Polymeric sheet material for use in making polymeric security documents such as banknotes

Cape , et al. October 13, 2

U.S. patent number 10,800,203 [Application Number 15/326,129] was granted by the patent office on 2020-10-13 for polymeric sheet material for use in making polymeric security documents such as banknotes. This patent grant is currently assigned to CRANE SECURITY TECHNOLOGIES, INC., VISUAL PHYSICS, LLC. The grantee listed for this patent is CRANE SECURITY TECHNOLOGIES, INC., VISUAL PHYSICS, LLC. Invention is credited to Samuel M. Cape, Paul F. Cote, Jonathan D. Gosnell.

| United States Patent | 10,800,203 |

| Cape , et al. | October 13, 2020 |

Polymeric sheet material for use in making polymeric security documents such as banknotes

Abstract

An improved polymeric sheet material for use in making polymeric security documents such as banknotes is provided. The inventive polymeric sheet material has one or more integrated and/or applied optical security devices. Polymeric security documents made using these improved polymeric sheet materials are also provided.

| Inventors: | Cape; Samuel M. (Woodstock, GA), Cote; Paul F. (Hollis, NH), Gosnell; Jonathan D. (Cumming, GA) | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Applicant: |

|

||||||||||

| Assignee: | VISUAL PHYSICS, LLC

(Alpharetta, GA) CRANE SECURITY TECHNOLOGIES, INC. (Nashua, NH) |

||||||||||

| Family ID: | 1000005111076 | ||||||||||

| Appl. No.: | 15/326,129 | ||||||||||

| Filed: | July 16, 2015 | ||||||||||

| PCT Filed: | July 16, 2015 | ||||||||||

| PCT No.: | PCT/US2015/040745 | ||||||||||

| 371(c)(1),(2),(4) Date: | January 13, 2017 | ||||||||||

| PCT Pub. No.: | WO2016/011249 | ||||||||||

| PCT Pub. Date: | January 21, 2016 |

Prior Publication Data

| Document Identifier | Publication Date | |

|---|---|---|

| US 20170210161 A1 | Jul 27, 2017 | |

Related U.S. Patent Documents

| Application Number | Filing Date | Patent Number | Issue Date | ||

|---|---|---|---|---|---|

| 62025637 | Jul 17, 2014 | ||||

| Current U.S. Class: | 1/1 |

| Current CPC Class: | B42D 25/29 (20141001); G03H 1/0011 (20130101); B42D 25/351 (20141001); B42D 25/43 (20141001); B41F 11/02 (20130101); G03H 1/0252 (20130101); B42D 25/455 (20141001); B42D 25/324 (20141001); B42D 25/47 (20141001); B42D 25/328 (20141001); B42D 25/46 (20141001); B42D 25/373 (20141001); G03H 2001/0216 (20130101); G03H 2223/19 (20130101); G03H 2250/35 (20130101) |

| Current International Class: | B42D 25/373 (20140101); G03H 1/00 (20060101); B41F 11/02 (20060101); B42D 25/455 (20140101); B42D 25/46 (20140101); B42D 25/29 (20140101); B42D 25/328 (20140101); B42D 25/351 (20140101); B42D 25/43 (20140101); G03H 1/02 (20060101); B42D 25/324 (20140101); B42D 25/47 (20140101) |

| Field of Search: | ;283/72,73,94,98,99,106,107,108,109,111,901 |

References Cited [Referenced By]

U.S. Patent Documents

| 992151 | May 1911 | Berthon |

| 1824353 | September 1931 | Jensen |

| 1849036 | March 1932 | Ernst |

| 1942841 | January 1934 | Shimizu |

| 2268351 | December 1941 | Tanaka |

| 2355902 | August 1944 | Berg |

| 2432896 | December 1947 | Hotchner |

| 2888855 | June 1959 | Tanaka |

| 2992103 | July 1961 | Land et al. |

| 3122853 | March 1964 | Koonz et al. |

| 3241429 | March 1966 | Rice et al. |

| 3264164 | August 1966 | Jerothe et al. |

| 3312006 | April 1967 | Rowland |

| 3357772 | December 1967 | Rowland |

| 3357773 | December 1967 | Rowland |

| 3463581 | August 1969 | Clay |

| 3609035 | September 1971 | Ataka |

| 3643361 | February 1972 | Eaves |

| 3704068 | November 1972 | Waly |

| 3801183 | April 1974 | Sevelin et al. |

| 3811213 | May 1974 | Eaves |

| 3887742 | June 1975 | Reinnagel |

| 4025673 | May 1977 | Reinnagel |

| 4073650 | February 1978 | Yevick |

| 4082426 | April 1978 | Brown |

| 4185191 | January 1980 | Stauffer |

| 4345833 | August 1982 | Siegmund |

| 4417784 | November 1983 | Knop et al. |

| 4498736 | February 1985 | Griffin |

| 4507349 | March 1985 | Fromson et al. |

| 4519632 | May 1985 | Parkinson et al. |

| 4534398 | August 1985 | Crane |

| 4634220 | January 1987 | Hockert et al. |

| 4645301 | February 1987 | Orensteen et al. |

| 4662651 | May 1987 | Mowry, Jr. |

| 4688894 | August 1987 | Hockert |

| 4691993 | September 1987 | Porter et al. |

| 4756972 | July 1988 | Kloosterboer et al. |

| 4765656 | August 1988 | Becker et al. |

| 4814594 | March 1989 | Drexler |

| 4892336 | January 1990 | Kaule et al. |

| 4892385 | January 1990 | Webster, Jr. et al. |

| 4920039 | April 1990 | Fotland et al. |

| 4935335 | June 1990 | Fotland |

| 4988126 | January 1991 | Heckenkamp et al. |

| 5044707 | September 1991 | Mallik |

| 5074649 | December 1991 | Hamanaka |

| 5085514 | February 1992 | Mallik et al. |

| 5135262 | August 1992 | Smith et al. |

| 5142383 | August 1992 | Mallik |

| 5211424 | May 1993 | Bliss |

| 5215864 | June 1993 | Laakmann |

| 5232764 | August 1993 | Oshima |

| 5254390 | October 1993 | Lu |

| 5282650 | February 1994 | Smith et al. |

| 5359454 | October 1994 | Steenblik et al. |

| 5384861 | January 1995 | Mattson et al. |

| 5393099 | February 1995 | D'Amato |

| 5393590 | February 1995 | Caspari |

| 5413839 | May 1995 | Chatwin et al. |

| 5433807 | July 1995 | Heckenkamp et al. |

| 5438928 | August 1995 | Chatwin et al. |

| 5442482 | August 1995 | Johnson et al. |

| 5449200 | September 1995 | Andric et al. |

| 5460679 | October 1995 | Abdel-Kader |

| 5461495 | October 1995 | Steenblik et al. |

| 5464690 | November 1995 | Boswell |

| 5468540 | November 1995 | Lu |

| 5479507 | December 1995 | Anderson |

| 5492370 | February 1996 | Chatwin et al. |

| 5503902 | April 1996 | Steenblik et al. |

| 5538753 | July 1996 | Antes et al. |

| 5543942 | August 1996 | Mizuguchi et al. |

| 5555476 | September 1996 | Suzuki et al. |

| 5567276 | October 1996 | Boehm et al. |

| 5568313 | October 1996 | Steenblik et al. |

| 5574083 | November 1996 | Brown et al. |

| 5575507 | November 1996 | Yamauchi et al. |

| 5598281 | January 1997 | Zimmerman et al. |

| 5623347 | April 1997 | Pizzanelli |

| 5623368 | April 1997 | Calderini et al. |

| 5626969 | May 1997 | Joson |

| 5631039 | May 1997 | Knight et al. |

| 5639126 | June 1997 | Dames et al. |

| 5642226 | June 1997 | Rosenthal |

| 5643678 | July 1997 | Boswell |

| 5670003 | September 1997 | Boswell |

| 5670096 | September 1997 | Lu |

| 5674580 | October 1997 | Boswell |

| 5688587 | November 1997 | Burchard et al. |

| 5695346 | December 1997 | Sekiguchi et al. |

| 5712731 | January 1998 | Drinkwater et al. |

| 5723200 | March 1998 | Oshima et al. |

| 5731064 | March 1998 | Suss |

| 5737126 | April 1998 | Lawandy |

| 5753349 | May 1998 | Boswell |

| 5759683 | June 1998 | Boswell |

| 5763349 | June 1998 | Zandona |

| 5783017 | July 1998 | Boswell |

| 5783275 | July 1998 | Muck et al. |

| 5800907 | September 1998 | Yumoto |

| 5810957 | September 1998 | Boswell |

| 5812313 | September 1998 | Johansen et al. |

| 5886798 | March 1999 | Staub et al. |

| 5933276 | August 1999 | Magee |

| 5949420 | September 1999 | Terlutter |

| 5995638 | November 1999 | Amidror et al. |

| 6030691 | February 2000 | Burchard et al. |

| 6036230 | March 2000 | Farber |

| 6036233 | March 2000 | Braun et al. |

| 6060143 | May 2000 | Tompkin et al. |

| 6084713 | July 2000 | Rosenthal |

| 6089614 | July 2000 | Howland et al. |

| 6106950 | August 2000 | Searle et al. |

| 6144795 | November 2000 | Dawes et al. |

| 6176582 | January 2001 | Grasnick |

| 6177953 | January 2001 | Vachette et al. |

| 6179338 | January 2001 | Bergmann et al. |

| 6195150 | February 2001 | Silverbrook |

| 6249588 | June 2001 | Amidror et al. |

| 6256149 | July 2001 | Rolfe |

| 6256150 | July 2001 | Rosenthal |

| 6283509 | September 2001 | Braun et al. |

| 6288842 | September 2001 | Florczak et al. |

| 6297911 | October 2001 | Nishikawa et al. |

| 6301363 | October 2001 | Mowry, Jr. |

| 6302989 | October 2001 | Kaule |

| 6328342 | December 2001 | Belousov et al. |

| 6329040 | December 2001 | Oshima et al. |

| 6329987 | December 2001 | Gottfried et al. |

| 6345104 | February 2002 | Rhoads |

| 6348999 | February 2002 | Summersgill et al. |

| 6350036 | February 2002 | Hannington et al. |

| 6369947 | April 2002 | Staub et al. |

| 6373965 | April 2002 | Liang |

| 6381071 | April 2002 | Dona et al. |

| 6396636 | May 2002 | Sawaki et al. |

| 6404555 | June 2002 | Nishikawa |

| 6405464 | June 2002 | Gulick, Jr. et al. |

| 6414794 | July 2002 | Rosenthal |

| 6424467 | July 2002 | Goggins |

| 6433844 | August 2002 | Li |

| 6450540 | September 2002 | Kim |

| 6467810 | October 2002 | Taylor et al. |

| 6473238 | October 2002 | Daniell |

| 6483644 | November 2002 | Gottfried et al. |

| 6500526 | December 2002 | Hannington |

| 6521324 | February 2003 | Debe et al. |

| 6542646 | April 2003 | Bar-Yona |

| 6558009 | May 2003 | Hannington et al. |

| 6587276 | July 2003 | Daniell |

| 6616803 | September 2003 | Isherwood et al. |

| 6618201 | September 2003 | Nishikawa et al. |

| 6641270 | November 2003 | Hannington et al. |

| 6671095 | December 2003 | Summersgill et al. |

| 6712399 | March 2004 | Drinkwater et al. |

| 6721101 | April 2004 | Daniell |

| 6724536 | April 2004 | Magee |

| 6726858 | April 2004 | Andrews |

| 6751024 | June 2004 | Rosenthal |

| 6761377 | July 2004 | Taylor et al. |

| 6795250 | September 2004 | Johnson et al. |

| 6803088 | October 2004 | Kaminsky et al. |

| 6819775 | November 2004 | Amidror et al. |

| 6833960 | December 2004 | Scarbrough et al. |

| 6856462 | February 2005 | Scarbrough et al. |

| 6870681 | March 2005 | Magee |

| 6900944 | May 2005 | Tomczyk |

| 6926764 | August 2005 | Bleikolm et al. |

| 6935756 | August 2005 | Sewall et al. |

| 7030997 | April 2006 | Neureuther et al. |

| 7058202 | June 2006 | Amidror |

| 7068434 | June 2006 | Florczak et al. |

| 7114750 | October 2006 | Alasia et al. |

| 7194105 | March 2007 | Hersch et al. |

| 7246824 | July 2007 | Hudson |

| 7254265 | August 2007 | Naske et al. |

| 7255911 | August 2007 | Lutz et al. |

| 7288320 | October 2007 | Steenblik et al. |

| 7333268 | February 2008 | Steenblik et al. |

| 7336422 | February 2008 | Dunn et al. |

| 7359120 | April 2008 | Raymond et al. |

| 7372631 | May 2008 | Ozawa |

| 7389939 | June 2008 | Jones et al. |

| 7422781 | September 2008 | Gosselin |

| 7457038 | November 2008 | Dolgoff |

| 7457039 | November 2008 | Raymond et al. |

| 7468842 | December 2008 | Steenblik et al. |

| 7504147 | March 2009 | Hannington |

| 7545567 | June 2009 | Tomczyk |

| 7609450 | October 2009 | Niemuth |

| 7630954 | December 2009 | Adamczyk et al. |

| 7686187 | March 2010 | Pottish et al. |

| 7712623 | May 2010 | Wentz et al. |

| 7719733 | May 2010 | Schilling et al. |

| 7738175 | June 2010 | Steenblik et al. |

| 7744002 | June 2010 | Jones et al. |

| 7751608 | July 2010 | Hersch et al. |

| 7762591 | July 2010 | Schilling et al. |

| 7763179 | July 2010 | Levy et al. |

| 7812935 | October 2010 | Cowburn et al. |

| 7820269 | October 2010 | Staub et al. |

| 7830627 | November 2010 | Commander et al. |

| 7849993 | December 2010 | Finkenzeller et al. |

| 8027093 | September 2011 | Commander et al. |

| 8057980 | November 2011 | Dunn et al. |

| 8111463 | February 2012 | Endle et al. |

| 8149511 | April 2012 | Kaule et al. |

| 8241732 | August 2012 | Hansen et al. |

| 8284492 | October 2012 | Crane et al. |

| 8367452 | February 2013 | Soma et al. |

| 8514492 | August 2013 | Schilling et al. |

| 8528941 | September 2013 | Dorfler et al. |

| 8537470 | September 2013 | Endle et al. |

| 8557369 | October 2013 | Hoffmuller et al. |

| 8693101 | April 2014 | Tomczyk et al. |

| 8739711 | June 2014 | Cote |

| 8867134 | October 2014 | Steenblik et al. |

| 8906184 | December 2014 | Hoffmann et al. |

| 8908276 | December 2014 | Holmes |

| 9019613 | April 2015 | Raymond et al. |

| 9132690 | September 2015 | Raymond et al. |

| 9399366 | July 2016 | Hoffmuller et al. |

| 9592700 | March 2017 | Raymond et al. |

| 9701150 | July 2017 | Raymond et al. |

| 9802437 | October 2017 | Holmes |

| 2001/0048968 | December 2001 | Cox et al. |

| 2002/0014967 | February 2002 | Crane et al. |

| 2002/0114078 | August 2002 | Halle et al. |

| 2002/0167485 | November 2002 | Hedrick |

| 2002/0185857 | December 2002 | Taylor et al. |

| 2003/0031861 | February 2003 | Reiter et al. |

| 2003/0112523 | June 2003 | Daniell |

| 2003/0157211 | August 2003 | Tsunetomo et al. |

| 2003/0179364 | September 2003 | Steenblik et al. |

| 2003/0183695 | October 2003 | Labrec et al. |

| 2003/0228014 | December 2003 | Alasia et al. |

| 2003/0232179 | December 2003 | Steenblik et al. |

| 2003/0234294 | December 2003 | Uchihiro et al. |

| 2004/0020086 | February 2004 | Hudson |

| 2004/0022967 | February 2004 | Lutz et al. |

| 2004/0065743 | April 2004 | Doublet |

| 2004/0100707 | May 2004 | Kay et al. |

| 2004/0140665 | July 2004 | Scarbrough et al. |

| 2004/0209049 | October 2004 | Bak |

| 2005/0094274 | May 2005 | Souparis |

| 2005/0104364 | May 2005 | Keller et al. |

| 2005/0161501 | July 2005 | Giering et al. |

| 2005/0180020 | August 2005 | Steenblik et al. |

| 2005/0247794 | November 2005 | Jones et al. |

| 2006/0003295 | January 2006 | Hersch et al. |

| 2006/0011449 | January 2006 | Knoll |

| 2006/0017979 | January 2006 | Goggins |

| 2006/0018021 | January 2006 | Tomkins et al. |

| 2006/0061267 | March 2006 | Yamasaki et al. |

| 2006/0227427 | October 2006 | Dolgoff |

| 2007/0058260 | March 2007 | Steenblik et al. |

| 2007/0092680 | April 2007 | Chaffins et al. |

| 2007/0164555 | July 2007 | Mang et al. |

| 2007/0183045 | August 2007 | Schilling et al. |

| 2007/0183047 | August 2007 | Phillips et al. |

| 2007/0273143 | November 2007 | Crane et al. |

| 2007/0284546 | December 2007 | Ryzi et al. |

| 2007/0291362 | December 2007 | Hill et al. |

| 2008/0037131 | February 2008 | Steenblik et al. |

| 2008/0067801 | March 2008 | Schilling |

| 2008/0116272 | May 2008 | Giering et al. |

| 2008/0130018 | June 2008 | Steenblik et al. |

| 2008/0143095 | June 2008 | Isherwood et al. |

| 2008/0160226 | July 2008 | Kaule et al. |

| 2008/0182084 | July 2008 | Tompkin et al. |

| 2009/0008923 | January 2009 | Kaule et al. |

| 2009/0061159 | March 2009 | Staub et al. |

| 2009/0243278 | October 2009 | Camus et al. |

| 2009/0261572 | October 2009 | Bleikolm et al. |

| 2009/0290221 | November 2009 | Hansen et al. |

| 2009/0310470 | December 2009 | Yrjonen |

| 2009/0315316 | December 2009 | Staub et al. |

| 2010/0001508 | January 2010 | Tompkin et al. |

| 2010/0018644 | January 2010 | Sacks et al. |

| 2010/0045024 | February 2010 | Attner et al. |

| 2010/0068459 | March 2010 | Wang et al. |

| 2010/0084851 | April 2010 | Schilling |

| 2010/0103528 | April 2010 | Endle et al. |

| 2010/0109317 | May 2010 | Hoffmuller et al. |

| 2010/0177094 | July 2010 | Kaule et al. |

| 2010/0182221 | July 2010 | Kaule et al. |

| 2010/0194532 | August 2010 | Kaule |

| 2010/0208036 | August 2010 | Kaule |

| 2010/0277805 | November 2010 | Schilling et al. |

| 2010/0308571 | December 2010 | Steenblik et al. |

| 2010/0328922 | December 2010 | Peters et al. |

| 2011/0017498 | January 2011 | Lauffer et al. |

| 2011/0019128 | January 2011 | Takata |

| 2011/0019283 | January 2011 | Steenblik et al. |

| 2011/0045255 | February 2011 | Jones et al. |

| 2011/0056638 | March 2011 | Rosset |

| 2011/0109078 | May 2011 | Hoffmuller |

| 2011/0179631 | July 2011 | Gates et al. |

| 2012/0019607 | January 2012 | Dunn et al. |

| 2012/0033305 | February 2012 | Moon et al. |

| 2012/0091703 | April 2012 | Maguire et al. |

| 2012/0098249 | April 2012 | Rahm |

| 2012/0105928 | May 2012 | Camus et al. |

| 2012/0153607 | June 2012 | Rahm et al. |

| 2012/0194916 | August 2012 | Cape et al. |

| 2012/0243744 | September 2012 | Camus et al. |

| 2013/0003354 | January 2013 | Meis et al. |

| 2013/0010048 | January 2013 | Dunn et al. |

| 2013/0038942 | February 2013 | Holmes |

| 2013/0044362 | February 2013 | Commander et al. |

| 2013/0056971 | March 2013 | Holmes |

| 2013/0069360 | March 2013 | Power et al. |

| 2013/0154250 | June 2013 | Dunn et al. |

| 2013/0154251 | June 2013 | Jolic |

| 2014/0174306 | June 2014 | Wening et al. |

| 2014/0175785 | June 2014 | Kaule et al. |

| 2014/0353959 | December 2014 | Lochbihler |

| 2014/0367957 | December 2014 | Jordan |

| 2014/0376091 | December 2014 | Jordan et al. |

| 2015/0152602 | June 2015 | Blake et al. |

| 2016/0101643 | April 2016 | Cape et al. |

| 2016/0176221 | June 2016 | Holmes |

| 2016/0257159 | September 2016 | Attner et al. |

| 2016/0325577 | November 2016 | Jordan |

| 2017/0015129 | January 2017 | Jordan |

| 2017/0173990 | June 2017 | Cape et al. |

| 2018/0178577 | June 2018 | Lister |

| 2009278275 | Jul 2012 | AU | |||

| 2741298 | Apr 2010 | CA | |||

| 1102865 | May 1995 | CN | |||

| 1126970 | Nov 2003 | CN | |||

| 1950570 | Apr 2007 | CN | |||

| 101019155 | Aug 2007 | CN | |||

| 101443692 | May 2009 | CN | |||

| 101563640 | Oct 2009 | CN | |||

| 101678664 | Mar 2010 | CN | |||

| 101978292 | Feb 2011 | CN | |||

| 102438838 | May 2012 | CN | |||

| 103097919 | May 2013 | CN | |||

| 103477250 | Dec 2013 | CN | |||

| 19804858 | Aug 1999 | DE | |||

| 19932240 | Jan 2001 | DE | |||

| 10100692 | Aug 2004 | DE | |||

| 102011114750 | Apr 2013 | DE | |||

| 102011115125 | Apr 2013 | DE | |||

| 0090130 | Oct 1983 | EP | |||

| 0092691 | Nov 1983 | EP | |||

| 0118222 | Sep 1984 | EP | |||

| 0156460 | Oct 1985 | EP | |||

| 0203752 | Dec 1986 | EP | |||

| 0253089 | Jan 1988 | EP | |||

| 0318717 | Jun 1989 | EP | |||

| 0415230 | Mar 1991 | EP | |||

| 0439092 | Jul 1991 | EP | |||

| 0319157 | Jul 1992 | EP | |||

| 0801324 | Oct 1997 | EP | |||

| 0887699 | Dec 1998 | EP | |||

| 0930174 | Jul 1999 | EP | |||

| 0997750 | May 2000 | EP | |||

| 1356952 | Oct 2003 | EP | |||

| 1002640 | May 2004 | EP | |||

| 1538554 | Jun 2005 | EP | |||

| 1354925 | Apr 2006 | EP | |||

| 1659449 | May 2006 | EP | |||

| 1743778 | Jan 2007 | EP | |||

| 1801636 | Jun 2007 | EP | |||

| 1876028 | Jan 2008 | EP | |||

| 1897700 | Mar 2008 | EP | |||

| 1931827 | Jan 2009 | EP | |||

| 2335937 | Jun 2011 | EP | |||

| 2338682 | Jun 2011 | EP | |||

| 2162294 | Mar 2012 | EP | |||

| 2803939 | Jul 2001 | FR | |||

| 2952194 | May 2011 | FR | |||

| 1095286 | Dec 1967 | GB | |||

| 2103669 | Feb 1983 | GB | |||

| 2168372 | Jun 1986 | GB | |||

| 2227451 | Jan 1990 | GB | |||

| 2362493 | Nov 2001 | GB | |||

| 2395724 | Jun 2004 | GB | |||

| 2433470 | Jun 2007 | GB | |||

| 2490780 | Nov 2012 | GB | |||

| 41-004953 | Mar 1941 | JP | |||

| 46-022600 | Jun 1971 | JP | |||

| 04-234699 | Aug 1992 | JP | |||

| H05-508119 | Nov 1993 | JP | |||

| 10-035083 | Feb 1998 | JP | |||

| 10-039108 | Feb 1998 | JP | |||

| 11-501590 | Feb 1999 | JP | |||

| 11-189000 | Jul 1999 | JP | |||

| 2000-056103 | Feb 2000 | JP | |||

| 2000-233563 | Aug 2000 | JP | |||

| 2000-256994 | Sep 2000 | JP | |||

| 2001-055000 | Feb 2001 | JP | |||

| 2001-516899 | Oct 2001 | JP | |||

| 2001-324949 | Nov 2001 | JP | |||

| 2002-169223 | Jun 2002 | JP | |||

| 2003-039583 | Feb 2003 | JP | |||

| 2003-165289 | Jun 2003 | JP | |||

| 2003-528349 | Sep 2003 | JP | |||

| 2003-326876 | Nov 2003 | JP | |||

| 2004-163530 | Jun 2004 | JP | |||

| 2004-262144 | Sep 2004 | JP | |||

| 2004-317636 | Nov 2004 | JP | |||

| 2005-193501 | Jul 2005 | JP | |||

| 2009-536885 | Oct 2009 | JP | |||

| 2009-262375 | Nov 2009 | JP | |||

| 2009-274293 | Nov 2009 | JP | |||

| 2011-502811 | Jan 2011 | JP | |||

| 2013-537640 | Oct 2013 | JP | |||

| 2014-514177 | Jun 2014 | JP | |||

| 10-0194536 | Jun 1999 | KR | |||

| 2002170350000 | Mar 2001 | KR | |||

| 2003119050000 | May 2003 | KR | |||

| 1005443000000 | Jan 2006 | KR | |||

| 1005613210000 | Mar 2006 | KR | |||

| 10-2008-0048578 | Jun 2008 | KR | |||

| 2111125 | May 1998 | RU | |||

| 2245566 | Jan 2005 | RU | |||

| 2010101854 | Jul 2011 | RU | |||

| 575740 | Feb 2004 | TW | |||

| WO 1992/008998 | May 1992 | WO | |||

| WO 1992/019994 | Nov 1992 | WO | |||

| WO 1993/024332 | Dec 1993 | WO | |||

| WO 1996/035971 | Nov 1996 | WO | |||

| WO 1997/019820 | Jun 1997 | WO | |||

| WO 1997/044769 | Nov 1997 | WO | |||

| WO 1998/013211 | Apr 1998 | WO | |||

| WO 1998/015418 | Apr 1998 | WO | |||

| WO 1998/026373 | Jun 1998 | WO | |||

| 1999014725 | Mar 1999 | WO | |||

| WO 1999/014725 | Mar 1999 | WO | |||

| 1999023513 | May 1999 | WO | |||

| WO 1999/023513 | May 1999 | WO | |||

| WO 1999/026793 | Jun 1999 | WO | |||

| WO 1999/066356 | Dec 1999 | WO | |||

| WO 2001/007268 | Feb 2001 | WO | |||

| WO 2001/011591 | Feb 2001 | WO | |||

| WO 2001/039138 | May 2001 | WO | |||

| WO 2001/053113 | Jul 2001 | WO | |||

| WO 2001/063341 | Aug 2001 | WO | |||

| WO 2001/071410 | Sep 2001 | WO | |||

| WO 2002/040291 | May 2002 | WO | |||

| WO 2002/043012 | May 2002 | WO | |||

| WO 2002/101669 | Dec 2002 | WO | |||

| WO 2003/005075 | Jan 2003 | WO | |||

| WO 2003/007276 | Jan 2003 | WO | |||

| WO 2003/022598 | Mar 2003 | WO | |||

| WO 2003/053713 | Jul 2003 | WO | |||

| WO 2003/061980 | Jul 2003 | WO | |||

| WO 2003/061983 | Jul 2003 | WO | |||

| WO 2003/082598 | Oct 2003 | WO | |||

| WO 2003/098188 | Nov 2003 | WO | |||

| WO 2004/022355 | Mar 2004 | WO | |||

| WO 2004/036507 | Apr 2004 | WO | |||

| WO 2004/087430 | Oct 2004 | WO | |||

| 2005052650 | Jun 2005 | WO | |||

| WO 2005/106601 | Nov 2005 | WO | |||

| WO 2006/029744 | Mar 2006 | WO | |||

| WO 2007/076952 | Jul 2007 | WO | |||

| WO 2007/133613 | Nov 2007 | WO | |||

| WO 2008/049632 | May 2008 | WO | |||

| WO 2009/000527 | Dec 2008 | WO | |||

| WO 2009/000528 | Dec 2008 | WO | |||

| WO 2009/000529 | Dec 2008 | WO | |||

| WO 2009/000530 | Dec 2008 | WO | |||

| WO 2009/118946 | Oct 2009 | WO | |||

| WO 2009/121784 | Oct 2009 | WO | |||

| WO 2010/015383 | Feb 2010 | WO | |||

| WO 2010/094691 | Aug 2010 | WO | |||

| WO 2010/099571 | Sep 2010 | WO | |||

| WO 2010/113114 | Oct 2010 | WO | |||

| WO 2010/136339 | Dec 2010 | WO | |||

| WO 2011/012460 | Feb 2011 | WO | |||

| WO 2011/015384 | Feb 2011 | WO | |||

| WO 2011/019912 | Feb 2011 | WO | |||

| WO 2011/044704 | Apr 2011 | WO | |||

| WO 2011/051669 | May 2011 | WO | |||

| WO 2011/107791 | Sep 2011 | WO | |||

| WO 2011/107793 | Sep 2011 | WO | |||

| WO 2011/122943 | Oct 2011 | WO | |||

| WO 2012/027779 | Mar 2012 | WO | |||

| WO 2012/103441 | Aug 2012 | WO | |||

| WO 2012/121622 | Sep 2012 | WO | |||

| 2013028534 | Feb 2013 | WO | |||

| WO 2013/028534 | Feb 2013 | WO | |||

| WO 2013/093848 | Jun 2013 | WO | |||

| WO 2013/098513 | Jul 2013 | WO | |||

| WO 2015/148878 | Oct 2015 | WO | |||

| WO 2016/063050 | Apr 2016 | WO | |||

| WO 2016/149760 | Sep 2016 | WO | |||

Other References

|

Article: "Spherical Lenses" (Jan. 18, 2009); pp. 1-12; retrieved from the Internet: URL:http://www.physicsinsights.org/simple_optics_spherical_lens- es-1.html. cited by applicant . Drinkwater, K. John, et al., "Development and applications of Diffractive Optical Security Devices for Banknotes and High Value Documents", Optical Security and Counterfeit Deterrence Techniques III, 2000, pp. 66-77, SPIE vol. 3973, San Jose, CA. cited by applicant . Fletcher, D.A., et al., "Near-field infrared imaging with a microfabricated solid immersion lens", Applied Physics Letters, Oct. 2, 2000, pp. 2109-2111, vol. 77, No. 14. cited by applicant . Gale, M. T., et al., Chapter 6--Replication, Micro Optics: Elements, Systems and Applications, 1997, pp. 153-177. cited by applicant . Hardwick, Bruce and Ghioghiu Ana, "Guardian Substrate as an Optical Medium for Security Devices", Optical Security and Counterfeit Deterrence Techniques III, 2000, pp. 176-179, SPIE vol. 3973, San Jose, CA. cited by applicant . Hutley, M.C., et al., "The Moire Magnifier", Pure Appl. Opt. 3, 1994, pp. 133-142, IOP Publishing Ltd., UK. cited by applicant . Hutley, M.C., "Integral Photography, Superlenses and the Moire Magnifier", European Optical Society, 1993, pp. 72-75, vol. 2, UK. cited by applicant . Hutley, M., et al., "Microlens Arrays", Physics World, Jul. 1991, pp. 27-32. cited by applicant . Kamal, H., et al., "Properties of Moire Magnifiers", Opt. Eng., Nov. 1998, pp. 3007-3014, vol. 37, No. 11. cited by applicant . Leech, Patrick W., et al., Printing via hot embossing of optically variable images in thermoplastic acrylic lacquer, Microelectronic Engineering, 2006, pp. 1961-1965, vol. 83, No. 10, Elsevier Publishers BV, Amsterdam, NL. cited by applicant . Lippmann, G., "Photgraphie--Epreuves Reversibles, Photographies Integrals", Academie des Sciences, 1908, pp. 446-451, vol. 146, Paris. cited by applicant . Liu, S., et al., "Artistic Effect and Application of Moire Patterns in Security Holograms", Applied Optics, Aug. 1995, pp. 4700-4702, vol. 34, No. 22. cited by applicant . Phillips, Roger W., et al., Security Enhancement of Holograms with Interference Coatings, Optical Security and Counterfeit Deterrence Techniques III, 2000, pp. 304-316, SPIE vol. 3973, San Jose, CA. cited by applicant . Steenblik, Richard A., et al., UNISON Micro-optic Security Film, Optical Security and Counterfeit Deterrence Techniques V, 2004, pp. 321-327, SPIE vol. 5310, San Jose, CA. cited by applicant . Van Renesse, Rudolf L., Optical Document Security, 1994, Artech House Inc., Norwood, MA. cited by applicant . Van Renesse, Rudolf L., Optical Document Security, 1998, 2nd edition, pp. 232-235, 240-241 and 320-321, Artech House Inc., Norwood, MA (ISBN 0-89006-982-4). cited by applicant . Van Renesse, Rudolf L., Optical Document Security, 2005, 3rd edition, pp. 62-169, Artech House Inc., Norwood, MA (ISBN 1-58053-258-6). cited by applicant . Wolpert, Gary R., Design and development of an effective optical variable device based security system incorporating additional synergistic security technologies, Optical Security and Counterfeit Deterrence Techniques III, 2000, pp. 55-61, SPIE vol. 3973, San Jose, CA. cited by applicant . Zhang, X., et al., "Concealed Holographic Coding for Security Applications by Using a Moire Technique", Applied Optics, Nov. 1997, pp. 8096-8097, vol. 36, No. 31. cited by applicant . Drinkwater, K. John, et al., "Development and applications of Diffractive Optical Security Devices for Banknotes and High Value Documents", Optical Security and Counterfeit Deterrence Techniques III, 2000, pp. 66-79, SPIE vol. 3973, San Jose, CA. cited by applicant . Liu, S., et al., "Artistic Effects and Application of Moire Patterns in Security Holograms", Applied Optics, Aug. 1995, pp. 4700-4702, vol. 34, No. 22. cited by applicant . Amidror, "A Generalized Fourier-Based Method for the Analysis of 2D Moire Envelope-Forms in Screen Superpositions", Journal of Modern Optics (London, GB), vol. 41, No. 9, Sep. 1, 1994, pp. 1837-1862, ISSN: 0950-0340. cited by applicant . Dunn, et al., "Three-Dimensional Virtual Images for Security Applications", Optical Security and Counterfeit Deterrence Techniques V, (published Jun. 3, 2004), Proc. SPIE 5310, pp. 328-336. cited by applicant . Muke, "Embossing of Optical Document Security Devices", Optical Security and Counterfeit Deterrence Techniques V, (published Jun. 3, 2004), Proc. SPIE 5310, pp. 341-349. cited by applicant . Amidror, "A Generalized Fourier-Based Method for the Analysis of 2D Moire Envelope-Forms in Screen Superpositions", Journal of Modem Optics (London, GB), vol. 41, No. 9, Sep. 1, 1994, pp. 1837-1862, ISSN: 0950-0340. cited by applicant . Office Action regarding Russian Application No. 2017104544/12(008106), dated Oct. 31, 2018, 6 pages. cited by applicant . Third Office Action regarding Chinese Patent Application No. 201580049896.5, dated Jan. 4, 2019, 12 pages. cited by applicant . China National Intellectual Property Administration, "First Office Action," Application No. CN201810391431.3, dated Jul. 29, 2019, 54 pages. cited by applicant . China National Intellectual Property Administration, "Fourth Office Action," Application No. CN201580049896.5, dated Sep. 3, 2019, 8 pages. cited by applicant . Japan Patent Office, Notice of Reasons for Rejection, Application No. JP 2017-502818, dated Jun. 25, 2019, 11 pages. cited by applicant . National Intellectual Property Administration, P.R. China, First Office Action and Search Report, Application No. CN201810391917.7, dated Apr. 25, 2019, 18 pages. cited by applicant . Indonesian Office Action in connection with Application No. ID P00201700996, dated May 27, 2019, 5 pages. cited by applicant . ISA/EP, International Search Report and Written Opinion of the International Searching Authority, International Application No. PCT/US2015/040745, dated Jan. 27, 2016, 32 pages. cited by applicant . Helmut Kipphan (ed.), "Section 2.2 Gravure Printing", Handbook of Print Media: Technologies and Production Methods, 2001, pp. 369-371, Heidelberger Druckmaschinen AG, Germany. cited by applicant . Lippmann, G., "Photographie--Epreuves Reversibles, Photographies Integrals", Academie des Sciences, 1908, pp. 446-451, vol. 146, Paris. cited by applicant . Brazil National Institute of Industrial Property, "Search Report," Application No. 112017000914-5, dated Mar. 24, 2020, 8 pages. cited by applicant . China National Intellectual Property Administration, "Office Action," Application No. 201580027596.7, dated Feb. 3, 2019, 58 pages. cited by applicant . Egyptian Patent Office, "Technical Report," Application No. EG2016091551, dated Oct. 23, 2019, 10 pages. cited by applicant . Intellectual Property India, "Examination report under sections 12 13 of the Patents Act, 1970 and the Patents Rules, 2003," Application No. IN201617035309, dated Nov. 28, 2019, 10 pages. cited by applicant . Indonesia Directorate General of Intellectual Property, "Office Action," Application No. P00201607186, dated Jan. 18, 2019, 6 pages. cited by applicant . Japan Patent Office, "Office Action," Application No. 2017-502936, dated Nov. 27, 2018, 7 pages. cited by applicant . Japan Patent Office, "Decision of Refusal," Application No. JP 2017-502936, dated Jul. 9, 2019, 5 pages. cited by applicant . Japan Patent Office, "Decision of Refusal," Application No. JP 2017-502818, dated Mar. 3, 2020, 5 pages. cited by applicant . IMPI--Mexican Institute of Industrial Property, Office Action in connection with Mexican Application No. MX/a/2016/012305, dated Jan. 17, 2020, 6 pages. cited by applicant . International Preliminary Report on Patentability for International Application No. PCT/US2018/035183, dated Dec. 19, 2019, 9 pages. cited by applicant . IP Australia, "Examination report No. 1 for standard patent application," Application No. AU 2015289606, dated Jan. 14, 2020, 2 pages. cited by applicant . National Intellectual Property Administration, P.R. China, "Second Office Action," Application No. 201810391917.7, dated Dec. 6, 2019, 8 pages. cited by applicant . Egyptian Patent Office, "Technical Report," Application No. EG 2017010085, dated Dec. 31, 2019, 11 pages. cited by applicant . IMPI--Mexican Institute of Industrial Property, Office Action in connection with Mexican Application No. MX/a/2017/000681, dated Dec. 16, 2019, 5 pages. cited by applicant . China National Intellectual Property Administration, "Second Office Action," Application No. CN201810391431.3, dated May 7, 2020, 20 pages. cited by applicant . China National Intellectual Property Administration, "Third Office Action," Application No. 201810391917.7, dated May 15, 2020, 7 pages. cited by applicant . USPTO, "Final Office Action," U.S. Appl. No. 16/596,642, dated Jul. 7, 2020, 9 pages. cited by applicant . Intellectual Property India, "Examination report under sections 12 & 13 of the Patents Act, 1970 and the Patents Rules, 2003," Application No. IN201717004418, dated Jun. 3, 2020, 6 pages. cited by applicant . Egyptian Patent Office, "Technical Report," Application No. EG 2017010085, dated Jun. 20, 2020, 3 pages. cited by applicant. |

Primary Examiner: Lewis; Justin V

Parent Case Text

CROSS-REFERENCE TO RELATED APPLICATIONS

This application claims benefit of and priority to U.S. Provisional Patent Application No. 62/025,637, filed on Jul. 17, 2014, which is incorporated herein by reference in its entirety.

Claims

What is claimed is:

1. An improved polymeric sheet material for use in making polymeric security documents, which is made up of a polymer or polymeric substrate having a thickness greater than or equal to 60 microns and one or more integrated or applied optical security devices which project one or more synthetic images, the one or more optical security devices being integrated to all or part of the polymer or polymeric substrate, wherein the polymer or polymeric substrate is substantially transparent, wherein, the improved polymeric sheet material has one or more integrated optical security devices, wherein the one or more integrated optical security devices is made up of an arrangement of image icons and a directly overlying arrangement of focusing elements that are located on an upper surface of the polymer or polymeric substrate, and a reflective layer that is located directly below the arrangement of image icons and the directly overlying arrangement of focusing elements on a lower surface of the polymer or polymeric substrate, wherein the reflective layer is a patterned metal layer comprising secondary image icons formed by patterned demetallization, the patterned demetallization defining demetallized holes through which light passes through the reflective layer the polymer or polymeric substrate and wherein the demetallized holes transmit light from behind the improved polymeric sheet material, the transmitted light appearing as one or more missing areas within the synthetic images.

2. A polymeric security document made using the improved polymeric sheet material of claim 1.

3. The improved polymeric sheet material of claim 1, the secondary image icons selected from a group comprising positive text, negative text, imagery, or line work.

4. The improved polymeric sheet material of claim 1, wherein the improved polymeric sheet material is a fold-over polymeric sheet material in the form of a polymer or polymeric substrate with one or more integrated optical security devices, wherein the one or more integrated optical security devices is made up of an embedded arrangement of focusing elements having at least two different sized focusing elements and a first arrangement of image icons, which are formed directly or applied onto remote portions of one surface of the polymer or polymeric substrate, and a second arrangement of different image icons, which are formed directly or applied on an opposing surface of the polymer or polymeric substrate directly opposite the first arrangement of image icons, wherein when a portion of the polymer or polymeric substrate containing the embedded arrangement of focusing elements is positioned directly over the portion of the polymer or polymeric substrate containing the first and second arrangements of image icons, at least two synthetic images are projected.

5. The improved polymeric sheet material of claim 1, wherein the improved polymeric sheet material is a fold-over polymeric sheet material in the form of a polymer or polymeric substrate with one or more integrated optical security devices, wherein the one or more integrated optical security devices is made up of an arrangement of focusing elements having embedded focusing elements and non-embedded focusing elements, which are all similarly-sized focusing elements, and a first arrangement of image icons, which are formed directly or applied onto remote portions of one surface of the substrate, and a second arrangement of different image icons, which is formed directly or applied onto an opposing surface of the polymer or polymeric substrate directly opposite the first arrangement of image icons, wherein when a portion of the polymer or polymeric substrate containing the arrangement of focusing elements is positioned directly over a portion of the polymer or polymeric substrate containing the first and second arrangements of image icons, at least two synthetic images are projected.

6. The improved polymeric sheet material of claim 1, wherein the improved polymeric sheet material is a fold-over polymeric sheet material in the form of a polymer or polymeric substrate with one or more integrated optical security devices, wherein the one or more integrated optical security devices is made up of an embedded arrangement of similarly sized focusing elements and a first arrangement of image icons, which are formed directly or applied onto remote portions of one surface of the polymer or polymeric substrate, and a second arrangement of different image icons, which is formed directly or applied onto an opposing surface of the polymer or polymeric substrate directly opposite the first arrangement of image icons, wherein when the portion of the polymer or polymeric substrate containing the embedded arrangement of similarly sized focusing elements is positioned directly over the portion of the polymer or polymeric substrate containing the first and second arrangements of image icons at a first distance, at least one image is projected, and when the portion of the polymer or polymeric substrate containing the embedded arrangement of similarly sized focusing elements is positioned directly over the portion of the substrate containing the first and second arrangements of image icons at a second distance, at least one different image is projected.

7. The improved polymeric sheet material of claim 1, wherein an opacifying coating is used to cover remaining portions of the polymer or polymeric substrate.

8. The improved polymeric sheet material of claim 1, wherein the image icons are formed from coated or filled voids or recesses on or within the polymer or polymeric substrate.

9. An improved polymeric sheet material for use in making polymeric security documents, which is made up of a polymer or polymeric substrate having a thickness greater than or equal to 60 microns and one or more integrated or applied optical security devices which project one or more synthetic images, the one or more optical security devices being integrated or applied to all or part of the polymer or polymeric substrate, wherein when the one or more optical security devices is positioned on or within only a portion of the polymer or polymeric substrate, wherein the improved polymeric sheet material is a fold-over polymeric sheet material having one or more integrated optical security devices, wherein the one or more integrated optical security devices is made up of an arrangement of metalized hybrid refractive/reflective focusing elements that are partially reflective and partially transparent positioned below a first arrangement of image icons on an upper surface of the polymer or polymeric substrate, a second arrangement of different image icons positioned directly below the first arrangement of image icons and the arrangement of metalized hybrid refractive/reflective focusing elements on a lower surface of the polymer or polymeric substrate, and a third arrangement of image icons positioned remotely from the second arrangement of different image icons on the lower surface of the polymer or polymeric substrate, wherein when the improved polymeric sheet material is folded such that the third arrangement of image icons is positioned over the arrangement of metallized hybrid refractive/reflective focusing elements and the first and second arrangements of image icons, the improved polymeric sheet material projects one or more synthetic images in transmitted light, which is viewable from the lower surface of the polymer or polymeric substrate.

10. The improved polymeric sheet material of claim 9, wherein an opacifying coating is used to cover remaining portions of the polymer or polymeric substrate.

11. An improved polymeric sheet material for use in making polymeric security documents, which is made up of a polymer or polymeric substrate having a thickness greater than or equal to 60 microns and one or more integrated or applied optical security devices which project one or more synthetic images, the one or more optical security devices being integrated or applied to all or part of the polymer or polymeric substrate, the one or more optical security devices is positioned on or within only a portion of the polymer or polymeric substrate, wherein the improved polymeric sheet material has one or more integrated optical security devices, wherein the one or more integrated optical security devices is made up of a first arrangement of focusing elements and a first arrangement of image icons, which are formed directly or applied onto all or part of one surface of the polymer or polymeric substrate, and a second arrangement of focusing elements and a second arrangement of image icons, which are formed directly or applied onto all or part of an opposing surface of the polymer or polymeric substrate, wherein the focusing elements on one surface of the substrate focus on image icons on an opposing surface of the polymer or polymeric substrate, the improved polymeric sheet material displaying one or more images on opposing surfaces, wherein the improved polymeric sheet material has: (a) an arrangement of non-embedded or open focusing elements on each side of the polymer or polymeric substrate, each arrangement of focusing elements having one or more of the following: i. a rotation angle that is different from the rotation angle of the other arrangement; ii. a lattice structure that is different from the lattice structure of the other arrangement; or iii. a pitch that is different from the pitch of the other arrangement; or (b) an arrangement of embedded or sealed focusing elements on each side of the polymer or polymeric substrate, each arrangement of focusing elements having one or more of the following: i. a rotation angle that is different from the rotation angle of the other arrangement; ii. a lattice structure that is different from the lattice structure of the other arrangement; or iii. a pitch that is different from the pitch of the other arrangement; or (c) an arrangement of non-embedded or open focusing elements on one side of the polymer or polymeric substrate and an arrangement of embedded focusing elements on an opposing side.

12. The improved polymeric sheet material of claim 11, wherein the improved polymeric sheet material has non-embedded or open focusing elements on one side of the polymer or polymeric substrate and embedded focusing elements on an opposing side of the polymer or polymeric substrate.

13. The improved polymeric sheet material of claim 11, wherein an opacifying coating is used to cover remaining portions of the polymer or polymeric substrate.

14. An improved polymeric sheet material for use in making polymeric security documents, which is made up of a polymer or polymeric substrate having a thickness greater than or equal to 60 microns and one or more integrated or applied optical security devices which project one or more synthetic images, the one or more optical security devices being integrated or applied to all or part of the polymer or polymeric substrate, wherein when the one or more optical security devices is positioned on or within only a portion of the polymer or polymeric substrate, wherein the improved polymeric sheet material has one or more integrated optical security devices made up of an arrangement of focusing elements and an arrangement of image icons, the arrangement of image icons comprising image icons formed from voids or recesses on or within the polymer or polymeric substrate which are filled or coated with a material having a different index of refraction than surrounding or underlying material, a dyed material, a metal, or a pigmented material, the voids or recesses each measuring from 0.5 to 8 microns in total depth and greater than or equal to 0.5 microns in total width, wherein the polymer or polymeric substrate serves as an optical spacer.

15. The improved polymeric sheet material of claim 14, wherein an opacifying coating is used to cover remaining portions of the polymer or polymeric substrate.

16. A method of forming an improved polymeric sheet material, the method comprising: forming a microstructure-bearing release liner comprising a lens mold layer adhered to a carrier film, wherein the lens mold layer is formed from a curable resin having a plurality of voids with negative lens geometries, the negative lens geometries made by ultraviolet curing the curable resin against a rigid surface having positive lens geometries; filling the plurality of voids with an optically functional ultraviolet curable liquid polymer, applying pressure with a nip roller to exclude excess liquid polymer, and simultaneously exposing the ultraviolet curable liquid polymer to ultraviolet radiation such that the optically functional ultraviolet curable polymer cures or hardens and can be lifted from the lens mold layer; applying a curable resin material to a surface of a second release liner and curing the curable resin material against a rigid icon mold to form one or more arrangements of image icons in a form of voids within a surface of the curable resin material; filling the voids with a material providing a contrast with the curable resin material to form a filled image icon layer; applying one or more adhesive layers to transferable layers; placing an adhesive side of each transferable layer in contact with opposing sides of the polymer or polymeric substrate; applying heat or pressure to each transferable layer causing an adhesive in the adhesive layer to bond securely to the polymer or polymeric substrate; and peeling away the release liner with lens mold layer and the second release liner, leaving behind focusing element and image icon layers.

Description

TECHNICAL FIELD

The present invention generally relates to an improved polymeric sheet material for use in making polymeric security documents such as banknotes, which is made up of a polymer or polymeric substrate having one or more integrated and/or applied optical security devices, and to polymeric security documents made using these improved polymeric sheet materials.

BACKGROUND AND SUMMARY OF THE INVENTION

Polymeric security documents such as banknotes are typically made from a polymer such as biaxially oriented polypropylene (BOPP). Such documents offer unique opportunities to incorporate security elements that are designed to discourage counterfeiting.

One such security element is an optical security device that projects synthetic images and generally comprises an arrangement of focusing elements (e.g., microlenses or micromirrors) and an arrangement of image icons (e.g., micro-sized image icons) located on or within a polymeric substrate. The image icon and focusing element arrangements are configured such that when the arrangement of image icons is viewed through or with the arrangement of focusing elements, one or more synthetic images are projected. These projected images may show a number of different optical effects. Material constructions capable of presenting such effects are described in, for example, U.S. Pat. No. 7,333,268 to Steenblik et al., U.S. Pat. No. 7,468,842 to Steenblik el al., and U.S. Pat. No. 7,738,175 to Steenblik et al.

The arrangements of focusing elements and image icons used in these optical security devices are formed from a variety of materials such as substantially transparent or clear, colored or colorless polymers such as acrylics, acrylated polyesters, acrylated urethanes, epoxies, polycarbonates, polypropylenes, polyesters, urethanes, and the like, using a multiplicity of methods that are known in the art of micro-optic and microstructure replication, including extrusion (e.g., extrusion embossing, soft embossing), radiation cured casting, and injection molding, reaction injection molding, and reaction casting.

By way of the present invention, innovative ways of combining these optical security devices with polymer or polymeric substrates for use in making polymeric security documents (e.g., banknotes) are provided. In particular, the present invention provides an improved polymeric sheet material made up of a polymer or polymeric substrate having one or more integrated and/or applied optical security devices, the optical security device(s) being integrated and/or applied to all or part of the substrate, wherein when the optical security device(s) is positioned on or within only part or a portion of the substrate, an opacifying coating may be used to cover remaining portions thereof.

Contemplated embodiments of the improved polymeric sheet material of the present invention in the form of a polymer or polymeric substrate with either an integrated or applied optical security device are described below. 1. A polymeric sheet material in which the optical security device is an integrated feature made up of an optionally embedded arrangement(s) of focusing elements and an arrangement(s) of image icons, which are formed directly (e.g., cast) or applied (e.g., transferred with adhesive) onto all or part of opposing surfaces of the polymer or polymeric substrate, which has a thickness greater than or equal to about 60 microns, wherein the substrate serves as an optical spacer; 2. A polymeric sheet material in which the optical security device is an integrated feature made up of an optionally embedded arrangement(s) of focusing elements located on or over an arrangement(s) of image icons, which are formed directly or applied onto all or part of one surface of the polymeric substrate, and a reflective (e.g., metal) surface, which is applied to all or part of an opposing surface of the substrate and which serves to provide a reflection of the image icons beyond the reflective surface so that the focusing elements can focus on the reflection of the image icons, thus allowing for the use of focusing elements with a focal length that extends beyond the arrangement(s) of image icons; 3. A polymeric sheet material in which the optical security device is an integrated feature made up of an optionally embedded first arrangement(s) of focusing elements located on or over a first arrangement(s) of image icons, which are formed directly or applied onto all or part of one surface of the polymeric substrate, and an optionally embedded second arrangement(s) of focusing elements located on or over a second arrangement(s) of the same or different image icons, which are formed directly or applied onto all or part of an opposing surface of the substrate. Here, the focusing elements on one surface of the substrate (e.g., the first arrangement(s) of focusing elements) focus on the image icons on an opposing surface of the substrate (e.g., the second arrangement(s) of image icons). The images projected from opposing surfaces of this substrate may be the same or different, and may have the same or different colors and/or optical effects (e.g., motion or movement, depth, floating); 4. A polymeric sheet material in which the optical security device is an applied feature made up of an arrangement(s) of concave or convex reflective focusing elements and an overlying arrangement(s) of image icons, and is either formed in place on, or transferred onto one or opposing surfaces of the polymeric substrate; 5. A "fold-over" polymeric sheet material in which the optical security device is an integrated feature made up of an optionally embedded arrangement(s) of focusing elements and a first arrangement(s) of image icons, which are formed directly or applied onto remote portions of one surface of the polymeric substrate, and a second arrangement(s) of the same or different image icons, which are formed directly or applied onto an opposing surface of the substrate (preferably directly opposite the first arrangement of image icons). In a preferred embodiment in which the first and second image icon arrangements are positioned opposite each other on the substrate, the arrangement(s) of focusing elements is an optionally embedded arrangement to two differently sized focusing elements and when that portion of the sheet material containing the arrangement(s) of focusing elements is positioned directly over the portion of the sheet material containing these arrangements, two images will be projected. The two images may be the same or different, and may have the same or different colors and/or optical effects; 6. A polymeric sheet material in the form of a "two-ply" polymer or polymeric substrate with an integrated optical security device in which either (i) the arrangement(s) of focusing elements is positioned between the two plies, and one or two arrangements of the same or different image icons are formed or applied onto all or part of one or opposing surfaces of the two-ply substrate, or (ii) one or two arrangements of the same or different image icons are positioned between the two plies, and one or two optionally embedded arrangements of focusing elements are formed or applied onto all or part of one or opposing surfaces of the two-ply substrate. Here, images are projected from one or opposing surfaces of the sheet material. The images may be the same or different, and may have the same or different colors and/or optical effects; 7. A polymeric sheet material in which the optical security device is an integrated or applied feature made up of a first arrangement(s) of image icons and an underlying arrangement(s) of hybrid refractive/reflective focusing elements, that is either formed in place on, or transferred onto a surface of the polymeric substrate, and a second arrangement(s) of image icons that is either formed in place on, or transferred onto an opposing surface of the substrate, the hybrid refractive/reflective focusing elements providing means for forming an image in transmitted light and a different image in reflected light; and 8. A polymeric sheet material in which the optical security device is an applied feature made up of an optionally embedded arrangement(s) of focusing elements and an arrangement(s) of image icons, separated by a thin spacer, and is either formed in place on, or transferred onto one or opposing surfaces of the polymeric substrate.

Also provided by way of the present invention is a polymeric security document (e.g., a banknote) made using the improved polymeric sheet material described above, which has printing or other identifying indicia on one or opposing sides thereof.

Other features and advantages of the invention will be apparent to one of ordinary skill from the following detailed description. Unless otherwise defined, all technical and scientific terms used herein have the same meaning as commonly understood by one of ordinary skill in the art to which this invention belongs. All publications, patent applications, patents and other references mentioned herein are incorporated by reference in their entirety. In case of conflict, the present specification, including definitions, will control. In addition, the materials, methods, and examples are illustrative only and not intended to be limiting.

BRIEF DESCRIPTION OF THE DRAWINGS

The present disclosure may be better understood with reference to the following drawings. Matching reference numerals designate corresponding parts throughout the drawings, and components in the drawings are not necessarily to scale, emphasis instead being placed upon clearly illustrating the principles of the present disclosure. While exemplary embodiments are disclosed in connection with the drawings, there is no intent to limit the present disclosure to the embodiment or embodiments disclosed herein. On the contrary, the intent is to cover all alternatives, modifications and equivalents.

Particular features of the disclosed invention are illustrated by reference to the accompanying drawings in which:

FIG. 1 is a cross-sectional side view of an embodiment of the improved polymeric sheet material of the present invention, where an arrangement of focusing elements and an arrangement of image icons are formed directly onto opposing surfaces of the polymer or polymeric substrate;

FIG. 2 is a cross-sectional side view of an embodiment similar to FIG. 1, but where the arrangement of focusing elements and the arrangement of image icons are transferred onto opposing surfaces of the substrate;

FIG. 3(a) is a cross-sectional side view of an embodiment of the improved polymeric sheet material of the present invention, where an arrangement of image icons and an overlying embedded arrangement of focusing elements are located on a top surface of the polymeric substrate, and a reflective layer is located on a bottom surface of the substrate;

FIG. 3(b) is a cross-sectional side view of the embodiment shown in FIG. 3(a) in which the reflective layer has been adjusted to include a demetalized "hole";

FIG. 3(c) is a top planar view of the embodiment shown in FIG. 3(b), the reflective layer adjusted to include the words "DEMET TEXT", which when placed over a white surface appear as light "missing" areas, while FIG. 3(d) is a top planar view of the embodiment shown in FIG. 3(c) placed over a dark surface, the words "DEMET TEXT" which now appear as dark "missing" areas;

FIG. 3(e) is a top planar view of the embodiment shown in FIG. 3(c) when viewed in transmitted light, the words "DEMET TEXT" appearing as light areas against an opaque background;

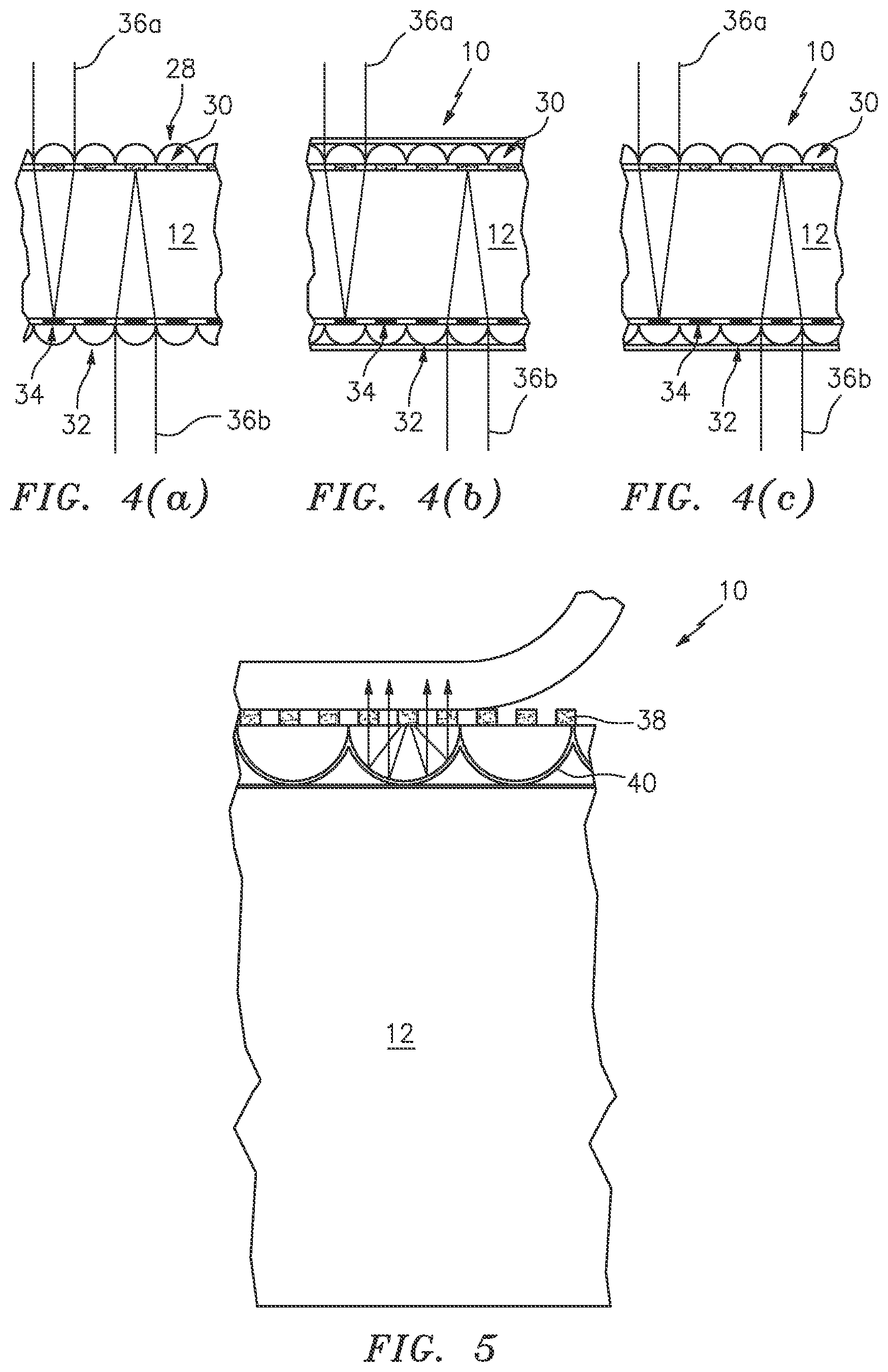

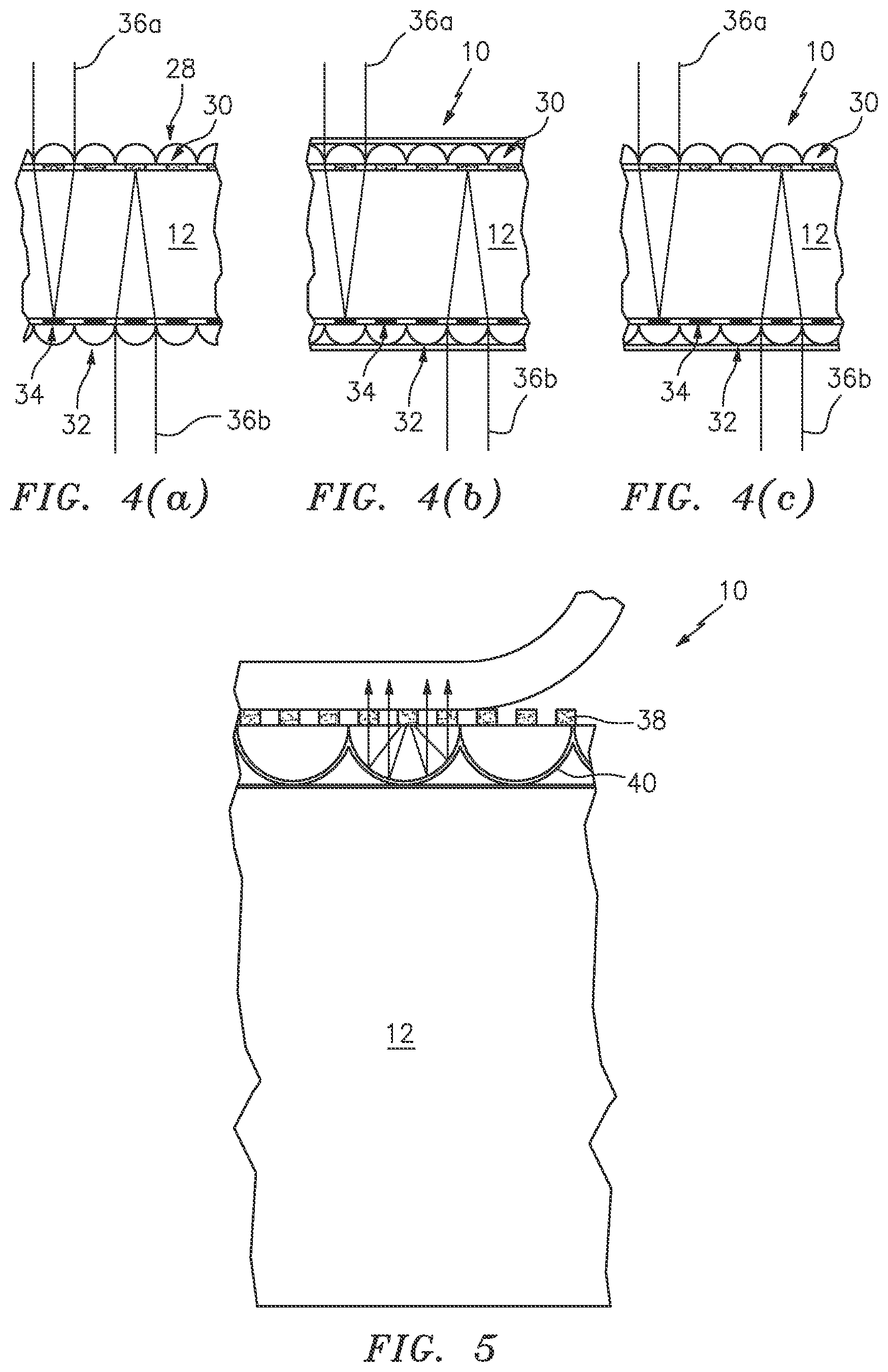

FIG. 4(a) is a cross-sectional side view of an embodiment of the improved polymeric sheet material of the present invention, where a first arrangement of image icons and a first arrangement of focusing elements are formed directly or applied onto one surface of the polymeric substrate, and a second arrangement of the same or different image icons and a second arrangement of focusing elements are formed directly or applied onto an opposing surface of the substrate. FIG. 4(b) is a cross-sectional side view of an embodiment similar to FIG. 4(a) but in which the focusing elements are embedded focusing elements. FIG. 4(c) is a cross-sectional side view of another embodiment similar to FIG. 4(a) but in which the focusing elements are embedded focusing elements on one side, and not embedded or open on the other side;

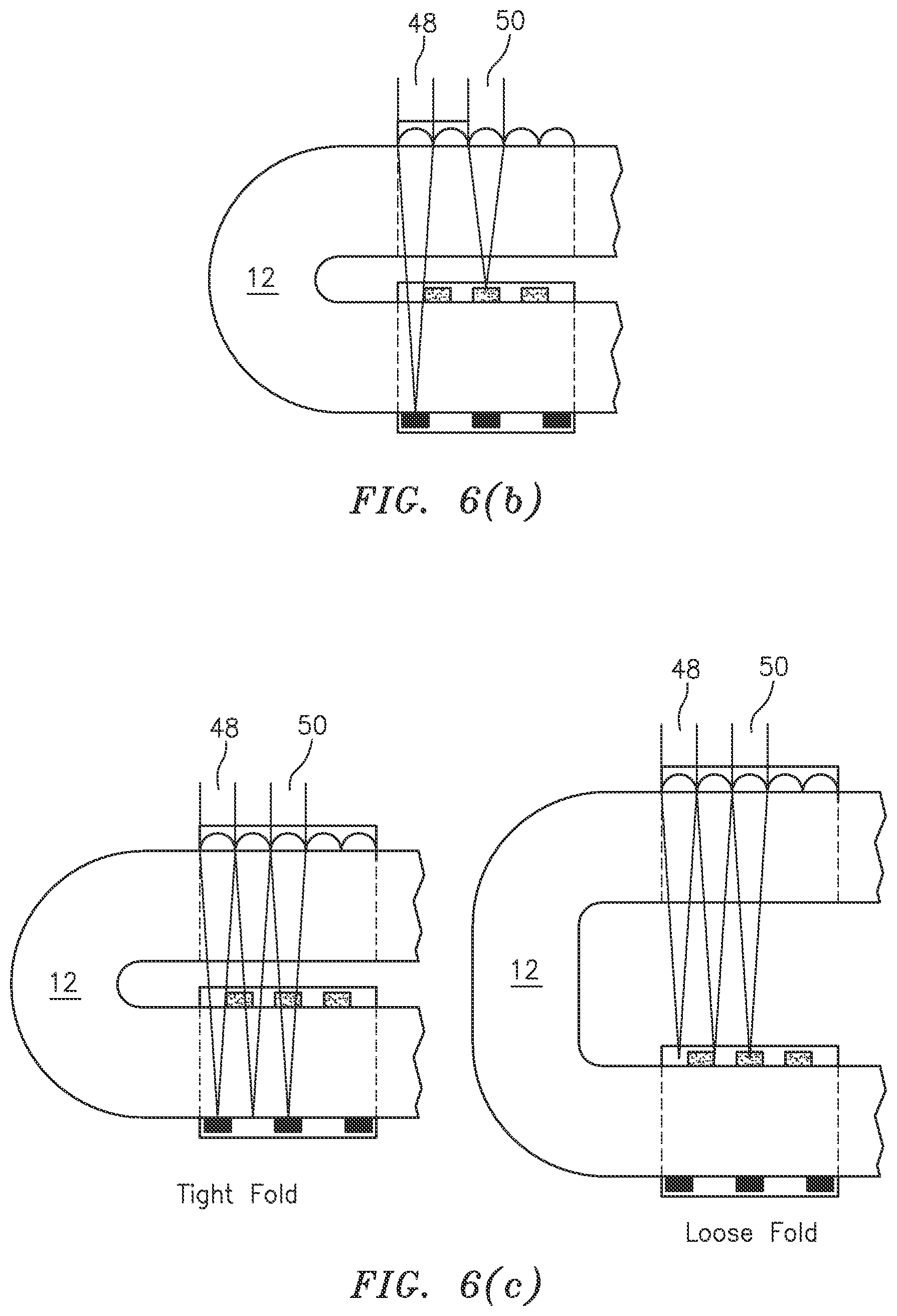

FIG. 5 is a cross-sectional side view of an embodiment of the inventive improved polymeric sheet material, where an optical security device in the form of an arrangement of image icons and an underlying arrangement of concave reflective focusing elements is shown being transferred onto one surface of the polymeric substrate;

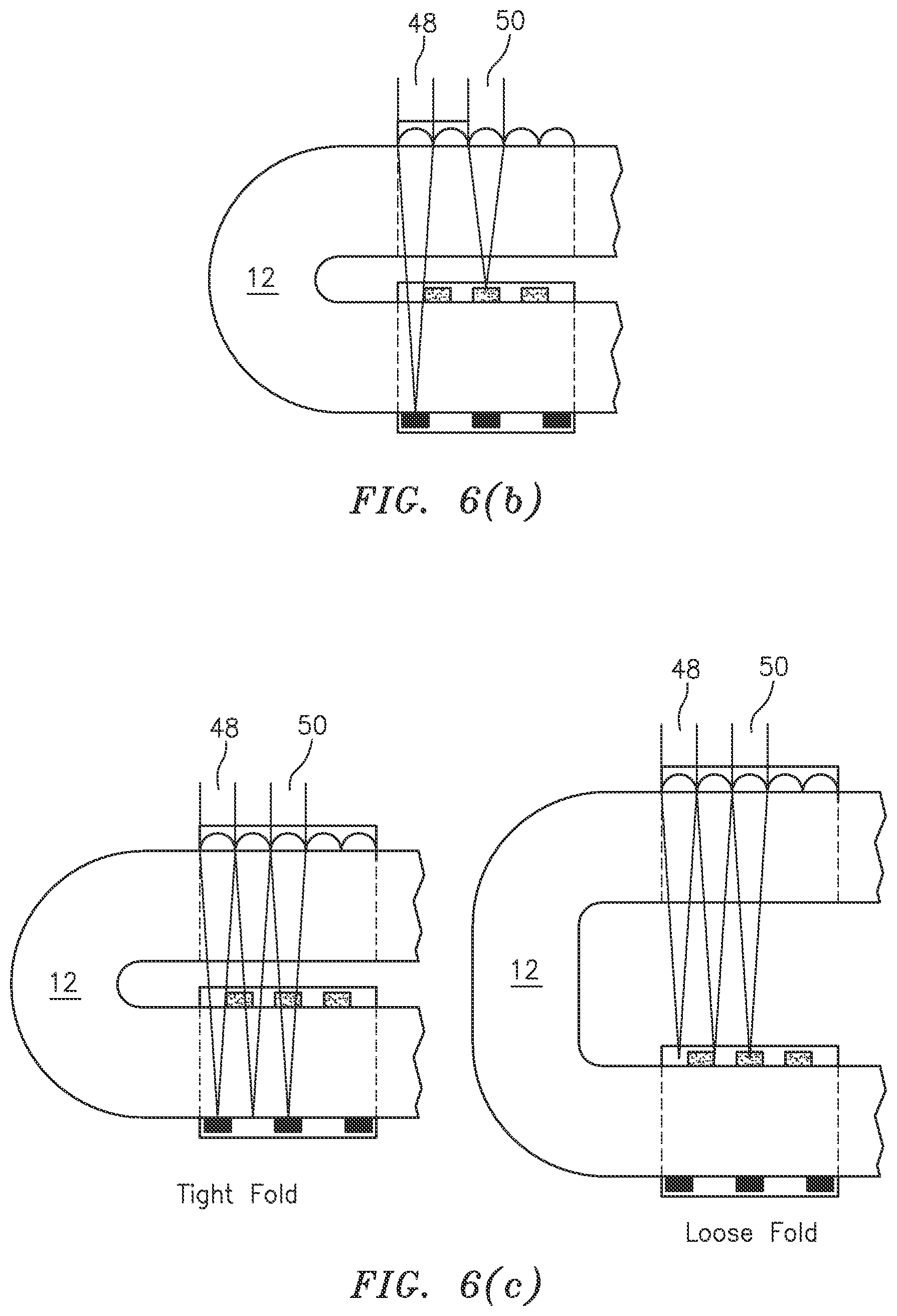

FIG. 6(a) is a cross-sectional side view of a "fold-over" embodiment of the inventive polymeric sheet material, where an integrated optical security device is made up of an embedded or sealed arrangement of focusing elements having two different sizes and a first arrangement of image icons placed in remote locations on one surface of the polymeric substrate, and a second arrangement of different image icons on an opposing surface of the substrate directly opposite the first arrangement of image icons, wherein both the first and second arrangements of image icons are viewed simultaneously. FIG. 6(b) is a cross-sectional side view of an embodiment similar to FIG. 6(a) but in which the focusing elements are the same size with some focusing elements embedded or sealed while other focusing elements are non-embedded or open, wherein again both the first and second arrangements of image icons are viewed simultaneously. FIG. 6(c) is a cross-sectional side view of another embodiment similar to FIG. 6(a) but in which the focusing elements are the same size, embedded or sealed and tuned to image the image icons on the same side of the substrate when the substrate is folded tightly, and to image the icons on the opposite side of the substrate when the substrate is folded loosely;

FIG. 7 is a cross-sectional side view of an embodiment of the improved polymeric sheet material in the form of a "two-ply" polymer or polymeric substrate with an integrated optical security device in which the arrangement of focusing elements is positioned between the two plies, and first and second arrangements of the same or different image icons are located on opposing surfaces of the two-ply substrate;

FIGS. 8(a),(b),(c) are cross-sectional side views of an embodiment of the improved polymeric sheet material of the present invention, where an applied optical security device in the form of two arrangements of image icons overlying and underlying an arrangement of "lightly metalized" hybrid refractive/reflective focusing elements are shown. The sheet material viewed in reflected light is shown in FIG. 8(a), while the sheet material viewed with a bright light directed toward the "back" of the substrate is shown in FIG. 8(b). In FIG. 8(c), the inventive sheet material, when used as a fold-over feature with remotely spaced image icons on the "top" of the substrate, is shown viewed with a bright light directed toward the "top" of the substrate; and

FIG. 9 is a cross-sectional side view of an embodiment similar to FIGS. 8(a),(b),(c), which employs different color image icons on opposing surfaces of the polymeric substrate and an opaque overprint on a portion of the image icons underlying the arrangement of "lightly metalized" hybrid refractive/reflective focusing elements on an opposing side of the substrate.

DETAILED DESCRIPTION OF THE INVENTION

As noted above, the present invention provides an improved polymeric sheet material in the form of a polymer or polymeric substrate that has one or more integrated and/or applied optical security devices. The polymer or polymeric substrate may comprise one or more layers of transparent polymer film, preferably transparent biaxially oriented polymer film. In a more preferred embodiment, the substrate is either a single layer BOPP film, or a laminate of two or more layers of BOPP film, each of which is coated with a heat-activated adhesive layer. The polymer or polymeric substrate typically ranges from greater than or equal to about 60 microns (preferably, from about 60 to about 90 microns) in total thickness.

For those embodiments in which the optical security device(s) is integrated and/or applied to only part of the substrate, an opacifying coating may be used to cover remaining portions thereof. The opacifying coating is made up of a major portion (.gtoreq.50%) of pigment and a minor portion (<50%) of a cross-linked polymeric binder.

For those embodiments in which the optical security device(s) is integrated and/or applied to the entire substrate, an opacifying coating may or may not be used. As will be readily appreciated by those skilled in the art, such a sheet material would be used to make an entirely micro-optic security document or banknote, which presents a number of distinct and unique advantages.

The optical security device of the inventive polymeric sheet material basically comprises one or more arrangements of optionally embedded cylindrical or non-cylindrical focusing elements and one or more arrangements of image icons. As noted above, these arrangements are configured such that when the arrangement of image icons is viewed through the arrangement of focusing elements, one or more synthetic images are projected.

The optionally embedded focusing elements used in the practice of this invention include, but are not limited to, refractive focusing elements, reflective focusing elements, hybrid refractive/reflective focusing elements, and combinations thereof. In one contemplated embodiment, the focusing elements are refractive microlenses. Examples of suitable focusing elements are disclosed in U.S. Pat. No. 7,333,268 to Steenblik et al., U.S. Pat. No. 7,468,842 to Steenblik el al., and U.S. Pat. No. 7,738,175 to Steenblik et al., all of which are fully incorporated by reference as if fully set forth herein.

The focusing elements have preferred widths (in the case of cylindrical lenses) and base diameters (in the case of non-cylindrical lenses) of either (i) less than or equal to 1 millimeter including widths/base diameters ranging from about 200 to about 500 microns and ranging from about 50 to about 199 microns, or (ii) less than about 50 microns including widths/base diameters ranging from less than about 45 microns and ranging from about 5 to about 40 microns.

Embedment of the focusing elements serves to improve the optical security device's resistance to optically degrading external effects. In one such embodiment, the refractive index from an outer surface of the optical security device to refracting interfaces is varied between a first and a second refractive index, the first refractive index being substantially or measurably different than the second refractive index. The phrase "substantially or measurably different", as used herein, means a difference in refractive index that causes the focal length(s) of the focusing elements to change at least about 0.1 micron.

The embedding material may be transparent, translucent, tinted, or pigmented and may provide additional functionality for security and authentication purposes, including support of automated currency authentication, verification, tracking, counting and detection systems, that rely on optical effects, electrical conductivity or electrical capacitance, magnetic field detection. Suitable materials can include adhesives, gels, glues, lacquers, liquids, molded polymers, and polymers or other materials containing organic or metallic dispersions.

The image icons may be printed on the polymer or polymeric substrate or may constitute microstructured image icons that are raised or recessed relative to a surface of the substrate. In a preferred embodiment, the image icons are formed as either voids or recesses on or within the substrate, or raised relative to the substrate. In either case, the image icons may be formed by casting or heat pressure processes.

In one embodiment contemplated by the present invention, the image icons are optionally coated and/or filled voids or recesses formed on or within the polymer or polymeric substrate. The voids or recesses may each measure from about 0.5 to about 8 microns in total depth and greater than or equal to about 0.5 microns in total width.

Exemplary embodiments of the inventive polymeric sheet material will now be disclosed in connection with the drawings. There is no intent, however, to limit the present disclosure to the embodiments disclosed herein. On the contrary, the intent is to cover all alternatives, modifications and equivalents.

In a first exemplary embodiment, which is best shown in FIG. 1, the improved polymeric sheet material of the present invention 10 is in the form of a polymer or polymeric substrate 12 with an integrated optical security device 14, the integrated device 14 made up of an arrangement of focusing elements (i.e., refractive microlenses) 16 and an arrangement of image icons 18, which are formed directly onto opposing surfaces of the substrate 12. Here, substrate 12 contributes to the optical functionality of the integrated optical security device 14, by serving as an optical spacer.

The refractive microlenses 16 each have a focal length such that the image icons 18 on the opposing side of the substrate 12 substantially intersect with a portion of their depth of focus, when viewed normal to the surface. These refractive microlenses 16 may have cylindrical, spheric or aspheric surfaces.

As noted above, the image icons may be formed from a printing method, or from voids or solid regions in a microstructure. In a preferred embodiment, the image icons are formed from optionally coated and/or filled voids or recesses on or within the substrate, the voids or recesses each measuring from about 0.5 to about 8 microns in total depth and greater than or equal to about 0.5 microns in total width. The voids or recesses may be filled or coated with a material having a different index of refraction than the surrounding or underlying material, a dyed material, a metal, or a pigmented material (e.g., a submicron particle pigmented coloring material). Such an approach has the benefit of almost unlimited spatial resolution.

As also noted above, the arrangements of focusing elements 16 and image icons 18 may be formed from a variety of materials such as substantially transparent or clear, colored or colorless polymers such as acrylics, acrylated polyesters, acrylated urethanes, epoxies, polycarbonates, polypropylenes, polyesters, urethanes, and the like.

In an exemplary method of manufacture, the image icons are formed as voids in a radiation cured liquid polymer (e.g., acrylated urethane) that is cast from an icon mold against the substrate 12. The image icon voids are then filled with a submicron particle pigmented coloring material by gravure-like doctor blading against the polymeric icon surface. The fill is then solidified by suitable means (e.g., solvent removal, radiation curing, or chemical reaction). Then, the lenses are cast against an opposing side of the substrate 12 by bringing that side against a lens mold filled with radiation curable polymer. The polymer is then solidified by application of ultraviolet (UV) light or other actinic radiation.

The integrated optical security device 14 in this exemplary embodiment and the integrated or applied optical security devices of the following exemplary embodiments may adopt any size or shape. For example, they may be formed in the shape of a patch, stripe (band or thread), or co-extensive layer.

In a second exemplary embodiment, which is best shown in FIG. 2, the arrangement of refractive microlenses 16 and the arrangement of image icons 18 are transferred onto all or part of opposing surfaces of the substrate 12.

An exemplary method of forming these transferable focusing element and image icon layers comprises: forming a microstructure-bearing release liner comprising a "lens mold" layer adhered to a carrier film (e.g., a UV transmissive carrier film), wherein the "lens mold" layer is formed from a curable resin having a plurality of voids with negative lens geometries, the negative lens geometries being made by UV curing the resin against a rigid surface having positive lens geometries (i.e., a positive lens mold); filling the plurality of voids with an optically functional UV curable liquid polymer (e.g., polyester acrylate), applying pressure with a nip roller to exclude excess liquid polymer, and simultaneously exposing the liquid polymer to UV radiation such that the UV curable polymer cures or hardens and can be lifted from the lens mold; applying a curable resin material to a surface of a release liner (e.g., a smooth or non-structured carrier substrate having a functional release coating) and curing the surface against a rigid icon mold to form one or more arrangements of image icons in the form of voids within a surface of the curable resin material; filling the voids with a material providing a contrast with the curable resin material to form a filled image Icon layer; and applying one or more adhesive layers (e.g., tack free thermally activated adhesive layers) to the transferable layers.

Once prepared, the transferable layers may be handled like a traditional transfer foil, that is, the material can be wound and unwound from a roll and further converted into a suitable final shape such as a patch, stripe (band or thread), or sheet by converting methods common in the security printing and packaging industries. In order to transfer the focusing element layer 16 and image icon layer 18 from the release liners, the adhesive side of each transferable layer is placed in contact with opposing sides of the polymer or polymeric substrate 12. Heat and/or pressure is applied causing the adhesive in adhesive layer 20 to bond securely to substrate 12. Then, the release liner with "lens mold" layer and the other release liner are peeled away, leaving behind the desired focusing element and image icon layers.

In a third exemplary embodiment, which is best shown in FIG. 3(a), the inventive polymeric sheet material 10 employs an integrated optical security device in the form of a film material 22 made up of an arrangement of image icons and an overlying optionally embedded arrangement of focusing elements that are located on a top surface of the polymer or polymeric substrate 12, and a reflective layer 24 (e.g., a vapor deposited metal layer) that is located directly below on a bottom surface of the substrate 12. As noted above, in this embodiment, the reflective layer 24 serves to provide a reflection of the image icons beyond the reflective surface so that the focusing elements can focus on the reflection of the image icons, thus allowing for the use of focusing elements with a focal length that extends beyond the arrangement(s) of image icons.

The film material 22 may be formed in place on the substrate 12 or the film material (with one or more adhesive layers) may be transferred to the substrate as a transfer film using previously noted techniques including mechanical, chemical, thermal and photo-induced separation techniques. The concept of separation of desired components from a carrier substrate is known in the art of holographic foil transfer, whereby a film with a release coating (i.e., release liner) is provided with optical coatings and adhesives, such that the optical coatings and adhesives can be transferred to a final substrate with application of heat and pressure.

Reflective layer 24 may be a vapor deposited metal layer. Metallization may be achieved, for example, by evaporated or sputtered aluminum, gold, rhodium, chromium, osmium, depleted uranium or silver, by chemically deposited silver, or by multi-layer interference films. This layer may contain image icons formed from patterned demetallization, or holographic features. In this exemplary embodiment, the focusing elements focus on the reflection of icons.

In a preferred embodiment, the reflective layer 24 is a patterned metal layer in which image icons (secondary image icons), which are positive or negative in relation to their background, are formed by patterned demetallization. The demetalized pattern or secondary image icons may adopt any form including, but not limited to, positive text, negative text, imagery, line work, and the like. These secondary image icons control which focusing elements will see a reflection and which focusing elements will not. By providing this control, a second image--one which blocks light and allows a clear image to be seen in transmitted light, is provided. This will be a static image, and not a synthetic image (e.g., a moving or three dimensional synthetic image).

The visual effect achieved by this preferred embodiment will be described in conjunction with FIGS. 3(b) 3(e). In FIG. 3(b), reflective layer 24 is adjusted to include demetalized "holes" (only one demetalized "hole" is shown in FIG. 3(b)). As a result, light passes straight through the optics in those areas. When looking at the inventive sheet material, one would see one or more synthetic images with missing bits where the "holes" are located. Depending on the color of the underlying substrate (or its transparency), the missing bits may appear to be light "missing" areas, or dark "missing" areas. By way of example, and as best shown in FIGS. 3(c), (d), (e), the reflective layer is adjusted to include the words "DEMET TEXT". In FIG. 3(c), these words are shown as light "missing" areas, which is indicative of the inventive polymeric sheet material being placed over a white surface (e.g., a white polymeric surface) or over a paper substrate. This effect may also be indicative of the inventive sheet material being viewed in a combination of reflected and transmitted light. In FIG. 3(d), these words are shown as dark "missing" areas, which is indicative of the sheet material being placed over a transparent polymer or polymeric substrate that is held against a dark background (shown in reflected light). As shown in FIG. 3(e), when the inventive sheet material is viewed in transmitted light, the micro-optic areas will be opaque (due to the presence of the metal reflective layer) and the demetalized areas (i.e., the words "DEMET TEXT") will appear light.