | Jackson |

| 6017177 | January 2000 | Lanham |

| 6019760 | February 2000 | Metz-Stavenhagen et al. |

| 6022350 | February 2000 | Ganem |

| 6053917 | April 2000 | Sherman et al. |

| 6063090 | May 2000 | Schlapfer |

| 6074391 | June 2000 | Metz-Stavenhagen et al. |

| 6077262 | June 2000 | Schlapfer et al. |

| 6077263 | June 2000 | Ameil et al. |

| 6083224 | July 2000 | Gertzbein et al. |

| 6090110 | July 2000 | Metz-Stavenhagen |

| 6126662 | October 2000 | Carmichael et al. |

| 6132432 | October 2000 | Richelsoph |

| 6183472 | February 2001 | Lutz |

| 6214006 | April 2001 | Metz-Stavenhagen |

| 6217331 | April 2001 | Rogers et al. |

| 6224598 | May 2001 | Jackson |

| 6248105 | June 2001 | Schlapfer et al. |

| 6261287 | July 2001 | Metz-Stavenhagen |

| 6273914 | August 2001 | Papas |

| 6280442 | August 2001 | Barker et al. |

| 6296642 | October 2001 | Morrison et al. |

| 6325802 | December 2001 | Frigg |

| 6355040 | March 2002 | Richelsoph et al. |

| 6361535 | March 2002 | Jackson |

| RE37665 | April 2002 | Ralph et al. |

| 6368321 | April 2002 | Jackson |

| 6402752 | June 2002 | Schaffler-Wachter et al. |

| 6440132 | August 2002 | Jackson |

| 6443953 | September 2002 | Perra et al. |

| 6443955 | September 2002 | Ahrend et al. |

| 6451021 | September 2002 | Ralph et al. |

| 6454768 | September 2002 | Jackson |

| 6454772 | September 2002 | Jackson |

| 6471705 | October 2002 | Biedermann et al. |

| 6482207 | November 2002 | Errico |

| 6485491 | November 2002 | Farris et al. |

| 6491696 | December 2002 | Kunkel |

| 6508820 | January 2003 | Bales |

| 6514255 | February 2003 | Ferree |

| 6520963 | February 2003 | McKinley |

| 6533226 | March 2003 | Geiger |

| 6537070 | March 2003 | Stucki-McCormick |

| 6537276 | March 2003 | Metz-Stavenhagen |

| 6554831 | April 2003 | Rivard et al. |

| 6558387 | May 2003 | Errico et al. |

| 6565565 | May 2003 | Yuan et al. |

| 6585740 | July 2003 | Schlapfer et al. |

| 6616667 | September 2003 | Steiger et al. |

| 6626908 | September 2003 | Cooper et al. |

| 6641586 | November 2003 | Varieur |

| 6641588 | November 2003 | Citron et al. |

| 6660004 | December 2003 | Barker et al. |

| 6689140 | February 2004 | Cohen |

| 6695852 | February 2004 | Gleason |

| 6716214 | April 2004 | Jackson |

| 6726687 | April 2004 | Jackson |

| 6736820 | May 2004 | Biedermann et al. |

| 6738527 | May 2004 | Kuwata et al. |

| 6740086 | May 2004 | Richelsoph |

| 6749613 | June 2004 | Conchy et al. |

| 6755829 | June 2004 | Bono et al. |

| 6770075 | August 2004 | Howland |

| 6780186 | August 2004 | Errico et al. |

| 6783527 | August 2004 | Drewry et al. |

| 6802844 | October 2004 | Ferree |

| 6827719 | December 2004 | Ralph et al. |

| 6835196 | December 2004 | Biedermann et al. |

| 6840940 | January 2005 | Ralph et al. |

| 6843791 | January 2005 | Serhan |

| 6866664 | March 2005 | Schaer et al. |

| 6869433 | March 2005 | Glascott |

| 6887275 | May 2005 | Carchidi et al. |

| 6918911 | July 2005 | Biedermann et al. |

| 6933440 | August 2005 | Ichikawa et al. |

| 6964666 | November 2005 | Jackson |

| 6974460 | December 2005 | Carbone et al. |

| 6981973 | January 2006 | McKinley |

| 7008227 | March 2006 | Carmichael et al. |

| 7018378 | March 2006 | Biedermann et al. |

| RE39089 | May 2006 | Ralph et al. |

| 7073415 | July 2006 | Casutt et al. |

| 7081117 | July 2006 | Bono et al. |

| 7087057 | August 2006 | Konieczynski et al. |

| D527678 | September 2006 | Warner |

| 7125410 | October 2006 | Freudiger |

| 7125426 | October 2006 | Moumene et al. |

| 7128743 | October 2006 | Metz-Stavenhagen |

| 7131467 | November 2006 | Gao et al. |

| 7144396 | December 2006 | Shluzas |

| 7163539 | January 2007 | Abdelgany et al. |

| 7175622 | February 2007 | Farris |

| 7186255 | March 2007 | Baynham et al. |

| 7211086 | May 2007 | Biedermann et al. |

| 7223268 | May 2007 | Biedermann |

| 7250052 | July 2007 | Landry et al. |

| 7270665 | September 2007 | Morrison et al. |

| 7316684 | January 2008 | Baccelli et al. |

| 7322548 | January 2008 | Mielke et al. |

| 7330490 | February 2008 | Furukawa et al. |

| 7338490 | March 2008 | Ogilvie et al. |

| 7445627 | November 2008 | Hawkes et al. |

| 7452360 | November 2008 | Trudeau et al. |

| 7476239 | January 2009 | Jackson |

| 7547319 | June 2009 | Segal et al. |

| 7591839 | September 2009 | Biedermann et al. |

| 7592546 | September 2009 | Johansson |

| 7645282 | January 2010 | Huxel et al. |

| 7648520 | January 2010 | Markworth |

| 7691131 | April 2010 | Graf |

| 7708762 | May 2010 | McCarthy et al. |

| 7766944 | August 2010 | Metz-Stavenhagen |

| 7780706 | August 2010 | Marino et al. |

| 7785352 | August 2010 | Snyder et al. |

| 7785354 | August 2010 | Biedermann et al. |

| 7799054 | September 2010 | Kwak et al. |

| 7803174 | September 2010 | Denis et al. |

| 7806895 | October 2010 | Weier et al. |

| 7819902 | October 2010 | Abdelgany et al. |

| 7951172 | May 2011 | Chao et al. |

| 7967849 | June 2011 | Carson et al. |

| 8001946 | August 2011 | Leitl |

| 8002806 | August 2011 | Justis |

| 8029513 | October 2011 | Konno et al. |

| 8029546 | October 2011 | Capote et al. |

| 8038701 | October 2011 | Rock et al. |

| 8096998 | January 2012 | Cresina |

| 8100946 | January 2012 | Strausbaugh et al. |

| 8137356 | March 2012 | Hestad et al. |

| 8162946 | April 2012 | Baccelli et al. |

| 8162986 | April 2012 | Zehnder |

| 8172772 | May 2012 | Zwolinski et al. |

| 8197517 | June 2012 | Lab et al. |

| 8216245 | July 2012 | Gil et al. |

| 8221464 | July 2012 | Belliard et al. |

| 8231626 | July 2012 | Hulliger et al. |

| 8241333 | August 2012 | Jackson |

| 8246659 | August 2012 | Vonwiller et al. |

| 8257367 | September 2012 | Bryant et al. |

| 8308782 | November 2012 | Jackson |

| 8317836 | November 2012 | Zucherman et al. |

| 8323318 | December 2012 | Baccelli et al. |

| 8444681 | May 2013 | Jackson et al. |

| 8469960 | June 2013 | Hutton et al. |

| 8469966 | June 2013 | Allen et al. |

| 8556938 | October 2013 | Jackson et al. |

| 8628558 | January 2014 | Harvey et al. |

| 8632572 | January 2014 | Darst Rice et al. |

| 8663298 | March 2014 | Keyer et al. |

| 8758411 | June 2014 | Rayon et al. |

| 8814910 | August 2014 | Baccelli et al. |

| 8840652 | September 2014 | Jackson |

| 8870869 | October 2014 | Meunier et al. |

| 8870870 | October 2014 | Baccelli et al. |

| 8882803 | November 2014 | Iott et al. |

| 8911470 | December 2014 | Mirza et al. |

| 8911478 | December 2014 | Jackson et al. |

| 8911479 | December 2014 | Jackson et al. |

| 8926672 | January 2015 | Jackson et al. |

| 8979904 | March 2015 | Jackson et al. |

| 8998959 | April 2015 | Jackson et al. |

| 8998961 | April 2015 | Ziemek et al. |

| 9039708 | May 2015 | Larroque-Lahitette |

| 9168069 | October 2015 | Jackson et al. |

| 9216041 | December 2015 | Jackson et al. |

| 9320546 | April 2016 | Keyer et al. |

| 9326796 | May 2016 | Harvey et al. |

| 9393047 | July 2016 | Jackson et al. |

| 9439681 | September 2016 | Keyer et al. |

| 9451993 | September 2016 | Jackson et al. |

| 9480517 | November 2016 | Jackson et al. |

| 9504496 | November 2016 | Jackson et al. |

| 9522021 | December 2016 | Jackson et al. |

| 9636146 | May 2017 | Jackson et al. |

| 9717533 | August 2017 | Jackson et al. |

| 9717534 | August 2017 | Jackson et al. |

| 10105163 | October 2018 | Keyer et al. |

| 10136923 | November 2018 | Keyer et al. |

| 10154859 | December 2018 | Keyer et al. |

| 2001/0047173 | November 2001 | Schlapfer et al. |

| 2002/0045899 | April 2002 | Errico et al. |

| 2002/0068940 | June 2002 | Gaines |

| 2002/0069537 | June 2002 | Wenzler |

| 2002/0072753 | June 2002 | Cohen |

| 2002/0103487 | August 2002 | Errico et al. |

| 2002/0117321 | August 2002 | Beebe et al. |

| 2002/0120272 | August 2002 | Yuan et al. |

| 2002/0138077 | September 2002 | Ferree |

| 2002/0143341 | October 2002 | Biedermann et al. |

| 2002/0151900 | October 2002 | Glascott |

| 2003/0100896 | May 2003 | Biedermann et al. |

| 2003/0100904 | May 2003 | Biedermann |

| 2003/0125741 | July 2003 | Biedermann et al. |

| 2003/0125742 | July 2003 | Yuan et al. |

| 2003/0149431 | August 2003 | Varieur |

| 2003/0153912 | August 2003 | Graf |

| 2003/0163133 | August 2003 | Altarac |

| 2003/0176861 | September 2003 | Reed |

| 2004/0006342 | January 2004 | Altarac et al. |

| 2004/0024464 | February 2004 | Errico et al. |

| 2004/0039384 | February 2004 | Boehm et al. |

| 2004/0111088 | June 2004 | Picetti et al. |

| 2004/0138660 | July 2004 | Serhan |

| 2004/0138662 | July 2004 | Landry |

| 2004/0143265 | July 2004 | Landry et al. |

| 2004/0153077 | August 2004 | Biedermann et al. |

| 2004/0157186 | August 2004 | Abels et al. |

| 2004/0162558 | August 2004 | Hegde et al. |

| 2004/0172022 | September 2004 | Landry et al. |

| 2004/0181224 | September 2004 | Biedermann et al. |

| 2004/0186473 | September 2004 | Cournoyer et al. |

| 2004/0186474 | September 2004 | Matthis et al. |

| 2004/0193160 | September 2004 | Richelsoph |

| 2004/0199169 | October 2004 | Koons et al. |

| 2004/0225292 | November 2004 | Sasso et al. |

| 2004/0230192 | November 2004 | Graf |

| 2004/0236330 | November 2004 | Purcell et al. |

| 2004/0249380 | December 2004 | Glascott |

| 2004/0267264 | December 2004 | Konieczynski et al. |

| 2005/0033298 | February 2005 | Hawkes et al. |

| 2005/0049588 | March 2005 | Jackson |

| 2005/0049589 | March 2005 | Jackson |

| 2005/0055026 | March 2005 | Biedermann et al. |

| 2005/0080415 | April 2005 | Keyer et al. |

| 2005/0080420 | April 2005 | Farris et al. |

| 2005/0143737 | June 2005 | Pafford et al. |

| 2005/0154389 | July 2005 | Selover et al. |

| 2005/0154391 | July 2005 | Doherty et al. |

| 2005/0171537 | August 2005 | Mazel et al. |

| 2005/0171542 | August 2005 | Biedermann et al. |

| 2005/0177154 | August 2005 | Moumene et al. |

| 2005/0177166 | August 2005 | Timm et al. |

| 2005/0177179 | August 2005 | Baynham et al. |

| 2005/0187548 | August 2005 | Butler et al. |

| 2005/0192571 | September 2005 | Abdelgany |

| 2005/0203515 | September 2005 | Doherty et al. |

| 2005/0203516 | September 2005 | Biedermann et al. |

| 2005/0209592 | September 2005 | Schlapfer et al. |

| 2005/0216001 | September 2005 | David |

| 2005/0216003 | September 2005 | Biedermann et al. |

| 2005/0228378 | October 2005 | Kalfas et al. |

| 2005/0228385 | October 2005 | Iott et al. |

| 2005/0234421 | October 2005 | Mishima et al. |

| 2005/0234451 | October 2005 | Markworth |

| 2005/0261687 | November 2005 | Garamszegi et al. |

| 2005/0277928 | December 2005 | Boschert |

| 2005/0283157 | December 2005 | Coates et al. |

| 2005/0288671 | December 2005 | Yuan et al. |

| 2006/0004357 | January 2006 | Lee et al. |

| 2006/0025767 | February 2006 | Khalili |

| 2006/0025770 | February 2006 | Schlapfer et al. |

| 2006/0036252 | February 2006 | Baynham et al. |

| 2006/0052818 | March 2006 | Drake et al. |

| 2006/0064091 | March 2006 | Ludwig et al. |

| 2006/0079892 | April 2006 | Roychowdhury et al. |

| 2006/0084993 | April 2006 | Landry et al. |

| 2006/0084995 | April 2006 | Biedermann et al. |

| 2006/0084996 | April 2006 | Metz-Stavenhagen |

| 2006/0089634 | April 2006 | Anderson et al. |

| 2006/0089643 | April 2006 | Mujwid |

| 2006/0100622 | May 2006 | Jackson |

| 2006/0106383 | May 2006 | Biedermann et al. |

| 2006/0111779 | May 2006 | Petersen |

| 2006/0129149 | June 2006 | Iott et al. |

| 2006/0142761 | June 2006 | Landry et al. |

| 2006/0149232 | July 2006 | Sasing |

| 2006/0149233 | July 2006 | Richelsoph |

| 2006/0149241 | July 2006 | Richelsoph et al. |

| 2006/0149265 | July 2006 | James et al. |

| 2006/0155277 | July 2006 | Metz-Stavenhagen |

| 2006/0173456 | August 2006 | Hawkes et al. |

| 2006/0200131 | September 2006 | Chao et al. |

| 2006/0212034 | September 2006 | Triplett et al. |

| 2006/0217717 | September 2006 | Whipple |

| 2006/0229611 | October 2006 | Avery et al. |

| 2006/0235385 | October 2006 | Whipple |

| 2006/0235393 | October 2006 | Bono et al. |

| 2006/0241594 | October 2006 | McCarthy et al. |

| 2006/0241599 | October 2006 | Konieczynski et al. |

| 2006/0241624 | October 2006 | Kizuka et al. |

| 2006/0247636 | November 2006 | Yuan et al. |

| 2006/0247668 | November 2006 | Park |

| 2006/0271047 | November 2006 | Jackson |

| 2006/0282080 | December 2006 | Todd et al. |

| 2006/0293659 | December 2006 | Alvarez |

| 2006/0293664 | December 2006 | Schumacher |

| 2007/0016200 | January 2007 | Jackson |

| 2007/0043365 | February 2007 | Ritland |

| 2007/0049932 | March 2007 | Richelsoph et al. |

| 2007/0055240 | March 2007 | Matthis et al. |

| 2007/0088357 | April 2007 | Johnson et al. |

| 2007/0090238 | April 2007 | Justis |

| 2007/0118118 | May 2007 | Kwak et al. |

| 2007/0118121 | May 2007 | Purcell et al. |

| 2007/0118123 | May 2007 | Strausbaugh et al. |

| 2007/0123860 | May 2007 | Francis et al. |

| 2007/0123870 | May 2007 | Jeon et al. |

| 2007/0135817 | June 2007 | Ensign |

| 2007/0161987 | July 2007 | Capote et al. |

| 2007/0161994 | July 2007 | Lowery et al. |

| 2007/0167946 | July 2007 | Triplett |

| 2007/0167949 | July 2007 | Altarac et al. |

| 2007/0179501 | August 2007 | Firkins |

| 2007/0191844 | August 2007 | Carls et al. |

| 2007/0198014 | August 2007 | Graf et al. |

| 2007/0225711 | September 2007 | Ensign |

| 2007/0233087 | October 2007 | Schlapfer |

| 2007/0233091 | October 2007 | Naifeh et al. |

| 2007/0246614 | October 2007 | Allmann et al. |

| 2007/0250061 | October 2007 | Chin et al. |

| 2007/0250064 | October 2007 | Darois et al. |

| 2007/0270805 | November 2007 | Miller et al. |

| 2007/0270817 | November 2007 | Rezach |

| 2007/0270820 | November 2007 | Dickinson et al. |

| 2007/0270880 | November 2007 | Lindemann et al. |

| 2007/0282339 | December 2007 | Schwab |

| 2007/0288004 | December 2007 | Alvarez |

| 2008/0021455 | January 2008 | Chao et al. |

| 2008/0021456 | January 2008 | Gupta et al. |

| 2008/0039843 | February 2008 | Abdou |

| 2008/0058805 | March 2008 | Stuart |

| 2008/0058812 | March 2008 | Zehnder |

| 2008/0086126 | April 2008 | Miller |

| 2008/0103502 | May 2008 | Capote et al. |

| 2008/0140075 | June 2008 | Ensign et al. |

| 2008/0140135 | June 2008 | Konieczynski et al. |

| 2008/0154277 | June 2008 | MacHalk et al. |

| 2008/0154308 | June 2008 | Sherman et al. |

| 2008/0177260 | July 2008 | McKinley et al. |

| 2008/0177323 | July 2008 | Null et al. |

| 2008/0188260 | August 2008 | Xiao et al. |

| 2008/0208257 | August 2008 | Matthys |

| 2008/0215095 | September 2008 | Biedermann et al. |

| 2008/0234743 | September 2008 | Marik |

| 2008/0243185 | October 2008 | Felix et al. |

| 2008/0249570 | October 2008 | Carson et al. |

| 2008/0262552 | October 2008 | Kim |

| 2008/0262553 | October 2008 | Hawkins et al. |

| 2008/0269810 | October 2008 | Zhang et al. |

| 2008/0294194 | November 2008 | Capote et al. |

| 2008/0294202 | November 2008 | Peterson et al. |

| 2008/0306553 | December 2008 | Zucherman et al. |

| 2008/0312692 | December 2008 | Brennan et al. |

| 2009/0088803 | April 2009 | Justis et al. |

| 2009/0093847 | April 2009 | Wilcox |

| 2009/0105770 | April 2009 | Berrevoets et al. |

| 2009/0149887 | June 2009 | Schlaepfer et al. |

| 2009/0187217 | July 2009 | Weiman |

| 2009/0198280 | August 2009 | Spratt et al. |

| 2009/0259256 | October 2009 | Miller |

| 2009/0270916 | October 2009 | Ramsay et al. |

| 2010/0004694 | January 2010 | Little |

| 2010/0042165 | February 2010 | Aflatoon |

| 2010/0057125 | March 2010 | Viker |

| 2010/0087864 | April 2010 | Klein et al. |

| 2010/0094345 | April 2010 | Saidha et al. |

| 2010/0145394 | June 2010 | Harvey et al. |

| 2010/0168797 | July 2010 | Graf |

| 2010/0191286 | July 2010 | Butler |

| 2010/0198272 | August 2010 | Keyer et al. |

| 2010/0241172 | September 2010 | Biyani et al. |

| 2010/0249843 | September 2010 | Wegrzyn, Iii |

| 2010/0276051 | November 2010 | Kanehira |

| 2010/0292736 | November 2010 | Schwab |

| 2010/0298890 | November 2010 | Marino |

| 2010/0305621 | December 2010 | Wang et al. |

| 2010/0313428 | December 2010 | Mocanu |

| 2010/0318131 | December 2010 | James |

| 2010/0324599 | December 2010 | Montello et al. |

| 2011/0087289 | April 2011 | Pram et al. |

| 2011/0106166 | May 2011 | Keyer et al. |

| 2011/0118791 | May 2011 | Nunley et al. |

| 2011/0213424 | September 2011 | Biedermann et al. |

| 2011/0230917 | September 2011 | Carson et al. |

| 2011/0270325 | November 2011 | Keyer et al. |

| 2011/0276051 | November 2011 | Blakemore et al. |

| 2012/0010629 | January 2012 | Mire et al. |

| 2012/0089194 | April 2012 | Wolf |

| 2012/0101533 | April 2012 | Purcell et al. |

| 2012/0109200 | May 2012 | Cahill et al. |

| 2012/0265249 | October 2012 | Fielding et al. |

| 2013/0012955 | January 2013 | Lin |

| 2013/0012995 | January 2013 | Trickett |

| 2013/0018421 | January 2013 | George et al. |

| 2013/0079827 | March 2013 | Davenport |

| 2013/0261680 | October 2013 | Baccelli et al. |

| 2013/0268011 | October 2013 | Rezach et al. |

| 2018/0036041 | February 2018 | Pram et al. |

| 2289629 | Nov 1998 | CA | |||

| 102368967 | Mar 2012 | CN | |||

| 102458279 | May 2012 | CN | |||

| 9314297 | Apr 1994 | DE | |||

| 4329220 | Mar 1995 | DE | |||

| 29903342 | Jun 1999 | DE | |||

| 29810798 | Oct 1999 | DE | |||

| 19912364 | Oct 2000 | DE | |||

| 20207785 | Sep 2003 | DE | |||

| 0408489 | Sep 1994 | EP | |||

| 0674880 | Oct 1995 | EP | |||

| 0828459 | Mar 1998 | EP | |||

| 0837656 | Apr 1998 | EP | |||

| 0612507 | Dec 1998 | EP | |||

| 0683644 | Jun 2000 | EP | |||

| 1198205 | Apr 2002 | EP | |||

| 1210914 | Jun 2002 | EP | |||

| 0807420 | Jul 2002 | EP | |||

| 1248573 | Oct 2002 | EP | |||

| 1269929 | Jan 2003 | EP | |||

| 1316295 | Jun 2003 | EP | |||

| 1323391 | Jul 2003 | EP | |||

| 1637085 | Mar 2006 | EP | |||

| 1313403 | Oct 2006 | EP | |||

| 1741396 | Jan 2007 | EP | |||

| 1665994 | Jun 2008 | EP | |||

| 1928358 | Jun 2008 | EP | |||

| 1961392 | Aug 2008 | EP | |||

| 2052690 | Apr 2009 | EP | |||

| 1294297 | Aug 2010 | EP | |||

| 0820252 | Sep 1959 | GB | |||

| 2414674 | Aug 2009 | GB | |||

| 2465156 | May 2010 | GB | |||

| 06-154258 | Jun 1994 | JP | |||

| 08-112291 | May 1996 | JP | |||

| 2005-510286 | Apr 2005 | JP | |||

| 2006-508748 | Mar 2006 | JP | |||

| 2006-154258 | Jun 2006 | JP | |||

| 2006-525102 | Nov 2006 | JP | |||

| 2009-535114 | Oct 2009 | JP | |||

| 2012-523927 | Oct 2012 | JP | |||

| 2012-530550 | Dec 2012 | JP | |||

| 10-2008-0112851 | Dec 2008 | KR | |||

| 10-0896043 | May 2009 | KR | |||

| 10-2012-0013312 | Feb 2012 | KR | |||

| 10-2012-0039622 | Apr 2012 | KR | |||

| 94/17736 | Aug 1994 | WO | |||

| 96/32071 | Oct 1996 | WO | |||

| 97/02786 | Jan 1997 | WO | |||

| 98/08454 | Mar 1998 | WO | |||

| 98/52482 | Nov 1998 | WO | |||

| 2000/015125 | Mar 2000 | WO | |||

| 00/21455 | Apr 2000 | WO | |||

| 01/06940 | Feb 2001 | WO | |||

| 01/52758 | Jul 2001 | WO | |||

| 02/00124 | Jan 2002 | WO | |||

| 02/17803 | Mar 2002 | WO | |||

| 02/76314 | Oct 2002 | WO | |||

| 2003/045261 | Jun 2003 | WO | |||

| 2004/052218 | Jun 2004 | WO | |||

| 2004/089245 | Oct 2004 | WO | |||

| 2004/098425 | Nov 2004 | WO | |||

| 2005/016161 | Feb 2005 | WO | |||

| 2006/088452 | Aug 2006 | WO | |||

| 2006/114437 | Nov 2006 | WO | |||

| 2006/116437 | Nov 2006 | WO | |||

| 2006/135555 | Dec 2006 | WO | |||

| 2007/038350 | Apr 2007 | WO | |||

| 2007/040824 | Apr 2007 | WO | |||

| 2007/045892 | Apr 2007 | WO | |||

| 2007/047711 | Apr 2007 | WO | |||

| 2007/127632 | Nov 2007 | WO | |||

| 2007/146032 | Dec 2007 | WO | |||

| 2008/027940 | Mar 2008 | WO | |||

| 2008/048953 | Apr 2008 | WO | |||

| 2008/069420 | Jun 2008 | WO | |||

| 2008/089096 | Jul 2008 | WO | |||

| 2008/146185 | Dec 2008 | WO | |||

| 2008/147663 | Dec 2008 | WO | |||

| 2009/001978 | Dec 2008 | WO | |||

| 2009/015100 | Jan 2009 | WO | |||

| 2010/030906 | Mar 2010 | WO | |||

| 2010/028287 | Jun 2010 | WO | |||

| 2010/120989 | Oct 2010 | WO | |||

| 2010/148231 | Dec 2010 | WO | |||

| 2012/154772 | Nov 2012 | WO | |||

Other References

|

International Patent Application No. PCT/US2010/039037: International Search Report dated Jan. 9, 2010, 5 pages. cited by applicant . International Patent Application No. PCT/US2010/039037: International Preliminary Report on Patentability dated Jul. 11, 2011, 14 pages. cited by applicant . Aebi et al., "AO ASIF Principles in Spine Surgery", Springer , 1998, 186-190. cited by applicant. |

Primary Examiner: Robert; Eduardo C

Assistant Examiner: Negrellirodriguez; Christina

Attorney, Agent or Firm: BakerHostetler

Parent Case Text

CROSS-REFERENCE TO RELATED APPLICATIONS

This Application is a continuation of U.S. patent application Ser. No. 12/817,920, filed Jun. 17, 2010, which claims the benefit of U.S. Provisional Application Ser. No. 61/187,902, filed Jun. 17, 2009, the disclosures of both of which are hereby incorporated by reference as if set forth in their entirety herein.

Claims

We claim:

1. A spinal construct extender configured to couple to a spine fixation rod, the spinal construct extender comprising: a fastener; an extension member having a body that defines a rod, the body having a proximal end, and an opposed distal end that is spaced from the proximal end along a first direction, the distal end configured to be received in a rod-receiving channel of a bone fixation element, an engagement member that extends from the proximal end of the body, the engagement member having an interior surface that defines an aperture that extends through the engagement member; and a bushing insertable in the aperture, the bushing having an interior surface that defines a hollow interior configured to receive the fastener such that the interior surface a engages the fastener to thereby couple the spinal construct extender to the spine fixation rod, wherein the bushing is configured to enable the engagement member and extension member to pivot relative to the fastener when the bushing is disposed in the aperture and the fastener is received in the hollow interior.

2. The spinal construct extender of claim 1, wherein the body is bent at a location between the proximal end and the distal end.

3. The spinal construct extender of claim 2, wherein the body is bent so as to define an s-shape between the proximal end and the distal end.

4. The spinal construct extender of claim 2, wherein the body is bent such that at least a portion of the distal end is lower than the proximal end along a direction that is perpendicular to the first direction.

5. The spinal construct extender of claim 2, wherein the body is bent such that an entirety of the distal end is lower than the proximal end along a direction that is perpendicular to the first direction.

6. The spinal construct extender of claim 1, wherein the bushing comprises a superior surface and an inferior surface, wherein the interior surface of the bushing extends between the superior and inferior surfaces.

7. The spinal construct extender of claim 1, wherein the bushing has a partially spherical external surface, opposite the internal surface.

8. The spinal construct extender of claim 7, wherein the interior surface of the engagement member is partially spherical.

9. The spinal construct extender of claim 1, wherein the hollow interior of the bushing is configured to receive a fastener coupled to the spine fixation rod.

10. The spinal construct extender of claim 1, wherein the bushing is polyaxially pivotable within the aperture.

11. The spinal construct extender of claim 1, wherein the bushing is configured such that a position of the bushing is fixed by pressing an exterior surface of the bushing against the interior surface of the engagement member.

12. The spinal construct extender of claim 1, wherein the distal end of the extension member is substantially cylindrically shaped.

13. The spinal construct extender of claim 1, wherein the hollow interior extends through the bushing along a central axis, and the bushing has an exterior surface that is spaced from the interior surface of the bushing along a direction that is perpendicular to the central axis.

14. The spinal construct extender of claim 1, wherein the fastener engages a spinal fixation rod so as to couple the spinal construct extender to the spinal fixation rod.

15. The spinal construct extender of claim 14, wherein the fastener defines a distal portion that is configured to engage the spinal fixation rod, and a threaded proximal portion configured to be received in the aperture.

16. The spinal construct extender of claim 15, wherein the threaded proximal portion defines external threading.

17. The spinal construct extender of claim 1, wherein the hollow interior of the bushing is configured to receive the fastener when the bushing is received in the aperture of the engagement member so as to couple the spinal construct extender to the spine fixation rod.

18. The spinal construct extender of claim 1, wherein the extension member and engagement member are integral with one another.

19. The spinal construct extender of claim 1, wherein the engagement member extends from the extension member such that a central axis of the aperture is angularly offset from a central axis of the proximal end of the extension member.

Description

TECHNICAL FIELD

The present disclosure relates generally to orthopedics, and in particular relates to implants and methods for extending existing posterior vertebral screw assemblies to additional levels.

BACKGROUND

The options that exist for revising and/or extending a posterior vertebral screw and rod construct in a patient are limited. Patients who have undergone previous spinal surgery often develop symptoms in adjacent spinal levels, which often cause pain and require additional surgery. Such additional spine surgeries often require existing hardware constructs to be extended one or more additional spinal levels. In such cases, a surgeon must decide if he can 1) extend the construct using the same hardware as the patient's existing hardware, 2) extend the construct using different hardware while leaving some of the patient's existing hardware in tact, or 3) remove all of the patient's existing hardware and replace it with new hardware, including the new spinal levels to be instrumented. Several disadvantages, however, characterize these approaches.

First, the patient's existing hardware must be identified via X-rays or fluoroscopy and, once identified, the surgeon must determine if the same make and model of hardware is available to the hospital or still on the market. The surgeon must also determine if his experience will allow him to revise and the existing hardware and/or add on new hardware, as some existing hardware systems are more difficult to revise or install. Based on these determinations, the surgeon may decide to revise using new hardware. Although a surgeon can choose the hardware of his choice, a connection between the existing hardware and the new hardware must be made, most often accomplished by creating a long incision long enough to uncover all previously fixed vertebral bodies along with the new vertebral body or bodies to be fixed, removing the underlying rod, implanting the new screws, and then inserting a new rod to the previously implanted rod and the newly implanted rod. Concerns exist, however, that such a technique may disturb certain spinal levels that were previously asymptomatic and, thus, results in pain that previously did not exist. Further, many verterbal screw systems are not compatible with one another, significantly limiting the new hardware options for adding to the existing construct. If the surgeon decides to remove all existing hardware and replace it with new hardware of his choice he again is disturbing some spinal levels that were previously asymptomatic. Each of these options for adding and replacing hardware is time-consuming, especially if the surgeon is unfamiliar with the patient's existing hardware.

SUMMARY

In accordance with one embodiment, an extender system is configured to be operatively coupled to a vertebral implant that is secured to a vertebra, the vertebral implant including a first bone anchor and a first anchor seat that receives the first bone anchor. The extender system includes an extension member including a body and an engagement member coupled to the body. The extender system further includes a fastener that is configured to couple the extension member to the vertebral implant. The extender system further includes a second bone anchor that is configured to attach the extension member to an underlying bone disposed adjacent the vertebra.

BRIEF DESCRIPTION OF THE DRAWINGS

The foregoing summary, as well as the following detailed description of preferred embodiments of the application, will be better understood when read in conjunction with the appended drawings. For the purposes of illustrating the revision connector devices of the present application, there is shown in the drawings preferred embodiments. It should be understood, however, that the application is not limited to the precise arrangements and instrumentalities shown. In the drawings:

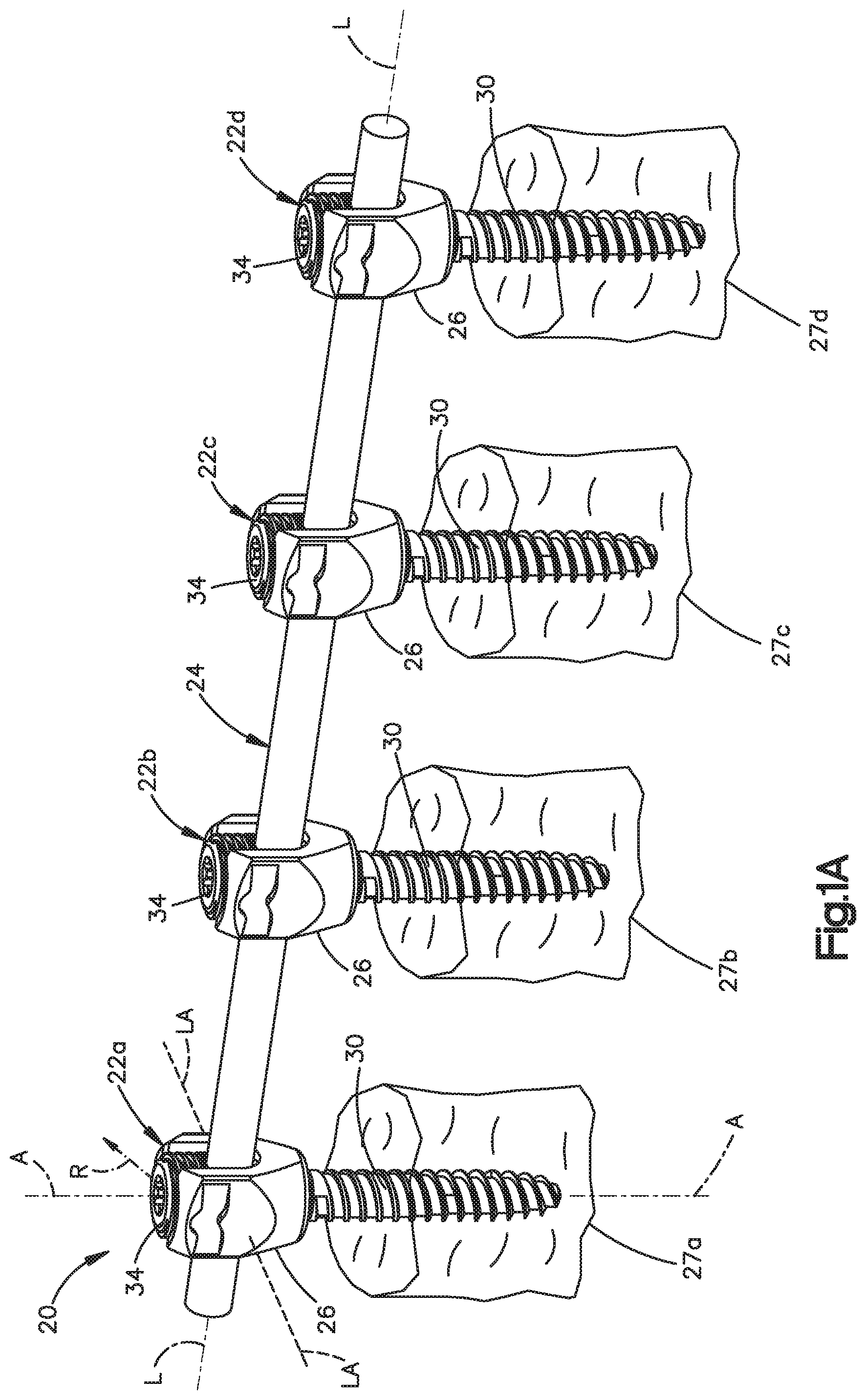

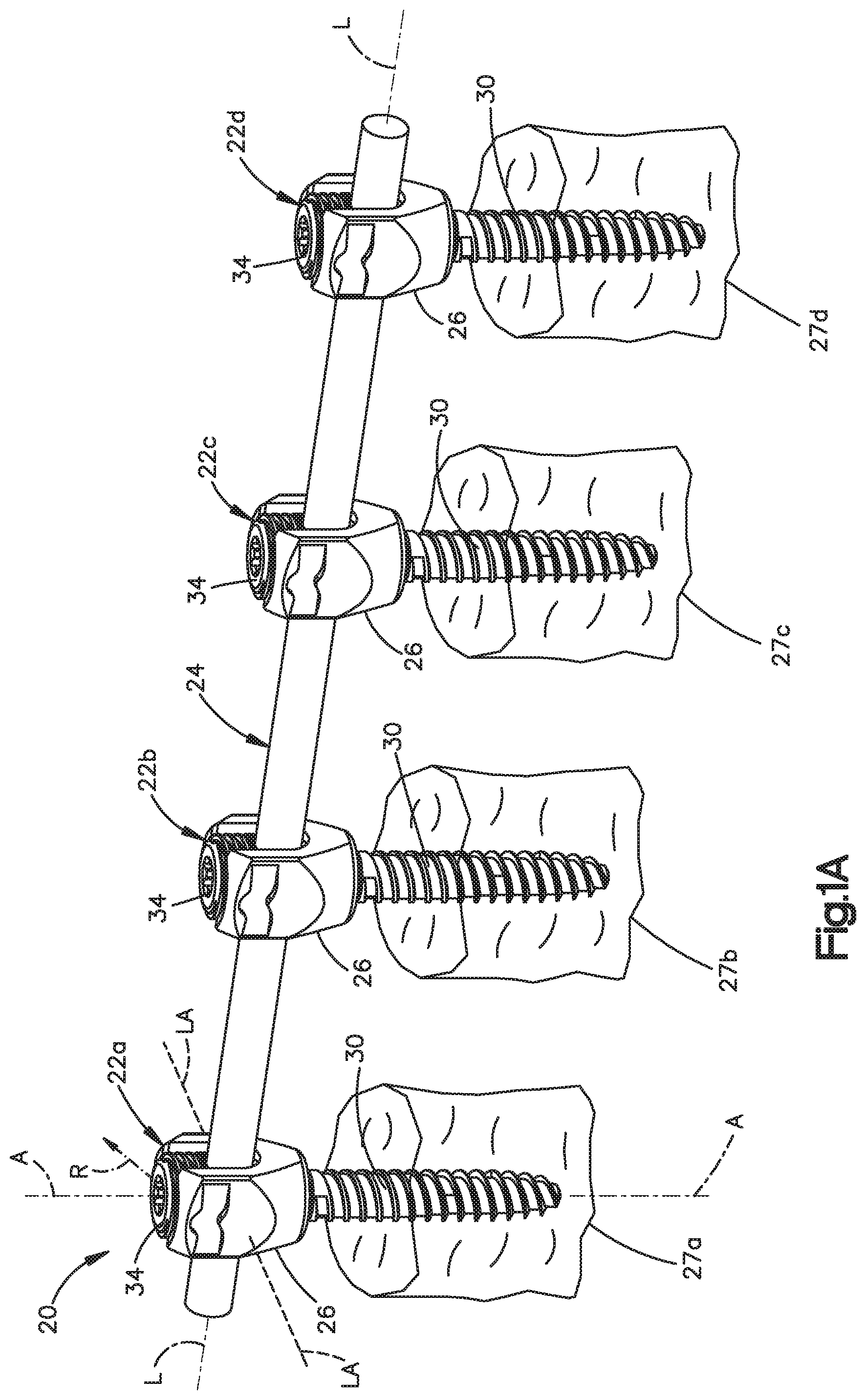

FIG. 1A is a perspective view of a bone fixation assembly constructed in accordance with one embodiment including a plurality of bone fixation elements connected to a previously implanted spine fixation rod, and illustrated schematically as each being previously secured to a vertebra;

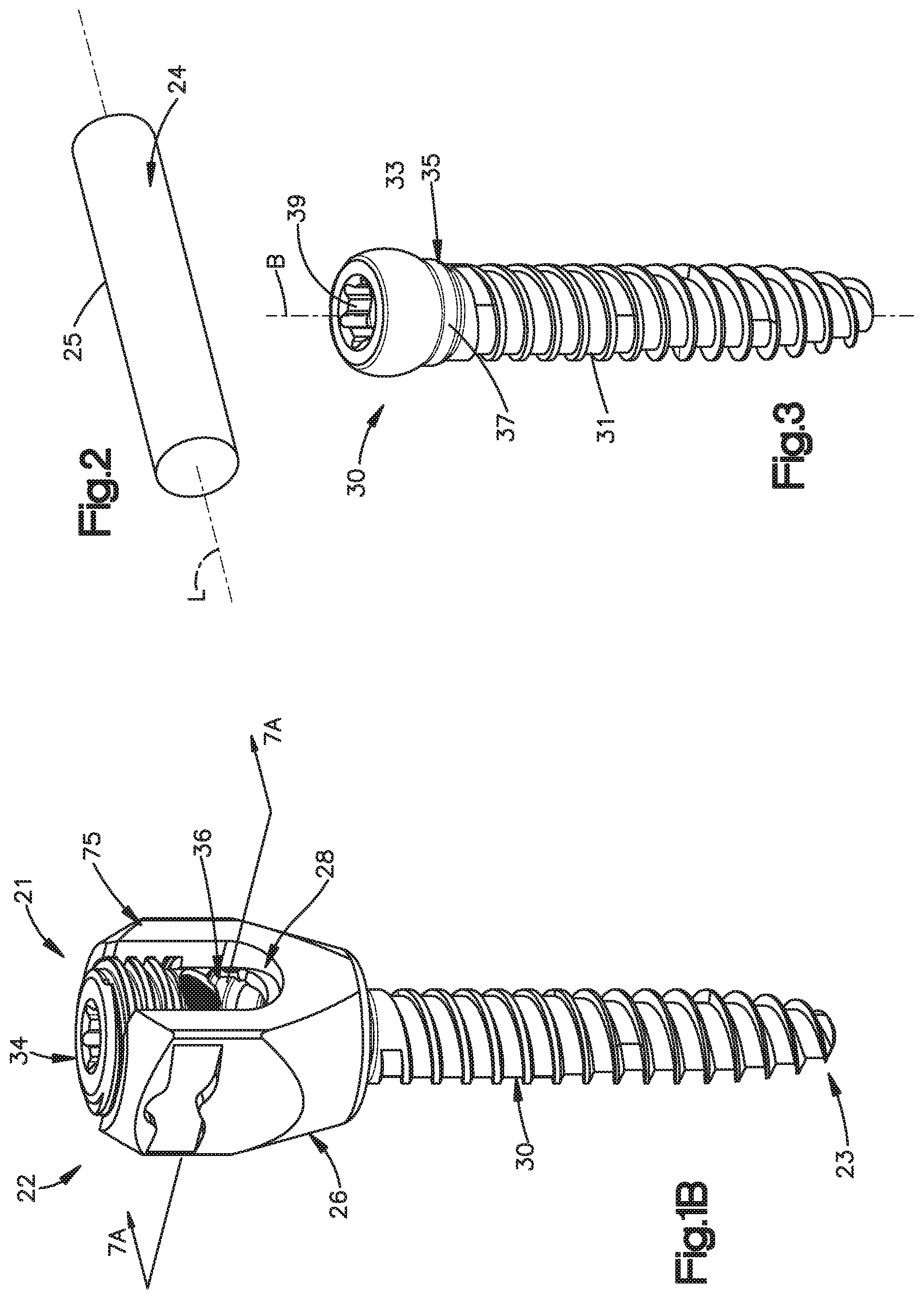

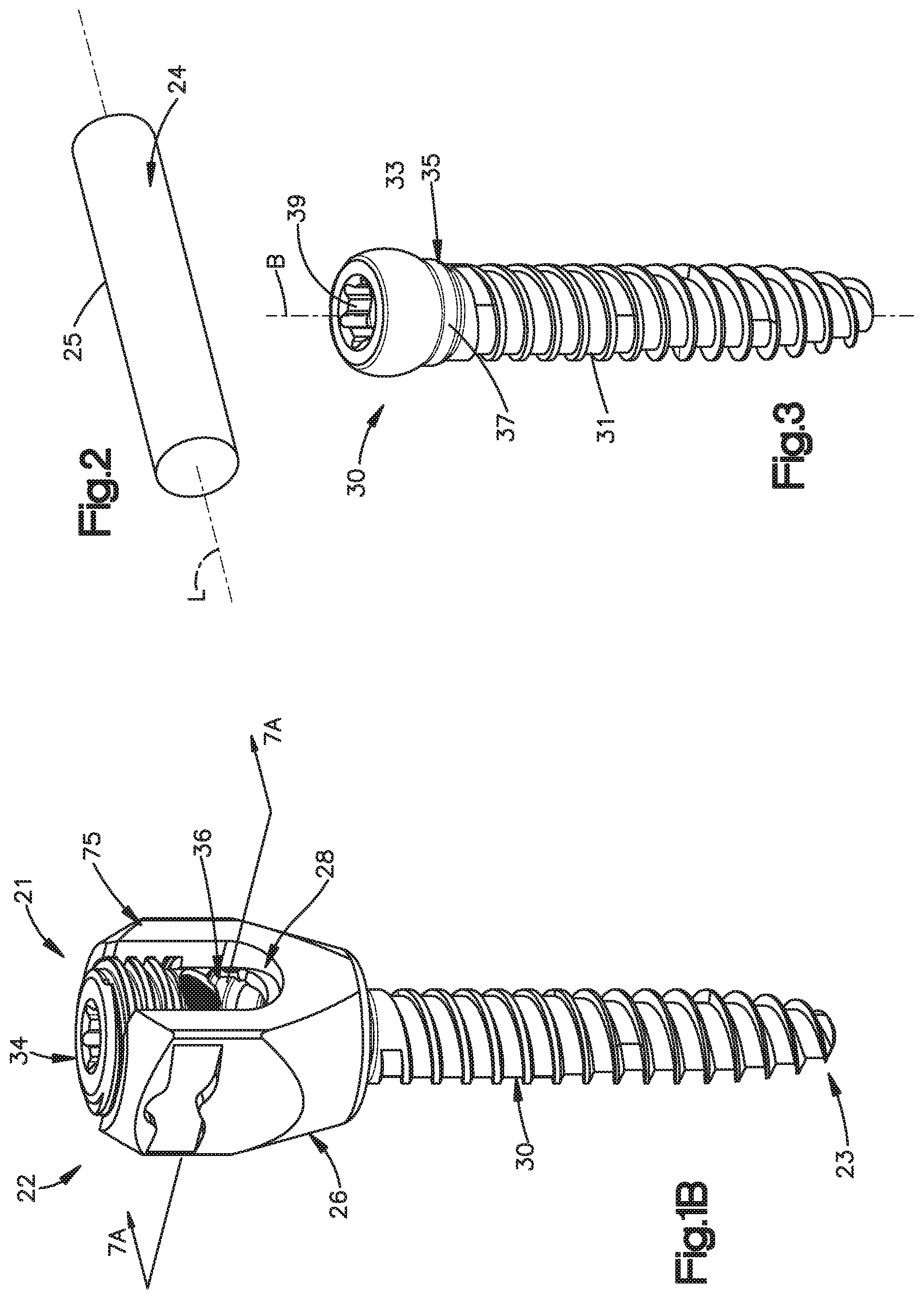

FIG. 1B is a perspective view of one of the bone fixation elements illustrated in FIG. 1A constructed in accordance with one embodiment, including an anchor seat, a bone anchor, a collet, and a locking cap;

FIG. 2 is a perspective view of the spine fixation rod illustrated in FIG. 1A;

FIG. 3 is a perspective view of the bone anchor illustrated in FIG. 1B;

FIG. 4 is a perspective view of the anchor seat illustrated in FIG. 1B;

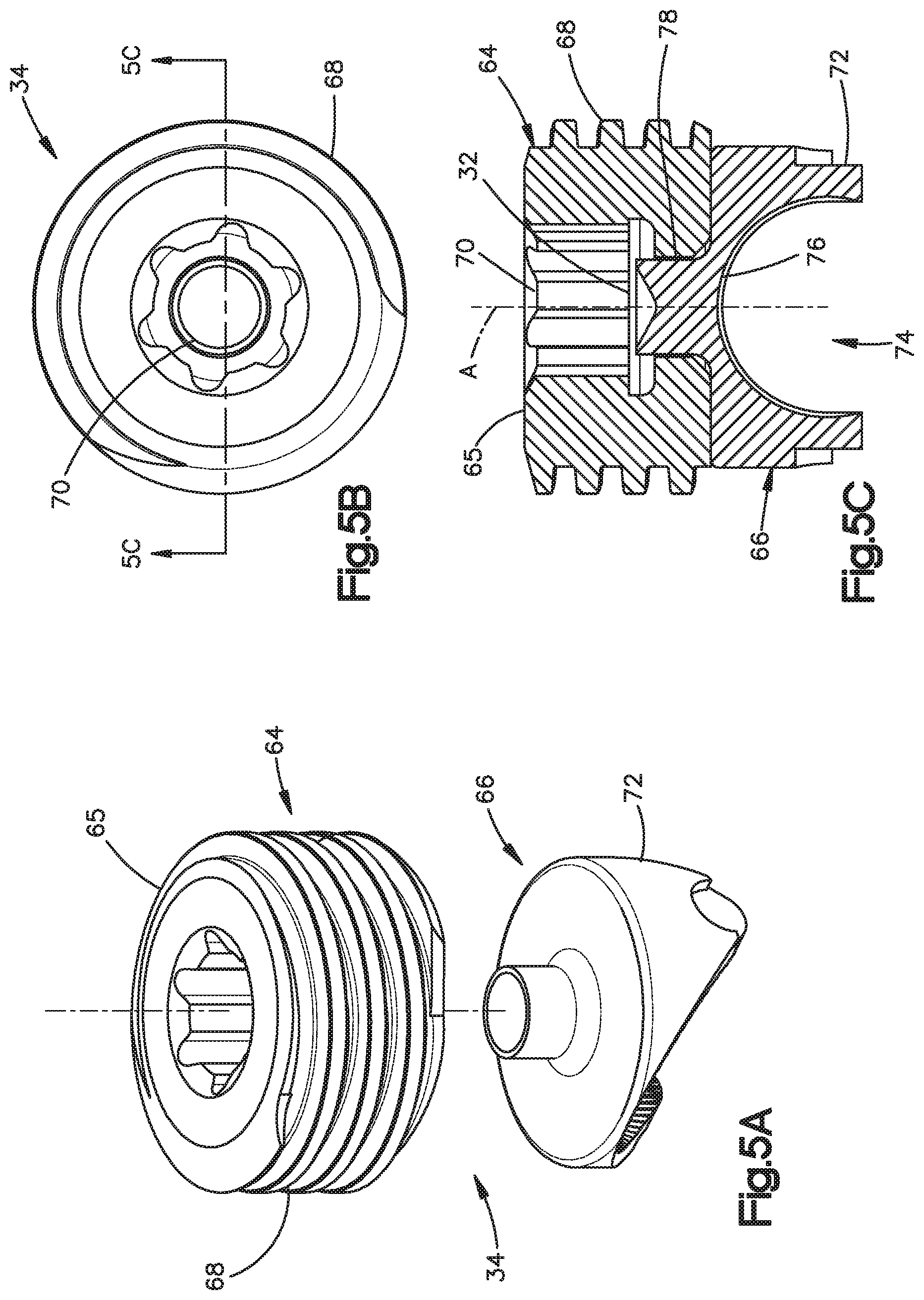

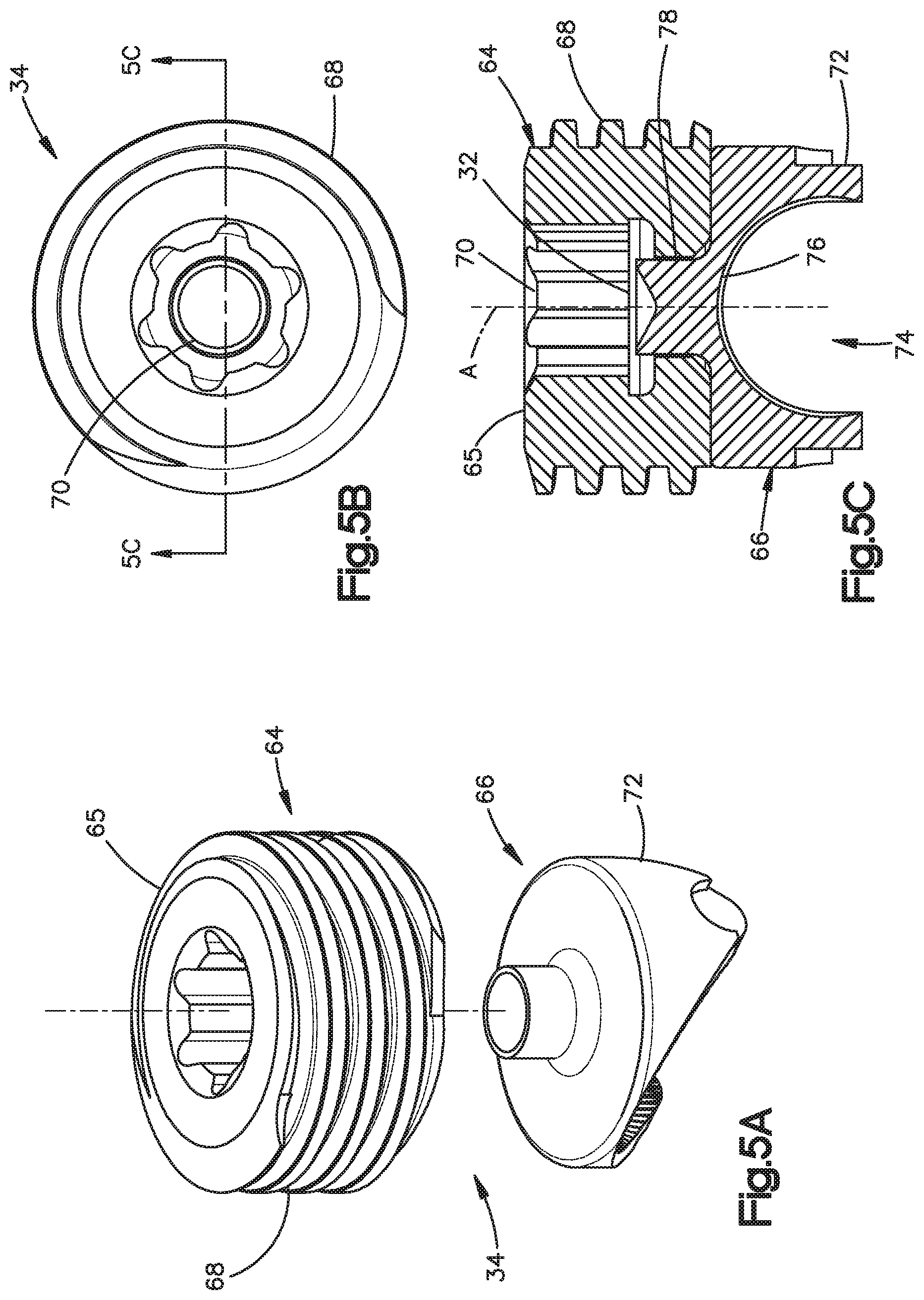

FIG. 5A is an exploded perspective view of the locking cap illustrated in FIG. 1B;

FIG. 5B is a top plan view of the locking cap illustrated in FIG. 5A;

FIG. 5C is a sectional side elevation view of the locking cap illustrated in FIG. 5B;

FIG. 6 is a perspective view of the collet illustrated in FIG. 1B;

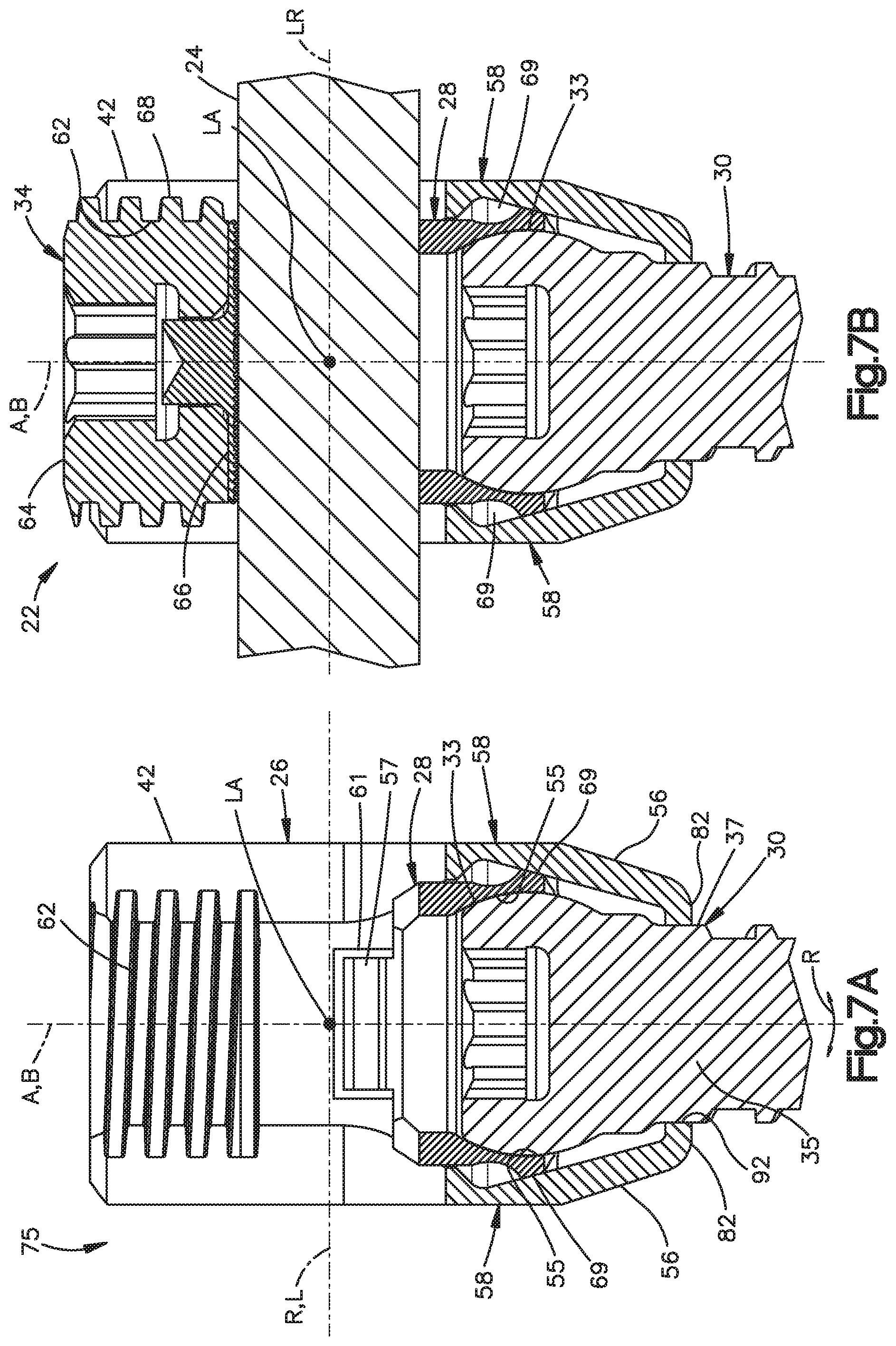

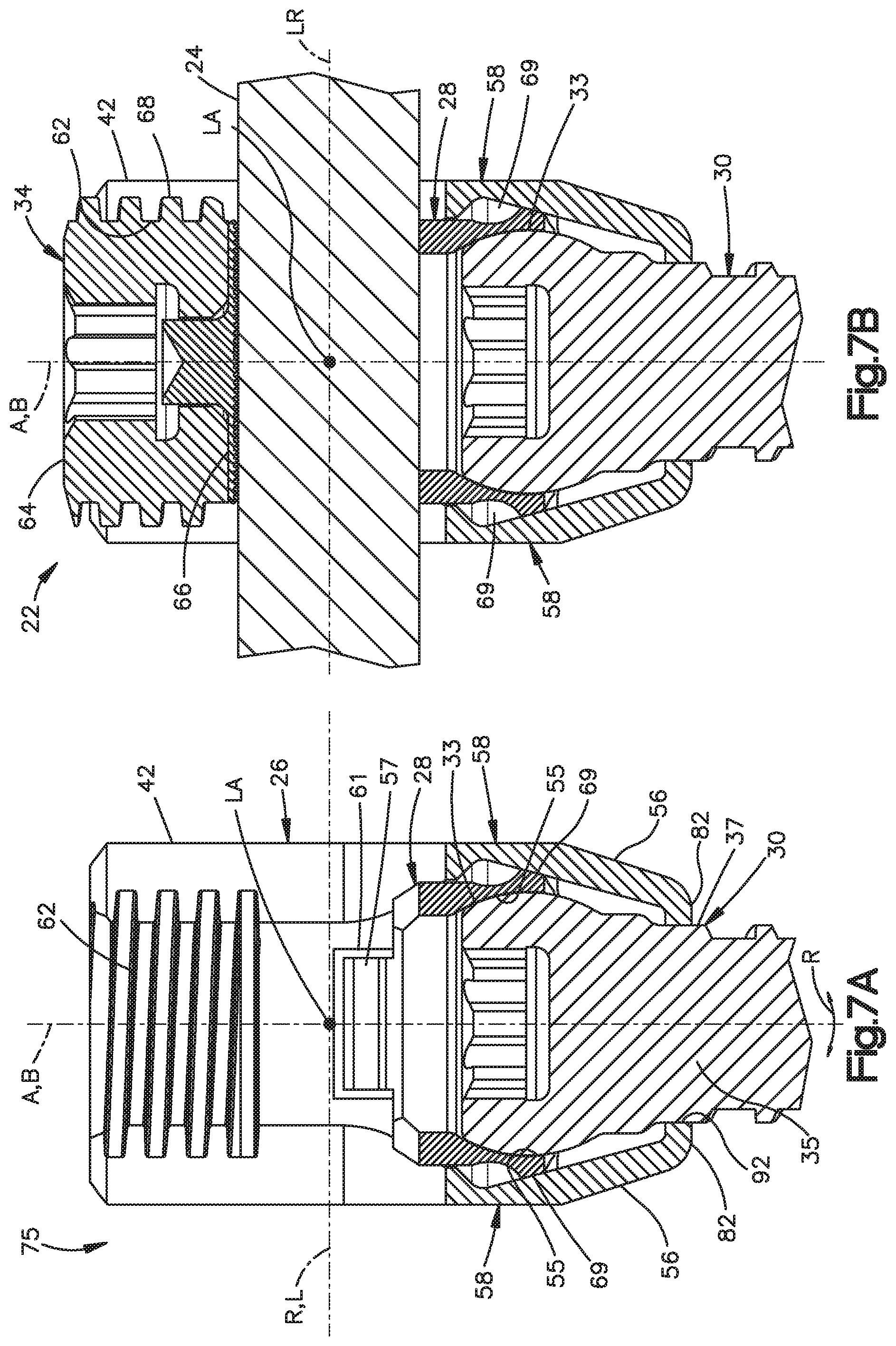

FIG. 7A is a sectional side elevation view of the bone fixation element illustrated in FIG. 1B taken along line 7A-7A, with the locking cap removed, to illustrate a vertebral screw assembly;

FIG. 7B is a sectional side elevation view similar to FIG. 7B, but showing a spine fixation rod extending through the anchor seat, and a locking cap affixed to the anchor seat;

FIGS. 8A-D are schematic views illustrating a method for assembling the bone fixation element illustrated in FIG. 1A;

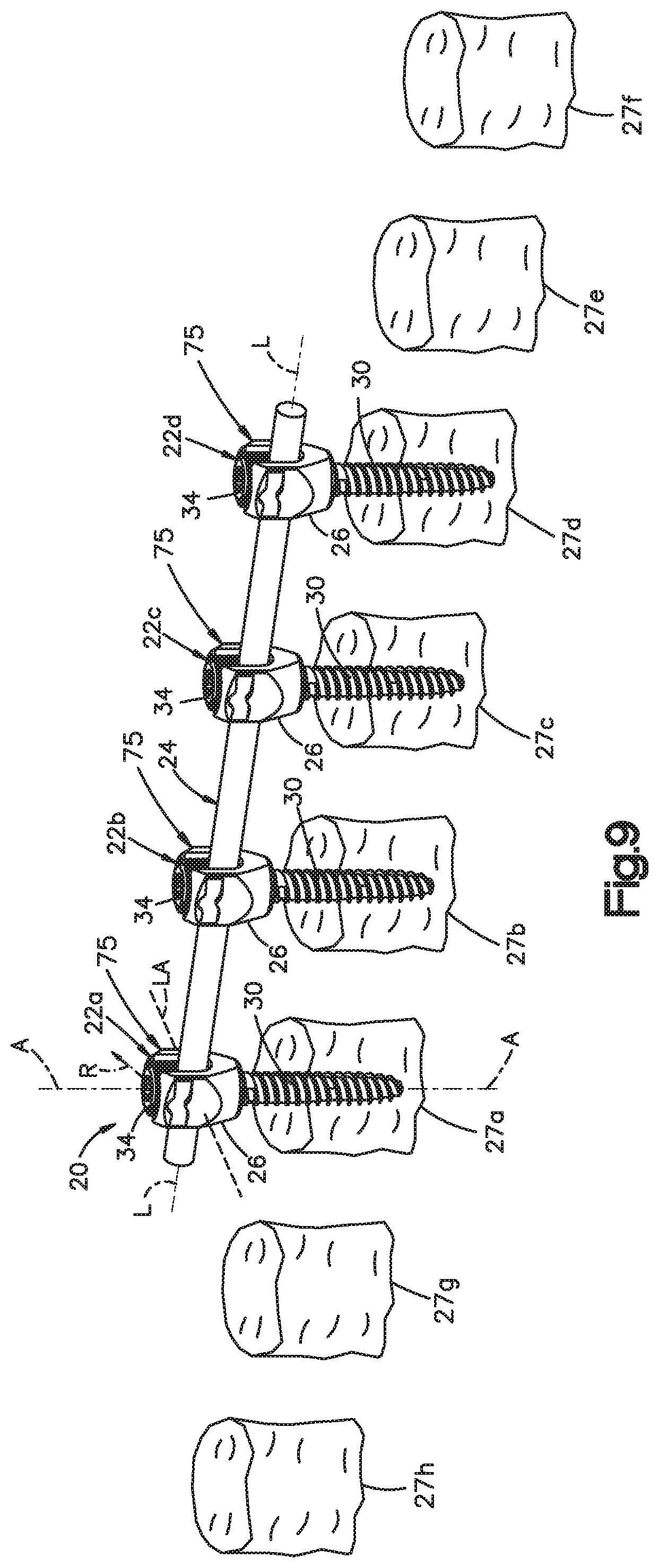

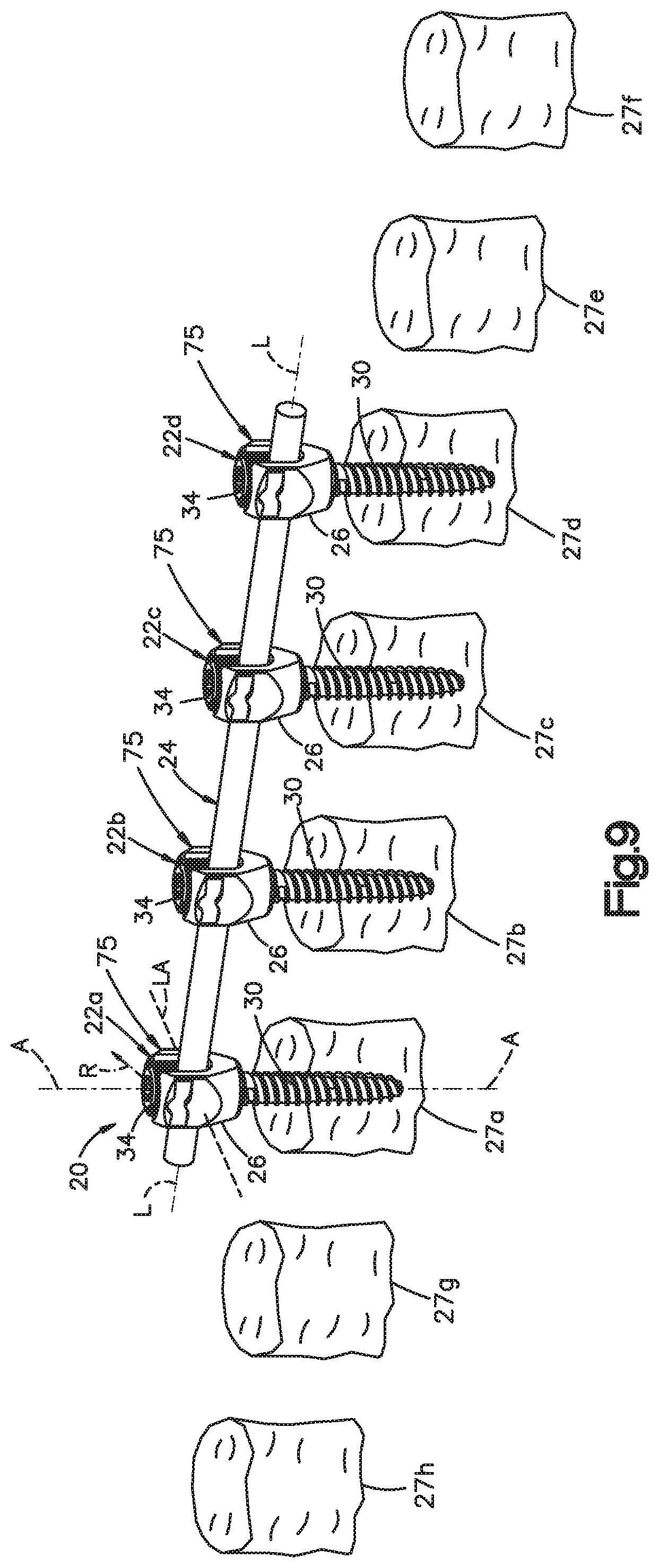

FIG. 9 is a perspective view similar to FIG. 1A, but showing a plurality of superior and inferior vertebrae with respect to the previously secured vertebrae;

FIG. 10A is an exploded view of an extender system constructed in accordance with one embodiment;

FIG. 10B is a sectional view through a portion of the extender system illustrated in FIG. 10A;

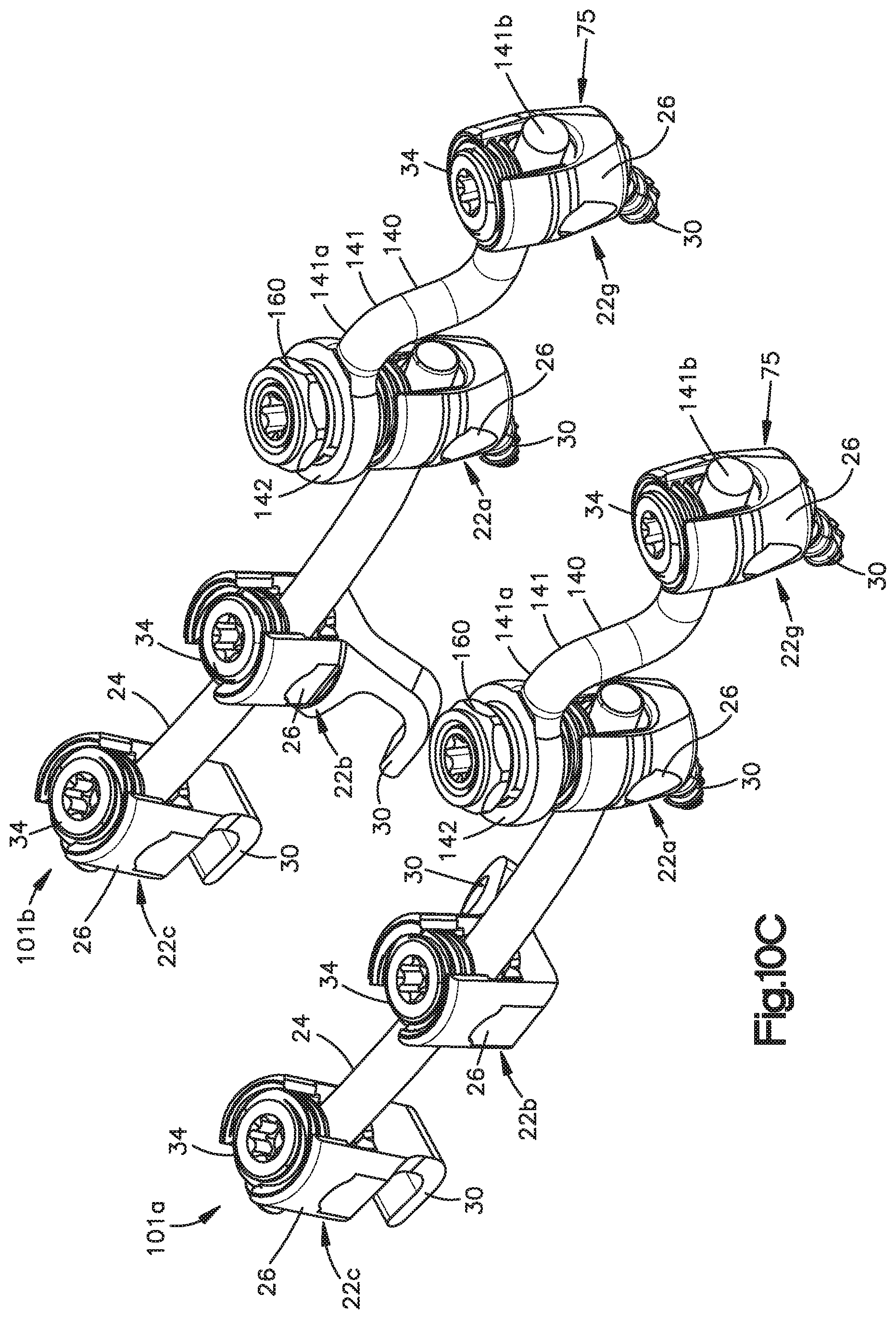

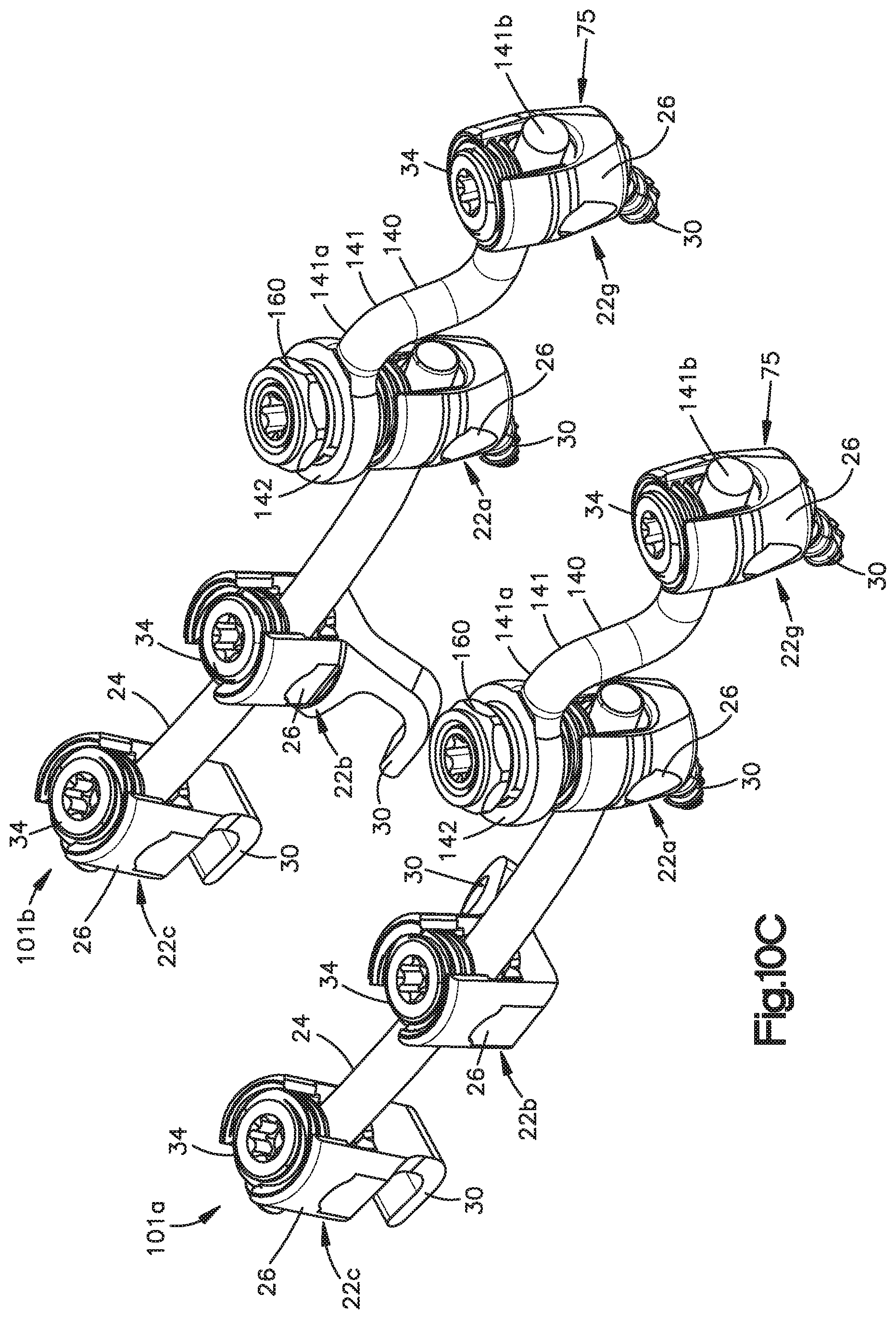

FIG. 10C is a perspective view of the extender system illustrated in FIG. 10A coupled to a previously implanted bone fixation assembly;

FIG. 10D is an enlarged side elevation view of a portion of the extender system illustrated in FIG. 10A coupled to a previously implanted bone fixation assembly;

FIG. 11A is an exploded view of a cascading extender system to be implanted into a plurality of vertebrae;

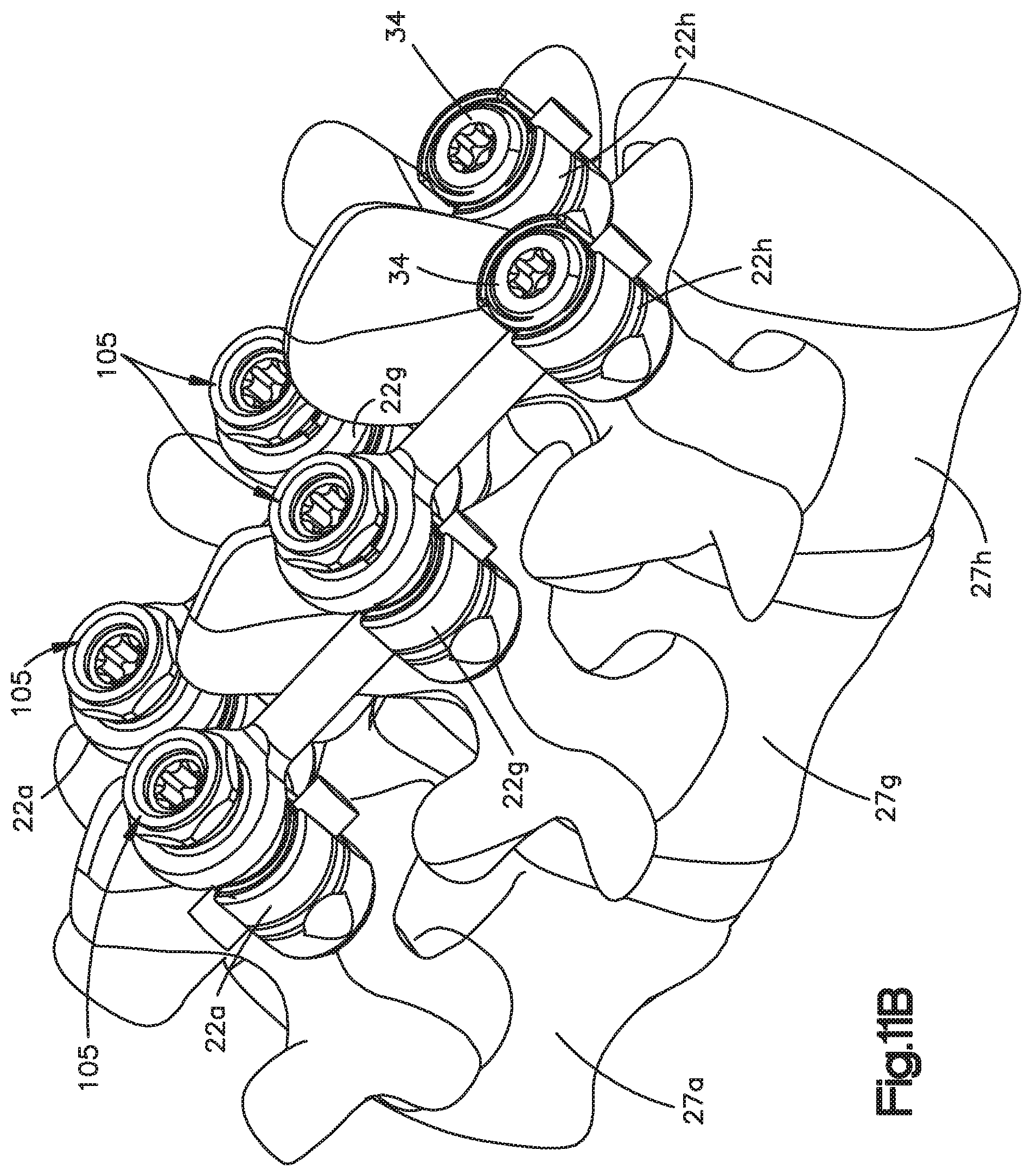

FIG. 11B is a perspective view of a pair of rows of the cascading extender system illustrated in FIG. 11A implanted into the vertebrae;

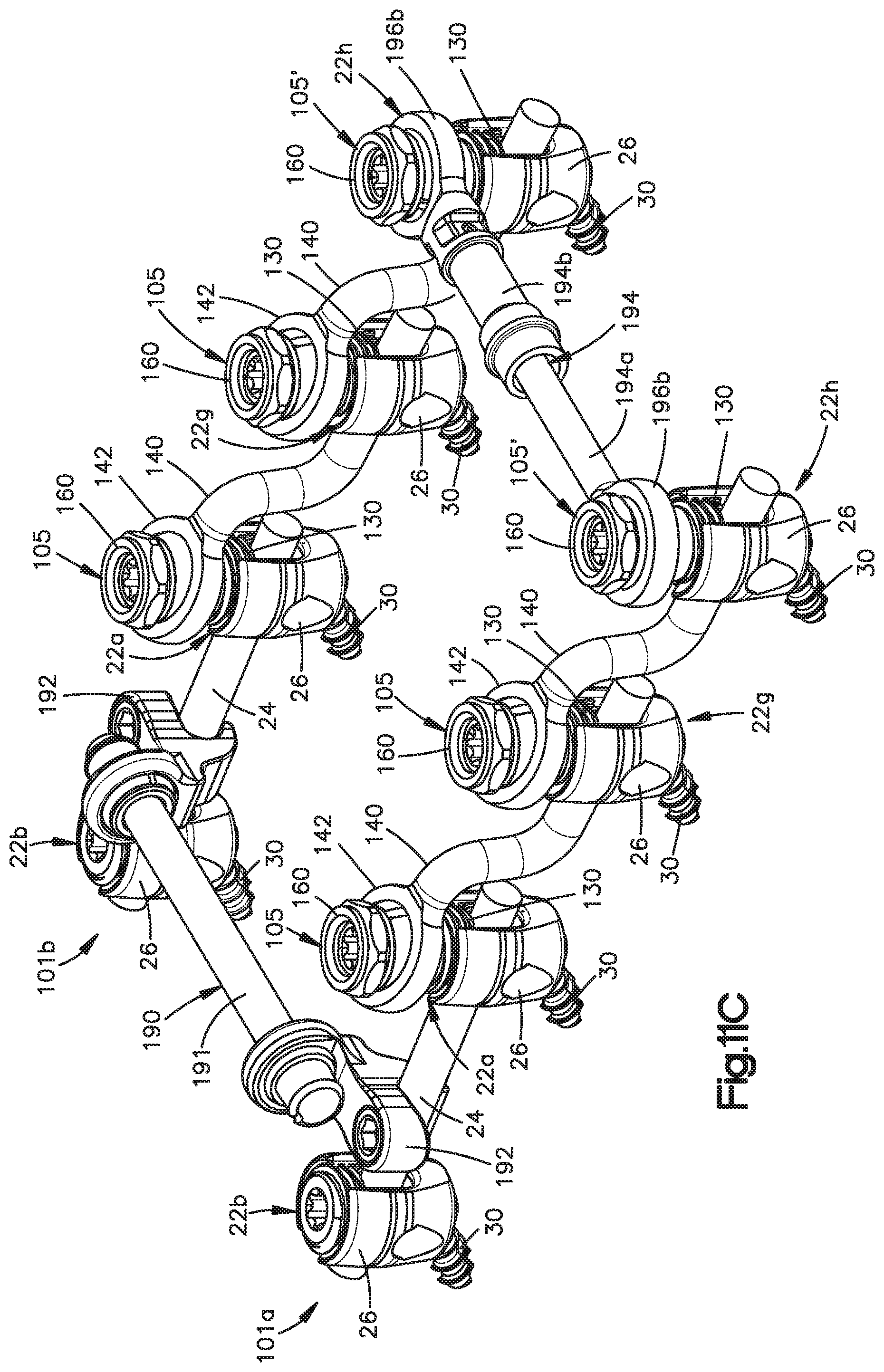

FIG. 11C is a perspective view of parallel rows of fixation elements connected by a cross bar;

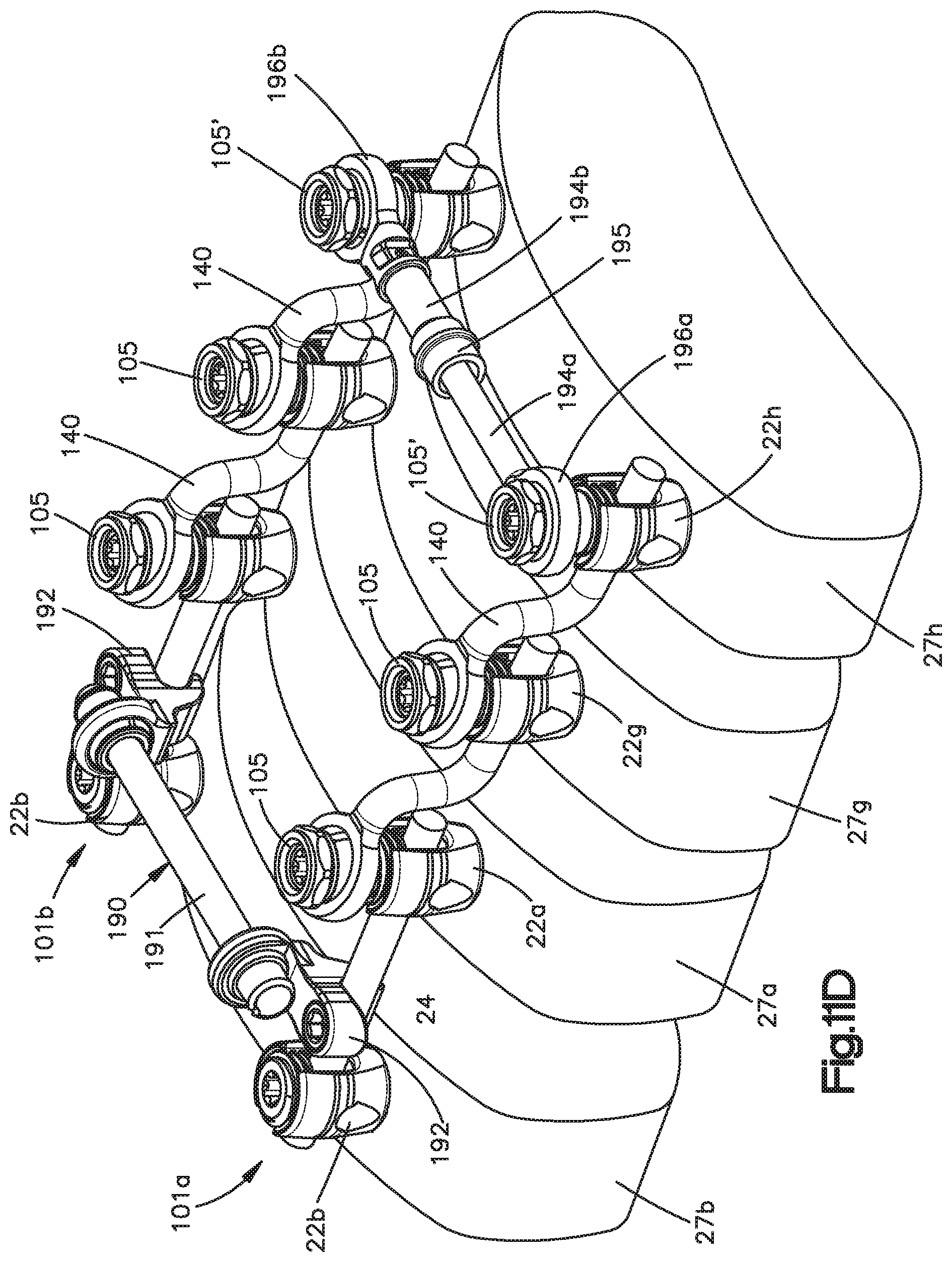

FIG. 11D is a perspective view of the fixation elements connected by a cross bar and implanted into a plurality of schematically illustrated vertebrae

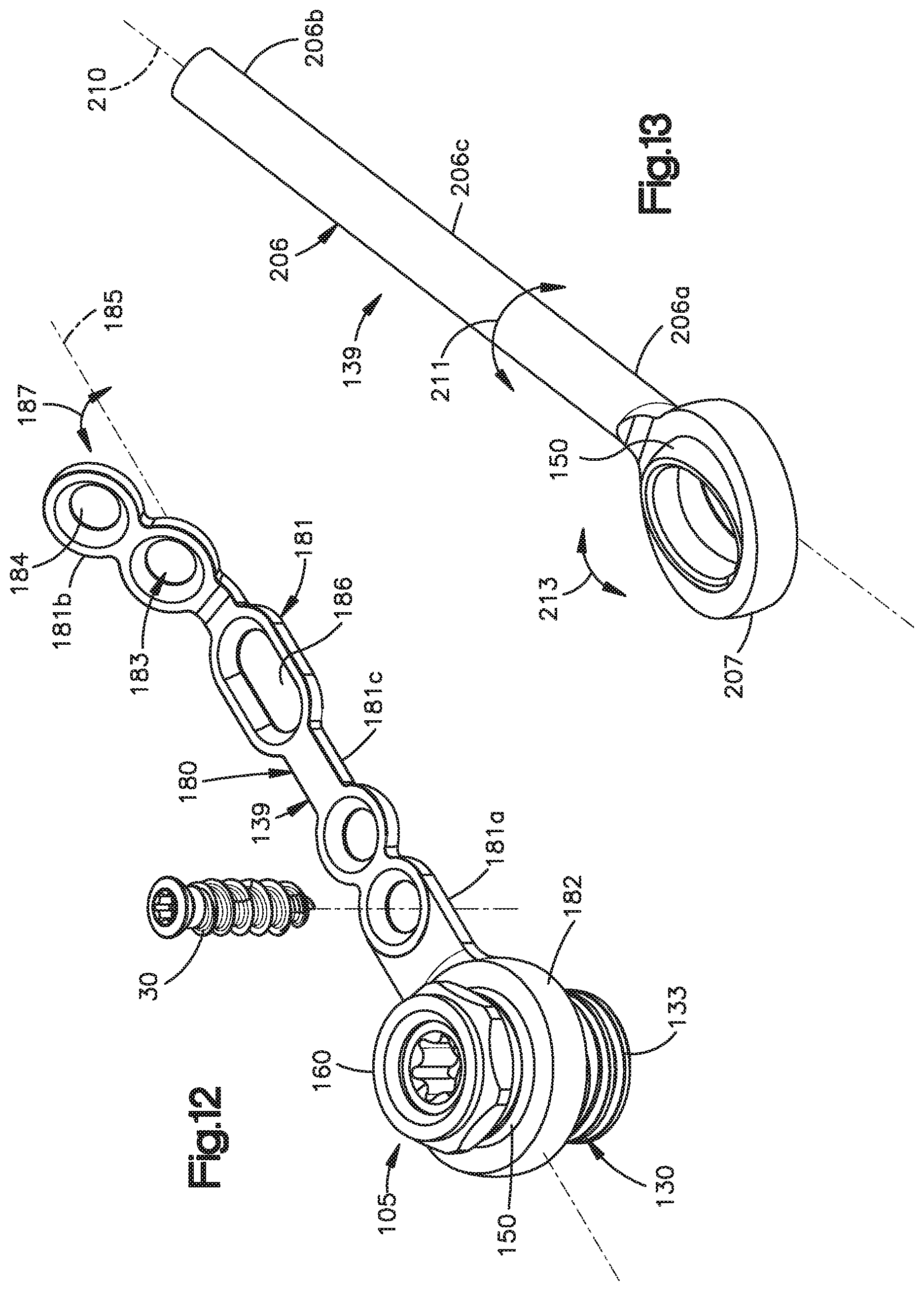

FIG. 12 is a perspective view of the extender system illustrated in FIG. 10A, but including an extension member constructed in accordance with an alternative embodiment;

FIG. 13 is a perspective view of the extender system illustrated in FIG. 10A, configured to connect a bone fixation element to a previously-implanted translaminar screw;

FIG. 14A is a perspective view of a pair of the extender systems illustrated in FIG. 10A configured to connect an occiput to a spine;

FIG. 14B is another perspective view of one of the extender systems illustrated in FIG. 14A;

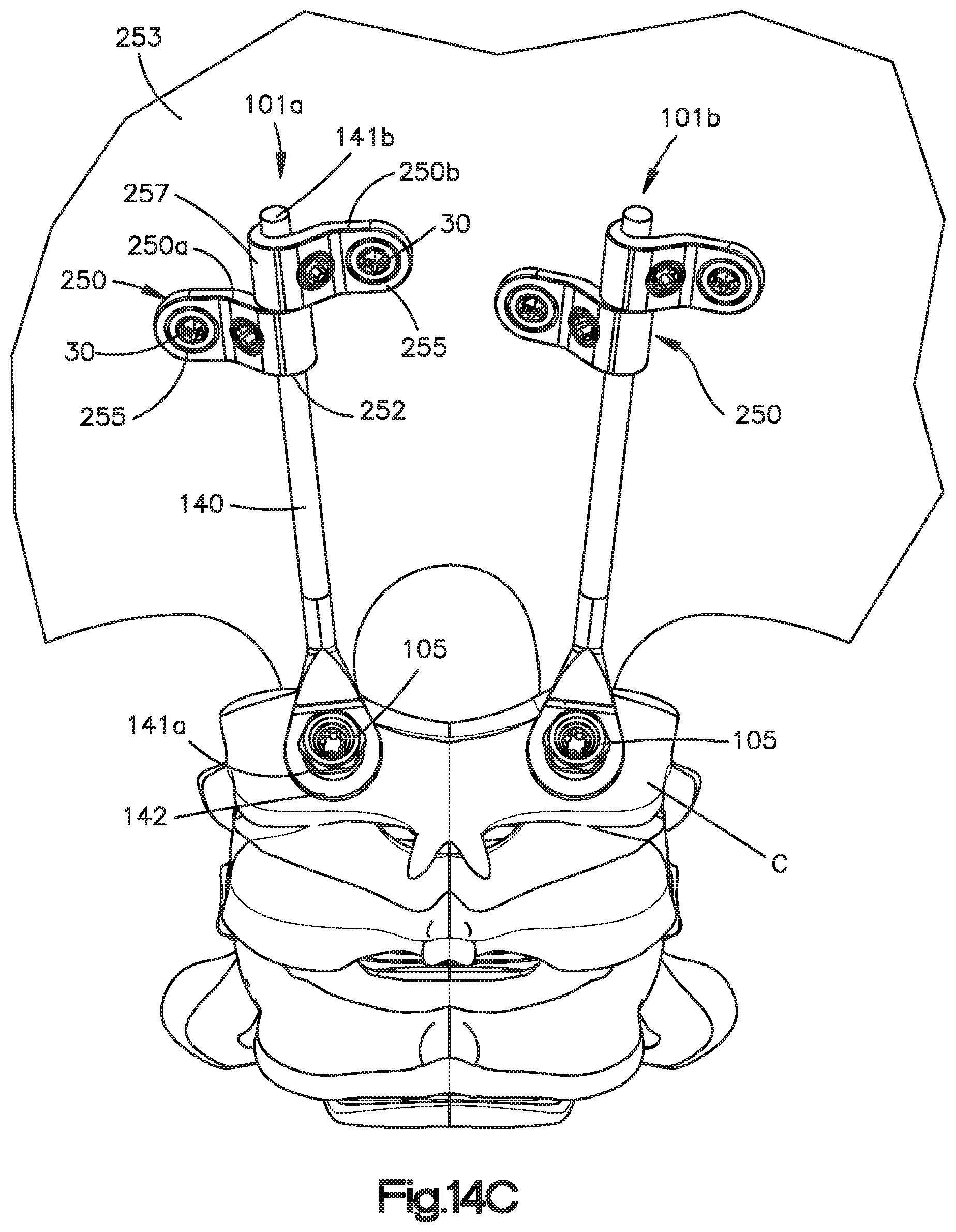

FIG. 14C is a perspective view of the extender systems illustrated in FIG. 14A connected between an occiput and a spine; and

FIG. 14D is another perspective view of one of the implanted extender systems illustrated in FIG. 14C.

DETAILED DESCRIPTION

Certain terminology may be used in the following description for convenience only and should not be considered as limiting in any way. For instance, a bone fixation assembly 20 includes one or more bone fixation elements 22, and four bone fixation elements 22A-D as illustrated in FIG. 1A. As shown in FIG. 1B, each bone fixation element 22 extends vertically along an axial direction A, and generally horizontally along a radial direction R that extends perpendicular to the axial direction A. Thus, the radial direction R includes a longitudinal direction L and a lateral direction LA that extends perpendicular to the longitudinal direction L. It should be appreciated that the directional terms "longitudinal," "lateral," can likewise apply to the bone fixation assembly 20 as extending horizontally, and the directional term "transverse" can refer to a vertical direction. The bone fixation element 22 defines an upper or posterior end 21 and a lower or inferior end 23, such that the directional terms "upper" and "lower" and derivatives thereof refer to a direction from the lower end 23 towards the upper end 21, and from the upper end 21 towards the lower end 23, respectively.

The words "inward," "outward," "upper," "lower," "distal," and "proximal," refer to directions toward or away from, respectively, the geometric center of the bone fixation assembly 20 and its components. The words, "anterior", "posterior", "superior," "inferior" and related words and/or phrases designate preferred positions and orientations in the human body to which reference is made and are not meant to be limiting. It should further be appreciated that while round structures define diameters as described herein, the round structures could be replaced with alternative (e.g., polygonal) structures which would define alternative cross-sectional dimensions opposed to diameters. The term "diameter" as used herein is intended to include all such alternatives unless otherwise specified. The terminology includes the above-listed words, derivatives thereof and words of similar import.

It should be appreciated that the directional terms are used herein with reference to the orientation of the bone fixation assembly 20 and its components as illustrated, and that the actual orientation of the bone fixation assembly 20 and its components may change during use. For instance, the axial direction is illustrated as extending along a vertical direction, and the radial direction is illustrated as extending along a horizontal direction, however the directions that encompass the various directions may differ during use, depending, for instance, on the desired orientation of the bone fixation assembly 20 during use. Accordingly, the directional terms are used herein merely for the purposes of clarity and convenience only, in a non-limiting manner.

Referring now to FIG. 1A, the bone fixation assembly 20 includes a plurality of bone fixation elements, such as bone fixation elements 22A-D, connected by a spine fixation rod 24 that extends along a longitudinal axis L. The bone fixation elements 22A-D each include a bone anchor 30 that is implanted (e.g., screwed) into a corresponding vertebra 27A-D. The bone fixation elements 22A-D can be implanted into the posterior region of the spine, or any suitable alternative region of the spine, for instance into the pedicle or other spinal region. The bone anchor 30 can be provided as a screw, hook, or alternatively constructed top loading bone anchor configured to attach to an underlying vertebra. Unless otherwise specified, the bone fixation assembly 20 and its components can be made from titanium-aluminum-niobium alloy (TAN), implant-grade 316L stainless steel, or any suitable alternative implant-grade material.

With continuing reference to FIG. 1A, the bone fixation elements 22A-D will be described as and may be generally implanted in the spine, for instance at the posterior portion of a lumbar, thoracic, or cervical vertebral body. In this regard, when the bone fixation elements 22A-D are joined by the rod 24, the assembly 20 fixes the relative position of the vertebrae (illustrated schematically at 27A-D). Accordingly, the bone fixation elements 22A-D can be referred to as vertebral implants, the spine fixation rod 24 can be referred to as a spine fixation rod, and the bone fixation assembly 20 can be referred to as a vertebral implant. However, it should be appreciated that the bone fixation assembly 20 can also be used for fixation of other parts of the body, such as joints, long bones, or bones in the hands, face, feet, extremities, cranium, and the like.

As shown in FIG. 2, the spine fixation rod 24 is elongate along a longitudinal axis L, and includes a body 25 that is cylindrical or tubular in shape. The longitudinal axis L extends generally in a cranial-caudal direction when the bone fixation assembly is affixed to the spine. The rod body 25 may include, but is not limited to, a solid body, a non-solid body, a flexible or dynamic body, or the like, and can assume any alternative shape as desired. It should thus be appreciated that the bone fixation assembly 20 is not limited in use to any particular spine fixation rod 24.

Referring now also to FIG. 1B, the bone fixation elements 22a-d of the bone fixation assembly 20 will now be described with respect to the bone fixation element 22. In particular, the bone fixation element 22 generally includes a vertebral implant 75, and a locking cap 34. The vertebral implant 75 is illustrated as including a bone anchor seat 26, a collet 28 disposed inside the anchor seat 26, a bone anchor 30 (shown as a threaded bone screw) having a head portion 33 (see FIG. 3) attached to the collet 28. The locking cap 34 is installed in the anchor seat 26 at a location above the collet 28, such that the spine fixation rod 24 is located in a rod slot 36 that is disposed, and as illustrated defined, between the collet 28 and the locking cap 34.

Referring also to FIG. 3, the bone anchor 30 is configured as a bone screw, or vertebral screw, that includes an externally threaded shaft 31 coupled at its upper end to an enlarged curved head 33. The shaft 31 extends axially along a central axis B of rotation, and can define any suitable diameter, length, and thread design so as to engage the underlying bone, such as a vertebra 27. Alternatively, the shaft 31 can be unthreaded so as to define a pin or a nail if desired. Thus, one skilled in the art will appreciate that the bone anchor 30 is not limited to any particular type of shaft 31. The bone anchor 30 may also be cannulated and fenestrated such that openings extend radially outward from a central hollow channel in a cannulated shaft to urge fluid out of the bone anchor 30 during injection or draw fluid into the central hollow channel from the radial sides of the anchor during extraction of material adjacent the anchor if desired.

The bone anchor 30 further includes a vertically extending neck 35 connected between the shaft 31 and the head 33. The neck 35 is illustrated as extending axially in a direction parallel to axis B, and includes an outer neck surface 37 that defines a neck diameter, which is less than the diameter of the head 33.

The head 33 can define at least a partially spherical curvature, such as a semi-spherical curvature, or can alternatively define any suitable curvature as desired to facilitate rotation with respect to the collet 28 as is described in more detail below. The head 33 also includes a drive surface 39 configured to receive a corresponding tip of a drive tool, such as a screw driver configured to rotate the bone anchor 30 into engagement with the vertebrae 27 or other underlying bone surface. The drive surface 39 can define a hexagon, a star drive pattern, a Phillips head pattern, a slot for a screw driver, threads configured to receive corresponding threads of a threaded drive post, or any suitable drive tool engaging structure as desired.

Referring now to FIG. 4, the anchor seat 26 includes an anchor seat body 38 that can be described as a generally cylindrical tubular body extending centrally along an axial axis A that extends generally in the anterior-posterior direction when the bone fixation element is implanted in the underlying vertebra. The body 38 includes a base 40 and a pair of spaced opposing arms 42 extending out (up in illustrated the orientation) from the base 40. The arms 42 can be substantially identically or identically constructed. The arms 42 define corresponding upper ends 46 that are also the upper ends of the body 38, and define an upper opening 48. The base 40 defines a lower end 50 that is also the lower end of the body 38, and defines a lower opening 52. The body 38 defines an axial bore 54 extending from the lower opening 52 to the upper opening 48.

The body 38 includes opposing support walls 56 and a pair of spaced opposing spacer walls 58 connected between the support walls 56. The support walls 56 can be substantially identically or identically constructed, and the spacer walls 58 can likewise be substantially identically or identically constructed. The arms 42 extend up from respective support walls 56, and can be shaped as desired. As illustrated, the arms 42 are arc-shaped with the axis of the arc passing through the plane of symmetry that bisects the anchor seat 26. Each arm 42 extends circumferentially about its axis less than 180.degree., such as between 60.degree. and 150.degree., for instance approximately 90.degree.. For instance, each arm 42 can extend circumferentially 90.5.degree. about its axis.

Accordingly, a gap G extends circumferentially between adjacent circumferentially outer ends of the arms 42. The opposing gaps G are in alignment with the axial bore 54. The arms 42 can be disposed radially opposite each other such that the gaps G, in combination with the aligned portion of the axial bore 54, define a rod-receiving channel 36 that is sized and configured to receive the spine fixation rod 24 such that the spine fixation rod 24 extends through the bone fixation element 22. Thus, the gaps G are aligned in the longitudinal direction. The spine fixation rod 24 can thus extend through the opposing gaps G and the axial bore 54. The arms 42 define radially inner and outer surfaces 60 and 62, respectively. The inner surfaces 60 define threads 62, and are configured to threadedly receive the locking cap 34, as will now be described.

In particular, referring to FIGS. 5A-C, the locking cap 34 is illustrated as a set screw 64 and a saddle 66 operatively coupled to the set screw 64. The set screw 64 includes a generally cylindrical set screw body 65 having external threads 68 configured to threadedly engage the threads 62 formed on the inner surfaces 60 of the arms 42. In accordance with one embodiment, the threads 68 and 62 can incorporate inclined load flanks forming an angle with respect to the axis A of the bone fixation element 22. The load flanks may converge so that the top surface of the thread and the bottom surface of the thread converge. The angle may be between 0 degrees (0.degree.) and 30 degrees (30.degree.), and in one embodiment can be about five degrees (5.degree.). One skilled in the art will appreciate that the threads may take on any alternative form as desired, including negative load threads, perpendicular threads, buttress threads, or the like.

The externally threaded set screw 64 generally provides flexibility when inserting the spine fixation rod 24 into the anchor seat body 38 such that the spine fixation rod 24 need not be completely reduced or seated within the body 38 prior to engagement of the locking cap 34. The set screw 64 is configured to be tightened within the anchor seat 26 against the spine fixation rod 24. The locking cap 34 may be constructed as desired for this purpose including, but not limited to, an externally threaded cap, a quarter-turn or partial-turn locking cap, a two-piece screw set, or the like.

The set screw 64 is illustrated as including a drive surface 70 provided as an internal recess extending vertically down into the upper end of the screw 64. The drive surface has any suitable shape configured to cooperate with a corresponding drive tool for threadedly securing the set screw 64 onto the anchor seat body 38. The drive surface 70 can define any shape as desired, for instance an external hexagon, a star drive pattern, a Phillips head pattern, a slot for a screw driver, a threading for a correspondingly threaded post, or the like.

With continuing reference to FIGS. 5A-C, the saddle 66 includes a saddle body 72 having a transverse recess 74 extending up into the bottom end of the saddle body 72. The recess 74 can define a round surface that extends about a longitudinally extending axis, such that the recess 74 is configured to receive the spine fixation rod 24 at a rod-contacting surface 76. The rod-contacting surface 76 can include a desired surface finish that adds roughness, such as, for example, a knurl, bead blasting, grooves, or other textured finish that increases surface roughness and enhances rod push through strength.

The saddle 66 can be coupled to the set screw 64 in any desired manner, including adhesion, mechanical fastening, and the like. In the illustrated embodiment, the saddle 66 includes a stem 78 extending centrally upward from the saddle body 72. The stem 78 is configured to be received in a central bore 32 extending vertically into the lower end of the set screw body 65, and can be fastened within the central bore with a rivet 80 or other like fastener. Accordingly, the saddle 66 is rotatable relative to the set screw 64, such that the saddle 66 can self-align with the spine fixation rod 24 as the set screw 64 is being rotated with respect to the anchor seat 26, for instance when the locking cap 34 is being tightened against the spine fixation rod 24.

Referring again to FIG. 4, and as described above, the anchor seat body 38 includes a pair of spaced opposing support walls 56 and a pair of spaced opposing spacer walls 58 connected between the support walls 56. The arms 42 extend up from respective support walls 56, such that the spacer walls 58 are disposed between the arms 42. Each of the spacer walls 58 defines opposing upper ends 84 and lower ends 82 that can be shaped as desired. The upper ends 84 are round in accordance with the illustrated embodiment, such that the upper ends 84 and the circumferentially outer ends of the arms 42 are adjoined to generally define a U-shape from a horizontal view through the gaps G. Thus, the upper ends 84 define the lower end of the gaps G.

The upper ends 84 can be shaped to conform generally with the outer surface of the spine fixation rod 24, such that the upper ends 84 receive and engage the spine fixation rod 24 during use. Alternatively, the upper ends 84 can be spaced slightly below the upper surface of the collet 28, such that the collet 28 supports the spine fixation rod 24 during use, as will be described in more detail below.

The support walls 56 each define opposing inner and outer surfaces 86 and 88, respectively. The support walls 56 and the spacer walls 58 flare inward toward the central axis A in a downward direction from the arms 42, and terminate at respective lower ends 90. The inner surfaces 86 of the opposing support walls 56 and spacer walls 58 at the lower end 90 define a distance D therebetween that is less than the distance between opposing radially opposing inner surfaces 60 of the arms 42. The distance D can be less than or greater than the diameter of the head 33 of the bone anchor 30. The inner surfaces 86 flare radially inward toward the central axis A, and toward each other, along a downward direction, and are each connected to bottommost, and innermost, surfaces that define respective abutment walls 92.

Referring also to FIGS. 4B and 7A, each abutment wall 92 defines respective inner abutment surfaces 93 that in turn define a distance therebetween that is substantially equal to the diameter of the neck 35, such that the abutment walls 92 are configured to abut opposing abutment surfaces of the bone anchor, which are illustrated as opposing sides of the outer neck surface 37 when the bone anchor 30 is disposed in the anchor seat 26. Thus, the abutment walls 92 can prevent or limit pivoting of the bone anchor 30 relative to the anchor seat 26 in a desired plane.

Referring now to FIG. 6, the collet 28 includes a collet body 45 that defines a first or upper end 47 sized and configured to contact or support at least a portion of the spine fixation rod 24 when the rod is received within the rod-receiving channel 36, and a second or lower end 49 sized and configured to contact or otherwise engage, directly or indirectly, a portion of the bone anchor head 33. The collet body 45 is annular, and thus defines an axial bore 53 extending between and through the upper and lower ends 47 and 49. The axial bore 53 is aligned with the axial bore 54 when the collet 28 is installed in the anchor seat 26.

Referring to FIGS. 6 and 7A-B, the upper end 47 defines radially opposing upwardly facing seat portions 51 having a curvature or semi-spherical shape corresponding to the outer surface of the spine fixation rod 24, and is therefore configured to receive or otherwise support at least a portion (e.g., a lower portion) of the rod 24. The lower end 49 defines an inner surface 55 defining a curvature or semi-spherical shape corresponding to the outer surface of the anchor head 33, and is therefore configured to receive or otherwise engage at least a portion of the head 33, so that the head can rotate with respect to the collet 28 and the anchor seat 26, and can further pivot with respect to the collet 28 as permitted by the anchor seat 26. Because the bone anchor 30 can freely rotate about its axis of rotation B relative to the anchor seat 26, and thus the anchor seat 26 can likewise rotate about the bone anchor 30, the rod-receiving channel 36 can be aligned with the spine fixation rod 24 without advancing or withdrawing the bone anchor 30 in or out of the underlying bone. Thus, the bone anchor 30 can maintain a constant insertion depth in the underlying bone (e.g., vertebra 27) while adjusting the orientation of the rod-receiving channel 36.

The collet 28 further includes a pair of flanges 57 extending up from the upper end 47 of the collet body 45 at a location radially between the seat portions 51. A locking lip 59 extends radially out from each flange 57. As best shown in FIG. 7A, the anchor seat 26 defines a pair of opposing recesses 61 (see FIG. 8A) formed radially in the opposing inner surfaces 86 of the support walls 56 at a location below the threaded inner surfaces 60 of the arms 42. During operation, the collet 28 can be inserted down into the anchor seat 26, thereby causing the flanges 57 to flex inwardly past the threaded inner surfaces 60, until the lips 59 clear the upper ends of the recesses 61, at which point the flanges 57 snap back out so that the lips 59 are disposed in the recesses 61. Interference between the lips 59 and the upper ends of the recesses 61 prevent the collet 28 from backing out through the upper end of the anchor seat 26. The recesses 61 further define a circumferential length substantially equal to that of the flanges 57 and locking lips 59, such that the collet 28 is rotationally fixed with respect to the anchor seat 26 in a position whereby the upper surface 47 is aligned with the spine fixation rod 24 when the spine fixation rod 24 is inserted into the anchor seat 26.

The lower end 49 of the collet 28 defines an outer diameter that is greater than the inner distance between the abutment walls 92. Accordingly, the collet 28 is unable to pass axially down through the lower end of the anchor body 26. The lower end 49 includes one or more slots 67 (illustrated as a plurality of slots) extending radially therethrough so as to define opposing pluralities of fingers 69 that are configured to pop over the head 33 of the bone anchor 30. When the collet 28 is disposed in the anchor seat 26 such that the lips 59 are disposed in the respective recesses 61, the fingers 69 are axially aligned with the abutment walls 92. Thus, as shown in FIGS. 7A-B, when the collet 28 and anchor 30 are installed in the anchor seat 24, the fingers 69 radially expand to conform to the outer surface of the anchor head 33 and the inner surfaces of the anchor seat 26. The inner diameters defined by the opposing fingers 69 are less than the outer diameter of the anchor head 33 to prevent the anchor 30 from being removed from the anchor seat 26 in an axially downward direction. The lower ends of the fingers 69 terminate at a location above the abutment walls 92. Accordingly, the fingers 69 do not interfere with the engagement between the anchor neck 35 and the abutment walls 92.

Referring now to FIGS. 8A-D, a method for assembling the vertebral implant 75 includes at step 1, inserting the bone anchor 30 vertically down through the axial bore 54, such that the shaft 31 extends through the lower opening 52 of the lower end 50 of the anchor seat 26, and the anchor head 33 is disposed above the abutment walls 92. This method step for inserting the bone anchor 30 into the anchor seat 26 can thus be referred to as top-end loading of the bone anchor 30 into the anchor seat 26. Next, at step 2, the collet 28 is inserted into the axial bore 54 to a location whereby the locking lips 59 can engage the lowermost threads 62 of the inner surface 60 of the arms 42. Next, at step 3, an upward force can be applied to the bone anchor 30 so as to insert the anchor head 33 into the lower end 49 of the collet 28. The locking lips 59 of the collet 28 brace against the anchor seat 26 inside the threads 62 to prevent the upward force applied by the screw 28 from causing the collet 28 to back out of the upper opening of the anchor seat 26. At step 4, a downward force is applied to the collet 28, thereby inserting the locking lips 59 into the recesses 61 in the manner described above, and locking the anchor 30 and collet 28 in the anchor seat 26.

During use, because the bone anchor 30 is rotatable with respect to the collet 28 and the anchor seat 26, a driving tool can engage the drive surface 39 of the head 33 so as to insert the threaded shaft 31 into the underlying bone, as shown in FIG. 1A. Next, as shown in FIGS. 8A-D, the anchor seat 26 can be rotated about axis A in the direction of Arrow R about the full 360.degree. range of angles so as to align the rod-receiving channel 36 with the longitudinal axis of the spine fixation rod 24. Thus, the vertebral implant 75 can be referred to as a polyaxial vertebral implant, and the bone fixation elements 22 can be referred to as polyaxial bone fixation elements. Alternatively, it should be appreciated that the bone fixation element can allow the anchor seat 26 to rotate in one plane with respect to the axis A, and can thus be referred to as a monaxial vertebral implant. It should be further appreciated that the vertebral implant can include a hook as the bone anchor 30 as opposed to a screw. Once the bone anchor 30 has reached a desired depth in the underlying vertebra, the spine fixation rod 24 can be inserted into the vertebral implant 75. In particular, the spine fixation rod 24 is inserted into the axial bore 54 either horizontally through the gaps G, or vertically down into the axial bore 54. It should be appreciated that the spine fixation rod 24 will be seated in the upper end 47 of the collet 28.

With continuing reference to FIGS. 8A-D, once the rod 24 is installed in the vertebral implant 75, the locking cap 34 can be attached to the assembly 75 so as to fully assemble the anchor assembly 22. In the illustrated embodiment, the external threads 68 of the set screw 64 are rotated within the inner threads 62 of the anchor seat arms 42, thereby causing the set screw and saddle 66 to move axially down in the axial bore 54. As the saddle 66 approaches the spine fixation rod 24, the saddle 66 is rotated with respect to the set screw 64 so as to bring the rod-contacting surface 76 into alignment with the spine fixation rod 24. Once the saddle 66 is aligned with the spine fixation rod 24, the set screw 64 is continuously threadedly inserted into the bone anchor 26, such that the locking cap 34 can be tightened against the rod 24, thereby applying a downward axial force to the rod 24. The locking cap 34 can be said to be in an initial position when installed in the locking cap 34 but before applying an axial force against the spine fixation rod 24. The axial force applied to the rod 24 by the locking cap 34 is transmitted to the collet 28, which causes the fingers 69 to ride along the inner surfaces 86 of the support walls 56 and spacer walls 58.

As the fingers 69 ride along the walls 56 and 58, they become radially inwardly displaced due to the inward flare of the inner surfaces of the walls 56 and 58, thereby radially biasing, or radially compressing, the fingers 69 against the anchor head 33. Increasing radial compression of the fingers 69 against the anchor head 33 causes frictional forces between the fingers 69 and the anchor head 33 that resist rotation of the anchor 30 about the axis A relative to the anchor seat 26, collet 28, and spine fixation rod 24. When the locking cap is fully tightened to a locked position, the resulting frictional forces prevent the anchor 30 from movement relative to the anchor seat 26, collet 28, and spine fixation rod 24. Thus, the locking cap 34 is configured to transmit a locking force onto the collet 28 and bone anchor 30 to fix or lock the position of the bone anchor 30 relative to the anchor seat 26 and spine fixation rod 24. It should thus be appreciated that the spine fixation rod 24 is thus implanted to the underlying vertebra that is engaged by the bone anchor 30.

It should be appreciated that the above-described method steps can be performed for each bone fixation element of the bone fixation assembly 20 as desired. Furthermore, it should be appreciated that the while the bone fixation elements 22a-d have been described as each including the vertebral implant 75 described above, the bone fixation elements 22a-d can include any alternatively constructed vertebral implant suitable for fixing the spine fixation rod 24 to the underlying vertebrae 27. For instance, the vertebral implant 75 can be constructed so as to permit the bone anchor 30 to be implanted into underlying bone before the anchor head 33 is inserted into the collet 28. In one embodiment, the abutment walls 92 are slotted so as to expand over the anchor head 33. Accordingly, the anchor seat 26 and collet 28 can be popped onto the head 33 from above instead of inserting the anchor 30 down through the anchor seat 26 in the manner described above. The method step of popping the anchor seat 26 over the head 33 can be referred to as bottom-end loading of the anchor 30 into the anchor seat 26. It should be further appreciated that while the bone fixation assembly 20, including the bone fixation elements 22 and vertebral implants 75, have been described in connection with one embodiment, the bone fixation assembly 20, including the bone fixation elements 22 and vertebral implants 75, can be constructed in accordance with any embodiment suitable to be implanted into a plurality of vertebrae and be connected by a spine fixation rod, such as described in U.S. patent application Ser. No. 11/603,428, filed Nov. 21, 2006, and published as U.S. Publication No. 2007/0118123, published on May 24, 2007, the disclosure of which is hereby incorporated by reference as if set forth in its entirety herein.

Referring now to FIG. 9, it should be appreciated that the while the spine fixation rod 24 is implanted in a plurality of vertebrae 27a-d in the bone fixation assembly 20, it may become desirable at a future date to extend the bone fixation assembly 20 to affix at least one such as a plurality of vertebrae to the vertebrae 27a-d. For instance, it may be desirable to affix at least one such as a plurality of inferior vertebrae 27e-f to the vertebrae 27a-d. Alternatively or additionally, it may be desirable to affix at least one such as a plurality of superior vertebrae 27g-h to the vertebrae 27a-d. Thus, the spine fixation rod 24 can be referred to herein as a previously implanted spine fixation rod. As illustrated, the vertebra 27a is the cranial-most vertebra that is secured to the spine fixation rod 24, and the vertebra 27d is the caudal-most vertebra that is secured to the spine fixation rod 24. The vertebra 27h is superior to the vertebra 27a, and the vertebra 27g is superior to the vertebra 27h. The vertebra 27e is inferior to the vertebra 27d, and the vertebra 27f is inferior to the vertebra 27e. The vertebrae 27g-h and 27e-f can be referred to as new vertebrae.

Referring now to FIGS. 10A-D, an extender system 100 includes a top-loading polyaxial spinal construct extender 105 that is configured to be operatively coupled to the spine fixation rod 24 of a previously implanted bone fixation element 22 or newly implantable bone fixation element so as to join one or more vertebrae, that have been joined together using the bone fixation system 20, with an adjacent bone. Thus the polyaxial spinal construct extender 105 can be configured to extend the bone fixation system 20 to one or more adjacent spinal levels. One having ordinary skill in the art will appreciate that the polyaxial spinal construct extender 105 is not limited to extending a construct that has already been implanted and may be utilized in original spinal surgeries, potentially in a minimally invasive manner, to fix multiple levels of a patient's vertebrae.

The polyaxial construct extender 105 includes a polyaxial extension member 139 constructed as a rod 140 that having a substantially cylindrical rod body 141 that defines a proximal end 141a and an opposed distal end 141b. The polyaxial extender rod 104 includes an engagement member illustrated as a loop 142 that is attached to the proximal rod body end 141a, and an aperture 143 extending vertically through the loop 142. The distal end 141b can be coplanar with the loop 142 as illustrated. Alternatively, the distal end 141b can be angularly or otherwise vertically offset with respect to the loop 142. The polyaxial extender rod 140 further includes a bushing 150 disposed within the aperture 143, and secured to the loop 142. The extender 105 further includes a tapered fastener illustrated as a tapered set screw 130 configured to connect to both the bushing 150 and the anchor seat 26 (either of the previously implanted bone fixation system 20 or of a new bone fixation system), and a locking member illustrated as a locking nut 160 configured to lock the extender rod 104 to the set screw 130.

The tapered set screw 130 includes a proximal portion 130a, a distal portion 130b, and a middle portion 130c disposed between the proximal portion 130a and the distal portion 130b. The set screw 130 includes at the proximal portion 130a a non-tapered exterior surface having an exterior set of threading 131 that is configured to engage an interior set of threading on the locking nut 160. The distal portion 130b of the tapered set screw 130 includes a non-tapered exterior surface 132 having an exterior set of threading 133 that is configured to engage a set of interior threading of the anchor seat 26. The set screw 130 includes at the middle portion 130c a tapered nonthreaded exterior surface 134 that is configured to abut the interior surface 151 of the bushing 150. The tapered exterior surface 134 is configured such that the circumference of the middle portion 130c increases along a direction from the proximal portion 130a toward the distal portion 130b.

The bushing 150 includes a flat superior surface 152, a flat inferior surface 153, a central longitudinal axis 154 extending between the superior surface 152 and the inferior surface 153, and a partially spherical exterior surface 155 extending between the flat superior and inferior surfaces 152 and 153, and an interior surface 151 surrounding a hollow interior 156. The bushing 150 includes a split 157 extending along the longitudinal axis through the exterior and interior surfaces 155 and 151 to allow the bushing to expand in circumference as the tapered middle portion 130c of the tapered set screw 130 is driven into the interior 156.

The interior surface 151 of the bushing 150 includes an inferior taper 151a and a superior taper 151b, such that the inferior taper 151a extends between the inferior surface 153 and a mid-point of the interior surface 151, while the superior taper 151b extends between the superior surface 152 and the point of the interior surface 151. The point of the interior surface 151 is generally the circular line at which the two tapers meet to form an apex 158. The inferior taper 151a and the superior taper 151b each preferably define an angle with respect to the longitudinal axis 154 that matches the taper angle of the exterior surface 134 of the middle portion 130c of the tapered set screw 130.

The bushing 150 is press fit into the aperture 143 of the loop 142 of the extender rod 140. The partially spherical exterior surface of the bushing 150 is generally similar or identical to the spherical geometry of the interior surface of the loop 142, such that the bushing 150 is polyaxially rotatable within the aperture 143 in an initial state prior to insertion of the screw 130. Once the screw 130 is inserted into the bushing 150, the tapered exterior surface 134 of the screw 130 rides along the interior surface 151 of the bushing, can causes the split 157 to expand, such that the exterior surface 155 of the busing is pressed against the interior surface loop 142, thereby locking the position of the bushing 150 inside the loop 142.

Referring now also again to FIG. 9, the system 100 can also include a newly implanted bone fixation element 22g disposed at an adjacent vertebra, for instance the superior vertebra 27g as illustrated, or the inferior vertebra 27e. The polyaxial extender rod 140 provides the spinal fixation rod that extends through the anchor seat 26 of the newly implanted bone fixation element 22g. Thus, the polyaxial extender rod 140 is coupled between the newly implanted bone fixation element 22g and another bone fixation element 22a, which can be part of a previously implanted bone fixation assembly 20.

Thus, during operation, the top loading polyaxial construct extender 105 may be implemented to extend a previously implanted spinal construct or bone fixation assembly 20 that includes the previously implanted bone fixation element 22a to an adjacent bone, illustrated as an adjacent spinal level, and create a rigid connection therebetween during revision surgery. An incision is made at the spinal level adjacent to, for example adjacent to the most cranial (or most caudal), level of an existing spinal construct in need of revision. The incision is made over the outermost preexisting bone fixation element 20 and the new vertebrae to be fixed, and an incision need not be made across the other vertebrae 27a-27d of the preexisting bone fixation element 20 because the preexisting spine fixation rod 24 is not removed. The new bone fixation element 22g, with the exception of the locking cap 34, is implanted into the adjacent spinal level 27g. Otherwise stated, the vertebral implant 75 of the new bone fixation element 22g is implanted into the adjacent spinal level 27g. Through the same incision, or using a second incision, the locking cap 34 is removed from an outermost, such as the cranial most, bone fixation element 22a (or caudal most bone fixation element 22d).